Colors

An important role is played by the color created with the help of building enamel. Even the most durable and stable coating in modern conditions can no longer be recognized as quite suitable for work, an aesthetic effect is also required. The pearlescent variety doesn't just look pretty, it creates a different feel. This result is achieved due to the powder, which refracts the light rays falling on it.

Only an experienced technician should work with the powdered reagent. Errors and deviations from technology lead to the formation of clods. The paste makes it possible to create a wide range of colors and always turns out to be uniform. But you won't be able to store it as long as the powder.

It is important to remember that golden pearlescent tint can be used only in interior decoration, outside it will fade very quickly due to exposure to ultraviolet radiation.

Glossy enamel pleases consumers with external smoothness and intense shine. Such coatings are resistant to water and can be used to decorate rooms with excessive moisture levels. Red and blue enamels PF-115 are capable of long-lasting saturated color. Even excessive moisture or temperature jerks are not dangerous for the coating

Importantly, the color does not change from opening the can until the end of drying.

Use of EP-773 enamel

Preparatory work

Before applying EP-773 enamel, the metal surface must have a uniform roughness, metallic luster, a darker shade of metal is allowed in areas where there was scale, and also degreased until there are no traces of fat on the filter paper after wiping the surface. Before applying paint, EP-773 enamel is cleaned by sandblasting or shot blasting, cleaning with cord-brushes is allowed.

For degreasing, the metal surface is wiped with a rag soaked in white spirit and a dry rag; it is not allowed to use volatile solvents for degreasing.

Surface painting with EP-773 enamel paint

EP-773 enamel should be well mixed, homogeneous throughout. Pre-mix EP-773 enamel paint with hardener No. 1 (for preparation of the composition) in the ratio specified in the quality certificate for each batch of material, and mix thoroughly for at least 10 minutes. Withstand 1 hour. If necessary, after adding the hardener, EP 773 enamel can be diluted with solvents 646, P-4 or toluene. Prepared EP-773 enamel is applied on the surface of the metal to be protected with a brush, roller or pneumatic spray at an ambient temperature and the painted surface not lower than 15 ° C. After one layer has dried (24 hours at 20 ° C), the next layers of enamel are applied in the same way. To flush the instrument use solvents 646, toluene, R-4. Store the enamel indoors, excluding direct sunlight and moisture.

Enamel ХВ-518

St. Petersburg paint and varnish plant brings to your attention the XB-518 enamel, which is a good protective layer against corrosion. This type of enamel is used in cases where metal surfaces are to be painted. But not all. Mainly, XB-518 is used for steel and aluminum products. But it is also used for wooden structures that are outdoors and exposed to atmospheric influences.

Unlike ХВ-1100, ХВ-125 and other enamels, ХВ-518 includes the addition of alkyd resins and plasticizers, which ensures smooth application of enamel to the painted surface.

To dilute this enamel, solvents R-4A and R-4 are used, and before applying to metal or wooden surfaces, primers VL-02 or GF-021 must be used.

XB-518 will extend the life of any metal structure or wood product. After all, it is our plant that worries about the quality of the materials provided to consumers.

GOSTU

TU 2313-034-05015319-2001,

TU 6-10-966-75

TYPE OF

Enamel ХВ-518 (paint ХВ-518) is a suspension of pigments in a solution of polyvinyl chloride chlorinated resin in a mixture of organic solvents with the addition of an alkyd resin and a plasticizer.

RECOMMENDED USE

Enamel HV-518 is used for anti-corrosion protection, pre-primed surface (primer FL-03K or AK-070) made of steel, aluminum and its alloys. It is also allowed to paint wooden products for special purposes, operated in an open atmosphere.

DESCRIPTION

CERTIFICATION

Hygienic conclusion of the Office of the Federal Service of Rospotrebnadzor in St. Petersburg, valid throughout Russia

SPECIFICATIONS

Color - protective; Drying time to Art. 3 at 20 ° C - 4 hours; Theoretical consumption - 84-96 g / m²; Recommended thickness of one-layer dry coating - 15-20 microns.

