Preparation and application technique

Before puttingty the base, it must be thoroughly dried and prepared. You should not even try to put putty on old paint or wallpaper - such repairs will not last long. In order for everything to be done efficiently and without unnecessary losses (both time and money), it is necessary to strip off all the old finish. After that, the base is cleaned of dirt, dust and degreased. Walls and ceilings made of highly absorbent materials must be additionally primed.

No matter how high-quality the leveling mixtures are, the final quality of work depends on the correct preparation and application. The main rule here is to observe the precise proportions indicated by the manufacturer and the mixing technique.

Small amounts of leveling mortar can be mixed by hand. However, using a mixer will be much more efficient. Especially when it comes to large volumes, which are unlikely to be mixed without special equipment.

When kneading, the dry mixture is poured into the water, but not vice versa!

The amount of solution should be calculated based on the amount of work that the repairman will have time to complete in an hour and a half.

Another important point is the application technique. This is especially true for beginners who have no experience with putty mixtures.

Everything will be much easier if you adhere to certain rules:

- In the work, it is necessary to use two spatulas, one for a set of the mixture, the other for the main work on the distribution of the putty. To capture the composition from the container, a narrow tool 80-100 mm wide is used. As for the wide spatula, its size should correspond to the area of the putty surface.

- In order for the mixture to lay down as evenly as possible, it is necessary to choose the right combination of the thickness of the putty, the angle of inclination of the working tool and the pressing force.

After all the work is completed, it is necessary to grind the walls (ceiling) and you can proceed with the finishing.

Finishing putty

Among the mixtures for fine finishing, the finishing putty "Prospectors" has become widespread. It contains small plaster particles, so the applied layer will be even, perfectly smooth. Among the assortment of the company there are different types of finishing agents, and each of them has a high level of adhesion to building substrates. They eliminate the unevenness of the base layer, closing even the smallest imperfections. The thickness of the layer of the finishing putty is usually about 0.5 cm. It is prepared in not too large portions, since it quickly hardens due to the gypsum base.

Information about the manufacturer

The company "Miners" was formed in Moscow in 1992 and initially was engaged only in the production of ready-made putty. Later, the range of really high-quality products was seriously expanded, a whole list of dry building mixtures was introduced into it. In a short time, the company organized high-tech production, introduced computerized control systems and established a powerful sales system.

Only selected raw materials and safe components are used in the recipe of the Miners putties, while the prices for the goods have remained quite affordable. Many putties can be used in the most difficult climatic conditions, while all of them are of guaranteed stable quality. Now the company has 15 production lines in the Moscow region and 4 branches in other regions of Russia, produces more than 80 items of goods for various finishing works.

Application Tips

Before applying the putty mixture, the manufacturer recommends treating the base with a primer (also from the Prospector company).

After the soil has dried, all existing cavities are filled with a spatula with a solution. After that, the solution is leveled

When carrying out work, it is important to observe the temperature regime (optimal - 10-30 degrees). Also, you should not carry out puttying work in direct sunlight.

Usually putty "Prospectors" gives a flat and smooth surface that does not require additional sanding, but if necessary, the surface or any part of it can be easily sanded with fine sandpaper.

The final finishing of surfaces (wallpapering, applying a paint layer or decorative plaster) is possible only after the final putty layer has completely dried.

If it is necessary to seal the seams between the sheets of drywall, then first, using a spatula, fill the gaps between the sheets with material and attach a reinforcing tape along the seam. Pressing it directly into the seam, remove the excess putty from the drywall with a spatula. When the solution is dry, you can start applying the next layer. And this must be done until the seam is completely equal to the surface of the drywall sheet. In the same way, the putty mixture is applied to the areas of sheet attachment.

For information on how to putty the walls yourself, see the next video.

