Main characteristics

Before purchasing glue and getting started, you need to familiarize yourself with the individual characteristics of this type of compound. Knowledge of the main characteristics will help determine whether the material will cope with the task at hand.

Technical Features of two-component polyurethane adhesive composition further.

- Product consumption per one square meter of surface is from 800 to 2000 grams. The indicator varies depending on the type of work and type of foundation.

- The work must be carried out under certain temperature conditions. The lowest indicator is - 20 C. And the maximum is 80 degrees with a plus sign.

- In the process of applying the glue, make sure that the temperature in the room remains within the range from + 15 to + 30 C.

- Store the product in a tightly closed container, away from sunlight. Temperature storage conditions: from zero to 50 degrees Celsius.

- The maximum shear strength is 3 Newtons per square meter. mm. Be sure to consider the limit when repairing and adjusting.

- It takes 24 to 48 hours for the glue to fully cure. It all depends on the layer. The thicker it is, the longer it takes to solidify.

- For one liter of liquid 1.55 kg.

- The composition of the glue is completely free of organic solvents.

- The adhesive can be used in conjunction with underfloor heating technology.

- The product differs from similar compositions in high adhesion to alkalis.

Tips & Tricks

Bonding parquet to a two-component layer is not an overly complicated procedure. Usually, the instructions attached to the product explain the sequence of work in sufficient detail.

A special surface preparation can prevent a decrease in adhesive adhesion. Substrates must be clean and dry. If there are cracks and irregularities on them, they should be eliminated.

To improve the adhesion of the material, it is possible to pre-apply in 2 layers of a primer composition. The latter should be given time to dry completely, after which you can start fixing the parquet.

Some formulations do not need to be pre-mixed when gluing two elements. In this case, an emulsion is applied to one half, and a hardener to the second part. The chemical reaction starts after the parts are pressed against each other.

The pot life should be considered when determining the amount of the mix to be mixed. On average, it takes from 45 to 90 minutes (you need to see more on the package), so you need to dilute as much glue as you can use during this time.

The finished glue is applied with a notched trowel to the working base. Better to do this in small squares. After the parquet is completely laid in this area, you can start applying glue to the next "square", etc.

When laying wooden elements, it should be remembered that they are prone to temperature changes in geometry, therefore parquet boards are mounted with a gap of 1-2 mm. When installing parquet, it is recommended to tap the lamellas. This eliminates the risk of voids underneath.

This super-strong and strong composition dries out for 24 hours, after this time you can start sanding the floor and applying varnishes to its surface.

In case of contact with skin, immediately rinse the affected area under running water. In the event of allergic reactions, as well as the ingress of glue on the mucous membranes, you should consult a doctor as soon as possible.The use of gloves and a protective mask during work allows you to prevent such situations.

You should not refuse to use epoxy-polyurethane glue due to the content of unsafe components in it. The toxicity of the two-component composition manifests itself exclusively at the time of application, completely volatilizing as it dries.

For the features of two-component glue, see the following video.

Advantages and disadvantages

To evaluate the range of possibilities of 2-component polyurethane-based formulations, it is necessary to familiarize yourself with the list of strengths and weaknesses of the product.

- Usage. The glue is actively used when working with various materials, be it synthetic or natural raw materials. The products are used when working with wood, metal, rubber, plastic (PVC), stone and textiles. A large scope of work has made the product popular and in demand all over the world.

- Temperature. A quality product is not afraid of sudden changes in temperature conditions. Even with constant fluctuations, all performance characteristics remain unchanged.

- Wear resistance. The adhesive layer retains its firmness and practicality even when exposed to water, oil or gasoline. But it is also worth noting that the product is not afraid of dampness, mold and mildew. Due to the special components in the composition, the multiplication of bacteria on the surface of the layer is impossible.

- Reliability. The adhesive firmly and permanently bonds various materials. It can be used for horizontal and vertical surfaces. With the correct use of a certified product, you can be sure of a secure fit. And also the composition boasts high mechanical properties.

- Additional features. When working with MDV panels or PVC (plastic) structures, the two-component product acts as a practical and durable sealant. High-quality sealing of seams will help to save heat in the room, as well as reduce the noise level.

Benefit Due to favorable consumption, the composition is economical to use

This characteristic is especially important if you plan to renovate a large facility.

Wide scope of use. On sale you will find a huge variety of products focused on a specific scope of work

The glue is used for the installation of parquet flooring, structures of various types, vehicles (boats), shoe repair, sealing and others.