MIX RATIO

DILUENT

Enamel XB-518 is diluted with R-4 or R-4A solvent.

CLEANING TOOLS

CONDITIONS OF VALIDITY

WARRANTY PERIOD OF STORAGE

Shelf life in unopened original packaging is 6 months from the date of production.

SURFACE PREPARATION

Before application, the surface must be cleaned of dirt and dust.

Stir the enamel XB-518 thoroughly until smooth, if necessary dilute with the above thinner.

APPLICATION METHODS

Apply by pneumatic spray or brush in 1 layer.

CONDITIONS OF APPLICATION

PRECAUTIONARY MEASURES

Materials are flammable! Do not work near open sources of fire. Perform work with good ventilation, wearing rubber gloves, using personal protective equipment

Avoid inhalation and digestion. When material gets on wash the skin with warm water and soap. Store enamel and varnish indoors in a tightly closed container, excluding direct sunlight and moisture at temperatures from minus 30 ° C to plus 30 ° C.

Certificate ХВ-518.doc

Packaging

As for the packaging of various types of enamel, it is most often subdivided into small and large. The first option is between 0.5 kg and 3 kg. Some types of enamel, sold as a dry mix, which must then be diluted, are sold in packs of 10 kg, and this is also considered a small package. Large packaging is more suitable for industrial purposes and starts from 15-20 kg. Accordingly, if the enamel is supplied in the form of an already diluted liquid substance, then a volume of 0.5-3 liters is considered a small package. Containers over 10 liters refer, as in the previous version, to large packaging.

All types of enamel, regardless of the initial state of aggregation, are packed in a special container made of polyurethane plastic or special types of light metal, where the packing materials comply with GOST. The lids of such containers are hermetically sealed with solders, so that after the first use it is no longer possible to talk about one hundred percent clogging. However, due to the volatility of toxic materials, some containers for enamel are equipped with special latches on the lid, so even after opening you can be sure that harmful vapors will not enter the apartment.

Enamel KhV-518 U-1

Enamel KhV-518 U-1 (protective) is intended for painting steel surfaces primed with a primer FL-03K (GOST 9109), VL-02 (GOST 12707), GF-021 (GOST 25129) and surfaces made of aluminum and its alloys, primed primer type AK-070 (GOST 25718) or VL-02 (GOST 12707) with overlapping primer AK-070, operated in atmospheric conditions.

The coating system, consisting of two layers of XV-518 U-1 enamel, applied to the primed surface with one layer of primer FL-03K (GOST 9109) or VL-02 (GOST 12707), or GF-021 (GOST 25129), the surface must remain protective properties in temperate climates for 10 years, taking into account the guaranteed shelf life.

The coating system, consisting of two layers of KhV-518U-1 enamel, applied to a surface primed with one layer of primer AK-070 (GOST 52718), must retain its protective properties in a temperate climate for 10 years, taking into account the guaranteed shelf life.

Enamel KhV-518 U-1 is applied to the surface to be painted by spraying, brush or other known method.

Enamel coating color. must be within the permissible deviations established by the control samples of color

The appearance of the enamel coating. after drying, the enamel should form a smooth, uniform surface without craters, pores and wrinkles; slight shagreen is allowed.

Conditional viscosity at a temperature of (20 ± 0.5) о С according to a B3-246 viscometer with a nozzle diameter of 4 mm. 20 - 40

Mass fraction of non-volatile substances,%. 24 - 34

Grinding degree, microns, no more. 40

Hiding power of the dried film, g / m 2, no more. 80

Drying time at a temperature of (20 ± 2) о С, h, no more, up to degree 3. 2.5

Coating adhesion, points, no more. 1

Film strength upon impact on a device of the U-1 type, cm, not less. 50

Film resistance to static action of water and gun grease at a temperature of (20 ± 2) о С, h, not less. 72

Film resistance to static impact of 3% NaCl solution at temperature (20 ± 2) о С, h, not less. 72

Film resistance to static effects of industrial oil, at a temperature of (20 ± 2) о С, h, not less. 72

Film resistance to static effects of diesel fuel at a temperature of (20 ± 2) о С, h, not less. 72

Applications in the military industry

The use of the KhV-518U-1 enamel for painting weapons instead of the KhV-518 enamel will significantly improve the protection of weapons and military equipment against corrosion during long-term storage, namely:

- to increase the shelf life of enamel from 6 months to 2 years;

- increase the service life of paint and varnish coatings from 5 years to 8 years;

- to increase the resistance of the enamel to the strategic effects of cannon grease;

- increase the adhesion of the enamel.

