Driva and molly fasteners

Depending on which dowel for drywall has the shape of a head and a thread, it is customary to distinguish types:

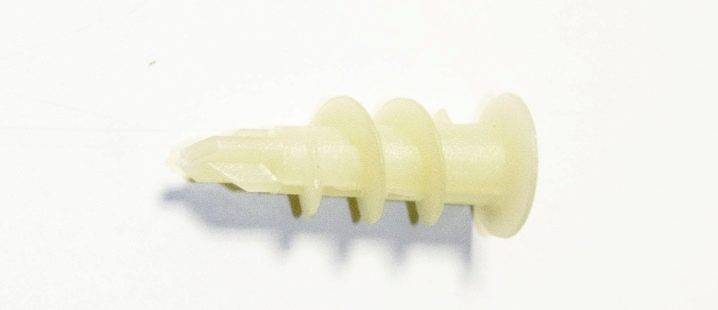

- Driva - available in two varieties: metal and plastic, the latter being considered more popular. Plastic drywall drywall withstands perfectly, and at the same time mounting them is simple. It is enough to drill a hole with a diameter of 6 mm and insert the product into it. After the cross-head, it must be cut into the sheet and screwed into the inner slot. Also, a drywall dowel for drywall provides for the dismantling of the mount.

- Molly - high quality and therefore expensive fasteners. They are characterized by high load thresholds and the ability to dismantle. The molly dowel for drywall has a simple operating principle. First you need to make an eight-millimeter hole with a drill. Then insert the product into the sheet and press the two-pronged side to it. In conclusion, you need to press the structure against the sheet with a screwdriver along the internal thread.

There are two types of drive: metal and plastic, this type of fasteners is very easy to install.

As you can see, there is a rich variety of fasteners. Therefore, when choosing them, remember that a certain drywall screw can be suitable for some purposes, and in other cases its use is unacceptable.

When the walls in the room are sheathed with drywall sheets, the question arises of how to mount a mount for small, light things to this material: paintings, photographs, small shelves and lamps, various souvenirs, jewelry and decorative elements.

After all, I don't want to, in order to hang some trifle, hammer in a huge metal nail or use a powerful dowel, create massive fasteners by drilling the wall itself, which can be a few centimeters from the drywall sheet, if the frame method of its installation is used. For such options, a butterfly dowel was invented, which is an excellent plastic fastener-anchor for hanging small and light objects on a drywall panel without screwing into the main wall.

How to use?

It is most comfortable to use the Driva dowel structure equipped with a drill. Then the installation becomes much easier. Metal and plastic fasteners are screwed into gypsum plasterboard (GKL) without preliminary drilling. However, when it is required to attach a plasterboard sheet to a metal profile, holes are initially drilled for plastic models with a drill for iron with an 8 mm diameter.

The metal dowel has a fairly stable tip, therefore it can be twisted without preliminary drilling. If the metal profile does not meet the standard, it has a thick wall, due to which the metal fasteners cannot be screwed into it, then holes are also made initially.

The event begins with the application of fixation points, after which they proceed according to the following scheme.

- The dowel is screwed in by means of a screwdriver, an electric drill with adjustable speed, or manually using a Phillips screwdriver. The size of the cross on the screwdriver and the bits must match the slots on the key. A screwdriver or electric drill should be set to low speed.

- By means of self-tapping screws screwed into the thorns, the necessary object is fixed.

- When there is an invisible or secret fastening on the interior element, and suspension is provided, and not a tight fit, the self-tapping screw is not screwed in all the way.The head of the self-tapping screw, as well as part of the required length, is left on the surface. An object is hung on them through the holes in the mount holders.

- If necessary, it is also possible to dismantle without much effort, since together with the screws, the dowels can be unscrewed freely.

And when working with drywall sheets, it sometimes becomes indispensable and the only possible type of fastening.

For more information about Driva dowels, see the video below.

Molly: dowel for plasterboard

All drywall anchors are distinguished by the fact that they are made according to the harpoon spacer principle, which gives a strong and reliable fastening. Fasteners are divided into 2 groups: straight through, expandable. It is convenient to mount structures on the ceiling with walk-throughs. They are used to attach chandeliers, sports equipment, etc. The spring dowel is great for attaching something to plasterboard walls, tiled. In order not to be mistaken with the choice for the implementation of their tasks, it will not be superfluous to consider the advantages and features of using each of the types of dowels.

The Molly dowel does not belong to cheap fasteners, the cost is quite high, but the quality is naturally at the proper level.

