How to choose plywood for formwork

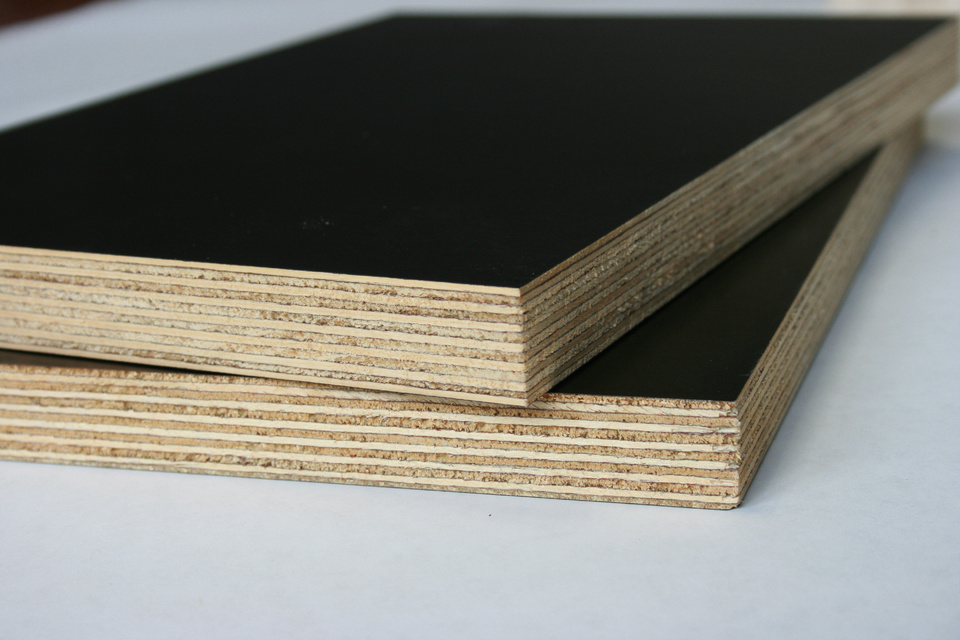

Various samples of plywood sheets are on sale. The material differs in composition and processing method. In addition, there are products from different manufacturers on the market.

If you need to purchase moisture-resistant plywood for formwork, you need to pay attention to the following criteria:

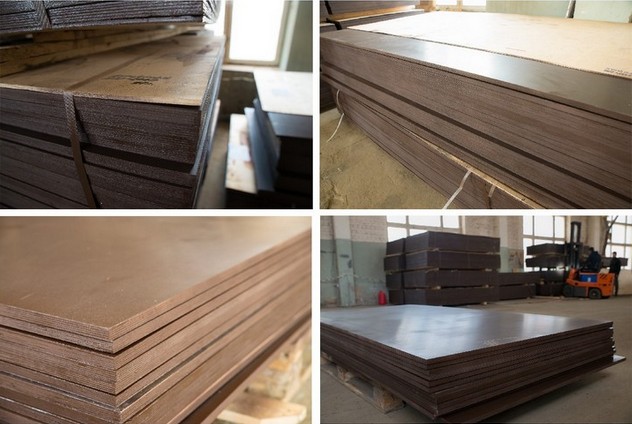

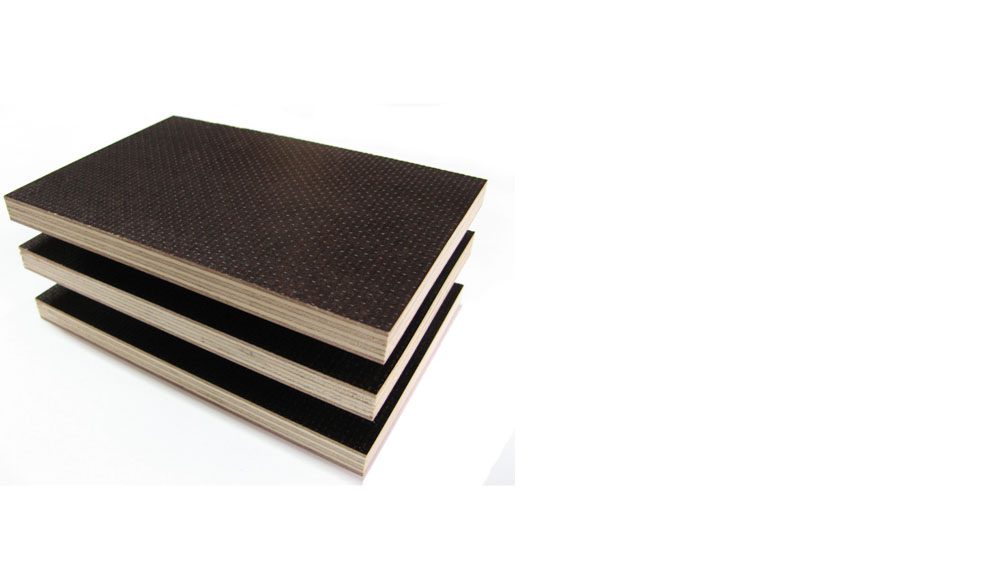

Thickness. Insofar as depends on the thickness of the plywood for formwork the cost of the material, there may be a quite understandable desire to save money. However, the savings should be reasonable. Using too thin plywood for formwork is difficult to achieve a good result. The shields of the structure will bend under the pressure of the concrete mixture and may even collapse. The optimal choice in this case is a material with a thickness of 10-12 mm, but if it is supposed to pour a thick layer of concrete (for example, when building a foundation), thicker and stronger sheets should be chosen, the optimal thickness in this case is 18 mm.

- Grade. The material is available in different classes. The most expensive option is the extra class. Cheaper - samples of I-IV class. The material is chosen taking into account the conditions of use, most often sheets of I or II class are used. They have a fairly high strength index.

- Material. When choosing, you need to take into account not only the composition of the adhesive composition, but also the veneer material. The most commonly used material is birch or conifers. These varieties are affordable. The more expensive varieties are teak, fir, and larch plywood. However, under difficult operating conditions, it may be more profitable to purchase a more expensive and durable material that can withstand a large number of cycles of use.

An important indicator that is taken into account when buying is the size of the plywood sheets. There are the following options:

Standard. These are square sheets with a side length of 1220 and 1525 mm, as well as a rectangular sheet 1525 mm long and 1220 mm wide. The advantage of this option is that the material is affordable.

- Large format. To create large panels, it is more convenient to use large-format plywood sheets. They are more expensive than standard ones, but they allow you to assemble shields that do not have joints.

- Non-standard. If necessary, you can order the production of sheets according to the specified dimensions. This is very convenient, but the material will cost significantly more.

An important selection criterion is the quality of surface treatment. The best option is sheets with a perfectly smooth and even texture. Application of smooth sheets with a glossy surface:

- facilitates the dismantling work, since the smooth surface is easily separated from the hardened concrete;

- monolithic surfaces are smooth, which facilitates their subsequent processing.