Types and characteristics

Currently, the company "Prospectors" produces the following types of finishing compositions:

- "Finishing putty";

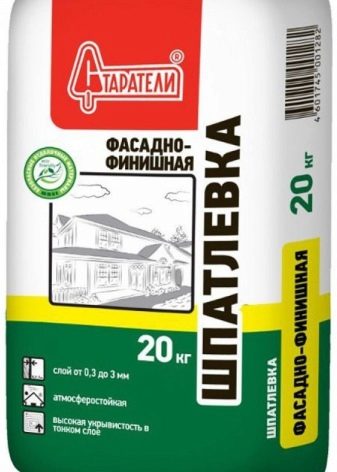

- "Front-finishing putty";

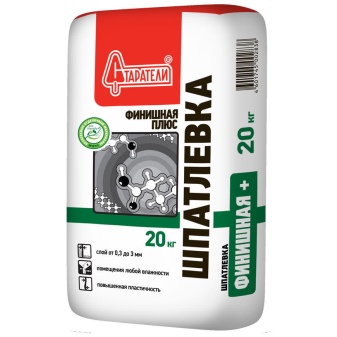

- "Finishing Putty Plus Moisture Resistant";

- "Ready putty Superfinishing";

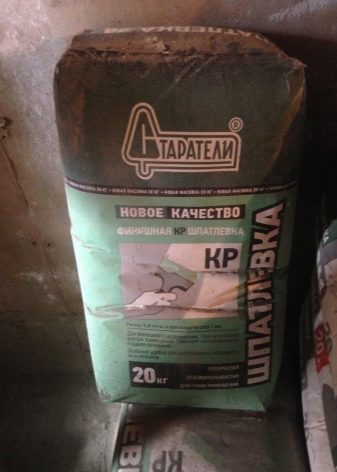

- Finishing putty KR.

"Finishing putty" is a dry gypsum white mixture used for plastering indoor surfaces.

The composition includes modifying additives.

The recommended thickness of the applied layer is 0.3-5 cm. Material consumption under this condition will be 900 g per square meter of surface.

It can be applied on plastered, concrete and brick substrates for subsequent painting or wallpapering.

It is not permitted to use this material in places where there will be contact with food or drinking water.

This type of putty is applied to a dry, clean and solid surface. If the base has crumbling or unreliable areas, these should be removed. Gypsum and other hygroscopic bases must be pre-treated with a primer.

The putty solution is prepared at the rate of 400-580 ml of water per kilogram of dry matter.

This type of material is sold in containers of 5, 12 and 20 kg.

"Front-finishing putty" is a mixture for plastering mainly outside the building. The material is also suitable for interior work.

The functional determines the following properties of this product: frost resistance, weather resistance, crack resistance.

The composition of the facade-finishing mixture includes white cement, modifying additives and natural filler of fine fraction.

The topcoat can be applied to a cement, concrete and reinforced concrete base for subsequent application of decorative plaster, painting and wallpapering.

Suitable for application in wet areas. Not recommended for use in places where food contact is expected.

The recommended thickness of the applied layer is from 0.3 to 3 mm. Consumption is a kilogram per square meter with a layer of 1 mm thick putty.

The solution is prepared at the rate of 320-400 ml per kilogram of dry powder.

The prepared solution retains its viability within three hours from the moment of mixing.

Packaging - only in bags of 20 kg.

"Finishing Putty Plus Moisture Resistant" is a white polymer-cement plastic material with increased resistance to moisture.

Can be applied on gypsum plaster, concrete and drywall surfaces.

The thickness of the putty layer recommended by the instructions is 0.3-3 mm. Material consumption - 800 grams per square meter (layer thickness 1 mm).

The base for applying the solution is prepared similarly to the finishing putty.

The solution is prepared at the rate of 350-400 ml per kilogram of dry powder.

The prepared solution retains its viability within six hours from the moment of mixing.

"Ready putty Superfinishing". This material is a ready-made putty mixture in the form of a paste.

It includes: reinforcing fibers, polymer binder, fine-grained fillers, antiseptic fraction and modifying additives.

