Types of facades

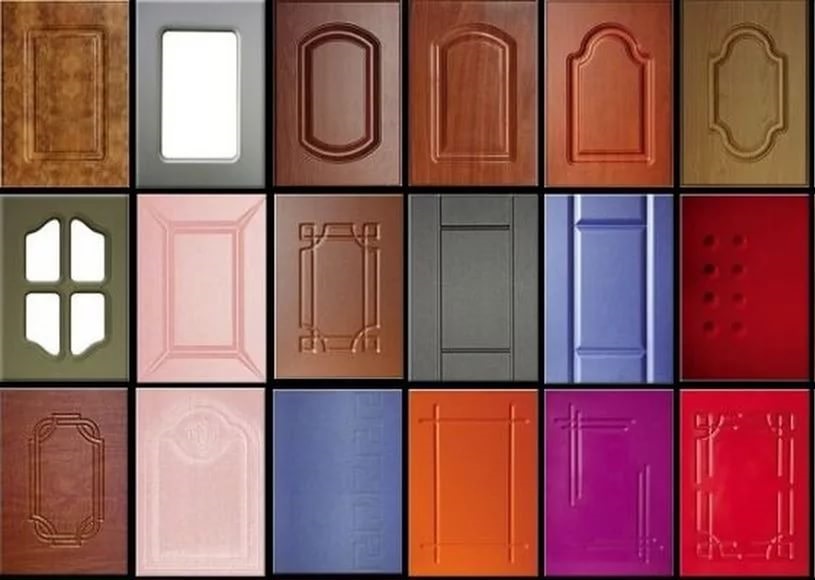

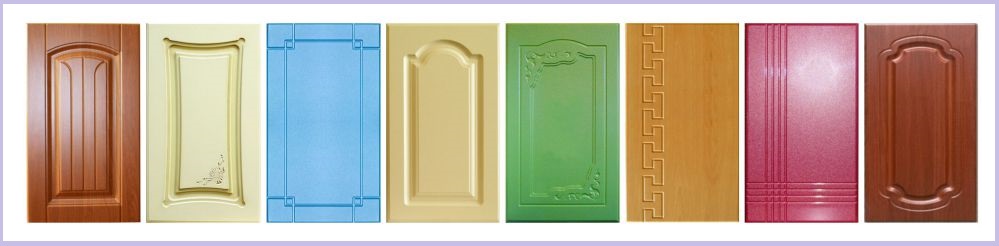

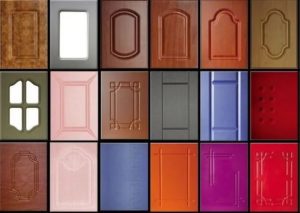

In addition to the material of manufacture, its shape and structure are important for the design of the facade.

