Do-it-yourself lining for a bath: a step-by-step process

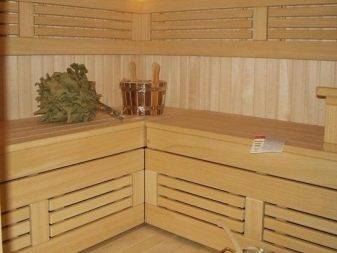

Before sheathe the bath room with your own hands, you should carry out all the engineering communications inside that need to be checked. And only after that the finishing itself begins.

First, a crate is assembled from a bar (aspen, from linden or alder). It is necessary to buy 6 cm self-tapping screws, the cost of which is low, with the help of which suspensions are attached at a distance of 60/70 cm from each other. The level will help to align the top and bottom bars correctly. A flat plane will be obtained if you attach a mounting cord to the beams. The bars are fixed to the suspensions using 3.5 cm self-tapping screws. The lathing is assembled with your own hands horizontally and vertically.

After that, the frame should be covered with an antiseptic and allowed to dry. Further, mineral wool between the sheathing timber will serve as thermal insulation. A waterproofing film is placed on top, which is attached to the frame beam with a stapler, overlapping the material 10 cm on top of each other and isolating the joints with special tape.

Then comes the do-it-yourself interior decoration. Planks are cut to the height of the room. To fix the slats, you should buy staples, studs or inconspicuous clamps. You can just buy nails. But if the surface is decorative, then it is better to buy inconspicuous clamps. You can buy carnations if the planks will be fixed directly in the locks. Finishing is done from one of the corners, gradually moving along the perimeter. The last rail is adjusted to the width and trimmed to size.

The final stage, how to cover the lining inside the bath? The boards can be varnished to prevent any texture changes or the color of the wood, stain that gives the desired shade, protective wax or oil. Planks in the washing and steam compartments must not be painted or varnished. For these premises, special processing of the lining for the bath is carried out before it is fixed on the walls. The wood is impregnated with a colorless, water-based antifungal antiseptic that will prevent mold and mildew growth, dark spots and protect against harmful insects. Before impregnating the boards on both sides, the material is sanded with fine sandpaper. The material dries within 2 days. For the steam room, the material is coated 1 time, for the washing and changing rooms - 2 times.

Extra class

This type is one of the most expensive and high quality products. Outwardly, it does not contain the slightest damage, vices, defects. As a rule, such arrays are obtained by the splicing method.

Without this technology, premium lining would be incredibly expensive, since there are actually too few suitable boards coming out of a solid canvas. They are smooth to the touch, without chips, cracks and knots, so it is not for nothing that they are considered elite, worthy of chic country interiors.

Manufacturers often provide such lumber with vacuum packaging in order to minimize the threat of deformation during transportation. They are supplemented with special fasteners for simple and more convenient installation (thus, the lining will not need to be adjusted during installation).

You should not trust the factory inscriptions on the box: it happens that there are perfect products on top, and low-quality ones under them. Therefore, when buying, ask the consultant to unroll the packaging in order to personally verify the grade of the wood.

Varnishes for lining

Varnishes are divided according to the substance that makes up the base:

- Acrylic;

- Polyurethane;

- Acrylic-polyurethane;

- Alkyd;

- Water-based.

Acrylic varnishes are versatile. Prevents dirt from concentrating on the surface. Dries quickly.Negative property - they begin to emit a specific smell when heated.

Varnishes containing polyurethane are suitable for the treatment of indoor and outdoor surfaces. There are translucent compositions and darker ones - toning. The lacquered panels will not turn yellow.

A combination lacquer containing both acrylic and polyurethane gives some shine to the coated products. Protects against fungal colonies and mold.

Alkyd compounds - protect wood from moisture. A negative property is a long drying time and an unpleasant odor, so the room will have to be ventilated for several hours. Complete drying is guaranteed after two days.

Water-based varnishes - the smell is almost completely absent, it dries very quickly, and most importantly, there is no harm to health. In addition, water-based varnishes do not support combustion, do not emit harmful substances when heated.

When buying any varnishes and paints for residential premises, you should carefully read the instructions on the bank. There should be a note that the composition is allowed to be used inside houses and apartments. If necessary, it is better to consult the seller.

In most cases, surfaces will have to be primed before varnishing.