Excellent result. Deformation of the layer during the laying of solid wood or parquet is excluded. Taking into account the individual technical characteristics, the material is recommended for use by beginners who do not have proper experience in the field of repair, installation and construction.

Only certified products have the above characteristics.

Among the huge assortment, the following compositions are especially popular:

- Alu 2-component (Cosmofen Duo) is a universal product;

- Uzin MK 92 S - effective glue for laying parquet;

- Molefix 8325 is a professional product with a wide range of applications.

This type of product has one significant drawback. Two-component adhesive has a long drying time. Not all experts consider this characteristic a disadvantage. This feature can also be called an advantage. The master has more time to carry out specific work. In addition, this disadvantage fully compensates for a number of advantages.

Parquet glue - types

By components and properties, the compositions are divided into the following main groups:

- Dispersive. They are water-based within acceptable limits and are environmentally friendly, safe, and fast drying. They are used for durable and moisture resistant species, such as oak.

- Solvent-based. The products are toxic and require special respiratory protection, however, they are reliable, durable and elastic, suitable for all breeds.

- Polyurethane (one- and two-component).They are distinguished by their strength, do not shrink, and significantly strengthen the coating. They can be called universal and the most purchased in Russia.

- On MS polymers. Modern high-quality products, as strong as polyurethane and elastic as silicone, they are easy to handle, they are environmentally friendly and provide good sound insulation.

- Hybrid. They are versatile and durable, withstand heavy loads, but are considered less elastic than the previous group. Typically used when pure MS polymers cannot be used.

Comparative characteristics of 2-component adhesives

When choosing a two-component parquet glue, a dilemma arises, whether to save money, or to take a more expensive and seemingly better option. We recommend that you primarily focus on the technical characteristics and give detailed differentiation by type of glue. In modern chemical production, well-known brands have sufficiently high-quality products and there is practically no glue that does not hold the parquet material on the base. But for the accuracy of the selection of the desired composition, nuances are important.