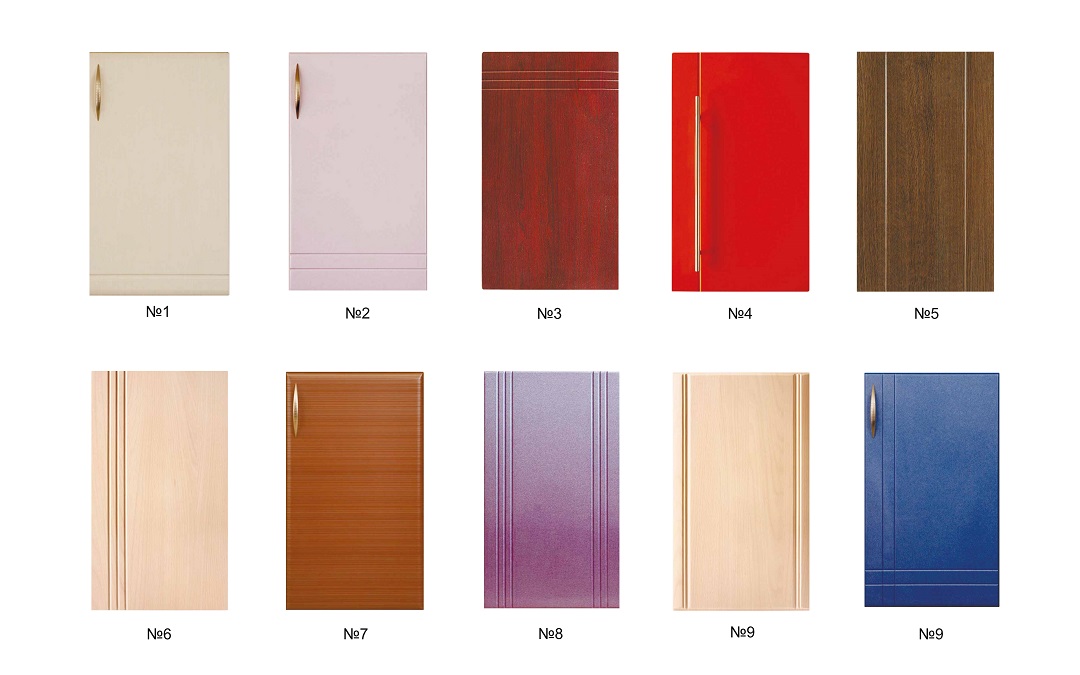

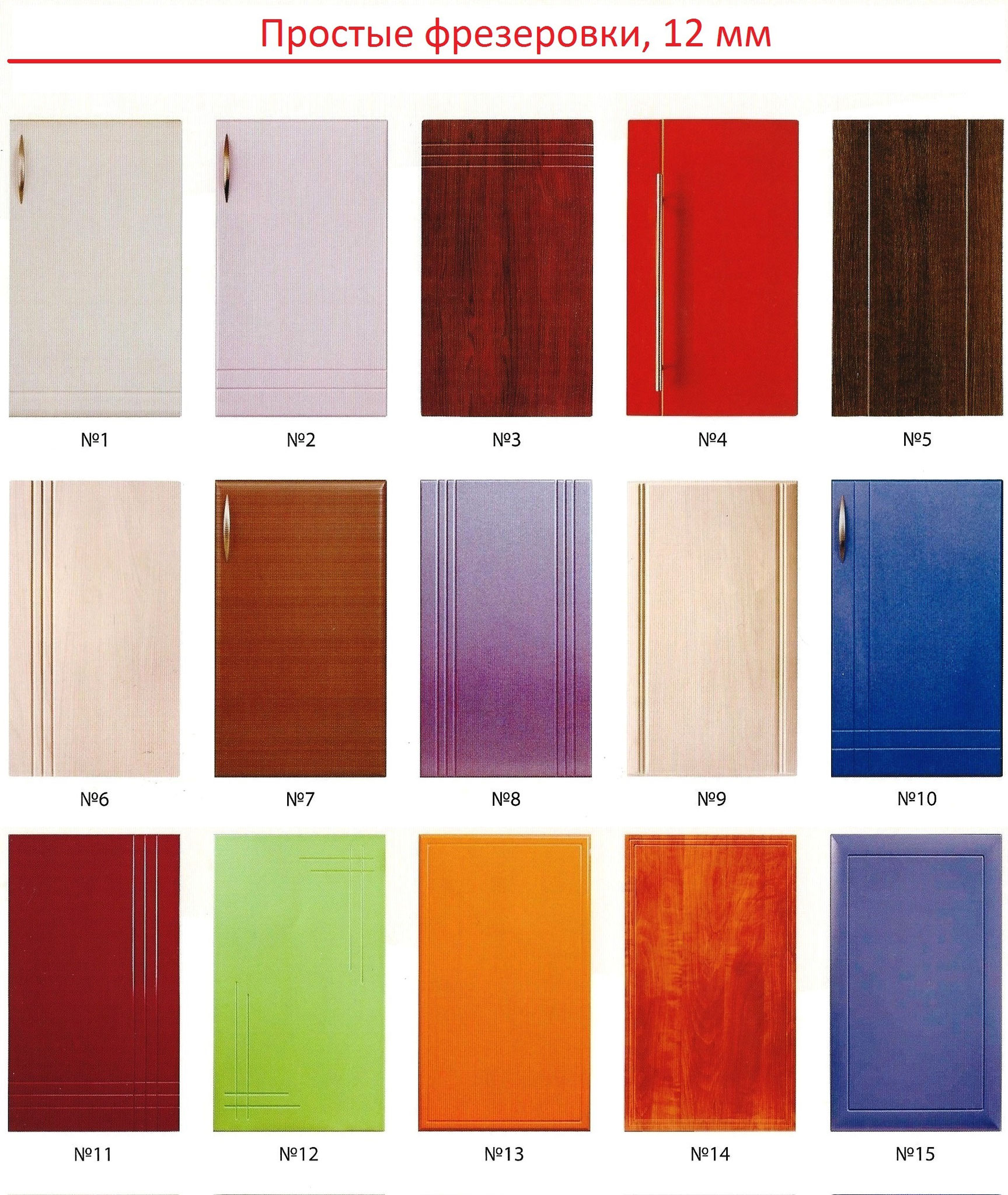

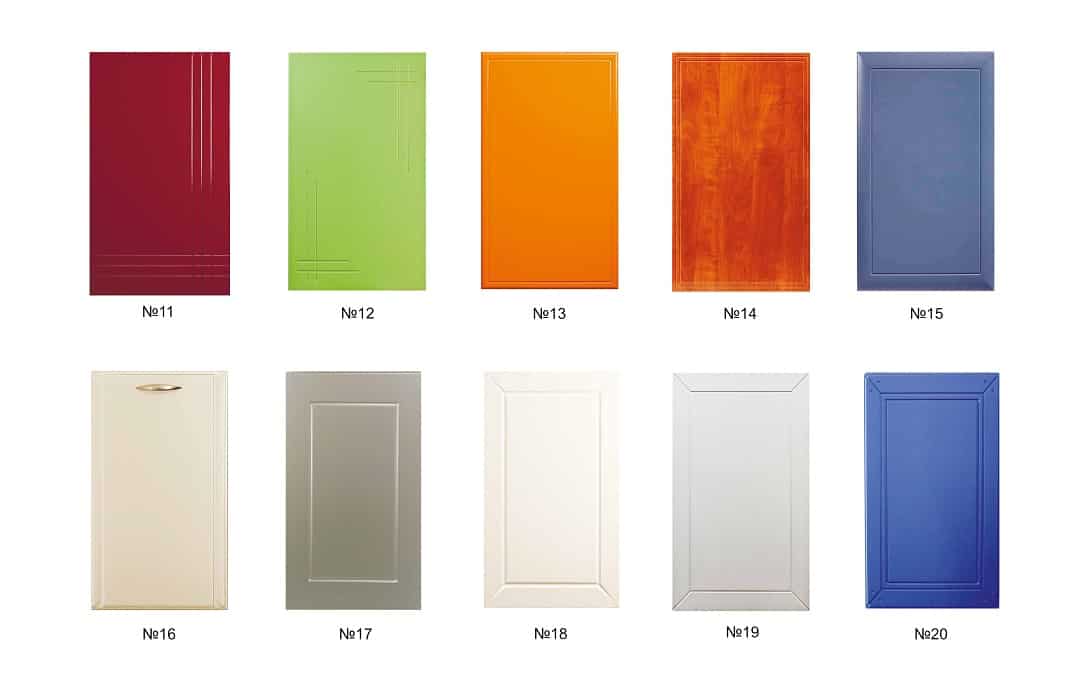

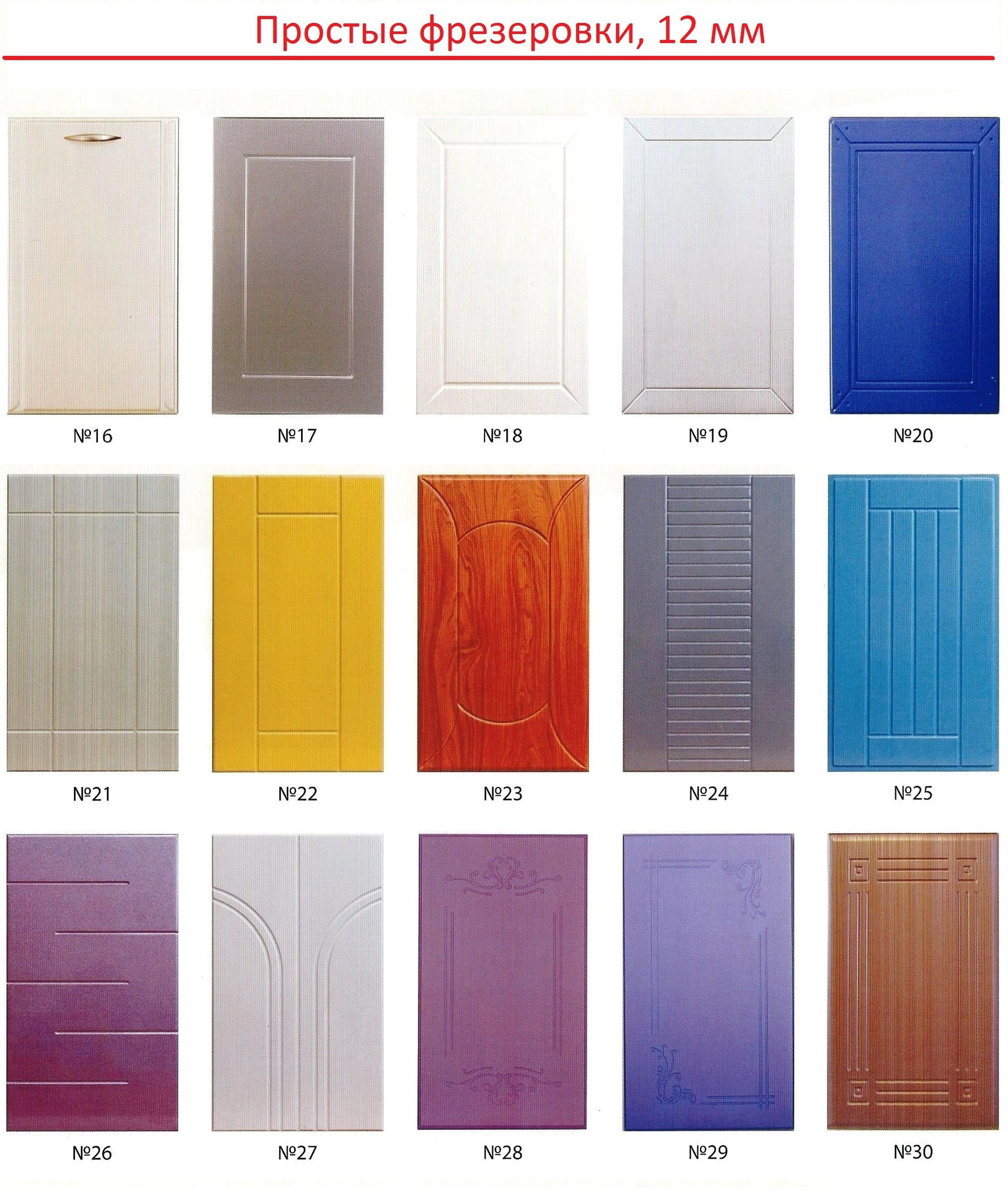

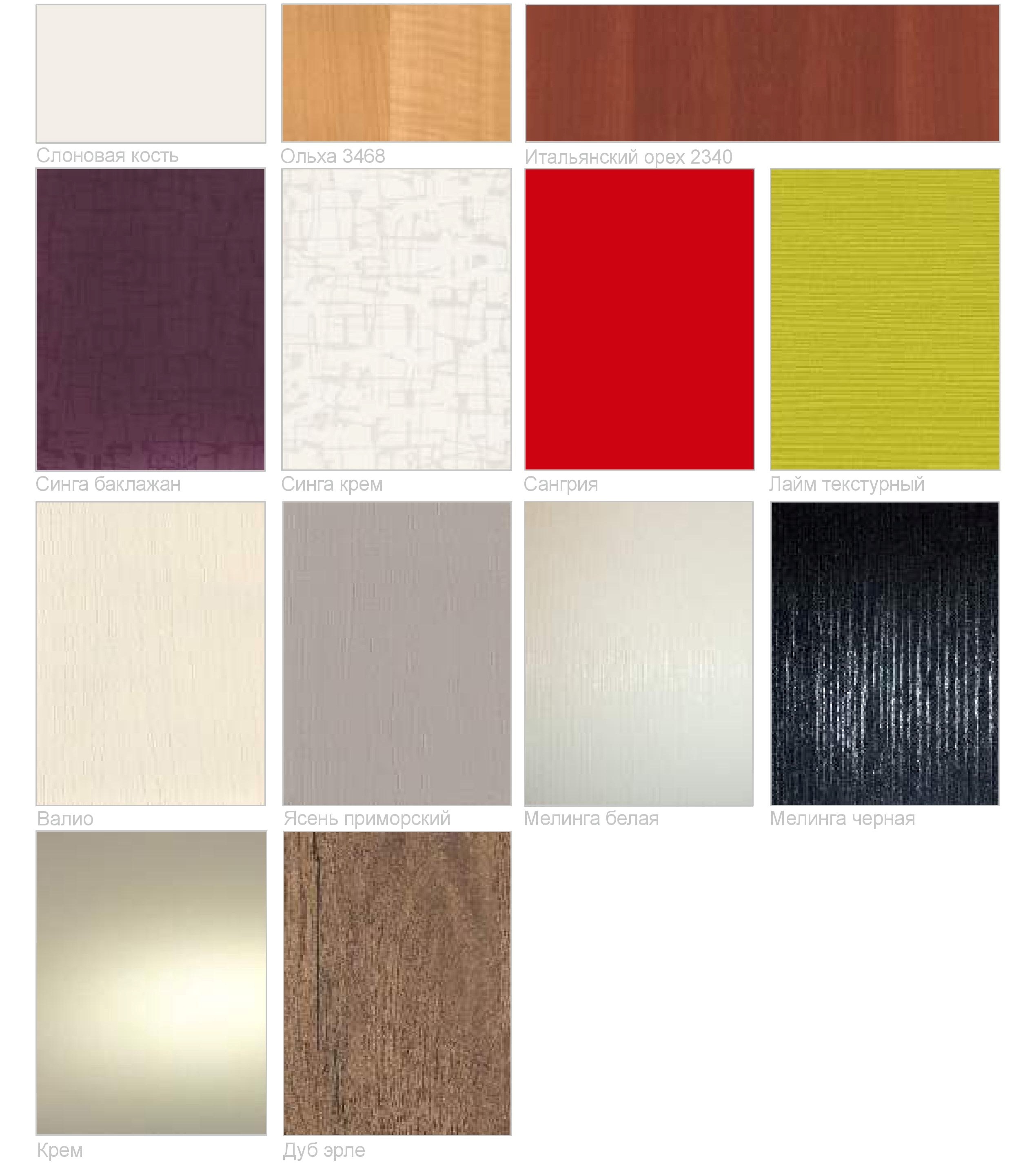

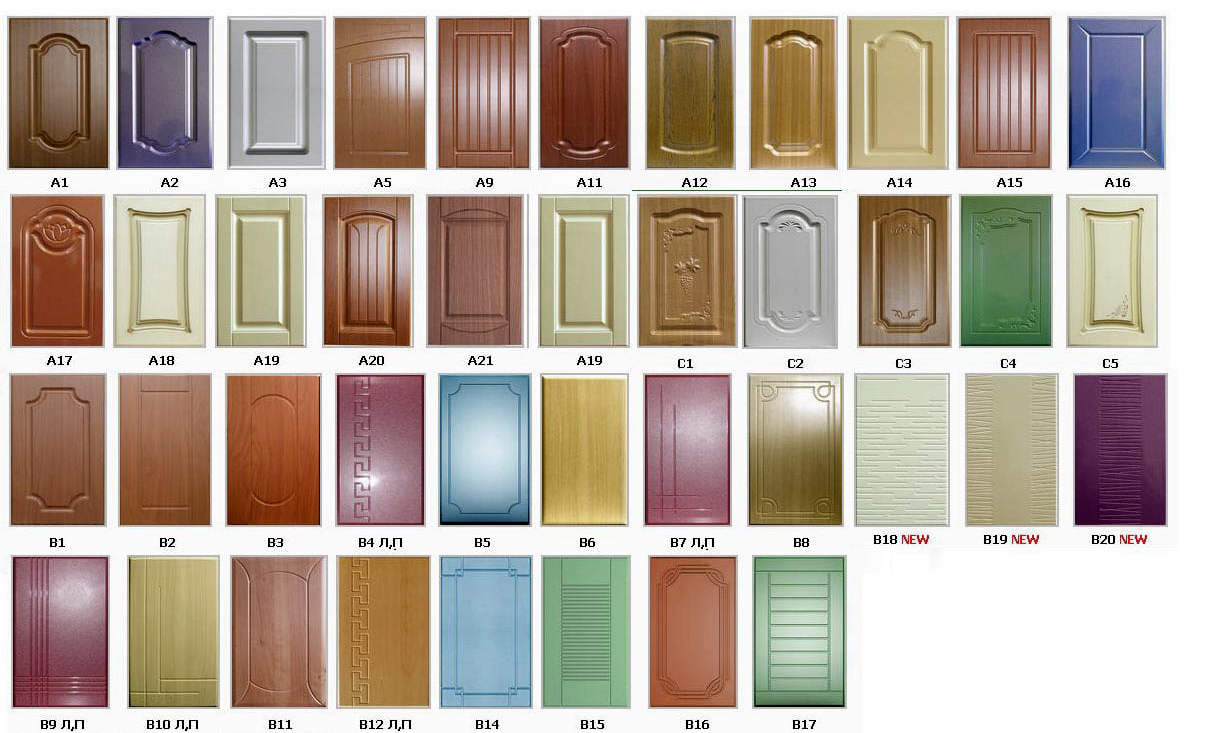

Solid facades (panel boards) have a flat or milled surface. Any color and shine is possible; differ from each other in the edging material.

The sash ends are exposed to constant mechanical stress and wear out faster, so the edges of the product are sealed with a more durable material - PVC or acrylic. The color can be chosen either coinciding with the main one, or contrasting.

For high-tech and modern interiors, panels in an aluminum frame are often used. In fact, this is the same edge, but made of metal. The design of the facade in an aluminum frame is more effective, the facade does not wear off and does not change its dimensions. However, the metal needs to be cleaned more often. The next photo shows panels in an aluminum frame.

For high-tech and modern interiors, panels in an aluminum frame are often used. In fact, this is the same edge, but made of metal. The design of the facade in an aluminum frame is more effective, the facade does not wear off and does not change its dimensions. However, the metal needs to be cleaned more often. The next photo shows panels in an aluminum frame.

