Areas of use

Before purchasing a two-component sealant, pay attention to the options recommended by the builders and renovators.

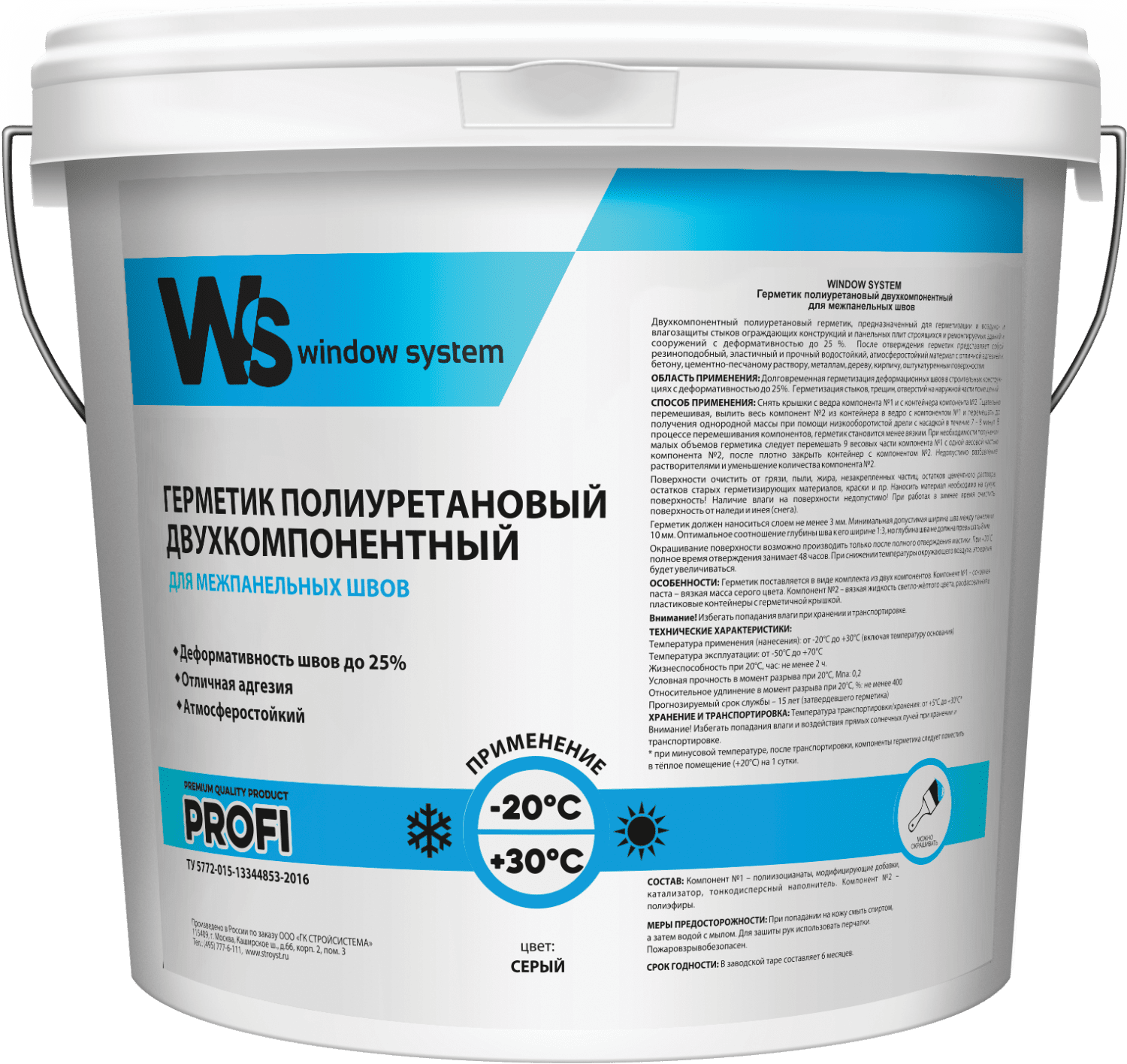

- "Neftezol" NF 88 (16 kg) - bitumen-polyurethane glue. Scope of application - gluing materials from metal, blocks, foam glass. Also suitable for sealing joints.

- Ecoroom PU-20 is designed for sealing expansion joints, cracks and crevices in the facade. It is characterized by excellent adhesion to concrete, metal and wood surfaces.

- "Tektor" 201 is a two-component mastic for sealing joints of fencing structures, panel slabs, during construction and repair work.

- Germotex is used to seal expansion joints and cracks on concrete floors and slabs. Contains synthetic rubber for good adhesion, reliability and structural integrity.