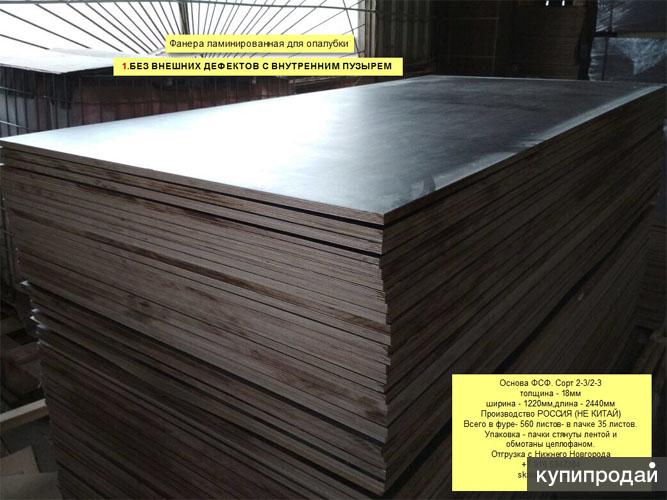

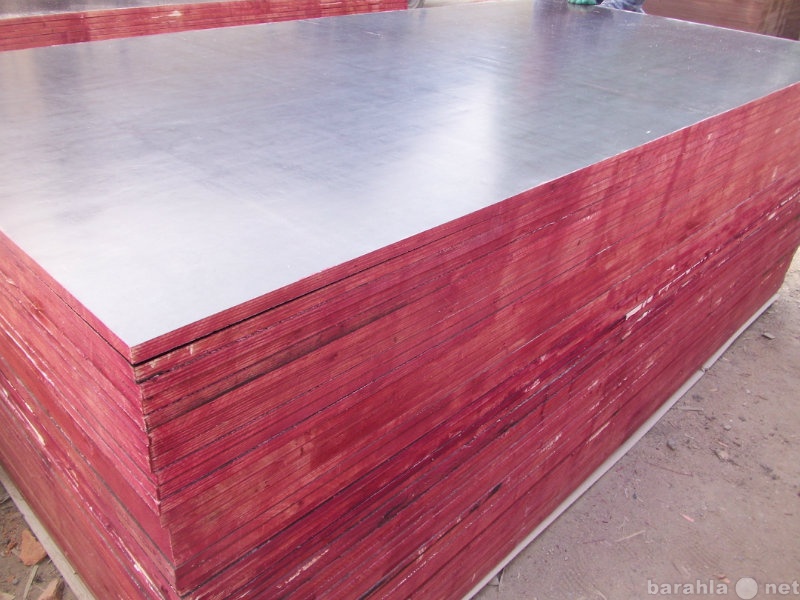

It is worth considering when choosing where the product is made. The most popular options are the material of domestic and Chinese production. Sheets produced in the DPRK have a lower cost.

This option is recommended to be used as an economy option for the construction of small architectural forms or for low-rise private construction. The formwork will withstand a limited number of cycles, so if the volume of construction is small, then the choice of a cheaper option is justified.

For large volumes of work, it is better to buy a domestic product, it is more expensive, but it is more durable. To increase turnover, that is, the ability to withstand more cycles of use, special lubricants can be used.

They are of two types - barrier and chemically active.The first option creates an additional protective layer, the second increases the resistance of the shields to moisture, as it contains hydrophobic substances. Diesel fuel, used engine oil, or wood paint can be used as lubricants.

So, plywood is a suitable material for the manufacture of various types of formwork. In order for the forms for pouring concrete to serve for a long time, it is necessary to choose the right base. When choosing, it is necessary to take into account a number of important indicators - the raw materials used, thickness, surface treatment quality, sheet dimensions. The right choice is a guarantee of high quality plywood formwork.

What is strip foundation formwork

According to the principle of use, the formwork is removable (collapsible) and non-removable. As the name implies, the removable one is disassembled after the concrete gains strength above the critical one (about 50%). Therefore, it can be used several times. Same kit depending on material can withstand from 3 to 8 fillings, industrial options can be used several dozen, and some hundreds of times.

Removable formwork is dismantled after the concrete has reached 50% strength

Permanent formwork becomes an inseparable part of the foundation. Such systems began to be used relatively recently. They are made mainly from extruded polystyrene foam. Blocks of different configurations are produced, which are interconnected with locks and metal pins. From blocks, as from a constructor, the required form is typed.

Fixed formwork becomes part of the foundation - it is also a heat insulator

Fixed formwork made of expanded polystyrene not only gives shape, but also at the same time is heat and hydro insulation, also has soundproofing properties. It costs a lot, but it immediately solves many problems, and the time spent on the foundation is significantly reduced.

There is another type of permanent formwork - hollow concrete blocks. They also have different configurations - wall, corner, radius, etc. They consist of two or three walls and several bridges that hold the walls in a certain position. They are connected to each other with locks, reinforced with rods.

Selection Tips

If you need to purchase plywood for formwork, then when choosing panels, pay special attention to the following criteria

- Price. A very low price indicates poor product quality, therefore, it is recommended to buy products at bases and in large hardware stores.