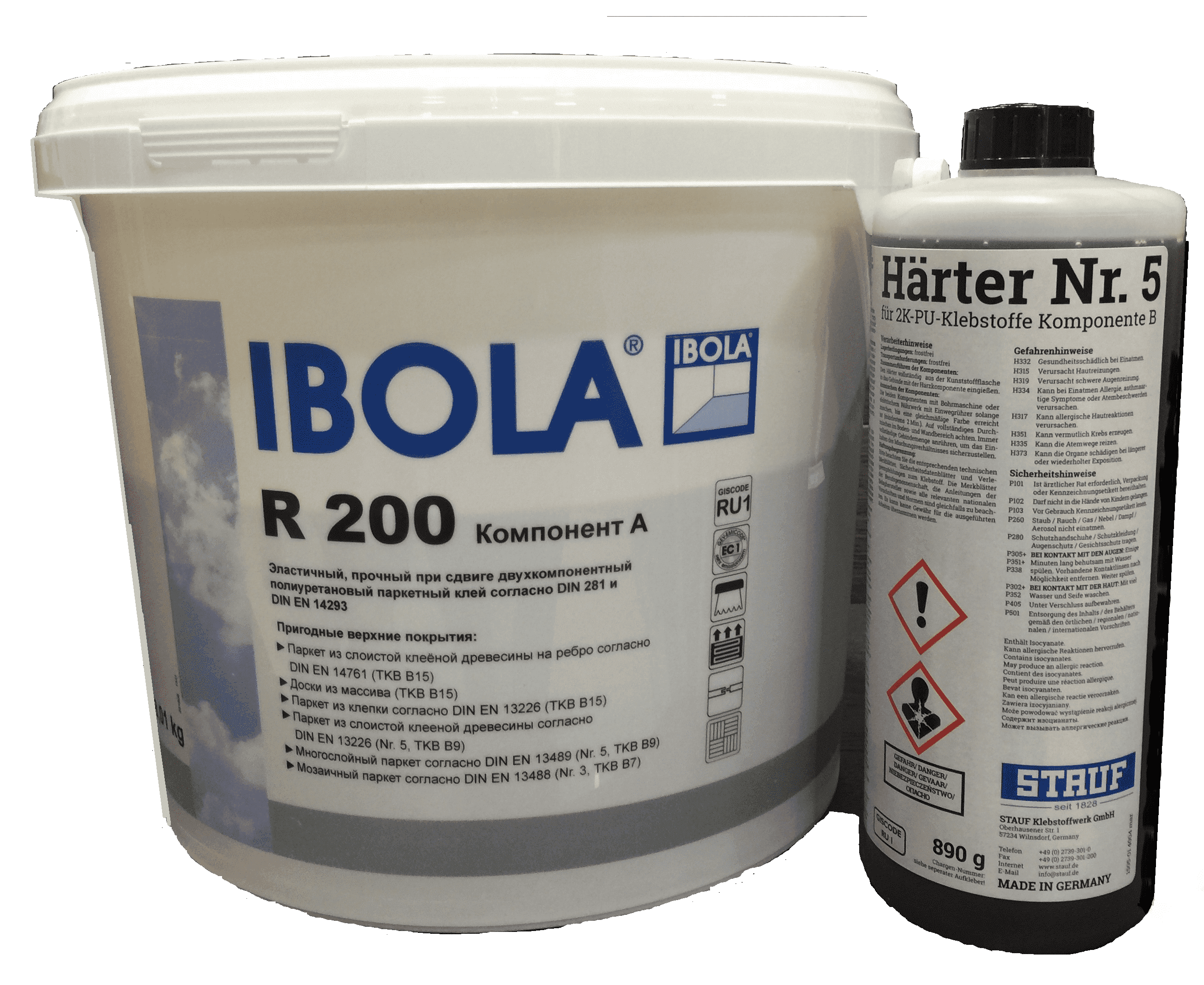

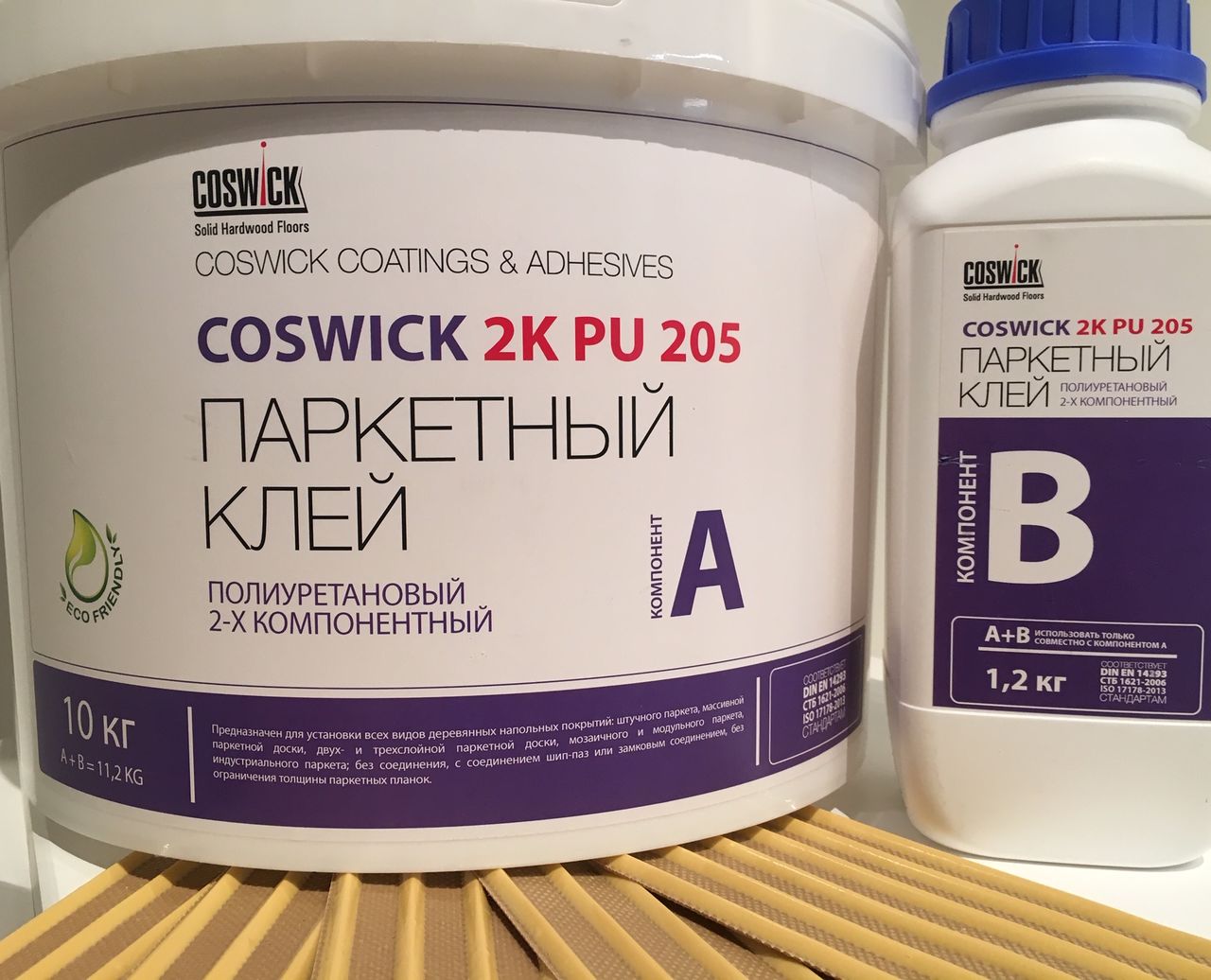

Epoxy-polyurethane two-component adhesives are quite tough, often with a specific odor when working with budget versions, due to the addition of a solvent and a toxic hardener. In ecological options, there is no solvent and the composition is cleaner, but the glue seam is also not elastic. The main advantage of such versions is a long working time for laying parquet elements up to 2 hours and high strength, versatility in application. But with unstable wood species and large dimensions, it is better to use hard-elastic polyurethane glue.

Examples of epoxy-polyurethane 2-component adhesives: Sipol (Lechner, Italy) 10 kg, Repox (Vermeister, Italy) 10 kg, Zero% (Vermeister, Italy) 10 kg can be considered as ecover.

Premium class polyurethane two-component adhesives have a hard-elastic glue line and the highest strength without restrictions on wood species and dimensions, whether it be engineered board, solid wood or modular parquet. Such adhesives have economical consumption and environmental certificates, reliability when laying large-sized massive boards from exotic species and retain their plasticity for many years even with cyclical changes in the linear dimensions of parquet planks. Working hours range from 30 to 90 minutes, depending on the room temperature.

Varnish mixtures for parquet on water

The market presents different variants of water-based varnishes, both one- and two-component for parquet treatment. It is believed that the leaders in this area are manufacturers from European countries:

- Italy;

- Germany;

- Sweden;

- France;

- Belgium.

It is their products that are in stable, well-deserved demand. One way or another, but among the range presented, you need to choose only proven varnish options with a high level of performance and environmental friendliness.

Example of Bona Traffic trains

Below are several options for parquet varnishes that deserve attention and trust:

- Bona Traffic is a water-based varnish made in Sweden. Differs in wear resistance, suitable for use in premises with a high level of traffic.