- "Sazilast 22" provides sealing of expansion joints, joints and cracks in the facade coating. Suitable for concrete, polymer concrete, foam concrete, brick. Differs in light gray color.

- Polikad M is a good sealant for insulating glass units. Contains polysulfide, plasticizer, pigment, fillers. It is considered an effective vapor barrier.

General information about joint sealants in concrete

The quality sealants on the market are produced according to the latest innovative developments. The action of building sealants is aimed at water and air tightness of expansion joints in concrete floors. They are made on the basis of modified polymers, synthetic, natural rubber, and other compounds that give the material increased elasticity. This is the main requirement for building raw materials. But the elasticity is possessed by different types of acriplast, with different properties.

The bulk is represented by types, which differ according to the formula, area of use, shrinkage properties, adhesion, strength, main components, etc.

According to the operating conditions, the concrete sealant is divided: for civilian objects, apartment buildings; industrial construction; works under water; hydraulic concreted buildings; sewerage and treatment facilities.

Acriplastics for concrete joints are also distributed according to their design features:

Peculiarities

Any sealant is formed by substances that, during the hardening process, become a strong shell that does not allow any substances to pass through. Air, water and various other substances do not penetrate into the applied product, which has acquired hardness.

A two-component mixture, unlike a one-component mixture, cannot be immediately ready for use. The original components are separated and stored in separate containers, with the start of work they must be thoroughly mixed using a special technology. Special measures must be taken so that the external environment does not have a detrimental effect on the composition used.

To prepare a sealant, you need to use a mixer - a mixer for construction work or an electric drill, on which a special nozzle is placed. For subsequent application, you will need a spatula or a special gun.

Germotex - polyurethane sealant for concrete joints (10 kg.) Krasko Germote

Shipping and payment

Germotex is a sealant for concrete expansion joints, a two-component polyurethane elastic sealant.

The joint sealant has a high strength of attachment to concrete, brick, glass, rubber, wood and metal surfaces, thereby ensuring the durability of building structures and saving on repeated repairs.

Possessing excellent elasticity, Germotex seam sealant resists abrasion, puncture, rupture better than other sealing materials, i.e. satisfies the most important requirements for floor sealing materials. The sealant has excellent adhesion (adhesion) to absolutely all building surfaces.

The elastic properties of the polyurethane system allow the use of a joint sealant not only in construction, but also where sealing on flexible joints is required.

for sealing and sealing cracks and joints of concrete floors and slabs,

for sealing joints subject to vibration and deformation,

for repairing seams and cracks in road surfaces,

for the device of expansion joints of bridge structures.

Container 10kg

Attention! The label is equipped with security elements against counterfeiting

Apply on a clean, dry surface at an ambient temperature and the surface to be treated from + 5 ° C to + 40 ° C.

It is recommended to pre-prime porous cement-sand substrates with PS-Grunt polyurethane primer.

Then mix the paste (component A) with the hardener (component B) until a homogeneous mass is obtained for 3 minutes. Fill the crack with the resulting composition with a pouring or spatula.

The pot life of the sealant is 40 minutes at a temperature of + 20 ° C.

The time for a full set of strength is from 5 to 7 days.

Operating temperature -50 ° C + 60 ° C.

The sealant is supplied in a container with a pre-calculated mass of paste and hardener.

Attention! The use of material in an amount other than the standard packaging is unacceptable, as this can lead to a violation of the proportions and deterioration of the material properties. When carrying out internal work, as well as after their completion, thoroughly ventilate the room

Use personal protective equipment

When carrying out internal work, as well as after their completion, thoroughly ventilate the room. Use personal protective equipment.

Do not heat, keep away from fire.

Store the composition in a tightly closed container, protecting it from heat and direct sunlight.

Before use, after transportation at low temperatures, the composition is kept for 24 hours at t (20 ± 2) ° C.

The guaranteed shelf life is 6 months from the date of manufacture.

Models

Ecoroom PU 20

The hermetic composition of Ecoroom PU 20 has unique technical parameters and helps to multiply the period of maintenance-free operation of the inter-panel joint. It can be used for deformed joints, it preserves cracks and cracks well. It has great adhesion to concrete, metal and wood, UV and weather resistant. The mixture can be painted with water-based or organic paints.

Ecoroom PU 20 is divided into two key components - the polyol part and the hardener. The paste is applied very easily and simply, mixed with a household electric drill for at least 10 minutes. Store the sealant under normal conditions for at least 24 hours before mixing. In its ready-to-use form, it becomes as elastic and rubber-like as possible.