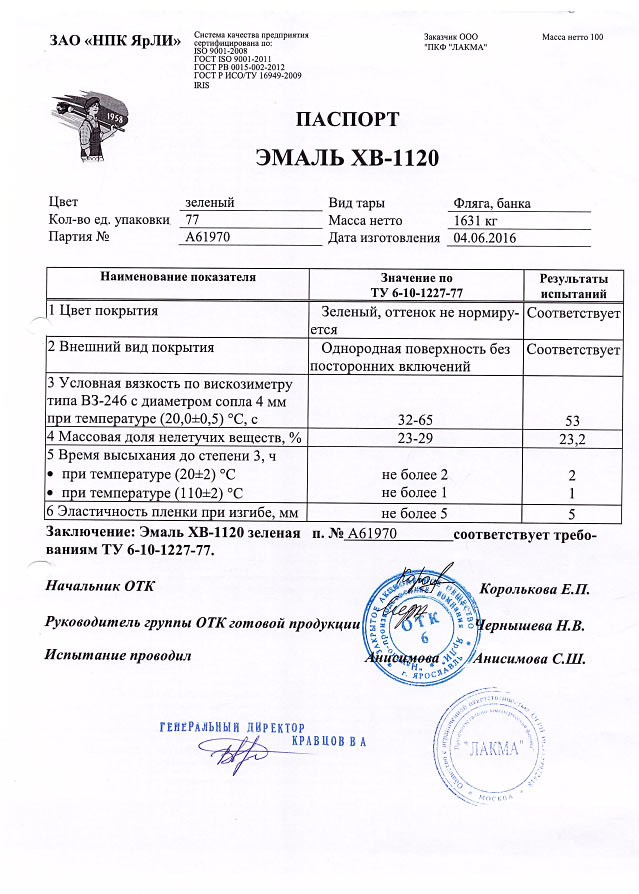

XB-1120

The paint and varnish material XB-1120 creates a protective coating after complete drying. The painted surface is reliably protected from the destructive effects of external factors. The product is protected from the effects of kerosene, gasoline, industrial oil, withstands changes in air temperature.

It is produced in the form of a ready-made suspension based on polyvinyl chloride, alkyd resins. It is produced in different colors.

Appointment

Designed for painting wooden and metal products. It is used for general industrial purposes. The structure or product is prepared in advance. They are cleared of all types of contaminants.

Diluent

R-4, R-5, R-5A are recommended as a solvent. when applied in an electric field - RE-5V, RE-6V. Application methods are pneumatic and airless. The humidity level does not exceed 80%. Consumption per square meter 150-200 grams.

Colors

Store shelves are flooded with enamels of completely unpredictable colors in the struggle for consumer choice. Since childhood, we are all familiar mainly with white enamel for the bathroom, but we should not be limited to this. One shade or another is obtained by mixing different coloring metals.

Blue enamel can be obtained by adding cobalt oxide or copper to the composition. She is often covered with pipes or even walls in outbuildings outside the city.

For a summer cottage fence or shutters, green enamel is often used, created from a mixture of chromium or copper oxides, as well as nickel.

Pink enamel is also popular now - it is used in the interiors of art spaces or beauty salons, for painting a girl's bicycle. This delicate shade is obtained from a mixture of chromium and tin oxides.

The most popular enamel color is black. It is often used in the interiors of living quarters, even for the same plumbing. This color is formed from a mixture of nickel oxides in a combination of iron and manganese, sometimes with the addition of cobalt and chromium compounds.