- 884 2-k Perfect Duo is a high quality two-component polyurethane Aqua clearcoat. Suitable for a durable, wear-resistant coating that is not susceptible to chemicals.

- Blanchon Intensive (Blanchon Intensive) - varnish made in France, is realized in three versions to create glossy, semi-matte and matte surfaces. Two-component, water-based, especially suitable for flooring in rooms with an increased level of stress. Suitable for finishing coatings in schools, offices, shopping malls, etc.

- Synteko Classic is a two-component parquet varnish with hardener.Demonstrates a high level of adhesion, is not sensitive to temperature extremes.

A two-component varnish with a hardener should be placed in a separate category of parquet finishing compounds. It includes, in addition to resins and solvents, targeted additives and a hardener. Parquet treated with such a varnish has high performance characteristics, is resistant to abrasion, mechanical damage, water and chemicals.

Another manufacturer of water-based varnishes

It is recommended to use varnish for surface treatment in rooms where special requirements are imposed on them. This type of varnish can be applied using rollers, as well as brushes or a spray gun.

In conclusion, we note that parquet varnish, both two- and one-component water-based or with a hardener, should perform the main functions - to protect the wooden base of the floor, to increase its service life. In addition, it is important to implement tasks in relation to placing the right emphasis on natural advantages: color, structure, wood pattern while maintaining its qualities even after repeated polishing.

Two-component parquet adhesive

Two-component parquet glue is a universal assembly chemistry that hardens quickly and provides high-quality bonding. The epoxy does not deform the boards.

Application area

Two-component adhesive is used for laying parquet or installing other floor coverings. It is suitable for classic wood species, as well as expensive exotic. There are frost-resistant types of two-component glue that can withstand severe temperature changes and mechanical stress, which do not give much shrinkage.