The material can be applied on moderately damp (not wet!) Substrates, which are initially cleaned of traces of dirt, fat deposits and accumulation of cement mortars. In some cases, when it is necessary to exclude the interaction of the sealant with the joint surfaces, they are treated with foamed polyethylene.

POLIKAD M

POLIKAD M - for sealing double-glazed windows. The composition does not require the use of solvents. The mixture includes polysulfide (otherwise called thiokol), a plasticizer and filler with another plasticizer, as well as a pigment.When mixing the initial substances, a slowly solidifying mixture is obtained, which, in the hardened state, almost does not allow vapors to pass through and forms an elastic surface similar in properties to rubber.

Polyurethane sealant

The highest elasticity polyurethane sealant suitable for metal, ceramic, brick, concrete and plastic surfaces. Differs in fast solidification, resistance to negative temperature values (withstands up to - 50 ° C), can be used in winter. There is a possibility of coloring the composition. The sealant loses its properties at temperatures above + 100 ° C.

This type of materials allows you to:

- reliably close the thermal and expansion joints of concrete, blind areas made from it;

- block the joints of concrete and foam concrete products, wall panels;

- block the soaking of the foundation;

- cover an artificial reservoir, pool, reservoir and surrounding structures.

"Germotex"

This mixture is designed to seal expansion joints and cracks appearing on concrete floors, slabs, to give them increased tightness. The base is synthetic rubber, due to which the material is very elastic and has increased adhesion. The basis for it can be any kind of building covering. The created surface is weakly susceptible to tearing, friction, and mechanically poorly pierced. The floor surface is solid and very stable.

For a two-component composition of the "Germotex" type, it is necessary to prepare the surface: the seams and cracks can be quite large, but they must be freed from dirt and dust. The substrate is checked to be dry or only slightly damp. When the air temperature drops to less than 10 degrees Celsius, it is unacceptable to use the composition.

For pre-treatment, cement and sand substrates are pre-treated with a polyurethane primer to reduce dust and improve adhesion. The paste for application should be homogeneous. A solvent (white spirit or gasoline) helps to get rid of the insufficient fluidity of the created mixture, which is added 8% by weight of the material.

For 16 kg of sealant, use 1.28 kg of solvents. Seams and cracks can be closed with a spatula if their depth is up to 70-80% in relation to the width. The shelf life after mixing is no more than 40 minutes at room temperature, the full strength is achieved in 5-7 days.

"Neftezol"

This is the name of the brand of polysulfide sealant. In appearance and structure, the drug is similar to rubber. Its chemical basis is a combination of polymer and liquid thiokol. The material is distinguished not only by its great elasticity, but also by excellent resistance to various acids. But you need to apply the prepared combination in a maximum of 120 minutes.

By varying the composition, you can change the curing time from a few hours to a day. Thiokol-based mixtures help to seal concrete and reinforced concrete joints, the level of deformation of which does not exceed ¼. Requirements for surface cleaning are no different from preparing for the use of other materials.

Classification of sealants

Acriplast is classified into groups according to the defining characteristics:

- Method of influencing the treated base: surface elements form a protective moisture-proof cover, and compositions of deep impact fill the concrete pores inside, not allowing moisture to pass through.

- According to the component formula, mixtures for interpanel seams and joints for interior work, with increased flexibility, thiokol materials are distinguished. Each of the materials has its own properties and characteristics.

- One-component sealants and binary mixes that require specific mixing. They have different degrees of flexibility, drying period, strength indicators.

When buying a sealant for cracks in concrete, one must take into account the scope of the material: internal processing or outdoor, a screed made recently or long ago. Basically, such sealants are universal and have good adhesion to wood, metal and other surfaces.

We recommend a video on the topic:

Peculiarities

Not allowed:

- applying a sealant to a surface with free moisture;

- dilution of the sealant;

- use of sealant in areas of prolonged contact with organic solvents and oils, with highly concentrated acids and alkalis;

-

it is not allowed to use sealant on bases formed by bitumen and bitumen-polymer materials, including roll ones.

Execution of works

Before applying the IZHORA polyurethane sealant, it is recommended to seal the joint or joint cavity with a cord made of foamed polyethylene. The IZHORA polyurethane sealant is applied with a spatula with a layer of at least 3 mm in one pass.

The minimum permissible joint width between panels is 10 mm.

The optimum ratio of the seam depth to its width is 1: 3.

The time for complete polymerization of the IZHORA polyurethane sealant depends on the temperature and humidity of the outside air and averages 48 hours.