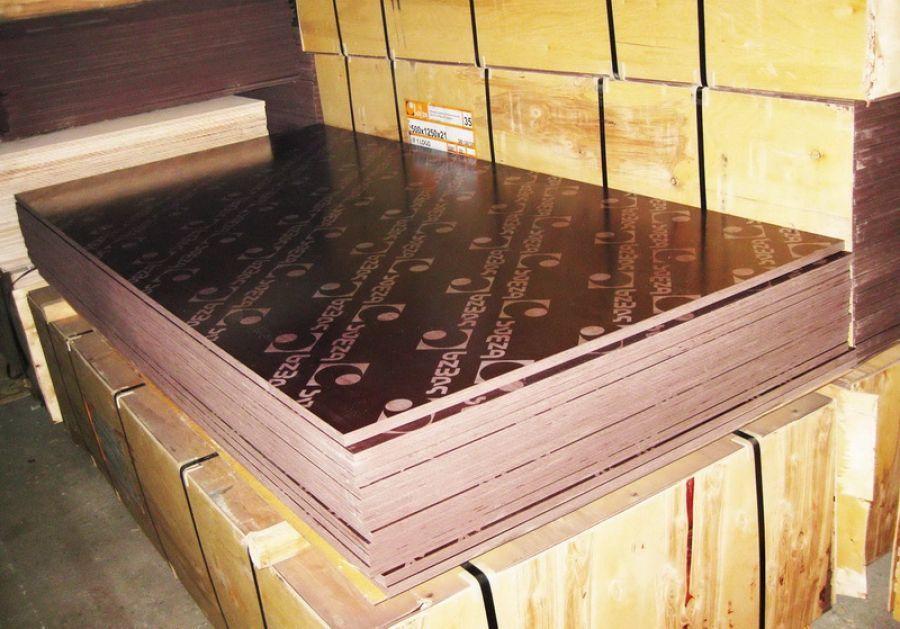

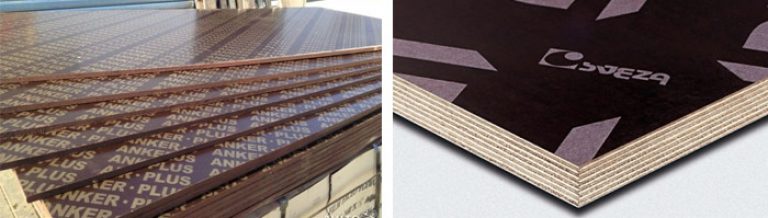

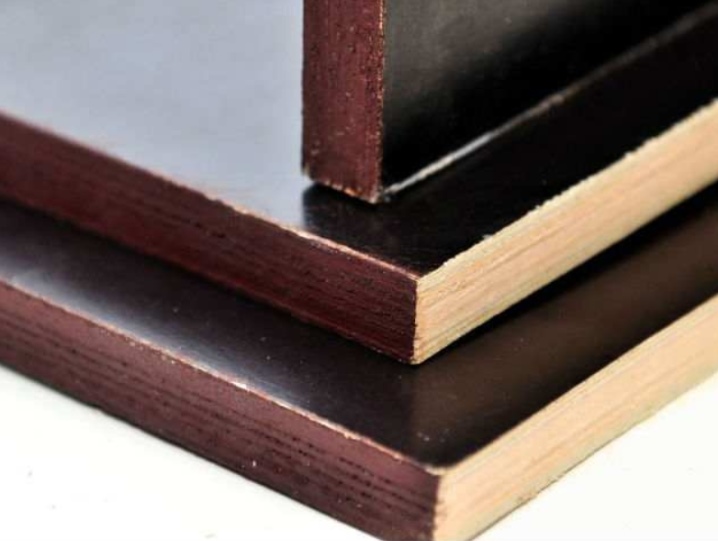

- Surface structure. The sheet should be free from defects and destruction. If the materials were stored with violations, then it is likely that there are distortions, which are quite difficult to correct. It is assumed that finishing plywood is usually brown and black.

- Marking. The designations make it possible to find out the key parameters of the material on the spot. The information is printed on the label or etched onto the material itself.

- Grade. The building material is produced in several grades - extra, I-IV. The higher the grade of the formwork material, the more difficult it will be to acquire it, since the minimum price will be quite high. However, at the same time, grade I / II panels will have the highest strength properties and performance parameters. As a result, the building material for the formwork is selected according to the conditions of use and loads.

- Availability of a certificate. The product is related to special, in this regard, the manufacturer must be tested and receive a corresponding certificate. The presence of a document certifying the conformity of the product with the established technical regulations or GOST is the main sign of the proper quality of the product, in addition, the document must be sealed with a genuine seal or a stamp of the organization certifying its authenticity, a photocopy will not work.

For information on how to choose the right plywood for formwork, see the next video.

What plywood to use for formwork. Plywood for formwork

Craftsmen know that during the pouring of the mortar, the raw materials from which the formwork is made undergo various mechanical processes, for example, the action of abrasive particles that make up the concrete. In addition, chemical factors act on it, because the concrete mixture is highly aggressive. Often the form comes into contact with moisture. For these reasons, the correct choice of material from which it will be built is of great importance. The correct choice will save you from deformation of the material used, and as a result, from a large consumption of mortar.

Before purchasing formwork plywood, you should think about the following questions:

- what kind of concrete mix will be used? The most important is the alkali ratio of the concrete, because a high PH will destroy plywood.