Berger Bond P2S two-component polyurethane parquet adhesive

The peculiarity of two-component glue is that it is packed in two separate containers. Before applying, its main component is mixed with a hardener, after which the mass must be thoroughly mixed. When solidified, the glue forms a hard surface. A feature of the epoxy composition is the ability to fill the pores of the subfloor. Chemistry has a high coefficient of adhesion and is widely used for mounting boards on a cement-sand base.

When choosing the type of epoxy composition, you need to decide which consistency is more preferable:

Adhesive consumption and well-known manufacturers

The consumption of glue directly depends on the evenness of the subfloor, usually this value is 900-1200 g / m2.

VERNISSAGE. Fastening systems. Part 3. Adhesives. Compatibility table

Among the well-known manufacturers of glue is the German brand UZIN, which produces a full range of floor chemicals: materials for preparing substrates and laying coatings, including glue, putties, primers, solvents.

Berger is one of the leading German manufacturers of floor primers and parquet chemicals. It uses modern technologies in the production of products, which allows the brand to enjoy success in many markets.

Sikadur is a brand that produces safe products that are free of toxic substances. The glue from this manufacturer is a combination of epoxy resin with special solvents, it can be applied to a damp base.

Order of use

Before using the glue, you need to carefully read the instructions. After that, you can proceed to the installation work:

- First you need to prepare the glue and make sure that the material is sufficiently stirred at the bottom of the container and its walls. It is recommended to knead with gloves.

- A notched trowel is used to apply chemicals to the subfloor. Prepare the amount of glue that will be used within an hour, maximum one and a half.

- Parquet boards should be laid with wet glue and tapped. Ensure sufficient wettability on the back of the dies.

- Sanding and varnishing is allowed only after 24 hours, when the coating is completely polymerized.

Store material in its original packaging in a cool place. Opened cans and remnants of the mixed adhesive harden quickly and therefore cannot be stored.

It is recommended to carry out work at a temperature of 18-25 degrees, the air humidity should not exceed 75%. Excessively low temperatures increase, and high temperatures shorten the setting, laying or drying time.

How to wash the glue

Epoxy can adhere to walls, batteries, and other surfaces. You can remove stains of this substance in the following ways:

Heating method. Epoxy based adhesive can soften. Therefore, you can heat the stain with a regular hair dryer and wait for the material to melt. After a while, clean off the softened glue with a spatula and wash the surface with a regular product.

Freezing. This method is more complex, but it is more effective. You need to purchase a refrigerant in the form of an aerosol. After protecting hands and eyes, it should be sprayed onto the stain. Thanks to this, within a few minutes, the frozen and brittle resin will be detached from the surface by the action of a spatula.

Chemical reaction. The tool can be removed using reagents. Among them: boric, nitric or hydrochloric acid

After carefully treating the surface, you can remove the dirt with a highly concentrated detergent.

Polyurethane mixtures - one-component adhesive

One of the most demanded for the installation of natural wood parquet is polyurethane glue, which, in turn, can be two-component and one-component. Both options are noteworthy.

One-component compounds are suitable for laying parquet flooring of any size. Solidification occurs due to the reaction of the contents of the mixture with the moisture that is part of the air. Quite often, one-component parquet glue is used to assemble the finished coating in the factory, given that the mixture does not deform the decorative and protective layer.

Even after complete drying, such mixtures do not shrink and this is their advantage.

The leader among the products of this plan is Artelit HB-820 glue, which is characterized by a low price. The composition requires a certain investment of time and effort to install the coating, while demonstrating high elasticity with low stickiness and weak initial adhesion. To achieve the desired grip, the die must be pressed firmly against the base and held in this position for several seconds.

For those who value quality first and foremost, Kiito Flex Silan, a one-component polyurethane adhesive for natural wood parquetry, will be indispensable. It can be used to lay dies of any size with both varnish and oil coating. Also suitable for mounting plywood base and wide solid boards.

The product has the ability to expand without deformation even with an increase in the size of the coating beyond the norm (for example, after flooding a room) with a subsequent return to the previous parameters. The disadvantage of the product is the high price, as well as the release of toxins during use. The mixture becomes safe one day after use.

Peculiarities

Polyurethane adhesive solutions are available in one and two components. Products differ in technical characteristics and composition, respectively. The main difference between this type of product and a similar product on the modern market is a wide temperature range of use. But they also note resistance to increased moisture and other external factors.

Among the advantages, experts highlight the use of indoor and outdoor premises, as well as versatility, durability and reliability. For the manufacture of 2-component glue, hardeners and polyesters are used.When working with the composition, it is necessary to carry out the mixing procedure of the two components.