Pearlescent VGT is the know-how of recent years, designed to work with different surfaces such as wood molding, plaster or metal. In addition to the already colored decorative plaster or clear colorless wallpaper, mother-of-pearl enamel can also be applied.

It contains such elements as pearlescent pigment, water-based dispersion acrylic polymer and modifying additives. Thanks to this, it was possible to obtain unusual shades such as gold, bronze, pearl, garnet, silvery white and even the color "chameleon".

Mother-of-pearl VGT enamel is used not so much to protect the surface from an aggressive environment, but to give an even greater decorative effect, characteristic shine and interesting texture to the element of the design decoration of the room. Nevertheless, such a coating is used both for application to objects that are permanently indoors and for objects that are outdoors for most of the year, having a high resistance to atmospheric changes and resistance to water and light.

If necessary, such enamel can be diluted with water as a solvent, but the proportion of water should not exceed 5%, otherwise the enamel will lose most of its protective properties.

What it is?

So, enamel is a special coating based on a suspension of pigments, which include fillers such as varnish. After drying, the enamel forms a glassy film on the surface of the things painted with it, which is much stronger than ordinary thin glass. It is usually covered with products made of materials such as bronze, steel, cast iron, copper, sometimes even silver and gold.

The advantages and disadvantages of enamel are immediately visible - it protects products from corrosion and even stops this process. This coating lasts longer than conventional paint - on average, 5-10 years. Another plus of enamel is its low coefficient of expansion, several times lower than that of metal. Due to this, excellent adhesion to the base, that is, the same metal, occurs, and the wear resistance and service life of such a coating is increased.

An equally important characteristic of enamel is the value of the modulus of longitudinal elasticity, which also increases the adhesion strength of the coating to the material. When it comes to applying to precious metals, then this feature helps the enamel to acquire a shine and brightness of color, which does not fade for decades.

If you have to work with certain types of enamel, for example, alkyd, indoors, then it must be thoroughly ventilated, preferably 1-2 days. It is necessary to work with enamel in protective clothing and a mask, and preferably in a respirator. If there are small children in the house, it is better to move them to another room for a couple of days. To solve this problem, stores began to sell weak solutions of enamel for household use - their smell is not so pungent, but they also serve less.

Any product officially supplied for public consumption must comply with GOST or interstate standard, that is, have a set of optimal technical characteristics and meet the correct percentage of constituent components. Enamels are not an exception, especially since they are considered quite hazardous substances for domestic use.

Before you buy this or that jar of enamel, read on the packaging which GOST it corresponds to and whether it corresponds at all. Each digital marking contains specific instructions on the composition and scope of the enamel coating. The decoding of the standard can be obtained by contacting the seller - consultant.

Questions about the material XB-785

Do you have any questions?

Use the Question-Answer section

06/04/19 At the non-ferrous metallurgy enterprise we use the coating of XB-785 enamel on the soil XC-010

12.12.17 ХВ 785 was applied, in addition to concrete walls and metal structures, to plasterboard partitions. What kind of trouble to expect?

22.11.17 HV-785 enamel white in accordance with GOST 7313-75 does it contain lead compounds and what pigment is used?

11/14/17 We used XB-785 enamel last year, painted the ice rinks. Now the enamel is falling off in large pieces

08/17/17 Is it possible to use XB-785 with XC-059 to cover pressure pipelines followed by backfilling with soil?

07/10/17 Can XB-785 be applied to the Spectrum primer-enamel?

Peculiarities

The main feature of enamel in comparison with conventional paint is the film that covers the metal surface after its application. The film can be both glossy and matte - it all depends on the elements contained in the coating. The color scheme of enamel is also very diverse - it is not always white, as we are used to seeing it on the surface of the bathroom or washbasin. Black and even multi-colored enamels are not uncommon now.

The best ratio of characteristics is possessed by alkyd enamels, consisting of synthesized alkyd varnishes and organic solvents. Special additives provide an antiseptic effect and resist the development of various fungi and mold. Such enamel is good not only for the bathroom and the outer walls of pipelines, but also for any premises and objects with a humid environment.