- what is the quality of the concrete plane needed?

- what kind of formwork do you need to make?

- how strong should plywood be?

- how many times do you want to use plywood?

- do you know the potential costs of each concrete pour?

In creating formwork, you can use different types of plywood. It all depends on the building being built. For 20 years, experts have been developing special types of plywood for specific purposes. Depending on the type of formwork, the number of cycles of using the same plywood sheet ranges from 1 to 200. The largest number of cycles can be achieved using specialized types of plywood, and providing the necessary maintenance. FC birch plywood can be called the most budgetary variety. It is designed for one-time work. It has a low water resistance threshold and a small sheet size. You can use it several times if you treat the sheet with industrial oil before starting work. In addition, unpolished sheets have different thicknesses, so there may be problems with their joining.

FSF birch plywood is characterized by higher water resistance in comparison with FC sheets. It has a low turnover rate, which can also be increased by applying industrial oil. As with the previous view, there may be problems with thickness and joints.

Softwood plywood, produced from pine or spruce raw materials, is almost always glued with phenolic compounds and belongs to the category of increased water resistance (FSF). This grade is recommended to be used in such forms where high quality of the plane is not required, and the turnover does not exceed five times.

Manufacturing of plywood formwork

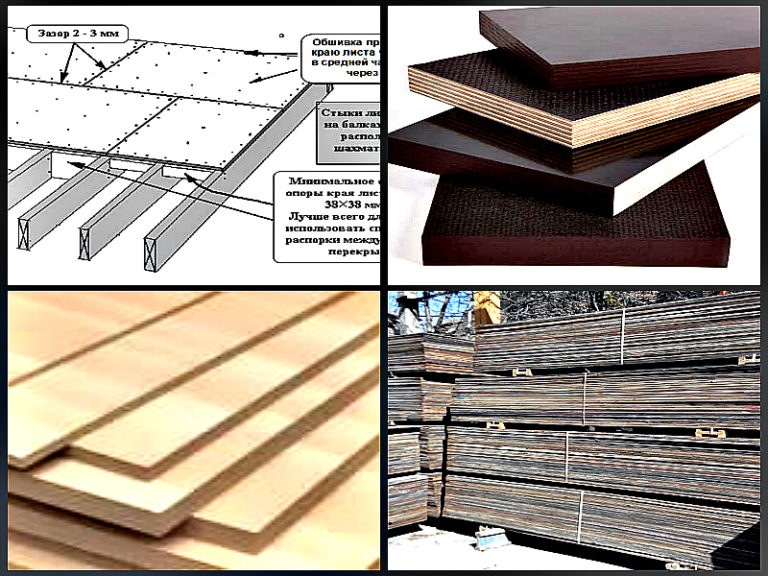

Before the installation of the formwork, a careful marking is done on the construction site. For example, when pouring the foundation, a trench is pulled out, the walls of which will help to correctly install the shields. But for walls of complex configuration or vaulted structures, most likely, several stages of formwork installation and subsequent grouting will be required.

The formwork limits the mortar from the inside and outside. In order to comply with the required dimensions in width, the following technology is used:

- holes are drilled in plywood sheets for a threaded rod or screw rod;

-

the ends of the stud (rod) should protrude beyond the outer side of the formwork, where the adjusting nuts are fixed on them;

- cut plastic tubes with a diameter exceeding the diameter of the stud and length according to the distance between the sheets;

- the tube is placed on the drilled holes, a pin is passed inside and nuts are attached to its ends.

The overall rigidity of the formwork on each side is provided with fasteners, props and battens. The slats are nailed or fixed on self-tapping screws

It is very important to ensure tightness on each side to prevent leakage of the solution. All cracks are caulked or filled with polyurethane foam

After the solution hardens, unscrew the nuts, remove the pins and dismantle the shields. The pipes remain sealed, although they can be knocked out or cut out if necessary.The holes in the concrete are partially sealed, partially left for wiring cables, pipes, ventilation devices, etc.

Video: installation of plywood formwork

It is even easier to purchase or rent laminated panels with fastening elements. They are specially produced for the installation of formwork and are structurally performed in such a way that there are no through slots at the joints.

The advent of film faced plywood gave impetus to monolithic construction

Going to the formwork plywood 18-21 mm thick... Catalogs and prices for these products can be found on the websites of manufacturers and suppliers.