Ready-made paste is used only for interior work in rooms with normal humidity levels. It is applied on gypsum plasterboards, gypsum plaster, tongue-and-groove plates, fiberglass. Subsequent coating can be wallpaper or paint.

The recommended maximum thickness of the putty applied is 2 mm. Consumption of paste with a layer of filler 0.3 mm is 500 g per square meter.

The adhesive ability of the material is up to 0.5 mPa.

Drying time of a 1 mm layer of putty is 4 hours.

The base for applying the solution is prepared similarly to the finishing putty.

Packaging - in plastic buckets of 7 and 15 kg.

"Finishing putty KR" is a finishing polymer highly plastic material for the repair of interiors. Recommended for use in dry rooms only.

It can be applied to concrete, gypsum-based plaster, but is most suitable for plasterboard processing. The boiling white color of this material and its good covering ability significantly save costs for the subsequent painting of the treated surface.

It is recommended to apply this type of filler with a layer of 0.3-3 mm. Material consumption for 1 mm of a layer with an area of 1 sq. M. will be 1.1 kilograms.

The finished mixture of KR putty has an increased vitality index - the solution can retain its properties for 24 hours from the moment of preparation.

Facade and finishing

The mixture has an ideal composition, intended for outdoor use, perfectly eliminates irregularities of any level of complexity. Finished surfaces resist contrasting weather changes. The prepared solution is suitable for use for no more than three hours. The basis for the manufacture of facade-finishing products is a gypsum composition, the main characteristics of which are non-toxicity and safety.

Can be combined with wood, plasterboard and other materials.

- High hardness.

- Weather resistance.

- Grinding capability.

- During shrinkage of structures, it does not move away from the base.

- Has a beneficial effect on the microclimate.

- High adhesion. Moreover, the mixture fixes the finishing materials so firmly that it can be used as assembly glue or as a stucco for decoration.

Description

Basic putty "Prospectors" is a dry mixture of white cement, which expands the area of use and speeds up the work time. If we compare with plasters based on gray Portland cement, the described composition has a light beige color, so finishing can be started immediately after the starting putty has dried.

If we consider the composition of the product, then "Prospectors" can be attributed to dry plasters. However, one of the important differences here is plasticity, which is inherent in putties. This indicates versatility. The mixture combines moisture resistance, leveling properties that are characteristic of gypsum putties and plasters.

Using the base putty "Prospectors", you can take advantage of another important advantage, which is expressed in the possibility of pasting wallpaper without additional puttying of the starting layer.This saves time and money.

The described mixture contains refined sand, the size of the fraction of which is 0.4 mm. The recipe provides for the addition of gypsum and ground clinker. There are also additives in the mixture that prevent shrinkage and improve elasticity, as well as help repel moisture. The mixture contains polymer plasticizers and additives.

The starting putty is a modified mixture, because marble flour, fine sand and cellulose ethers are added to it, which helps to retain moisture and allows you to apply the composition in a layer up to one centimeter.

Finishing putty "Prospectors" - features

Finishing putty Prospector or other type is of high quality, produced using modern technologies. It is produced by the Moscow company of the same name, which is distinguished by the production of high quality building materials at reasonable prices. When creating putty polymer Prospectors, modern European equipment is used.

The products are dry mixes with a high level of plasticity, which makes them versatile for use. The base putty is light beige. The mixtures are moisture resistant, leveling properties, which are more pronounced in the gypsum miner putty.

The products are dry mixes with a high level of plasticity, which makes them versatile for use.

The products are dry mixes with a high level of plasticity, which makes them versatile for use.

The following technical characteristics are inherent in the mixtures:

- Operating temperature indicators range from +5 to +30 degrees;

- Consumption, per layer up to a millimeter thick, is 1.1 kilograms per square meter;

- The shelf life of the prepared mixture varies from one and a half to 24 hours, depending on the type of product;

- The adhesion index is not less than 0.25MPa;

- Frost resistance up to 30-35 cycles.