Most enamels also contain anti-corrosion additives, which is especially important for metal surfaces in the open air, exposed to temperature extremes and water.

Some types of enamel have a high cure rate when cold dried. So, coatings for interior premises will freeze for 6 - 12 hours, and pentaphthalic enamels are suitable for outdoor objects. Due to their chemical composition, they set in 3 - 4 hours, so that all work can be completed before the onset of rain.

Possessing high elasticity, enamels fit well even on the most uncomfortable surfaces and uneven joints, covering everything with an even layer of glassy film. Also, during the restoration of the bath, the enamel, being elastic, stretches well with a viscous mixture along the entire perimeter, leaving no irregularities with high-quality application.

The compositions of most types of enamel are also distinguished by a high degree of strength and opacity, although it all depends on the method of application - be it an ordinary brush, roller or spray gun. Of course, when applied in one layer, the enamel will be less dense than with multi-layer work, but in any case, the original surface will not be visible, as when applying one layer of ordinary paint.

How to choose?

Most often, the choice of enamel for outdoor work is made in favor of organosilicon compounds, which are very strong and serve for a long time. The variety of possible shades is another significant plus of such products.

When performing interior work, first of all, the type of surface to be trimmed is taken into account. Of great importance is how important the hydrophobic properties of the paint and varnish material are.

Of the decorative parameters, color and texture, the degree of gloss are essential. The polyurethane compound is very durable, but the increased price limits the use of such enamels. Nitrocellulose variations are suitable mainly for wood finishing.

Lattices, machine tools and other metal products will become more attractive after using hammer enamel. Preparing the surface for painting with them is not difficult.

When coloring batteries, it is worth paying attention not only to the hydrophobic properties of the composition, but also to its resistance to significant heating.

It is equally important to think about the safety of the mixture used, which, even at temperatures above 100 degrees, should not emit toxic substances.

XB-5286S

Enamel is not considered universal. Narrow scope of application.Protects the hulls of ships and oil platforms from fouling by microorganisms. Produced in one brown color. The formed coating protects against corrosion. The paint is applied in one layer. The service life of the product is two years. The paint and varnish material belongs to the group of flammable

Observe safety precautions when working

Appointment

The application profile is very narrow. They are used only in the shipbuilding industry and in the repair of ships of an unlimited navigation area. The paint is applied in a well-ventilated room. Use personal protective equipment, rubber gloves to protect the skin of the hands. Avoid contact with the skin, inside the body.

Diluent

Dilute with solvent if necessary. It is one of the multifunctional solvents. The dilution method is the same as with other solvents. Transparent color liquid. There is a pungent odor. Wear personal protective equipment. Its shelf life from the manufacturer is one year. It effectively dilutes quickly to the desired consistency.

Drying time

The coating dries completely in 8 hours. The enamel is very dense. The layer is thick. It is applied in one layer. Dries at a temperature of +20 degrees C.

Enamel XB-518 protective

Enamel XB-518 is used for painting pre-primed steel and aluminum surfaces operated in atmospheric conditions.

Appointment

Enamel XB-518 protective refers to enamels with special properties. It is intended for painting pre-primed surfaces made of steel, aluminum and its alloys. It is also used independently, without priming, for a short time, for wooden surfaces in special-purpose products. It is used for application on plastic, plastics (on EP-0010 putty).

APPLICATION:

Enamel is used to protect metal products exposed to the static effect of water and industrial oils, including cannon grease, in the atmospheric conditions of zones with cold, temperate and tropical climates. Enamel is applied in 2-3 layers on primers: GF-0119, GF-0163, GF-032, GF-031, GF-021, PF-0142, PF-020, PF-033, FL-03K, FL-03Zh, FL-086, V-KF-093, XV-050, XC-010, XC-068, XC-059, AK-070, AK-069, KF-030, VL-02 (with overlapping primer AK-070) or similar. The choice of primer, on which the enamel is applied, depends on the surface to be painted and the climatic conditions of use of the coating.