Table: average prices for formwork plywood

| Laminated plywood | |||

| Manufacturer | Size, mm | Thickness, mm | Price, rub |

| China | 1220 x 2440 | 21 | 1850 |

| 1220 x 2440 | 18 | 1550 | |

| Russia | 1500 x 3000 | 21 | 3700 |

| 1500 x 3000 | 18 | 3300 | |

| 1220 x 2440 | 21 | 2400 | |

| 1220 x 2440 | 18 | 2200 | |

| Plywood FSF, non-laminated | |||

| Russia | 1500 x 3000 | 21 | 2200 |

| 1220 x 2440 | 18 | 1400 |

The calculation of the costs of formwork and plywood turnover is carried out according to the methods developed by the Ministry of Construction of the Russian Federation. In design and construction organizations, this is done by qualified estimators. A self-estimated calculation can be done using an online calculator. Such services are provided free of charge by manufacturers and suppliers on their websites.

Film faced plywood turnover

The formwork turnover is understood as the number of cycles of its installation, concrete pouring and dismantling without loss of operational properties. As a rule, this figure is several tens of times.

Table: Film faced plywood turnover

| Plywood | Class | ||

| Small-shield | I | II | III |

| Turnover | |||

| for floors | >20 | >10 | to 10 |

| for walls | >60 | >30 | up to 30 |

| Large-panel | I | II | III |

| for walls | >80 | >60 | up to 60 |

Types of removable formwork

In construction, several different types of formwork are used for monolithic construction. The choice of the option is carried out taking into account the project of the structure being erected.

Large-panel

The use of large-panel formwork is advisable for the construction of large objects. The set consists of large-area shields, which are structurally connected with supporting elements.

For ease of use, the boards are equipped with special scaffolds for moving workers, and a jack system is used for height leveling.

The use of this equipment allows to quickly assemble formwork forms of the required configuration. The disadvantage is the difficulty of ensuring the quality of the casting in the corners of the molds. In addition, the assembly requires the use of lifting equipment.

Small-shield

Small-panel formwork kits are used for the construction of a wide variety of structures, including small architectural forms. This option is suitable for casting vertical, oblique and horizontal shapes of various shapes.

Consists of shields weighing less than 50 kg, as well as supporting and fastening elements. If necessary, the shields can be docked, enlarging the structure vertically.

An important advantage of this option is the maximum technological flexibility, the possibility of assembly by hand or using light cranes. The disadvantages include the high labor intensity of the assembly, as well as the need for additional measures to ensure the high quality of the surfaces of the cast walls.

Lifting-adjustable

These are demountable structures specially designed for the erection of vertical structures with a height of more than 40 meters with a constant and variable cross-section. The package includes external and internal shields of the working floor, jacks fixed to the frames, drive stations.

As the concrete mortar hardens, the formwork rises with jacks higher. The advantages of the equipment are high speed of construction and maximum technological flexibility.

The disadvantages include the increased complexity of the construction of floors, as well as the high technical complexity of the equipment.Due to the latter circumstance, highly qualified workers are allowed to work with this type of formwork.

Volume-adjustable

Volumetric movable formwork consists of blocks, which, after assembly, form a formwork in the shape of the letter "P". It is used for simultaneous concreting of walls and floors of premises. This provides additional strength to buildings. The disadvantages include:

- relatively little technological flexibility;

- the equipment is difficult to assemble, therefore, it is necessary to use a highly qualified workforce.

Sliding

Sliding formwork is mainly used for the construction of tall monolithic structures with a small diameter, for example, chimneys. The principle of operation is the ability to move the formwork vertically upward without interrupting the concreting process. This equipment allows you to do without dismantling the structure and installing it in a new place. The shields just slide up.

The disadvantage of this equipment is its high cost in comparison with sets of demountable formwork. However, in some cases, this option is cost effective. Another important circumstance is the need for the continuity of the pouring process, which is why the work has to be carried out in three shifts.

Plywood for concreting. What kind of plywood, besides film faced, can be used for formwork?

For pouring a foundation or erecting a monolithic floor, we can also recommend buying plywood for formwork of the following types:

FC. In the production of building materials, carbamide glue is used. It contains a fairly large amount of formaldehyde resins. Therefore, FC plywood for formwork is not suitable for non-removable systems, and excellent for split structures. These boards are moisture resistant. The coefficient of resistance to moisture is lower than that of film faced plywood for formwork 18 mm, but with careful use the board turnover will be up to 20-25 times high. For this type of plywood for formwork, the price will fluctuate in the range from 750 to 1,950 rubles per sheet (the price is indicated for a 18 mm thick slab).