In the photo - facades of MDF plastic in an aluminum frame

In the photo - facades of MDF plastic in an aluminum frame

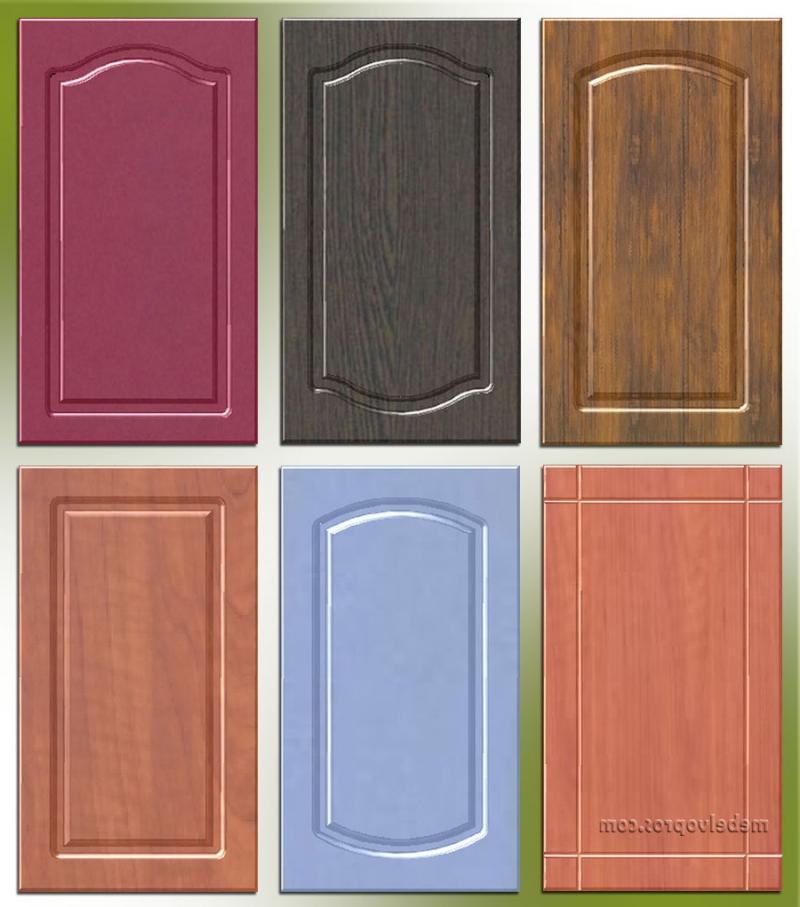

- Paneled - a panel is inserted into a rectangular frame made of MDF or chipboard slats. The latter can be made of wood material, solid wood, glass or acrylic plastic. Plastic in an aluminum frame is often confused with a paneled facade, but in the first case, one facade cannot be replaced with another.

- Curved - facades of complex curved shapes. They look delightful in the interior, especially glossy ones or with a "chameleon" effect. Not every technology is suitable for coating. Which option is better - acrylic, PVC or even enamel - depends on your budget and personal preference. The photo shows a corner kitchen with radial facades.

Plastic kitchens involve the use of a variety of materials and designs. Before choosing any of them, you need to find out what kind of plastic is meant and what qualities it has.

Plastic kitchens involve the use of a variety of materials and designs. Before choosing any of them, you need to find out what kind of plastic is meant and what qualities it has.

Selection Tips

To begin with, determine the material of the doors. If you like to update your furnishings every five years, then plastic or acrylic headsets are for you. They are inexpensive, manufacturing technologies are constantly being improved, so you will have a bright, practical kitchen that meets fashion trends. If you need a solid set that will last for a long time, then it is better to choose models with doors made of wood, veneer, metal or ceramics. They are distinguished by their durability, strength, and the texture of natural raw materials gives them solidity.

Instagram @ximkimebel

Instagram @mykitchen_moscow

Instagram @classic_mebel_ufa

Having decided on the material, they choose the shape of the facade. It can be solid or framed. Solid ones are suitable for any interior. Frames look more interesting, but they need to fit into the existing style of the apartment.

The next question is to choose between matte and glossy surfaces. Caring for them has its own characteristics. Until recently, gloss was considered the favorite, the trend in recent years is shifting towards matte finishes. When choosing a color, consider the area of the kitchen, its illumination. The rest of the decoration of the apartment is of great importance. To make the kitchen fit into the overall design, you can use the same colors and textures in its design as in other rooms.

Instagram @ legacy4room

Instagram @ ab.mebel_

Wooden facade

Wood is classic, tradition and elegance. Such facades fit perfectly into the classic and Scandinavian style, look good in country and provence. Wood gives the room a special warmth and comfort.

Advantages of wooden facades:

- environmental friendliness and the presence of a pleasant natural woody aroma;

- presentable appearance, solidity and elegance;

- durability;

- maintainability. If, over time, scratches, scuffs and other defects appear on the wood, they can be easily eliminated using special equipment. It remains only to apply a layer of varnish or paint - and the facade will become like new;

- the ability to quickly transform the appearance. With the help of varnish, paint or stain, wood can be given any shade and appearance. There are aging techniques, and an inexpensive pine facade can be transformed so that it will not be distinguished from its mahogany counterpart;

- solid wood is a dense homogeneous material, and therefore the fasteners hold well in it.

Minuses:

high price. A natural wood facade is not a cheap pleasure, because some manufacturers make the technology a little cheaper. The frame of the sash is made of solid wood, and a panel from another material is inserted inside, incl. glass or MDF. By the way, veneered MDF is outwardly difficult to distinguish from wood. It turns out to save money, to preserve the woody aroma, and not to suffer in terms of aesthetics;

if the protective coating is broken, moisture can enter the wood, causing the sash to swell, subsequent difficulties in opening them, squeaks and the appearance of mold. So the protective coating must be protected and renewed as needed;

humidity, which varies widely in the kitchen, can affect the size of the facade. Variations within 2-3 mm are possible;

wood suffers from rotting and darkening, but there are species that are more resistant to these phenomena than others

These are, for example, larch, oak and beech;

detergents must be chosen carefully. It is not allowed to use abrasives, and some products may contain substances hazardous to wood.

There are also those who reproach the tree for lack of variety. Taking into account the unique shade of each breed, wide possibilities of finishing (varnishing, staining, patinating, etc.) and decoration (creating carvings and panels), it becomes obvious that wooden facades are quite diverse.

For the manufacture of a kitchen facade, different types of wood are used:

- pine is the most budgetary species, it costs a little more than wood-based panels, it is highly soft, therefore even pets can scratch the material. The restoration will have to be carried out too often, and if we consider that each damage is a risk of moisture getting inside the material, it is better to look towards other species, and use the pine as much as possible to make the frame;

- ash is much denser than pine, but a couple of times more expensive. The wood has a light, slightly yellowish tint, looks great in a Scandinavian interior, but if desired, it can be given a different shade;

- oak is a durable expensive wood of a rich color, this is a real classic, although it may seem to some that such a facade looks gloomy;

- beech resembles oak in color, costs a little cheaper, shows itself perfectly in operation;

- larch has an important advantage - moisture resistance. This wood was used in the construction of the foundations of Venetian houses, for the construction of ships, therefore it will withstand steam in the kitchen;

- cedar, cherry, mahogany, and exotic woods are less common materials. Such facades are expensive, but they also look exclusive.

Wooden facades are heavy, therefore experts advise combining them with solid wood frames - glued plates may simply not withstand the load.

Painting and alternative processing methods

Considering kitchens based on MDF, you can see that they are matte, glossy, painted, laminated, with milling, etc. If you are interested in MDF kitchen facades, there is a separate material, where all types of decoration and coverings are presented.