PROPERTIES:

Enamel XB-518 is applied both to a primed and non-primed surface by spraying or with a brush. It is easy to use, it is produced with a low viscosity, therefore it does not require a large amount of solvent, it is easy to apply, it dries quickly enough under natural conditions, it is compatible with most paintwork materials. With initial viscosity, it can be applied with a brush; when applied by spraying, it is diluted with a solvent R-4A or R-4. The coating formed by the enamel is elastic, at the same time it has high strength and hardness, it is resistant in the atmosphere of various climatic zones, to the static effect of water, industrial oils (gun grease). You can buy hv-518 from us. After drying, the enamel XB-518 forms a flat, smooth surface without wrinkles, pockmarks and foreign inclusions, of a protective color (the color must be within the permissible deviations established by the control color samples).

Specifications XB-518

Nominal viscosity of KhV-518 according to the VZ-246 viscometer with a nozzle diameter of 4 mm at a temperature of (20.0 + 0.5) oC, s

Mass fraction of non-volatile substances,%

Drying time to degree 3 at temperature (20 + 2) оС, h, no more

Hiding power of the dried film, g / m2, no more

Flexural elasticity of the film, mm, no more

Film strength upon impact on the U-1 device, cm, not less

Pendulum hardness of the film: TML, pendulum A, rel. units, not less

М-3, conv. units, not less

Adhesion, points, no more

Film resistance to static impact of water at a temperature of (20 + 2) оС, h, not less

Film resistance to the static effect of gun grease at a temperature of (20 + 2) оС, h, not less

at a temperature (60 + 5) оС, h, not less

Recommended paint schemes

steel - primer GF-0119, GF-0163, GF-032, GF-031, GF-021, PF-0142, PF-020, PF-033, FL-03K, FL-03Zh, FL-086, V-KF -093, XB-050, XC-010, XC-068, XC-059, AK-070, AK-069, KF-030, VL-02 (with overlapping primer AK-070) or similar, on a rusty surface "Unicor "Or rust converter - 1 layer + HV-518 enamel - 2-3 layers;

aluminum and its alloys - primer AK-070 (or VL-02 with overlapping AK-070) or similar, on a rusty surface "Unicor" or rust converter - 1 layer + HV-518 enamel - 2-3 layers.

Without priming: wooden surfaces, plastic (or with EP-0010 putty) - 2-3 layers of XB-518 enamel.

Container and packaging

Enamel XB-518 is produced in industrial containers. Large containers (drums 20 or 25 kg, barrels 50 kg and small packaging 0.8 kg)

The enamel is stored in a tightly closed container, protecting it from moisture, heat and direct sunlight at temperatures from -40C to + 40C.

The guaranteed shelf life of XB-518 protective enamel is 6 months from the date of manufacture.

Application features

- White enamel can only be used on surfaces that will not be exposed to excessive dirt and dust.

- Wood enamels with a higher concentration of artificial varnishes and a lower content of fillers look better than ordinary coatings.

- EP series alkyd-epoxy material is unsuitable for the regions of the Far North.

- And the materials of the FL series (phenolic oil) dry rapidly without loss of quality and at the same time form very strong coatings.

Contrary to popular belief, quick-drying paint does not contain ingredients that are harmful to health. Moreover, it contains mainly natural non-toxic substances. Such paintwork materials do not slip, therefore they can be used in any premises.

For ILLUSION acrylic enamel with the chameleon effect, see the following video.

Tips & Tricks

The correct application of the enamel often determines how evenly it will lay on the surface and how long it will last.

Here are some tips from professionals in the field:

- For airless spraying, it is not recommended to dilute the enamel with a solvent, since without a certain degree of viscosity such a coating simply will not evenly come out through the sprayer under the required pressure. It is better to use a nozzle with the thinnest possible diameter, no more than 0.3 mm. The pressure, on the other hand, must be strong enough, about 150 bar.

- If the composition is sprayed by air, then such a universal solvent as solvent will come to the rescue. However, do not overdo it with the addition of this substance, do not add more than 5% of the total mass of the composition. Unlike the first option, it is better to take the nozzle here much thicker - about 2 mm, and, on the contrary, reduce the pressure to 4 bar.