A number of craftsmen prefer to use factory varnishes and impregnations based on oil and wax. They penetrate deep into the pores of the wood, flow into all microcracks, provide protection against moisture and mechanical stress.

For example, alkyd-oil solutions have a beneficial effect on the properties of aspen lining, protecting it from cracks and deformation. It is believed that the processing of wood with impregnations and varnishes can extend the life of products by 3-4 times.

Varnishes are applied in accordance with the rules:

- On dry and clean surfaces;

- After applying the primer;

- First, the ends are painted over;

- The temperature is not lower than +5 degrees;

- Humidity not less than 70%.

An antiseptic is applied before the varnishes. In addition to a brush and a roller, you can use a spray gun; with good skill, you will get the most even surface without defects.

For a dressing room or kitchen, water-based or wax varnishes are suitable.

In some cases, aspen lining is covered with special fire retardants. There are combined mixtures: fire protection + antiseptic.

When finishing wood products, there are common mistakes. First, the use of cheap Chinese chemical products that could be harmful. It is not recommended to purchase varnishes, paints, impregnations and primers on the markets without appropriate certificates.

Secondly, there is a discrepancy between the type of impregnation / primer in relation to the finishing varnish or the type of paint. Otherwise, it will not be possible to achieve high-quality coverage.

Varieties

For the production of wood planks, different types of trees, types of raw materials, forms of surface treatment are used, which determines the existence of different types of products. It is much easier to choose a product, having an idea of the specific features of the material, its technical characteristics, and the expected operating conditions.

When determining the grade of products, foreign manufacturers rely on European standards, domestic - both on European and on their own standards, developed taking into account the requirements of GOST.

Extra

The best products are designated as extra. Old-school consumers call this category "top grade". The lining of the highest grade has practically no defects: worm or wane spots, blueness, sprouting, areas with rot. In most cases, spliced material belongs to this category, because in solid wood, be it linden, larch or other conifers, it is extremely difficult to find a large amount of ideal raw materials.

The lamellas of the highest grade have an absolutely smooth surface without knots, spots, chips, cracks; it is packed by vacuum sealing in a film to avoid damage during transportation and storage

The products should be fixed very carefully using special adhesives. Competently mounted cladding, covered with good varnish, has an elite look, is a worthy decoration of expensive interiors

3> A (first)

According to the long-familiar classification, the next group of products can be called 1st grade products. Now it is customary to designate it with the letter A. In a minimum amount, it can have microscopic cracks, resin inclusions that do not have a through character.

The sizes of knots are regulated, the diameter cannot exceed 15 mm, and the knots should not be germinated. The maximum permissible size of black knots is 7 mm. Products of this grade are most often used for cladding residential and administrative premises; the formation of a decent appearance of a high-quality surface can be completed by processing with wax, oil or just varnish.

In (second)

Lamellas of grade B are habitually called clapboard of the 2nd grade, which informs the buyer in advance about the possible presence of minor defects. Each section with a length of up to 60 cm may have small flaws: cracks, dents, chips, with a total area of no more than 3 cm.The sizes of knots and bluish spots are also limited, should not occupy more than 10% of the plank area.

It is important to know that all the indicated defects in the 2nd grade products cannot have a continuous form.

This should be noted during inspection. For the installation of such a lining, experience is needed, because at the ends there may be small areas with unplanned wood.

They do not interfere with the docking, do not spoil the appearance of the cladding when installed correctly. Small flaws of the front surface are masked with grouting, staining.

C (third)

Planks of grade C have the most loyal requirements for quality and low prices, they are mainly used for finishing technical premises. Installation of such products requires experience, great efforts; to some extent, the surface can be improved by additional work on finishing, painting.

The cladding usually has knots, cracks, chips, roughness in an amount that is noticeable to the naked eye even with a cursory examination. Unfortunately, some manufacturing plants in category C introduce completely defective material with an unlimited number of serious defects, although by standards the total area of stains should not exceed 20%. Regulatory documents do not contain any restrictions on the number and shape of knots in this type of product.

> When choosing a lining, the buyer should study not only the accompanying certificates, but also inspect the material on his own. Unfortunately, unscrupulous manufacturers and trade representatives tend to sell products of not the best quality at inflated prices. To make a purchase, it is advisable to contact reputable suppliers with a positive reputation. Good quality lining will make surfaces attractive for years to come.