The constituent components of mixtures can be:

- Cement is white or standard;

- Natural fillers;

- Polymer and modifying additional elements;

- Reinforcing fibers;

- Antiseptic substances.

The shelf life of the prepared mixture varies from one and a half to 24 hours, depending on the type of product.

The shelf life of the prepared mixture varies from one and a half to 24 hours, depending on the type of product.

Advantages and disadvantages

Like any product, Prospectors Polymer Putty has its positive and negative sides. To decide whether to stop your choice on this particular brand, you need to study them. The advantages are:

- Containers of various sizes are produced, which allows you to purchase the required amount;

- Long shelf life, up to 12 months, however, it must be stored according to the rules, the place must be dry;

- Fast drying rate to shorten the repair period;

- High strength indicator;

- Acceptable cost.

KR putties and others also have disadvantages, these include:

It is advisable to apply putty material at temperatures from +11 degrees, when the temperatures are lower, then the drying period is difficult

This is usually important when working outdoors;

Not high indicators of resistance to ultraviolet radiation, therefore, additional treatment with protective agents is required .. Various containers are produced in volume, which allows you to purchase the required amount.

Containers of various sizes are produced, which allows you to purchase the required amount.

How to apply, the nuances of using the composition

Before applying the filler material, it is required to prepare the surface well. If there is an old coating on the wall, then it must be removed, otherwise the new finish will not last long.

When the previous finishing material is removed, proceed to cleaning the wall, degreasing it. If the base is made of absorbent material, then first apply a primer, it will reduce the waste of other mixtures.

Even a high-quality mixture will not be able to give a good result if the preparatory work is done poorly, or it is prepared incorrectly.When preparing the solution, strictly follow the instructions indicated by the manufacturer.

It is better to mix the components in plastic buckets, because you need to cook in small portions, which will be designed for an hour and a half of work. It will be easier to wash such a container to prepare a new portion. If the volume of the mixture will be prepared small, then manual mixing is possible, for a larger amount it is advisable to use a construction mixer to make it easier to prepare a homogeneous mixture.

If the volume of the mixture will be prepared in a small amount, then manual mixing is possible; for a larger amount, it is advisable to use a construction mixer.

If the volume of the mixture will be prepared in a small amount, then manual mixing is possible; for a larger amount, it is advisable to use a construction mixer.

After the initial mixing, wait 5 minutes and mix the solution again. Apply the solution according to the rules described below:

- When working, you will need 2 spatulas, the first 80-100 mm in size, the second wide one should be selected based on the area of the room. A mixture is collected on a narrower one, after which it is transferred to a wide one and distributed over the surface;

- When working, they determine which inclination of the tool is better to do, what thickness will be made and the pressing force;

- Usually 2 layers are required, each must dry before applying the next mixture, priming is carried out before the second.

To the finish line they get a flat wall that needs to be sanded.

Usually 2 layers are required, each must dry before applying the next mixture, priming is carried out before the second.

Usually 2 layers are required, each must dry before applying the next mixture, priming is carried out before the second.

How to calculate consumption per 1 m2

Calculating material consumption requires knowledge of the area to be treated. Average consumption depends on the type of product chosen, it is indicated on the package. For example, for basic ones, it is equal to 1 kilogram per 1 square meter.

Calculating material consumption requires knowledge of the area to be treated.

Calculating material consumption requires knowledge of the area to be treated.

Putties Prospectors have shown themselves to be a quality product that is easy to work with. To carry out a good repair, it is necessary to perform preparatory work, and only then apply a putty layer, the composition should be selected based on the working conditions and the task at hand.

Features and characteristics

Repair and interior decoration of any room involves the purchase of various finishing building materials. Among the huge assortment, it is sometimes very difficult to choose a high-quality and inexpensive putty. In this case, advice from experienced repair and interior decoration masters will help. According to experienced specialists, the putty produced by the company "Starateli" is the best option.