MDF is already a kind of classic.Furniture from this material can be bought to order, or you can take a ready-made version of any color, size, etc.

Painted facades for the kitchen, unlike other options based on MDF, can cost 20-50% more. Basically, they choose which is better - dyed or film. When comparing them, there are a number of advantages and disadvantages.

Advantages

Reading the reviews, based on personal experience, as well as communicating with other craftsmen, several conclusions were made about the strengths of painted MDF.

In comparison with film products, the advantages are as follows:

- Unique products. They are varied in color and design. The film does not give such a choice;

- Temperature resistance. The paint makes the coating more resistant to temperatures;

- The best protection against mechanical stress. It is extremely simple to scratch the film;

- A product of any shape and configuration is subject to coloring;

- At the same time, you can paint new panels, or restore old film. The film is simply removed and the facade is painted;

- Painted facades must be polished. It's like with cars. The paint is polished, a protective layer is applied if necessary, the gloss is restored.

The benefits are really significant.

But it is also worth looking at the shortcomings.

disadvantages

Since this is enamel that is being varnished, the material has some expected drawbacks.

Weaknesses include the following points:

- Weak resistance to abrasion and some chemicals... Such a facade cannot be cleaned with metal brushes or scrapers. The process of destruction may also begin from exposure to alkalis, concentrated acids, solvents, etc.;

- It is better to protect such a kitchen from direct sunlight.... This problem is mainly related to the dyeing of not the best quality. But still, over time, the enamel can fade;

- High price... This is a really strong argument for many buyers;

- Chips may appear... Yes, they can potentially be repainted, but the appearance will no longer be the same. You will have to buy a special and rather expensive paint with a hardener.

In an extreme case, the replacement of kitchen facades is performed, when it will no longer be possible to correct the situation with ordinary staining.

How much the advantages outweigh the disadvantages, or vice versa, everyone decides for himself.

Be sure to leave reviews for those who have already ordered a kitchen based on painted MDF facades. It will be interesting to know your opinion on this matter.

Painted facades

Painted facades have a bright, attractive and memorable look. The whole palette of colors to choose from. Finding the right one for yourself is not difficult. In addition, various special effects can be added to the color of the coating: for example, artificially aging or adding a metallic sheen.

The workpieces are pre-applied with a primer, then a layer of enamel, and then a layer of varnish. To give the color depth, varnish can be applied in several layers. It is the thickness of the varnish layer that determines the ease of use and maintenance of this type of material.

Speaking of care, even the heaviest dirt, including fatty ones, is easily erased from the painted surface, these are simply irreplaceable qualities for the kitchen. In addition, enamel facades do not accumulate odors and also tolerate high humidity well.

However, the coating is not without its drawbacks. So, it is easily susceptible to mechanical stress - chips are easily formed on it. At the same time, it is almost impossible to restore the original appearance of the product. Further, when using painted facades, it is necessary to avoid the ingress of alcohol-containing liquids on them, since they are capable of forming stains that will be quite difficult to remove.

How to choose the right material for facades

Kitchen sets made of MDF and plastic have their pros and cons, but the final choice of facade finishing will depend on the quality of the material used.

Here are the basic rules for the selection of facades for the kitchen:

The emission class of MDF is important as it determines the effects of formaldehyde resins on the body. E1 class material is more environmentally friendly and of higher quality, while E2 class MDF emits formaldehyde, therefore it is prohibited in the production of children's furniture. This indicator is necessarily indicated by the manufacturer in the quality certificate.

A set with convex or concave facades costs 10-15% more than a regular set.

Veneered MDF facades are considered an analogue of wooden furniture

This option is optimal in terms of quality and price.

If the budget for the purchase is limited, then you should pay attention to the kitchen facades, covered with paper-resin film. They are of low quality and low price.

The weak point of the ends of the doors is their finish

For this reason, choose 1.2-1.5mm thick aluminum or ABS-branded edgebands and avoid melamine finishes. Veneered or wood edging is more expensive compared to recent models.

The best option for all characteristics is facades with a glossy finish with several layers of enamel painting. Sometimes the formed gloss is covered with acrylic. It has both positive and negative sides. Minus - acrylic facades deteriorate with any mechanical action. Plus - they are easily repaired. Gloss is also covered with PVC film. Such facades for the kitchen have more disadvantages than advantages. Therefore, this type of finish belongs to the budget options.

Custom kitchen headsets are in demand, but such furniture is 30% more expensive than standard ones.

Brand choice is another important criterion. High-quality facades of Russian production are offered by well-known companies: "Maria", "Kitchen Dvor", "Call", Elt and "Atlas-Lux". Facades of European production are significantly more expensive, including due to their popularity and high quality. Check out the following cuisines: Italian Aster Cucine, Scavolini, Pedini, Snaidero, Czech Hanak, German ALNO and Nolte Kuchen.

Inspect the specimen before purchasing to select the ideal panels. It should not contain bubbles, scratches or dents, coating peeling, chips, waviness on the edge, etc.

Some nuances related to the choice of plastic facades:

- choose plastic for cladding kitchen facades if the interior is decorated in a modern style;

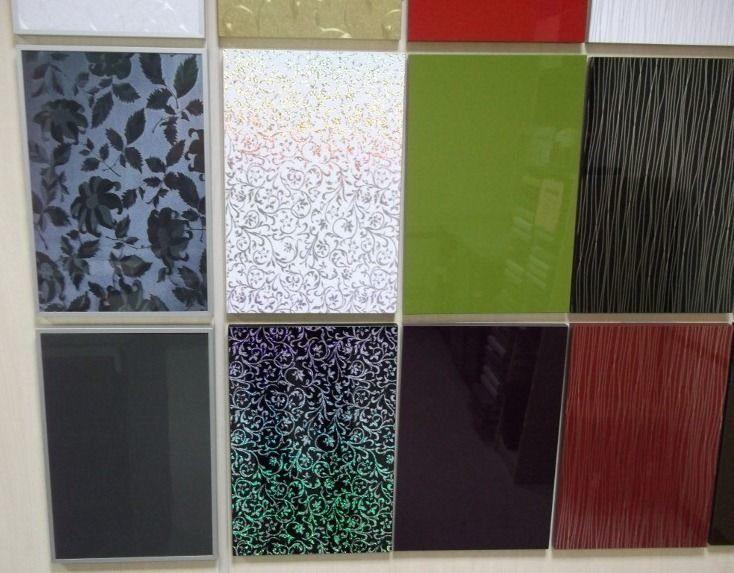

- it is better to place the facades with drawings on the upper cabinets - this way the interior of the kitchen will look more interesting;

- the combination of matte and glossy surfaces will give the room a cosiness and visual expansion of the space, since the gloss reflects objects and makes the room wider. And the matte sheen of the facades creates comfort;

- a reliable option for protecting the ends - edge-postforming;

- a practical solution that will add a touch of flavor to the interior is the use of frame facades with an aluminum profile or MDF frame.

There is no single answer to the question of which is better for the kitchen: MDF or plastic. The choice of kitchen finishing material largely depends on objective factors: the budget, the interior of the room, the quality characteristics of the coating, etc.

Other types of furniture fronts

Glass furniture fronts - processed (polished) glass at the edges (including curved glass) with various coatings, are most often used as a decorative element of furniture.

Facades made of artificial stone based on acrylic resin are distinguished by high reliability, durability and ... cost.

Louvered furniture facades are made of solid natural wood. Promotes excellent ventilation of the interior of the furniture.

Roller shutters are a modern version of vertically opening furniture fronts, the so-called furniture blinds.They are made of plastic profiles with different coating colors, including those imitating valuable wood species.

Facades covered with leather (natural or artificial) - they look spectacular, practical, functional and unpretentious in maintenance.