Peculiarities

Lining is a type of board for covering rooms. Not so long ago there was a period of frenzied popularity of clapboard decoration of houses, rooms, balconies, verandas and various gazebos. Now, with the development of the construction industry, designers have cooled somewhat towards this type of finish. But there are rooms in the house, in which finishing boards will be the best option for decoration. First of all, these are baths, saunas and steam rooms.

The choice of a tree such as linden for decoration is very relevant. People who are fond of traditional medicine have known for a long time about the healing properties of linden blossom and honey. But for wood, valuable properties are also characteristic.Qualitative characteristics allow the use of linden lining for both external and internal decoration of buildings.

Below are the advantages of linden cladding boards.

- Structure. In terms of use for construction and furniture work, linden is an excellent option. By its nature, the trunk contains few natural defects. The products are uniform, visually perfect, smooth and with minimal relief. This adds comfort to the interior decoration of the baths.

- Density. In washrooms with a heating system, ventilation and air exchange must be provided to avoid overheating of the medium. Wall and floor coverings should also not get scalding hot. In this regard, linden, which has a loose structure, fits perfectly (the density value is within 530 kg / m3).

- Operational characteristics. Linden lining can withstand high temperatures and sudden changes, as well as high levels of humidity. For steam rooms and baths, this is very important, since the temperatures there reach 140 degrees, and the humidity level is more than 90%. The durability of the board allows us to hope for its long service life. The cheapest types of lining are capable of not losing their qualities for 10 years. Elite types of materials, combined with proper care and cleaning, will last up to 30 years. Over time, the finish begins to darken, but this can also be corrected with additional processing.

- Another indisputable advantage of linden cladding is the simplicity of its implementation. Even a not very trained finisher will be able to do the job at the proper level without much difficulty.

With all the range of advantages, any material has its drawbacks.

- Like any tree, lining can suffer from the influence of microorganisms, especially at high humidity. Mold and mildew can become a massive and difficult problem if antibacterial treatment is not carried out in time.

- Under the influence of external factors and the proximity of metal structures, the wood darkens over time.

- Compared to other tree species, linden material costs several times more.

Features and characteristics of materials for the log house and decoration of the bath

The history of both the Russian bath and the Finnish sauna is based on the beneficial effects of steam and temperature on the human body. Bath procedures have become an integral part of the history of many peoples, where they were given a special place - cleansing the body and getting rid of ailments. No wonder the Russian bath was one of the most important attributes of the life of the Slavs. But is it only thanks to the steam and high temperature that the bath has such miraculous properties? Of course not, steam and temperature can also be in a room made of concrete and brick, but there will be no effect in such a steam room. This means that only natural materials are able to give their properties for the benefit of humans. And here linden and aspen have a special role.

Aspen features

The use of aspen as a building and finishing material in the construction of a bath has a special place. The wood, which has such an interesting white color with light brown stains, is excellent for arranging both external walls and interior decoration of a bath. Aspen saw cut has a pure white color, which has no analogues among deciduous and coniferous species. The tree itself lends itself well to processing. Due to its relatively low density, it is easy to shape it into any shape. But this is only part of the useful properties of aspen. The fact is that, unlike conifers, wood contains a very small amount of resins and oils, which makes it possible to use wood to decorate the most important premises - steam rooms and rest rooms

The second important property is the improvement over time in the strength of the wood. While other types of wood, under the influence of moisture and temperature, begin to lose color, strength, undergo warping and rotting, aspen, on the contrary, acquires resistance and strength

When finishing a steam room, literally after a couple of years of use, it can compete in hardness with such hard species of wood as oak.

It is also important that aspen is not subject to decay, on the contrary, it has antiseptic properties, it was not for nothing that the Slavs used aspen as one of the attributes of the fight against evil spirits. Water in wells from an aspen log house is distinguished not only by its taste, but also by its bacterial composition.

It does not deteriorate for a long time, and bacteria do not multiply in it.

Aspen in the bath

Since ancient times, several technologies have been used to process aspen, one of which provided specific drying of wood, after which the aspen could be used for the construction of walls, in this it was not inferior in quality to spruce and pine.

It is worth saying that aspen is cheaper compared to linden, this cheapness makes it the main competitor of linden as the main material for building a bath.

Features and characteristics of linden

In Slavic mythology, the linden was attributed to miraculous properties as a healing tree that can relieve many diseases, give strength and protect against ailments. Linden, according to many healers, has the ability to take away negative energy; next to it, lightness and calmness are felt. Of course, with such characteristics, linden has become one of the most necessary materials for the construction of a bath.