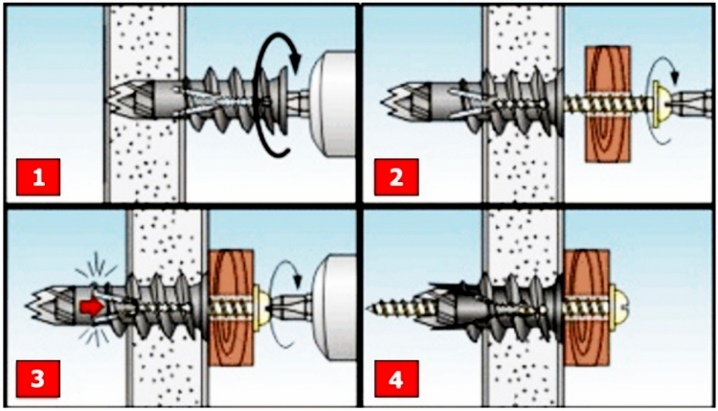

Molly's dowel works according to the following principle:

- A hole is made under the dowel with an 8 mm drill.

- Then the dowel is inserted into the hole, the side with 2 teeth is pressed tightly against the gypsum board, so that there is no turning.

- Next, the screw, which comes with the dowel, is screwed to the sheet along the internal thread with a screwdriver.

The advantages of this type of fastener include the ability to cope with the highest loads and the ability to dismantle if necessary. Screws are included.

Fixing rules

When carrying out the installation of fasteners, it is necessary to adhere to clear rules. This is the key to excellent results and reliable grip. Listening to the following recommendations, everyone can fix the dowels on drywall without professional skills.

The work procedure consists of the following stages:

it is necessary to accurately calculate and indicate the location of the elements. When using profile guides, you need to securely fix them by pressing the gypsum board to the profile;

You can find out how to independently carry out the installation of drywall by watching the video below.

Photo of a spacer dowel

We also recommend viewing:

- Crab system for shaped pipes

- What is a lifting shackle

- What is foundation bolt

- Why do you need a grover washer

- Dowel-clamp for cable fastening

- Lifting crane hook

- How to choose cable clamps

- Features of furniture fasteners

- Wood grouse wood screw

- Which toilet mount is better to choose

- Fasteners for timber structures

- Fasteners for plastic windows

- Advantages and Disadvantages of Screw Nails

- Best plastic dowels

- How to choose a threaded rod

- Self-tapping screw with drill

- How to choose self-tapping screws for metal

- How to choose a drywall dowel

- The most reliable pipe fittings

- The best screws for concrete

- How to choose pipe brackets

- High Strength Bolt Parameters

- Hex bolt

- Varieties of anchor bolts

- Construction nails

- How to use the drop-in anchor

- How to select and install a wedge anchor

- Features of dowel screws

- Hammer-in metal dowel

- What is a dowel-nail

- How to choose and apply a chemical anchor

- Sink bracket

- Types of brackets and fasteners for shelves

- How to choose a steel chain

- Choosing a bracket for the cornice

- Brackets for satellite dishes

- Choosing the best plastic clamps

- What is a construction bracket

- The best roofing screws

- What are wood screws

- How to choose a wall mount for your TV

Installation features

Drywall is a soft material, therefore, when working with it, it is required to limit the force of the screwdriver. You cannot use punch mode when you start drilling the dowel hole.If the wall is already tiled, then you need to drill a hole in it that matches the size of the dowel thickness. It is better in this situation to take the MOLLY dowel. Drilling should be done with a drill with a victorious tip.

The fastest in terms of fastening is the DRIVA dowel. It has huge advantages - the sheet does not need to be drilled, so the integrity of the back side will not be compromised. In contrast, MOLLY requires pre-drilling and the use of special pliers. Not every beginner will master the correct opening of such a dowel from the back of the sheet the first time. The dowel, named after a beautiful insect, also requires a preliminary drilling procedure, and is considered average in terms of fastener speed and the amount of effort expended.

Types of dowels

Drive type dowel

Perhaps the most popular plasterboard fastener. It can be with or without a drill, metal or plastic. Making a hole for its fastening, use a drill with a diameter of 8mm. The manufacturer declares the shear workload that the gypsum board can withstand using this dowel, 25 kg, while the maximum load is up to 50 kg.

The popularity of the Driva dowel is due to its fairly high reliability and relatively low price. The strength of such an attachment is achieved by distributing the load over a large area, which is provided by the shape of the dowel.

Drywall dowel for drywall is simple and effective

Flat dowel-nail

Such a dowel is made of refractory steel, it is quite simple and convenient to use, since it does not require additional drilling and, accordingly, will get rid of dust. It can be hammered into drywall with a hammer or pressed by hand if you can.