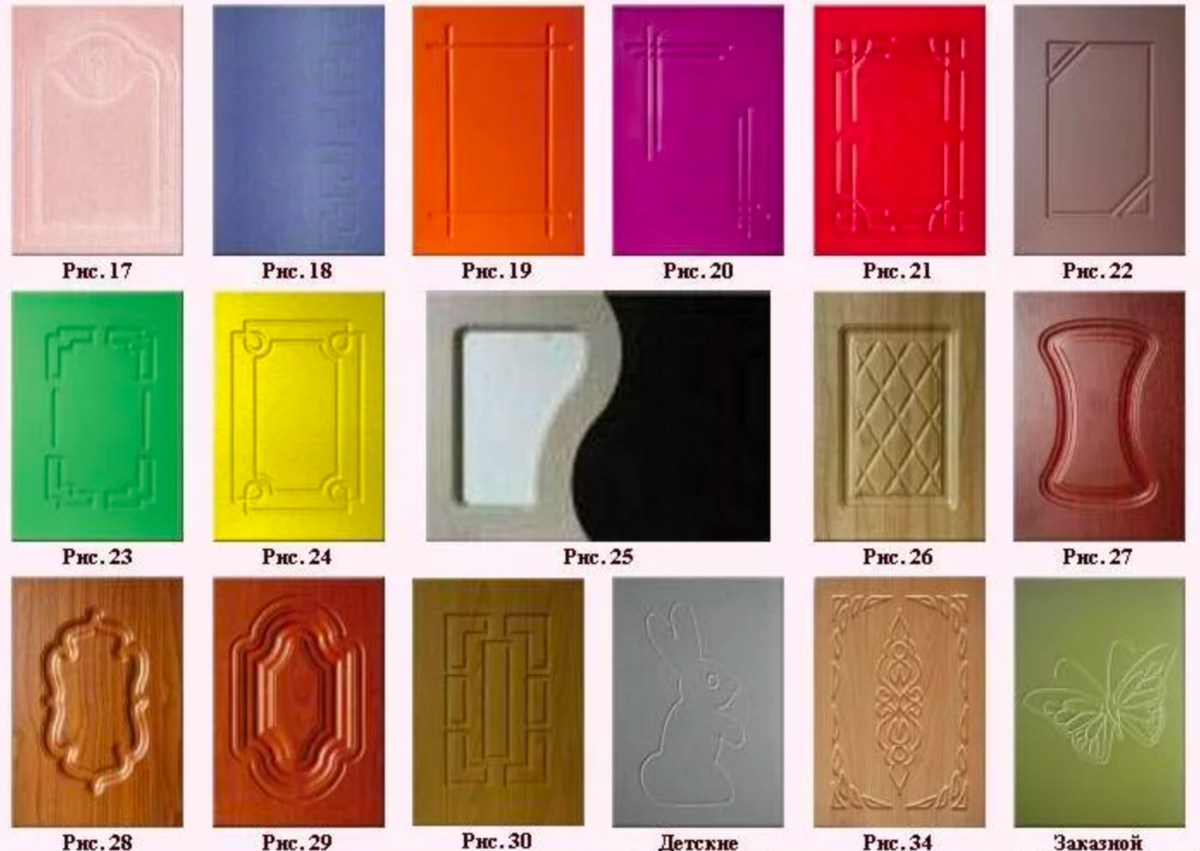

3D facades - made of MDF board with surface milling imitating waves, sand dunes, flames, bark of natural wood and other ornaments. Lined with PVC foil, or painted in a color that emphasizes the desired special effect.

Facades with photo printing - an image is applied to the surface of the MDF facade using a special technology, which is covered with a protective layer of glossy or matte acrylic varnish.

Acryline facades - a new direction, is a MDF board covered with high-gloss acrylic plastic, which has a variety of colors, is unpretentious in maintenance and is an environmentally friendly material.

Furniture facades made of specific materials (plywood, OSB panels, stainless steel) are suitable both for arranging utility rooms and for creating a unique interior style.

In conclusion, I would like to say that when choosing a furniture facade, it is not so important to know which facade is better in terms of technical quality characteristics, how much it is necessary to have an idea of its appearance, the ability to harmoniously create a comfortable environment or integrate into the existing interior, in the end, it is simply pleasing to the eye and cheer up

Which is better: plastic or film on the kitchen facade

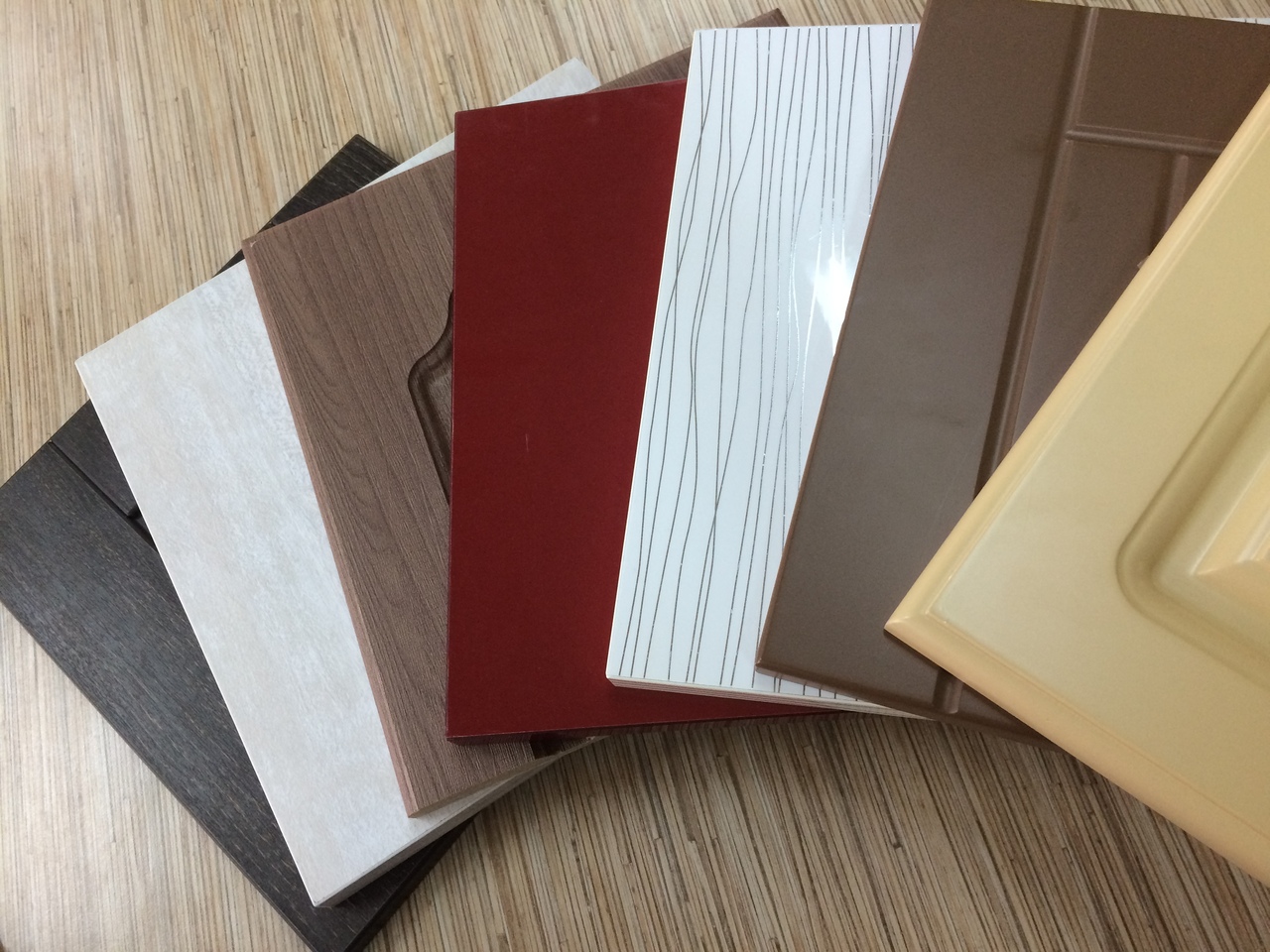

If MDF for the kitchen is the optimal basis for the facade, then there are always difficulties with the choice of the top layer. What to prefer: plastic, enamel, film? Evaluate the appearance, compare the cost, and, most importantly, determine exactly how much time you are willing to spend every day taking care of furniture.