Like aspen, linden has a wonderful natural white color. But at the same time, unlike aspen, warm tones prevail in it, warmth and lively energy are felt in it. Another factor that contributed to the popularity of linden in the construction of baths and saunas is the softness of the tree. Indeed, linden has a very soft and pliable wood. It is very easy to work with it, it is perfectly cut, it is easy to plan. Sculptors prefer to work with linden as one of the most convenient materials.

Well, as for the bath, it is worth mentioning here that the royal bath is the name of a log house in which only the lower crown, standing on a stone foundation, is made of bog oak, and all other logs are necessarily linden. Here the whole point is that linden, unlike white aspen, has no smell, after all, the smell of aspen with a characteristic bitterness is felt for quite a long time, while linden is completely devoid of this smell.

True, it is worth mentioning the disadvantages of linden. Unlike aspen, a linden tree can have many flaws, because in addition to the healing properties of the tree, it often becomes a habitat for birds. The tree has many knots and is often attacked by pests.

Surface finishing

Varnishing will help extend the life of wood surfaces and change their appearance at the discretion of the owner. Regular paints are not recommended as they will cover the texture of the wood. Before varnishing, you need to treat the surfaces with a fine sandpaper, and then remove the dust.

Varnishes are applied to the surface with a roller or a soft brush in several layers. The coating should be renewed every few years, this will prolong the life of aspen lining panels. In the steam room, you do not need to apply synthetic varnish, when heated and temperature changes, it will most likely fall off, in addition, the fresh smell of wood is very pleasantly felt in the bath.

One of the old ways to protect the walls in a bath is to impregnate with vegetable oil in two layers. Now there are special impregnations of European and Russian firms. You need to focus on the purpose of the composition: for baths or saunas.

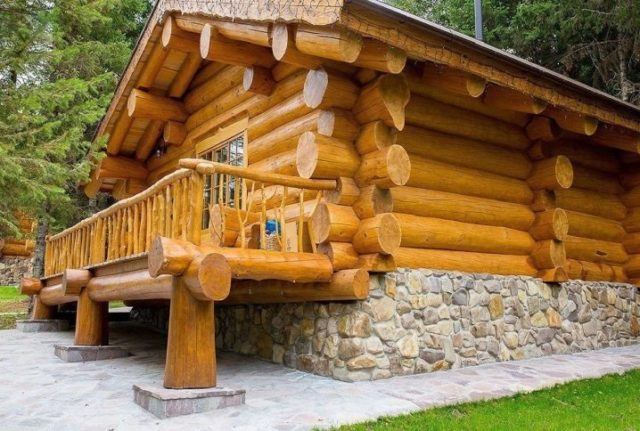

Bath cedar

The noble cedar tree belongs to the elite category. The material has exceptional qualities, and not only functional, but also medicinal.

Cedar wood is impregnated with unusual resinous substances. They call it gum, emphasizing its special qualities. It has an antibacterial effect not only on the wood itself, but also on the environment.When heated, the substances begin to evaporate, disinfecting the room and saving a person from a wide variety of diseases, so cedar is ideal for a steam room.

Important! In Siberia, a bath, decorated with cedar clapboard, is advised for those suffering from diseases of the respiratory system. The tree can even cure bronchial asthma.

Log cedar bath

Cedar is the best option for a bath. The qualities of wood provide a log house and durability, and beauty, and convenience:

- cedar has the lowest thermal conductivity in comparison with other conifers, in a cedar bath it is warm even in the most bitter frosts;

- the wood is resinous, provides excellent antiseptic properties, respectively, it does not rot, is not susceptible to the action of fungus and even insects are not able to damage it;

- cedar resins are healing, cedar finish provides an excellent antibacterial effect and natural air ionization;

- cedar is resistant to moisture and temperature extremes. The cedar bath is very durable and will last for at least half a century;

- both the logs and the lining are very beautiful, and do not need any processing: the natural color and texture are beyond praise.

There is only one drawback of cedar wood or lining - high cost.