- The easiest way to apply enamel is with a roller or brush. The only advice here is to also dilute the composition with a solvent no more than 5% of the total mass. To avoid discarding leftover solvent, it can then be used to rinse all application tools for reuse.

Views

When any enamel dries, the solvent evaporates, and the resins become stronger. Of decisive importance in assessing the properties of a composition is the concentration of the binder in its composition. This parameter directly affects the visible gloss and properties when pouring liquid paints and varnishes. The total drying time does not exceed 3 hours, but the recipes can vary greatly.

The composition of enamels can include various types of resins:

- perchlorovinyl;

- nitrocellulose;

- polyvinyl chloride and a number of others.

Regardless of the specific type, during the curing process, not only physical, but also chemical changes in the coatings take place. Thanks to them, the enamel surface is durable and resistant even to attempts to dissolve it with the previous composition.

- Epoxy, urea formaldehyde and alkyd enamel paints dry for about a day.Aerosol enamel differs from ordinary enamel not so much in chemical composition (it can be different), but in simplified application. A side effect of this is, unfortunately, a noticeably higher consumption compared to manual painting.

- Nitro-based formulations were originally developed for car refinishing. Their developers were able to achieve unusually fast drying (15 - 30 minutes). But the finishers, albeit not immediately, also appreciated the characteristics of such coloring compositions.

- Oil enamel is a phthalic resin to which vegetable oil and pigments have been added. The coating formed with its help is extremely durable, with a pleasant shine.

Selection and application

When choosing a certain type of enamel, it is better to first familiarize yourself with which brand is used for what purposes. In the store you can find a huge number of enamels for approximately the same types of surface, so it is better to know in advance so as not to overpay or buy a very persistent and caustic type of enamel where one could do without it.

According to GOST marking on containers, the following information can now be determined:

- what surfaces the enamel is used for;

- what is the rate of drying of the enamel, as well as the degree of its viscosity, elasticity and toxicity;

- what percentage of non-volatile harmful substances is in it;

- how many layers are necessary for the full functioning of the coating, as well as the way in which it can be painted with enamel;

- what kind of solvent or primer is used in conjunction with this type of coating;

- what similar paint and varnish coatings the enamel is compatible with;

- whether it is necessary to dilute or mix it, and also how long after dilution is given to work until it thickens.

Enamel serves as a coating for the following objects: road signs, electrical equipment, cars, house facades, roofs, tableware and whole sets, interior details and, of course, the familiar bathroom restoration.

Enamel is also successfully used in jewelry and as a decoration for luxury interior items. For the needs of jewelers, they use cloisonné enamel, known since ancient times, which is difficult to manufacture and is not sold in ordinary hardware stores.

Basic color compositions

| Colour | Composition of pigments | The amount of pigment,% by weight |

|---|---|---|

| Orange | Chalk. cinnabar, yellow crown | 60, 25, 15 |

| Beige | Chalk. cinnabar, umber | 35, 11.4 |

| Cherry | Chalk, Mars Red, Cinnabar | 45, 46. 9 |

| Blue | Chalk, chromium oxide, ultramarine | 80, 15, 5 |

| Yellow, lemon | Chalk. lemon crown | 88, 12 |

| Green | Chalk, chromium oxide | 75-88, 25-12 |

| Red | Chalk, orange crown, cinnabar | 50, 25, 25 |

| Brown | Chalk, cinnabar, pigment green | 49, 5, 49. 5, 1 |

| Crimson | Chalk, Mars Red, Ultramarine | 79, 16, 5 |

| Orange | Chalk. CZK orange | 95, 5 |

| Ocher | Chalk, ocher, yellow crown, iron red lead | 74, 15, 8, 3 |

| Blue | Blue paint MO-5, green paint ZP-5 | 95, 5 |

| Lilac | Chalk. mars red, ultramarine | 79, 16, 5 |

| Black | Technical carbon | 100 |