Advantages and disadvantages of film headsets

The best combination of price, quality and aesthetics - for film facades with MDF-base. The material is unpretentious to maintain. Easy to clean with common household chemicals. The film can only deform under the influence of high temperature, steam. It is necessary to ensure that the sun's rays do not fall on the surface from the window.

The advantage is an unlimited number of design options, the ability to individually combine colors and textures, covering complex shapes.

Poppies on PVC film: designer kit

A matte film with a wood grain pattern is used to create classic headsets with carved facades.

Practical surface: no stains visible on the matte finish

Both film and plastic can serve as canvas for photo printing. Multi-colored drawings and photographs are also of practical value: they are less noticeable for water stains than on plain glossy facades.

Bright and extraordinary kitchen: film on MDF

Designers combine several colors and textures in 2 basic shades, just like in this “chocolate” kitchen.

Floral printed wrap

Design and operation of plastic headsets

Plastic MDF facades look bright: rich colors, mirror shine. The material is not afraid of the sun, high temperatures and humidity levels. But glossy plastic panels require regular maintenance. Fingerprints remain on the mirror surface, splashes of clean water leave stains.

Semi-matte plastic textures are more practical than glossy ones.

The most fashionable color of the season in a plastic kitchen facade

Glossy plastic, even in a dark color, will make a small kitchen extraordinary and spacious.

Small set with a plastic front

Lovers of gloss will have to polish the kitchen to a shine every day.

Solid color set: zest - shade

The latest "squeak" in kitchen fashion: plastic in an aluminum profile.

Acid-colored plastic with aluminum edging

Painted MDF: stylish solutions for modern kitchens

Unlike plastic and film, enamel adheres perfectly to any surface.Painted facades require careful handling and specific maintenance. The lacquered enamel must not be cleaned with conventional products containing chlorine and some surfactants. Cleaning with powders is prohibited.

Gold painted kitchen: enamel on MDF

It is best not to use hard sponges. Under aggressive action, the varnish becomes covered with a mesh of small scratches, the surface loses its shine. You can restore the original appearance by polishing, but the upper protective layer becomes thinner during polishing. It will not be possible to carry out the procedure repeatedly.

Enamel is the choice for kitchens with complex facades.

Glossy red painted headset

A combination of two colors and an interesting solution for the shape of the doors: with longitudinal stripes and contrasting colors.

Anthracite and red: a successful combination of shape, color and shine

Futuristic 3D facades without external fittings. You just need to touch the door to open the cabinet. The laconic form and complex texture are a play of contrast.

Painted textured MDF panels

Airbrushing is a feature that emphasizes the uniqueness. Each drawing is created only once.

Kitchen with a twinkle: airbrushing on enamel

Veneer and solid wood: the luxury of natural wood ↑

Veneer is increasingly being combined with other facade decoration options. For example, a patina, enamel or varnish is applied to a veneered facade. Facades with veneer are combined in one set with painted or film panels.

Patinated veneer on MDF

The veneer in a warm golden hue contrasts with the black gloss of the plastic and the photo printing on the dark glass of the apron - an interesting idea.

Design project: veneer in one set with plastic and glass

The veneer in a fashionable light-colored zebrano texture will perfectly fit into a small modern kitchen with a snow-white top tier of cabinets.

Film and veneered MDF in one set

Video: how facades are made with PVC film ↑

Video: the manufacturer shows the whole process of covering MDF panels with decorative film.

If you are at a loss with the choice of finishing decor, contact the designer. A specialist will advise which type of coating will be the best for your kitchen unit. When ordering an individual production, be sure to ask what material the base is made of. Find out which manufacturer's materials are used to cover the facades. Ask for a warranty in case there is a problem with the topcoat.

Base for PVC film coating - materials and requirements

Upon request, the next note will be on the topic - do-it-yourself wall sliding wardrobe at home with a photo. We believe you will like it.

The PVC coated panel consists of three parts:

- basics;

- films;

- edge cladding (sides).

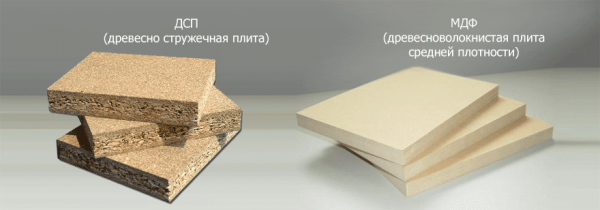

Not all substrates are suitable for wrapping. Manufacturers use two types - chipboard and MDF.

Chipboard facades are more affordable, but their durability is a very controversial issue. This material perfectly absorbs moisture and swells due to which the film begins to peel off. Moreover, the poisonous resins that make up the chipboard can evaporate into the air if the integrity of the coating is disturbed and have a toxic effect on the human body and domestic tetrapods.

It is thanks to the cheap chipboard structures that the film-based coating has an undeserved reputation for poor quality and unreliable material.

In theory, PVC can also be coated with perfectly sanded real wood panels. However, in general, the manufacturer strives not to hide, but on the contrary, to highlight the appearance and natural pattern, thanks to which the tree is also not suitable for applying a film.

PVC coating is recommended for facades made of medium density fiberboard - an environmentally friendly and non-hazardous material and high performance.It does not change its initial shape, is resistant to moisture and high temperatures, and its even surface without notches reduces the risk of film peeling.

Characteristics and manufacturing of furniture facades

Before starting a conversation about facades from an MDF profile, it is necessary to explain the composition of the MDF slab - the main element of this entire structure. What is this material that is so popular among furniture manufacturers?

To obtain this component, they use the process of processing the smallest sawdust from different types of wood, which are first dried and then pressed using a hot method. It turns out a medium density fiberboard.

Before pressing, the wood is treated with a special adhesive composition, which includes paraffin and lignin. Therefore, we can safely say that MDF is an environmentally friendly material and does not cause allergic reactions.

These panels are most widely used for interior decoration. Ceiling decoration is also produced with MDF plates. Nowadays, 3D panels for walls have also become popular.

Here is about moisture resistant mdf for walls. MDF panels can be glued to the wall. Manufacturing frame facades from profile mdf is present in any furniture production. A profile, the thickness of which can be 15-22 mm and a width of 50-80 mm, is connected in a square or rectangular frame. The profile groove has a size of 4 to 10 millimeters.

The appropriate material is installed in it, depending on the style of use of the part. For example, an mdf profile can be filled with a mirror, laminated mdf panels for walls, colored, transparent glass or facade chipboard.

Frame facade with mirror

If the thickness of the filling is less than ten millimeters, a silicone sealant is added to the basic filling material. Let's say the stained glass that will be inserted has a thickness of 7 mm. Then the silicone base will hold the facade filling well enough in the grooves.

The frame profile itself can be laminated with pvc film, painted or finished with natural veneer. The pvc film protects sharp corners during the operation of the part, as they are more often subjected to physical stress.