Cedar lining for a bath

Cedar lining for a bath has all the advantages of a log. For a steam room, such material is ideal, although not as effective as aspen:

- gum resin evaporates, but does not emit when heated, therefore cedar lining does not burn and does not leave resinous stains;

- cedar lining guarantees an excellent healing effect;

- the specific fibrous structure of the tree ensures the absence of cracks and chips even at the ends;

- the lining is very beautiful: the colors are even, muted, the knots are small, the panels are smooth and delicate to the touch;

- the material is not afraid of moisture, steam, mold, or decay, so it does not need any processing.

Important! Over time, the cedar lining darkens, or rather, acquires a brownish tint.

Bath from cedar: photo

Cedar is an excellent building material and allows you to implement any project - from a traditional Russian bath to a complex hotel complex.

Decorating with a pair of cedar clapboard is no less spectacular and beautiful and is suitable for any style.

What kinds of wood panels are there?

- Extra class products. This includes perfectly flat and clean products. Such panels are free from natural defects and knots. The wood itself is white and smooth. The tone of the product is uniform along the entire length of the plank. This group is characterized by the highest cost.

- Category A finishes. Small knots are occasionally found on such products. Slight differences in the shade of the panels are possible. The products are characterized by high strength, but not as smooth as the previous version. This material costs a little less than the "Extra" aspen lining. It can be used for finishing any surfaces.

- Grade B panels. Such materials are characterized by the presence of a small amount of chipping, scratches and knots. Boards differ in the color of the wood, they may fail earlier due to knots falling out.

There is another option - class C products. This group includes low-grade materials.

Linden or aspen for a bath: which is better

It's really difficult to choose between these two materials. Linden is traditionally considered the best tree for a bath and deservedly so. However, the aspen, despite its external unattractiveness, is a serious competitor to it.

Linden wood is soft, it is easily processed, therefore, the construction of a bath requires less costs. If dried logs were used, the building does not shrink and can be used immediately after construction is completed.

Aspen, on the other hand, is processed with great difficulty. Since the bath requires well-dried material, this makes construction an expensive and time-consuming task.

The softness of linden is also its disadvantage - the tree is short-lived, and dry aspen acquires the hardness of a stone and serves for an exceptionally long time. Linden does not need to be processed for aesthetic purposes, even an unskinned log looks great, not like a lining. To give the aspen an aesthetic look, you should chop off the bark from the log, sand and shave it. In addition, repeated grinding will be required - the latter is performed 3 years after the laying. Otherwise, instead of a silvery-white bath, you get a gray, unsightly and with dark spots.

Linden is not resistant to rotting and fungal attack. The bathhouse needs periodic treatment with special preparations. Aspen is not susceptible to rotting or fungi. The only treatment that may be needed is from wasps. For some reason, the latter are very fond of this tree.

Linden is more expensive than aspen, so it is really difficult to choose.

Important! A log house for a bath made of aspen and linden, which is confirmed by the reviews of the builders, does not require additional finishing of the steam room. Both breeds are definitely suitable for sauna cladding.

How to distinguish linden from aspen

Linden and aspen lining is very easy to confuse. It is not so easy to distinguish wood.

First of all, they pay attention to the color. Linden lining has very light wood, but still has a coffee shade.

Against its background, aspen has an almost snowy whiteness.

Linden board has a characteristic sweet aroma. The smell of aspen is bitter, more like birch sap. Aspen lining is rarely truly smooth, since this tree is difficult to process, and linden is smooth and silky;

Knots in aspen lining come across more often. They are darker and more visible. In category B, even knots falling out are possible here.

To distinguish linden lining from aspen boards, you need to not only inspect, but also try to touch.

What is better in the steam room: aspen or linden

The choice between linden and aspen clapboard is even more difficult. The materials have a number of properties in common that are very useful for the sauna and steam room:

- both linden and aspen do not heat up as much as other types of wood;

- shelves and walls, finished with clapboard, remain pleasant to the touch and do not burn;

- both wood species give off aromatic oils that are beneficial to health;

- the lining looks equally aesthetically pleasing;

- both linden and aspen tolerate steam very well.

There are also differences between linden and aspen:

- the smell of a linden tree is deservedly considered the most pleasant, while in aspen it is bitter and not everyone likes it;

- linden darkens over time, aspen practically does not change color;

- linden lining is susceptible to fungus, the finish should be processed, and the aspen is devoid of this drawback;

- linden costs almost 2 times more than aspen lining, but linden wood includes much less knots and streaks and looks more beautiful.

For a pair of lining from linden or aspen are equally good. The choice determines the taste of the owner.