Peculiarities

The type of fastener dowel-clamp appeared on the construction market not too long ago. Due to their functionality, convenience and simplicity, the hardware immediately won recognition from professional electricians. The dowel clamp is designed for laying and fixing the cable in an open or closed way. It makes it possible to fix the main wiring of cables, wires, thin and flexible pipes to supporting supports made of materials such as concrete, stone, foam concrete, brickwork, as well as to wood or drywall.

- The use of a dowel-clamp allows significant savings in the case when it comes to large volumes - instead of a set of dowel-nail, only one fastening element is used. Due to the same feature, the installation is much faster.

- Plastic hardware, and even more so metal, is able to withstand large temperature changes. Such a wide range allows the use of fasteners both for indoor and outdoor work in almost all regions of the country.

- The material of manufacture is in most cases resistant to ultraviolet rays.

- Fastening elements are capable of holding a large mass, and replacing those that have failed is not difficult.

The dowel clamp also has some disadvantages, although not too serious, compared to a large number of its advantages.

- The material from which the plastic fasteners are made does not burn, but becomes plastic and deforms during a fire.

- Visually, hardware does not look very attractive. But if we consider that the cable itself is not a wall decoration, this drawback of the dowel-clamp can be considered insignificant.

Dimensions (edit)

The most common bracket, which is in the greatest demand for wiring, has standard girth diameters of 5-10, 11-18, 19-25 mm. The required drill diameter for these dimensions is 6 mm, and the minimum immersion depth is 35, 40, 45 mm.

The dimensions of the dowels-clamps are selected depending on the parameters of the cable. For a round cable with a size of 5x10, a clamp size of 5-10 mm is suitable; 11x18 cable needs a clamp 11–18 mm in size. The size of the cable 6x40 will require the purchase of hardware 6–40 mm. Dimensions 6x12; 5x10; 6x17 need, respectively, dowels-clamps 12, 10, 17 mm.

For flat cable, fasteners of the following sizes are suitable: 19x25, 12x6, 12-6, 32, 14, 6x35, 26, 8, 50, 100x12, 8x45, 20 mm.

Species overview

This type of hardware is highly specialized, so the assortment, although not too large, is quite sufficient and allows you to make the necessary choice.