In addition, the processing of the profile with this compound gives it even greater strength than processing with melamine film. In the manufacture of frame mdf facades, it will not be difficult to manufacture custom-made parts. The profile can be easily made in the format of the dimensions provided.

A huge palette of colors for filling the frame allows you to create a large selection of colors for frame facades made of mdf, while the price will remain invariably affordable for a wide range of consumers.

Various colors

Care Tips

Caring for facades with a foil is easy. This does not require special means, but ordinary detergents are suitable.

Requirements for the content of products using PVC:

- avoid prolonged exposure to moisture on the material;

- do not allow surfaces to cool below –15 degrees Celsius;

- place furniture away from heating and heating devices, stoves and ovens so that the film does not peel off;

- temperatures above +70 degrees Celsius are destructive for polyvinyl chloride boards;

- for cleaning, do not use chlorinated and aggressive compounds, solvents and agents that contain solids that can damage film products.

If in some places the PVC layer leaves the base, the problem can be solved with liquid nails, ordinary PVA wallpaper glue or Moment glue.

For more useful and interesting information about film facades made of MDF, see the next video.

Pasting a kitchen set with foil at home

To successfully glue the MDF kitchen facade or an apron at home, you need to properly conduct the preparatory stage. It consists of the following points:

- Preparation of facades for pasting.To improve the adhesion of the adhesive backing to the part to be restored, it must be cleaned of dust and dirt, degreased with alcohol or quaternary ammonium detergents. If there are deep scratches and chips, they must be putty.

- Preparing the walls. For sticking as a kitchen apron on a plastered wall or drywall, the surface of the base is putty, sanded and primed. Painted walls are cleaned of dust and degreased.

- Preparation of materials. Before starting work, the film for the facades of the kitchen and the apron is unrolled, information is read on the back side, and patterns are made in accordance with the marking grid and the dimensions of the parts (surfaces).

The gluing process takes place on each part separately.

The work is carried out in the following order:

- Try on the pattern for the part, and make sure that it fits neatly into place.

- Release the edge of the pattern from the protective paper by about 5 cm. And carefully align it with the edge of the part, trying not to skew.

- Gradually detach the paper backing and roll the pattern onto the surface of the facade. The principle of pasting is similar to working with wallpaper - smoothing is carried out from the center line to the edges, trying to expel "bubbles" beyond the border of the part.

- For pasting embossed details with inner corners and edges, the film can be slightly warmed up with a regular hair dryer to make it more plastic and "softer".

- When a fold or crease is formed, when the pattern is displaced to the side relative to the axis (border) of the part, the facade film for the kitchen must be carefully separated from the surface and glued again.

A video of how to glue the kitchen set yourself with a film below:

Watch the video how the kitchen facade is pasted over with self-adhesive film with a print:

What are MDF facades in PVC film

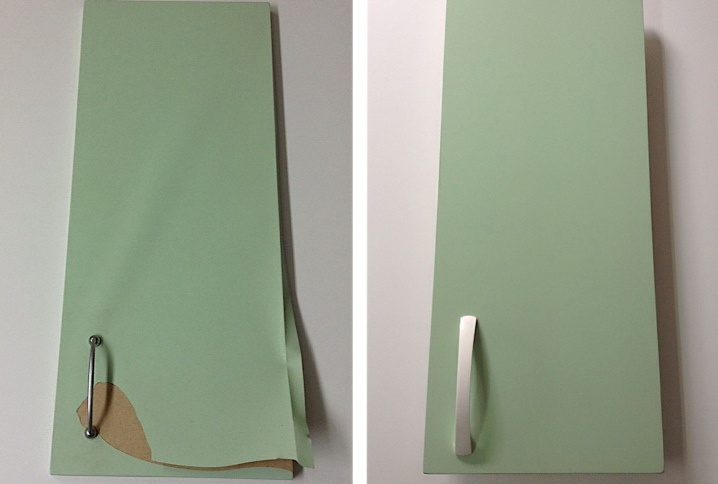

Photo: this is what a MDF kitchen door looks like without a film

Each type of facade has its own "set" of decorative processing options. The most limited choice for chipboard is only lamination in the factory, followed by gluing the edge of the blanks from the ends. Particleboard facades are straight slabs that cannot be milled, sanded or painted.

And most of all the possibilities for finishing and processing have MDF facades. They, like chipboard, can be laminated at the factory and imitate any "smooth" or "volumetric" texture. Plates can be milled, sanded, painted, enamelled. But the most economical option for decorative finishing is pasting of MDF parts with PVC film.

Films for MDF facades have a wide variety of colors and textures

Films for MDF facades have a wide variety of colors and textures

In the factory, the production of facades looks like this:

- cut out the detail;

- if necessary, a volumetric drawing is milled;

- polish the surface;

- pressed with PVC film.

What is the difference between chipboard and MDF: features of production and processing

Budget materials for the kitchen facade - wood shavings and fiber boards. Commercial markings - chipboard and MDF. Despite the fact that both types of boards are made from shredded wood, their characteristics and performance are different.

Kitchen: MDF facades with foil

The difference in structure is visible to the naked eye

What is a chipboard plate: characteristics ↑

Choosing which facade is better to choose for the kitchen, buyers, focusing on low cost, prefer chipboard. Particle board is made from waste from the woodworking industry.

Wood shavings, specially crushed, are filled with glue. Among the ingredients are synthetic resins, which, when exposed to high temperatures, melt and glue the chips together. The resin-embedded material is pressed under high pressure.

Internal structure of the slab: inhomogeneity of particles and cavities

As a result, a sufficiently strong board is obtained from a mixture of wood chips and glue. Slabs of different thickness are formed depending on the purpose - from 5-6 mm to 5 cm. Finished slabs must be sanded until the surface is completely smooth.

The budget is the main advantage of the material. There are many more disadvantages:

The internal structure of the slab is heterogeneous.

It is impossible to form a textured surface, the slabs are only smooth.

The complexity of processing, the material is easily cleaved.

Finished chipboard

The main disadvantage is the release of formaldehyde compounds into the air. The material does not tolerate moisture well, swells when wet. The surface and edges must be covered with a film or laminated - this way the risk of harmful substances entering the air is reduced.

MDF: how and from what facades are made ↑

MDF facades - what is it? MDF is a wood fiber board. Instead of shavings from production waste, finely dispersed wood fibers are used for manufacturing. Fibers also adhere under pressure when exposed to high temperatures.

MDF slab section

The fundamental difference is in the production process. In the manufacture of MDF boards, synthetic resins are not used. When the fiber mass is heated, natural resins are released, sticking the particles together. Paraffin or lignin is used as an additional adhesive composition. These substances melt and fix the fibers in the internal structure. This method of production makes it possible to obtain a material that is not a source of vapors of harmful substances.

Advantages:

Affordable price.

Ease of processing.

Curved MDF kitchen cabinet doors

Possibility of making bent shapes, fine milling.

Fine workmanship: framed fronts, milling and texture

Environmental friendliness.

What material is better for a kitchen facade: advantages and disadvantages of plates

The answer to the question of which cuisine is better to choose is unambiguous. If you have to choose between budget chipboard and MDF boards, give preference to MDF. The difference in price is small, but such a facade will last much longer.

Chipboard facades with foil

An exception can be made only for laminated chipboard boards, which are used as inserts in an aluminum profile. It is the edge parts of the slabs that are most vulnerable to water ingress.

MDF options with film

Do not use standard chipboard coated with paper foil for countertop installation. In places where the sink is embedded, in a couple of years not aesthetic waves will appear, but the upper decorative layer will simply peel off from the base.

Chipboard can be used for the manufacture of the frame of the headset, side parts of cabinets, shelves.