Many manufacturers add special catalysts. With their help, you can accelerate or, conversely, slow down the polymerization of the adhesive. Today, products of this type are offered by domestic and foreign brands.

Scope of application

Two-component adhesive is suitable for those cases where it is necessary to provide improved adhesion of various surfaces - wood and concrete, metals, leather, glass, etc. For bonding non-porous materials (except synthetic ones), epoxy-polyurethane composition is well suited.

This glue has increased strength when metal powder is added to it. In terms of its qualities, it begins to resemble "cold welding". When added to the composition of fiberglass, its strength characteristics and vibration resistance are also significantly increased. This allows the use of epoxy-polyurethane glue also for the repair of mechanisms and machines. It is suitable for aluminum, cast iron, iron, but cannot be installed over galvanized and copper surfaces.

The absence of water and solvents in the composition, as well as resistance to abrasion, thixotropy (no shrinkage of the seams) make it optimal for gluing wooden flooring, in particular, laying parquet flooring, massive parquet boards and parquet mosaics. It also allows you to securely attach plywood to concrete and other surfaces without the use of fasteners (nails, screws).

Two-component compositions withstand high-temperature exposure well, therefore they are used when organizing a warm floor system. There is also a variety of two-component polyurethane compounds that are used as sealants. With their help, it is possible to eliminate minor seams. The ratio of emulsion and hardener in such a product is 1: 1.

Due to the strength of the bond, which is guaranteed by the use of a two-component adhesive, it is used for laying tiles and mosaics, including heavy ceramic ones. Installation of tiles can be carried out both horizontally and vertically directed bases. Tile adhesive usually has a slightly higher viscosity.

The strength and adhesive properties of two-component compounds are so high that they are used to join stone, natural or artificial. As you know, this material is distinguished by its high weight and porous surface. However, the two-component product is even suitable for bonding marble, granite.

Finally, two-component compounds, due to their strength, moisture resistance and safety, are used in shoe repairs. In shoemakers, they are used primarily for gluing soles, heels and other elements. Such glue is also suitable for repairing leather and suede accessories.

Despite the wide scope of application of two-component glue, it cannot be used in places with high humidity (in such places, laying parquet is, in principle, illogical). If there is a possibility of capillary rise of moisture, then this adhesive can only be used if there is a high-quality vapor barrier.

Two-component parquet adhesive: compositional features

The entire range of such products can be divided into three types:

Two-component polyurethane adhesives. This is the most common and most purchased option of all. It has average elasticity and stiffness, it does not have a pungent odor, it is suitable for work in residential premises and, in general, is absolutely universal - suitable for all wood flooring of any species, including exotic ones. It is distinguished by a limited working time - about an hour - one and a half, as well as strength, elasticity of seams, no shrinkage and resistance to increased operational loads

Application is possible both on a cement and on a plywood base, it is only important that it be dry, even, without traces of construction dust, in order to prevent local deformation of the future canvas.

Epoxy-polyurethane. Epoxy products in their pure form form a very strong, but low elastic layer, therefore they are rarely used today.

Epoxy - polyurethane compounds in this sense are much more reliable, since they have high strength, thanks to the epoxy base, and good elasticity, thanks to the addition of polyurethane. Its working time is longer than that of pure polyurethane - from one and a half to two hours.

Powder adhesives. Powdery diluent giving an ultra-strong layer, ideal for plywood, board and block parquet. It is economically used, has frost resistance and a small viability - about forty minutes.

Characteristics and application

The main advantages of two-component compounds: increased strength of the joints, no shrinkage and negative impact on all types of wood, rapid hardening. The only difficulty is the need to mix the components of the product. When choosing, you need to correlate the manufacturer's recommendations with the existing working conditions (wood species, installation method, and so on).

Laying is carried out on dry, absolutely clean and primed surfaces in rooms with low humidity. The components are mixed in the recommended proportions with a construction mixer for two to three minutes

The mixture is applied with a spatula with great care so as not to spoil the appearance of the material to be laid.

In most cases, the planks are pressed by hand and weights are placed on local areas for better adhesion. Although more expensive polyurethane-based products work almost instantly and do not require such measures. To preserve the aesthetic appearance of the finished parquet surface, it is necessary to use cleaners or napkins impregnated with a special composition. Such measures will save you from unnecessary, unnecessary hassle of removing dried remnants of the adhesive layer.