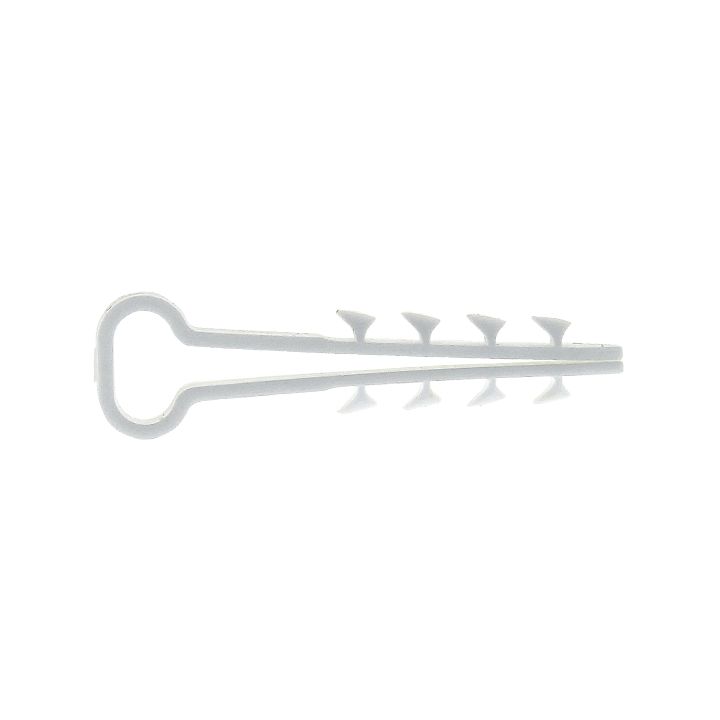

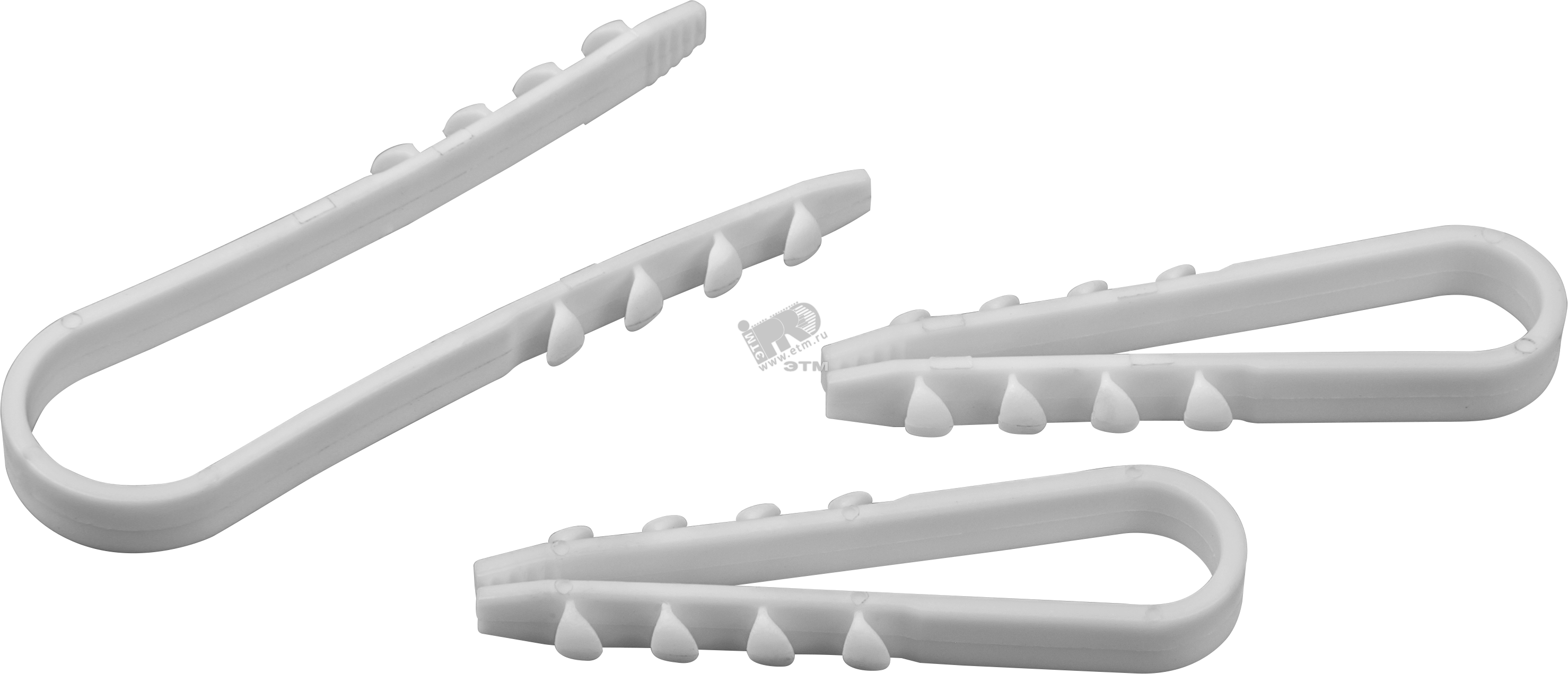

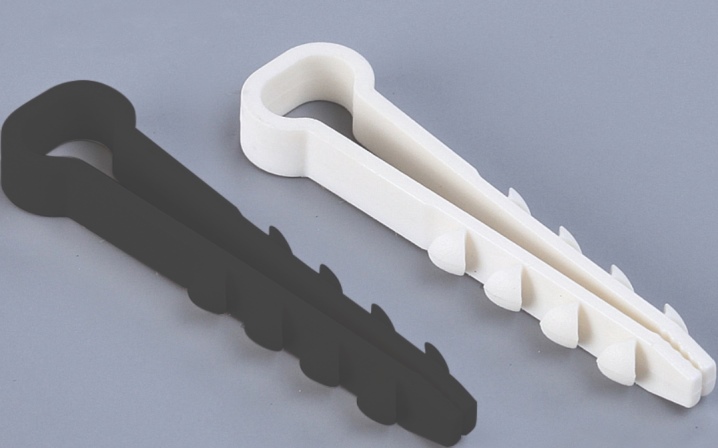

The dowel-clamp is a simple bracket made of plastic, on one side of which there is a clamp in the form of a loop, on the other - spacer teeth, it can be round or flattened. Manufacturers produce this type in two color options - black and white, the buyer chooses the color of the wiring. Hardware with a screw is basically a plumbing option. Fire-resistant fasteners have a special polymer coating. In general, fasteners are classified according to different parameters. Let's consider the main ones.

By design

First of all, the dowels-clamps differ in their design features.

"Bedbug" is a universal fastener used in many cases. This is a one-leg hardware combined with a metal bracket and a press washer. The use of a "bug" requires monitoring the integrity of the insulation and additional insulation with heat-resistant tape at the joints. The fasteners can support up to 10 kg.

The first subspecies is a one-piece construction, when the rod is already in the dowel

At the same time, the strength of the entire model increases, but the requirements for caution become more stringent, because the dowel is mounted into the wall together with the cable.

In the second option, the T-shaped fastening hardware has an arc shape without a loop. Hardware of this kind is used to install a cable of a certain size, whose diameter exactly corresponds to the diameter of the arc. This type of spacer is available with one or two arcs, which allows parallel installation.

By material