Package

|

|

Polyurethane sealant IZHORA is supplied as a set of two components: Set of 12.5 kg. |

Calculator

| Calculator | |

| Joint depth, mm | |

| Joint width, mm | |

| Seam length, m | |

| Required amount of material, kg |

We draw your attention to the fact that the obtained value is an approximate

Certificates

| 1. Certificate of conformity of the GOST R certification system No. ROSS RU.AG91.N02321 for polyurethane sealant IZHORA and polyurethane sealant IZHORA "Winter" (valid from 21.04.2017 to 20.04.2020) |  |

| 2. Expert opinion based on the results of sanitary and epidemiological examination No. 01.05.P.10544.03.14 for polyurethane sealant IZHORA (valid from 28.03.2014) | |

| 3. Certificate of state registration of the Customs Union No.RU.78.01.05.008.Е.000234.04.14 for polyurethane sealant IZHORA (valid from 01.04.2014) | |

| 4. Conclusion of OS "VNIIGScertification" on the optional certification of materials LAKHTA, SLAVYANKA and IZHORA | |

| 5. Conclusion on the optional certification of materials LAKHTA, SLAVYANKA and IZHORA in the Certification System in the field of fire safety |

Specifications

| Specifications | Indicators |

| Consumption of sealant when sealing a seam 8x24 mm, kg / running m | 0,27 |

| Viability at a temperature of + 20 ± 2 ° С, hours, not less | 6 |

| The nature of destruction at the moment of rupture | cohesive |

| Conditional strength at the moment of rupture at a temperature of + 20 ° С, MPa | 0,5 |

|

Elongation at the moment of rupture at a temperature of + 20 ° С,% |

600 |

| Brittleness temperature according to Fraas, ° С | –65 |

| Conditional stress at 100% elongation, MPa | 0,5 |

| Bond strength to concrete, MPa | 0,6 |

|

Bond strength to metal, MPa |

0,5 |

| Water absorption in 24 hours,% by weight | 0,5 |

| Density, kg / l | 1,4±0,1 |

| Application temperature (environment), ° С | +5…+40 |

| Shelf life, months | 12 |

Recommendations

For operation, the components of the sealant, which must be stored in special separate containers before use, must be mixed using a special technology. Care must be taken that the environment does not negatively affect the product. During storage, the container with the hardener must be protected from moisture.

For cooking, you should use a special mixer, which is a construction mixer or an electric drill. A nozzle is put on the device, then you need to use a spatula or a special gun.

When working with a two-component sealant, there are a few more tips to consider:

- observe all proportions indicated in the instructions;

- watch the air temperature during operation - it should not be lower than indicated on the package;

- thoroughly clean and wipe the surface well before work;

- mix only the right amount - no more, as the sealant hardens very quickly;

- do not take breaks and delays, as the prepared material, again during its inactivity, can harden;

- in the case of an unsuitable consistency, one of the components cannot be added - a new composition must be made.

Thus, two-component sealants have a wide range of applications, and the current market offers many options from various manufacturers. However, in order to get the highest quality result from the use of two-component varieties, all preparation conditions must be observed.

For information on how to use a two-component sealant, see the following video.

Advantages

As noted, two-component sealants have a long service life.

This is not the only benefit - there are other benefits:

- the possibility of using at low temperatures;

- strength, elasticity and durability of the seams;

- excellent adhesion properties;

- indicative physical and mechanical qualities;

- exact time of vulcanization;

- UV resistance;

- the possibility of staining with organic and water-based paints;

- wide range of applications.

The main advantage of two-component polyurethane sealants is reliable frost resistance. This is due to the fact that the moisture contained in the atmosphere does not participate in the hardening process of the material, and therefore this option is perfect for outdoor work.

Sealant with adhesive properties

An adhesive sealant is chemically characterized as a combination of polymers and modifying impurities; used as a basis:

- silicates;

- rubber;

- bitumen;

- polyurethane;

- silicone;

- acrylic.

In damp rooms and on smooth surfaces, water-resistant, silicone-based adhesive sealants are most often needed. It is this solution that is advised to choose for most construction work in sanitary facilities, for sealing and joining surfaces. It is necessary to focus on the nuances of the chemical composition. So, by the number and variety of individual substances, one can judge the level of viscosity, adhesion, protection from fungi and the type of staining. When fungicides are formulated, the material is classified as "sanitary".

Adhesive with the properties of a sealant is permissible to operate at temperatures from -50 to +150 degrees, but some options, due to special additives, can withstand more significant heating. Summing up, we can say that the choice of two-component sealing compounds is huge, and each of them has certain specific properties that need to be carefully studied.

The use of a two-component sealant for sealing interpanel seams is described in detail in the video.