The principle of operation of the dowel-nail is that when a self-tapping screw is screwed into it, the initially flat front part opens up, forming a reliable stop.

It is used for sheets with a thickness of up to 12.5 mm inclusive. Self-tapping screws are chosen with a diameter of 3.5-5mm. The working load for pulling out, declared by the manufacturer, is 15 kg, for shear - 30 kg, the maximum shear load, obtained empirically, is 48 kg. Among other things, the dowel-nail is reusable, that is, it can be dismantled and mounted in another place several times.

The flat dowel-nail for drywall is very easy to install, since it does not require drilling

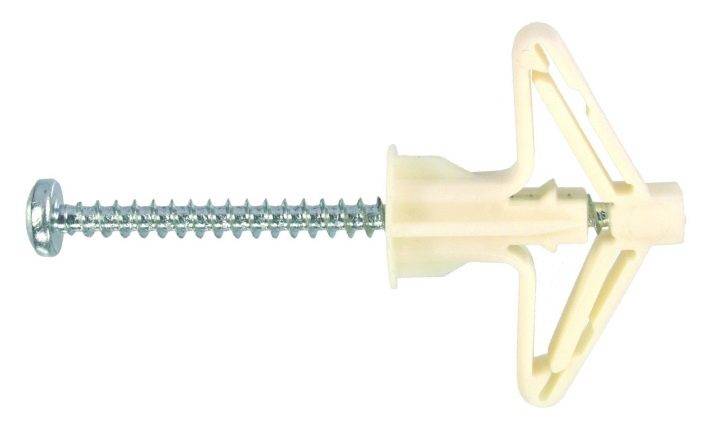

Universal expansion dowel Butterfly

The butterfly dowel is suitable for both drywall and concrete base. The hole for its installation is drilled with a drill with a diameter of 8 mm, the diameter of the complete self-tapping screw is 4.5 mm.

For the butterfly dowel, we recommend using self-tapping screws without skipping the thread, because when screwing, reaching the smooth neck, the screw will start to scroll, and the dowel will not take the desired shape in the form of a stop.

In general, the plastic butterfly dowel works roughly like the others, creating an emphasis behind the gypsum board when screwing in the self-tapping screw. In shape, such an emphasis is somewhat reminiscent of a butterfly, hence the name of the fastener. The design working load for the dowel is 25 kg, the maximum working load is 55 kg.

The Butterfly dowel for drywall is the most popular because it is equally inexpensive, convenient and effective.

Dowel molly

The Molly dowel, or rather the Molly anchor (after all, this is an independent fastening unit that does not require an additional self-tapping screw) is another popular type of fastening for drywall, made of metal. This dowel, unlike the previous ones, is produced in various sizes and, accordingly, for different loads.

For example, for Molly, the minimum size marked 4/16/38 (4 is the screw diameter, 16 is the neck length and the maximum sheet thickness for which it can be used, 38 is the total length of the element), the working load is 25 kg, the maximum shear is 47kg.

To make holes for Molly, choose a drill 2 times larger than the diameter of the neck (the first number in the marking), that is, for a four it will be 8 mm, for a six - 12, etc.

To install the Molly dowel, you need a special tool that brings the fastener to "combat readiness". With its help, the screw is slightly pulled towards itself, while the hooks are bent. Then you can turn the screw with a screwdriver, bending the hooks until they stop. All this should be done by inserting the dowel into the hole in the drywall.

If there is no special tool, you can put the anchor into action using nippers (side cutters) or even an ordinary flat screwdriver.

Molly drywall plug - the solution for professionals

Fischer's twisting plastic dowel

When screwing a self-tapping screw into such a dowel, the latter twists, forming an emphasis behind a sheet of drywall, hence the name of the fastener. The drilling diameter for such a dowel is 8 mm, the diameter of the self-tapping screw is 5 mm.

When tightening the self-tapping screw, the main task is not to squeeze too hard, otherwise it will begin to turn, and the fasteners will need to be done again. For this reason, when using a screwdriver for tightening, set the minimum speed on it.

The working load for the detachment of the twisting dowel is 10 kg, for the cut - 25 kg, the crash load - 70 kg.

A twisting plastic drywall plug is an interesting and effective solution, backed by Fischer's reliability

Types of dowels for drywall profiles

Dowels for profiles - fasteners used in the installation of guide profiles and hangers for the frame under the gypsum board.