Basic

The base mix is very popular and in high demand among buyers. This material is used for finishing both the inner surfaces of the walls and the outer ones.

The base putty is resistant to high humidity, it is applied to the surface in a thin layer, no more than eight millimeters thick. The presence of a substance such as cement in the mixture significantly expands the scope of use of this material. In some cases, covering the surface with a base putty is used as a base for painting walls.

Finish

Also, the finishing mixture "Prospectors" was widely used for finishing works of various premises. Finishing putty "Prospectors" is deservedly considered one of the best mixtures of this kind. The developers have tried to choose the smallest particles for it, creating an impeccably flat surface. This material contains gypsum. This component gives the solution certain properties.

There are several varieties of this brand, but each of them has excellent, unsurpassed adhesion. So, the finishing compound is able to cover any deformations of the base layer and easily fits on a variety of building materials. Builders can prepare the mortar of the desired consistency by varying it flexibly.

The finishing solution is applied in an even layer, no more than five millimeters thick. You should not prepare a large amount of solution at once, as the finished mixture tends to dry quickly.

Finishing putty KR, created on the basis of PVA, is a high-tech mixture with excellent characteristics, suitable for interior decoration of premises with low humidity levels. Crystal white putty is made on a polymer basis. The manufacturer provides packaging of 20 kg. The applied layer of this material has excellent adhesion properties and dries quickly. When finishing the wall surfaces with the KR finishing solution, the room must have a positive temperature.

The Finishnaya Plus mixture is made on a polymer basis, which includes cement. This putty is used for interior decoration of premises as a leveling layer on the surface of concrete, plastered and plasterboard walls. This material is resistant to high humidity, so this putty can be used for finishing any premises. Such a cement mixture in bags has mostly positive reviews.

Types of putties and their composition

All materials of the Prospector series can be divided into base (cement), gypsum and polymer materials. You can choose a suitable filler from the general list.

Finished superfinish

Composition based on polymers in a plastic can. It is implemented in finished form. Has a snow-white color, contains finely ground fillers with a fraction of up to 60 microns. Contains reinforcing fibers and modifiers to increase strength. Thanks to antiseptics, it does not support the growth of microorganisms. It is used in rooms with low or normal humidity, excellent for gypsum board, fiberglass, walls with already applied gypsum plaster. It is widely used for finishing under wallpaper and for painting.

Facade and finishing

Facade putty "Prospectors" is made on the basis of cement, natural fillers and various modifiers. Suitable for outdoor and indoor use, wet rooms, walls and ceilings, easily adheres to concrete and reinforced concrete walls. Suitable for painting, decorative plaster, wallpaper. The features of the putty are as follows:

- applied with a layer of 0.3-3 mm;

- crack-resistant;

- frost-resistant;

- weatherproof;

- perfectly white.

Facade finishing putty Prospectors 20 kg

Facade finishing putty Prospectors 20 kg

Facade

Available as a dry mix. It is characterized by a high level of resistance to moisture, therefore it is excellent for finishing external walls and other structures. The finished layer up to 1 cm thick dries quickly, has an even light beige color, perfectly aligns concrete, foam concrete, aerated concrete and other types of bases. It is also used for work on bricks, cement plaster. Withstands up to 50 defrost / freeze cycles.

Basic white and basic gray

Base mixes for internal use. Designed for rough leveling of walls and ceilings in order to create a reliable base for finishing. Made on the basis of cement polymer additives, formula improvers, modifiers

Before applying the base compounds, it is important to prepare the base well, remove all types of dirt from it, which reduce the reliability of adhesion to the finishing layer. The purpose of the mixtures is varied:

- for facades and interior surfaces;

- for any level of humidity;

- for all types of mineral substrates - concrete, brick, reinforced concrete, aerated concrete, foam concrete;

- for vertical, horizontal structures.