The most demanded and popular type of nylon fastener, due to its high strength. Polyamide components are involved in the production of nylon, they are much stronger than polyester ones, withstand temperatures plus 85 degrees Celsius. Ideal for multi-wire backbone routing and fixing. However, fasteners cannot be used in cases where hot piping is to be used.

Nuances of choice

To make the right choice of mounting hardware, it is necessary to take into account several parameters: from the diameter and cross-section of the cable, the weight of the future line to the structure of the supporting base. The technical characteristics of metalware-clamps are regulated by the state only in some cases - the clumsy GOST does not have time to respond to the constant updating of specialized mounting fasteners. The buyer should be guided by the accepted European DIN and ISO standards. Fasteners of multicomponent structures have received the GOST 26998-86 regulation.

When choosing fasteners, you should use the advice of professionals:

- the anchor type of hardware-clamps is selected according to the required diameter and required length;

- for a cable with a flat section, clamps with a flattened loop are selected;

- for corrugation, the best option is a clip;

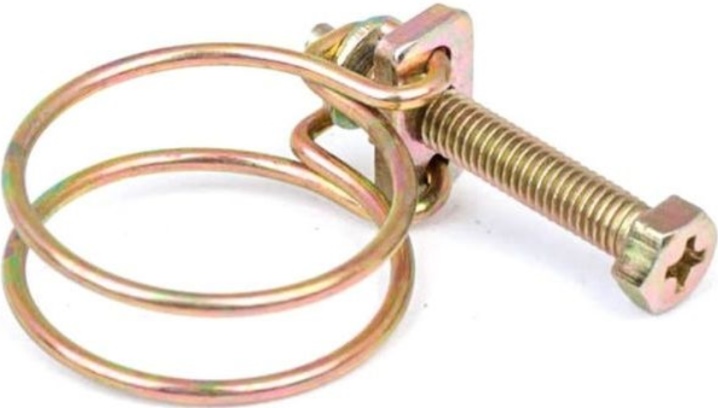

- for a pipeline with an increased diameter, a plumbing dowel-clamp with collapsible brackets is selected;

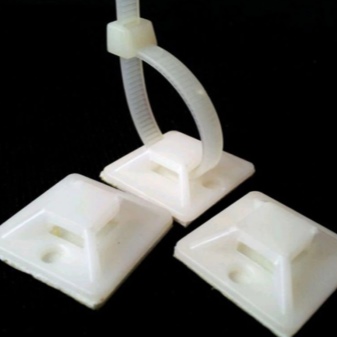

- a platform with a clamp is ideal for multiple trunk lines;

- if you have to fix the cable on a solid base, a metal "bug" with a one-leg bracket is chosen.