Distinguish:

- dowel nail;

- dowel-wedge (anchor);

- butterfly;

- Driva;

- Knauf-Hartmut;

- Fischer Pd ";

- umbrella;

- chemical anchors.

The main types of dowels used in the installation of the frame base

To understand which dowel should be used in a certain situation, all options are considered below.

Dowel-nail for drywall profile

The most common fasteners for mounting the GKL frame. According to the method of fastening, two types are distinguished: manual driving and with the help of an assembly gun.

The second type is a fastening element consisting of a nail and a washer. They are used for mounting heavy massive structures to a concrete base.

This type of fastener is not applicable to work with gypsum board

I mark the products by size. Dimensional specifications indicate the diameter of the base and the length of the nail. When working with a drywall profile, the best option is 6/40, 6/60 mm, where 6 is the diameter, 40 and 60 is the length. They fix the guide profiles to the rough base, and also fix the direct suspensions.

Dowel-wedge

A wedge or anchor wedge is a reliable fastener. Dowel for fixing profiles on concrete and solid brick walls. Withstands heavy loads. Fastening is possible even at a small distance from the edge of the base. Anchor wedge is produced in sizes from 8/45 mm to 16/150 mm.

Fasteners are used for through and pre-assembly

Butterfly dowel

According to dimensional characteristics, there are:

- 8/28 mm. The smallest, suitable for attaching light objects. Self-tapping screws are not included. Must be purchased separately, size 3.5 x 35 mm.

- 10/50 mm. Self-tapping screws with a size of 3.5 x 55 mm. Withstands loads up to 24 kg. Suitable for fixing furniture shelves and cabinets.

- Metal dowel-butterfly. The second name is Molly. Suitable for use on walls made of hollow materials. Sizes range from 4/21 to 6/80.

Observing all the rules for fastening, "butterflies" serve as durability for a long time

You can find out more about the sizes and types of butterfly dowels on our website.

We advise you to watch a video about the process of attaching the "butterfly".

Driva

They produce two types of hardware: with and without a drill, from nylon, metal. For hanging heavy objects on a plasterboard surface, a galvanized part is used.

The shape is a conical cylinder. The thread pitch is large.Flat hat with cross recess. They are used for the installation of small-sized, lightweight structures. Sizes 12 x 38, 12 x 42, 14 x 38, 15 x 29.

Knauf-Hartmut

The fastener consists of:

- U-shaped profile;

- plastic antennae and bushings;

- screw with dimensions 5/60 mm.

Principle of operation:

- drill a hole in the wall;

- insert the profile plate into the hole using the guiding antennae;

- break off the antennae;

- screw in the screw.

Withstands loads up to 55 kg.

Fastener for mounting heavy objects

"Fischer Pd"

Fastening device for working with drywall and profile. Plastic cylinder with sleeve and side blades. Principle of operation:

- drill a hole, the diameter is equal to the dimensions of the sleeve;

- insert a phisher;

- fix with a screw.

The mount can carry up to 16 kg. Sizes - 10/28.

When fixing, the side blades should be opened and pressed against the base from the back.

Umbrella

It got its name from the principle of operation. After fixing in the hole, the side blades unbend and the fastener looks like an open umbrella. This contributes to the distribution of the load, the ability to withstand heavy weight.

Chemical anchors

It is a cartridge with a capsule containing an adhesive liquid. Under mechanical stress, the capsule bursts, the glue enters the hole.

Due to its properties, it is a monolithic fastener that can withstand heavy loads

The principle of the design of the "butterfly" anchor

The butterfly dowel is a kind of self-tapping fastening device, which, due to its specific shape, is clamped when twisted, tightly fitting with special paws to the back wall of the drywall sheet, which increases the area of the material on which pressure is exerted from the weight of the suspended object. In other words, a dowel of this shape distributes the load exerted on the drywall.

This fastener-anchor has a number of design characteristics:

- intended for fastening on a single (10-12 mm) or double (20-24 mm) layer of wall drywall (the fastener can also be used on chipboard, gypsum fiber board and other sheet materials of appropriate thickness);

- sold with self-tapping screws suitable for its length and type of thread, but can be used with other screws, if they are suitable for dimensional parameters;

- on the part of the dowel that is located inside the drywall sheet, ribbed elements are applied to prevent the anchor-fastener from rotating around its axis;

- the internal thread on the far head of the dowel contributes to its folding and clamping, and special internal lugs attached to this head contribute to the greater rigidity of the structure in a twisted state.

Installing a butterfly dowel in drywall

Work on installing a butterfly dowel in drywall is not particularly difficult, it is quite possible to cope with them on your own, without the involvement of professional craftsmen.