Finishing - fast-hardening leveling

Contains gypsum of fine fraction, as well as improving additives. Suitable only for rooms with low to normal humidity. Evens out minor flaws and prepares the walls for finishing. Perfectly superimposed and reliably adhered to substrates made of gypsum, gypsum plasterboard, cement, reinforced concrete, concrete.

Finish KR

It has a snow-white color, it is sold dry in packages of 20 kg. The composition includes the finest mineral fillers, special polymer components, as well as PVA glue. It is used for finishing walls, ceilings and other structures inside the premises. Not suitable for rooms with high humidity. Dries quickly, adheres tightly to various types of building substrates, but is best suited for working with gypsum substrates, drywall, concrete and reinforced concrete. The finished coating will be so smooth that you can stick the thinnest wallpapers on it or use it for painting.

Finish Plus moisture resistant

Cement-polymer based putty. It is applied in a layer within 0.3-3 mm, forms a perfectly even, smooth, white coating. Plastic, does not shrink and does not crack after drying. It is not afraid of moisture due to its high level of moisture resistance. It is used outdoors and indoors. Perfectly aligns walls made of mineral materials, gypsum plasterboard.

Plaster leveling

Designed to eliminate various types of irregularities, chips, cracks, pits. It allows you to reliably repair defects on mineral substrates, previously plastered walls and ceilings. Prepares structures for painting, gluing wallpaper, seals seams between gypsum plasterboards, cracks and other damage to gypsum board, fills joints in concrete structures and between prefabricated elements. Suitable only for indoor work in dry rooms.

Application technique

For novice craftsmen, the process of applying the putty is very difficult. Here are some guidelines to avoid problems while working:

- The speed of drying of the mixture baffles the slow putters. After all, the main principle of applying the starting composition of the Prospector is that the surface is putty in one go. The application of the mixture to the walls is carried out in parallel strips, so that one strip is layered on the previous one before it begins to set. Otherwise, the surface will not turn out smooth. The stripes run in any direction: vertically, horizontally or diagonally.

- The work is done with at least two spatulas. A narrow 80 or 100 mm spatula is used to scoop the solution out of the container, and work with wide spatulas. The width of the working trowel is selected depending on the surface area.

Work tool

It is important to achieve a uniform layer thickness. In the absence of skill, this is difficult to achieve.

The master does this reflexively, and the beginner will have to constantly monitor the angle of inclination of the spatula and the force of pressing. It is necessary to "feel" the optimal combination of the density of the mixture, the angle of inclination and the pressing force of the spatula. Too small an angle will result in a thick and uneven layer. Excessive pressure will cause the filler to squeeze out around the edges of the trowel and create unwanted streaks.

After the first coat is applied, the putty should dry completely. This usually takes 24 hours at normal humidity. During this time, excess moisture will not remain in the thickness of the putty.

Before the secondary application of the starting composition, the surface is again primed. This will prevent uneven drying of the second coat and improve adhesion.

The last layer before gluing the wallpaper is sanded with mesh No. 60 and No. 80.

Expert advice:

All used tools are cleaned with water immediately after the end of work. The dried mixture is removed only mechanically, which can damage the spatulas.

Ready-to-use building mixtures accelerated many works, made them less labor-intensive. And the simplicity of their preparation and application today has allowed many home craftsmen to independently carry out repairs at a professional level.

How to prepare finishing mortar?

Correctly preparing the finishing solution is a very important point, since it depends on how high-quality the coating will be and how easy it is to work with the finished solution.The most important point in this process is the careful observance of all the necessary proportions and the uniformity of mixing the solution.

You should follow the advice of experts when mixing the solution.

- To prepare the mixture, it is better to use a plastic container in the shape of a cylinder. The smooth walls of the container are much easier to clean after finishing work.

- The required amount of water is poured into the prepared container, then, stirring constantly, the mixture is gradually poured, which will avoid lumps.

- A small amount of the solution can be mixed by hand. If a significant amount of ready-mixed mixture is required for finishing the room, it is more advisable to use a mixer. The putty consumption must be calculated in advance, before starting work.