- FSF. In the manufacture of plywood waterproof for formwork, phenol-formaldehyde adhesive is used. It gives the material the best characteristics - strength and maximum moisture resistance. At the same time, FSF plywood for formwork has improved wear resistance properties. Its turnover reaches 35-43 times. But due to the adhesive composition used (it releases phenol under the influence of temperature and moisture), it is recommended to use it only for outdoor work. Durable plywood for formwork has a price per sheet ranging from 1,400 to 2,800 rubles.

- FBK. Binds the layers of the board with a bakelite varnish composition. It is resistant to moisture, not afraid of temperature extremes and resistant to atmospheric and climatic loads. Simply put, this moisture-resistant formwork plywood, the price of which will vary from 1,700 to 3,500 rubles / sheet, can be used in any operating conditions. Finnish plywood for formwork FB has similar characteristics of wear resistance and mechanical strength. It is also chosen for work in high humidity conditions.

- FBS. Most commonly used material. In its production, veneer (raw material) is treated with special compositions containing alcohol bakelite glue. As a result, the formwork sheets acquire an additional quality - resistance to microorganisms. The FBS slab has a high density, which means that it can withstand high vertical and horizontal loads. Therefore, using this type of plywood for formwork, the thickness of the sheet can be chosen as small - 8-15 mm (depending on the characteristics of the foundation, overlap). The presence of glue in the layers gives the moisture-resistant formwork plywood increased flexibility characteristics. Therefore, the building material also has excellent bending strength.In our catalog, the assortment of FBS plywood for used formwork is presented, the price per sheet of which will be equal to 2,500-3,800 rubles. The cost of unused material will vary from 5,600 to 10,450 rubles / sheet.

Formwork materials

Today, many different materials are used to build formwork. Let's figure out which types of formwork are advisable to use in private construction, and which are suitable only for professionals.

Wood

Formwork from wooden panels can be assembled by hand, as panels should not weigh more than 70 kg. The main elements of the formwork are made from boards with a thickness of 25 mm, however, if the design load is large, then thicker boards can be used.

The optimal board width is 150 mm. If you use wider boards, then the risk of warping the shields increases. Shields are hammered together using wooden blocks or planks.

Well-dried wood cannot be used for the manufacture of molds, since it will actively absorb liquid from the poured concrete solution. The optimum wood moisture level is 25%. When assembling shields, it is necessary to ensure their tightness. Large gaps between the boards are clogged with slats, small ones are sealed with tow.

Plywood

A more convenient option for the material for assembling the formwork is plywood. This option is used for the assembly of horizontal and vertical structures. An important advantage is that the concrete surface of the cast structure is perfectly smooth.

Types of plywood used for formwork assembly:

FBA. An environmentally friendly type of material, albuminocasein glue is used for gluing the layers. This variant is only suitable for one-time use as a formwork panel material.

- FSF. The material contains phenolforma-dehilicate resin, due to which the plywood acquires moisture resistance. Formwork panels made of this material can withstand several cycles of use.

- Laminated. The presence of the laminating layer increases the moisture resistance and smoothness of the plywood. This option is ideal for assembling formwork panels.

Bakelized. Bakelite resin is used for gluing the layers. This gives the material high resistance to aggressive environments and strength. The material is well suited for the assembly of formwork, but it is rarely used, since it has a high price.

Metal shields

Formwork with metal panels is an excellent option if you need to perform a large amount of monolithic work. Differs in high cost, therefore it is rarely used in private construction.

The material perfectly maintains the given geometric shape, has a minimum adhesion to concrete, and has high turnover rates. Shields made of steel are especially reliable, but they have an impressive weight.

Aluminum shields are lighter, but they are less resistant to deformation and difficult to repair. Therefore, it is steel metal shields that are the most practical.

Plastic

Relatively recently, they began to use formwork kits with plastic panels. This equipment has many advantages over other options. First, the shields are relatively lightweight and easy to assemble. Secondly, the material is resistant to wear and stress.

Thirdly, concrete mortar does not adhere to plastic shields, therefore, lubricant should be used in minimal quantities. Universal kits are produced from plastic, from which molds of any configuration can be easily assembled.