Installation instructions

The installation of dowels-clamps is almost the same as the installation of ordinary dowels - the slight difference is that first a clamp is put on the cable, and then it is carefully hammered into the prepared recess. The drilled hole should match the diameter of the fastener, but the depth is made 10 mm more than the length of the dowel. The maximum distance between the installed fasteners should not exceed 25 cm, for turns - no more than 10 cm.

Each type of fittings has its own installation method. The fixation points are determined taking into account the parameters of the fence, the horizontal and vertical directions of the wiring, the number and radius of corners, the weight of the cable, and the environment. These data are decisive for the optimal choice of the method of how exactly to fix the hardware, their required amount, installation technology, as well as the wiring and installation schemes.

Hidden

The hidden method of trunk laying is used in residential premises if the material of the supporting base allows you to lay grooves. For laying wires in grooves or prepared cable channels, additional installation of dowels-clamps is possible. A single cable is most often fixed with alabaster, but this method is ineffective when it comes to a large specific gravity or a lot of wires. Alabaster successfully replaces clamps that crush a lot of wires into a system group. Often, electricians mark the wiring with tags installed on the screed. In the same way, cables installed in special boxes are fixed.

Installation of a flat cable using a dowel clamp

Using a level and such an auxiliary tool as a cord, points are marked on the wall for fixing the hardware. Drill holes for dowels with an electric drill in advance.

The clamps are fixed in place. The cable body is threaded through the clamp frame, tightening so that there is no sagging.

Fixation on a self-adhesive pad

On painted or varnished surfaces covered with plastic facades, pasted over with wallpaper, you have to use a self-adhesive pad.The base of such a platform is double-sided tape. It must be remembered that the adhesive composition will "flow" at temperatures above 450 degrees, and at low humidity it will lose its elasticity, the base will dry out, harden and fall off the wall. Self-adhesive pad is the fastest way of installation. The protective film is removed from the back side, the platform itself is pressed against the surface of the supporting base with force. A tie is inserted into the grooves of the fastener, with which the wires and cables are fixed.

- Cable clamps. For such a fixation, a general installation plan is drawn up, attachment points are marked on the surface. The mounting holes are drilled for the dowel fixing points. Clamps are installed taking into account the selected type. They can be fixed with self-tapping screws or screws in a fastening device, inserted into the holes with serrated ends. Anchors are screwed into wooden surfaces.

- The "helicopter" dowel is pre-assembled from two halves, waiting for the final click. The assembled "helicopter" is inserted into the prepared hole, the spacer wedge is carefully driven in. After that, the line is fixed with a loop of the clamp.

Open

A similar method of laying backbone networks is used in non-residential buildings intended for production or storage.

Fixing the thin cable

In such cases, it is customary to use clamps with a nail. Thin TV and Internet wires are lightweight and do not require a reinforced structure. Small studs installed in clamps do a great job with this.

Clips styling

Clips are used for mounting low-voltage cables on the soft surface of wooden walls. The hardware is fixed to the surface with self-tapping screws, each product has a pair of holes. The cable is pressed into the bracket until it is firmly seated.

- The metal dowel "bug" grips the pipeline or cable with a single-leg bracket, fixes it to the surface, then screwed into a clean drilled hole.

- The plumbing screw clamp with rubber pads is pre-disassembled. The dowel is mounted on the wall, after which the bracket is screwed onto the hairpin, the pipe is inserted into it and fixed with the second bracket.

- Dowel clamp with tape. It is quite simple to mount such hardware to the wall - a loop is made from the tape, wires are inserted into it, after which the tape is fixed on the supporting support, the excess ends are cut off.

The following video tells about the installation of clamp dowels.