- It is necessary to take into account the fact that the solution must be kneaded twice. A dry mixture is poured into a container with water, thoroughly mixed. Next, you need to let the solution stand for a while and stir again thoroughly.

Each package of dry material contains detailed instructions in which you can find the exact proportions of water and putty to create a high-quality solution, and an accurate description of each stage of mixing the mixture. Therefore, before mixing the solution, you need to carefully read the instructions. Only if all parameters and conditions are observed, a solution of the required consistency will be obtained.

Dry building mixes "Prospectors" are practical and fairly easy to use. The use of these materials greatly simplifies the process of interior decoration.

In the video below you will see the difference in the application of plaster and finishing putty from the Prospector.

Features of the putty

Depending on the composition, different variants of Prospectors putties are very different from each other. Most of them are based on mineral components (white or gray cement, gypsum, etc.), and also contain reinforcing fibers, antiseptics, fillers, modifiers, polymer additives. Thanks to the modern formulation, the putties are characterized by the following properties:

- Plastic. Any material is easily applied, leveled with a thin layer over the surface, does not flow down, does not form roughness. It fills well all irregularities, cracks, which increases the density and strength of the finished coating.

- High adhesion. Putties adhere reliably to many building substrates, including unprimed ones.

- Waterproof. After drying, the products do not have large pores, so the formed film will not only be strong, but also moisture resistant.

- Environmental friendliness. All putties "Prospectors" are safe, do not emit harmful substances, including during heating and burning.

- Resistance to negative factors. The materials are resistant to ultraviolet radiation, wind and precipitation, chemicals.

- Versatility. The product line includes products for facades, for interior work, leveling and finishing. In addition, putties fit well on concrete, brick, stone and other bases, therefore they can rightfully be considered universal.

Putty mixtures by Prospectors

Putty mixtures by Prospectors

All putty pastes are easy to sand after drying, resulting in a perfectly smooth finish. They are sold in bags of 5 and 20 kg, as well as in plastic buckets of 7-15 kg. The shelf life of the formulations is 1 year.

Peculiarities

Putty "Prospectors" is a domestic product with European quality. The recipes for the preparation of leveling compounds are based on time-tested standards combined with the latest modern developments.

Modern putties from this manufacturer have the following technical characteristics:

- working temperature - from +5 to + 30 ° С;

- consumption (with a layer thickness of 1 mm) - 1.1 kg / m2;

- batch proportion - 0.3-0.36 l / kg;

- the viability of the diluted mixture is from 1.5 to 24 hours (depending on the type of solution);

- adhesion - not less than 0.25 MPa;

- frost resistance - 30-35 cycles.

The composition of putties from "Prospectors" (also depending on the type) includes:

- regular or most often white cement;

- natural fillers;

- polymeric and modifying additives;

- reinforcing fibers;

- antiseptic.

Due to their composition, the putties of this manufacturer differ:

- Plasticity. They can be easily applied in an even and thin layer to the surface of the substrate. In this case, the solutions "do not slip" and do not form roughness.

- Good adhesion to non-primed surfaces.

- Waterproof. This becomes possible due to the fact that the putty does not form pores when it dries.

- Environmentally friendly. The material is completely safe and does not emit toxins even when heated and burned.

- Versatility. It can be used both for interior decoration of premises and for leveling of facade walls. It fits perfectly on substrates made of stone, wood, brick and other materials.

- Resistant to external negative factors, including natural phenomena and ultraviolet light.

- Fast drying ability. At t about 20 ° C, the putty dries no longer than a day.

In addition, such a putty is easy to sand, after which a perfectly flat surface is obtained.

The composition is sold in strong kraft bags of 20 kg, packages of 5 kg or in plastic buckets of 7 and 15 kg. Putty in buckets - ready-made, in bags - in the form of a dry powder, which must be diluted with water according to the instructions. The shelf life of the mixture is 12 months from the date of manufacture.