The most common size of such dowels is 10x50. Most plasterboard structures are fastened with a butterfly dowel of this size.

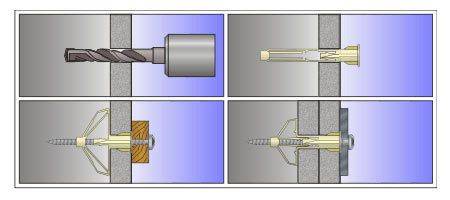

The order of installation is as follows:

First of all, the required markup is carried out; Using a drill or punch, a hole of the required diameter is drilled in the base

It is impossible not to note the extraordinary versatility of this fastener-anchor - with equal efficiency it can be used for fastening both drywall and chipboard, plywood, MDF and other materials.

When choosing the optimal self-tapping dowel, one should take into account not only the diameter of the head and the length of the leg, but also the material from which the base is made.

As for the maximum permissible load that such dowels can withstand, it is 28 kg.

Trade marks

The greatest demand in the domestic market is for a butterfly dowel for drywall from the following manufacturers:

Butterfly dowel and its advantages

The dowel for butterflies for drywall is characterized by a number of indisputable advantages that distinguish them favorably from many competitive offers.

The most valuable among them are the following:

- Convenience and ease of installation work;

- Easy screwing of the fastening screw;

- Reusability without compromising the quality and reliability of the connection;

- The presence of longitudinal ribs that prevent the element from turning;

- Long period of effective engagement;

Increased strength of the connection, achieved by expanding the area of contact of the dowel to the base by straightening additional supports.

The use of a butterfly dowel for drywall allows you to securely fix the sheets with a minimum of effort, regardless of the configuration of the base and the complexity of the structure being formed.

Working with such fasteners is notable for its simplicity, the main thing is to choose high-quality self-tapping screws and exactly follow the instructions for their use.

Video for installing a butterfly dowel in a drywall wall

Overview of dowels and other drywall fixings

First of all, the task of these devices is to transfer a point load to as large an area as possible in order to redistribute it. Different dowels solve this problem in different ways and, accordingly, are designed for different maximum loads.

Of course, the photo shows the maximum loads for the most common dowels, from those used when attaching heavy (or not very) objects to the gypsum board, but by analogy, or rather by the area to which the weight is transferred with their help, it is possible to calculate with sufficient accuracy which of the mountings should be applied in one case or another. And there are options.

Firstly, if the suspended load is small and static (photograph or small picture), then it is quite possible to do with a self-tapping screw for drywall or even a nail.

Secondly, if the distance between the drywall sheet and the main wall or ceiling is less than 35 mm, then you just need to consider one of the options for transferring the load to them and use for this a choice:

- quick-assembly dowel-nails;

- anchor;

- wedge dowels.

In this case, the gypsum plasterboard will only perform at most a supporting function, and the entire load will be transferred to the base located behind it.

Thirdly, for not very heavy things and in the absence of a sufficient distance behind the gypsum board, the DRIVA dowel may well suit you.

They are available in plastic and metal, with different shanks to fit through drywall or screw-in attachments with a cutting edge. The principle of operation is simple: the screw of the thread of the high profile drive expands the support area. Manufacturers claim that such a dowel is capable of carrying up to 25 - 30 kg of load, but we would recommend focusing on 10 - 15 kg. If it is possible to use several drives, and not one butterfly dowel or moth dowel for gypsum cardboard, then we also consider this case preferable.

Fourthly, we would put the BIS GOLD dowel next in terms of ease of use. It is not often used by our plasterboard masters, but it performs its function quite confidently. The principle of its action is intuitively clear from the photo.

It only remains for us to add that one such dowel will provide hanging of 8 - 10 kg of load on a vertical surface, and you decide whether this method of fastening is suitable for your case.

Fifthly, from drywall dowels of a simple design and designed for a weight close to those mentioned above, we can recommend the FISHER dowel screw.

The option for attaching a certain bracket using a dowel screw, shown in the photo below, is also quite functional, but the thickness of the bracket shelf did not allow the hooks on the tapered barrel to snap onto the corresponding hooks of the main part, finally fixing the dowel.

Nevertheless, such a dowel, like a drive, is intended for flush installation in a drywall sheet. After the hooks snap into place, the self-tapping screw can be screwed in - unscrewed many times, and the dowel body will be firmly fixed in the gypsum board.

Sixth, you can apply the so-called. dowel U, it is also sometimes called universal or multifunctional.

Modern dowel-nails for drywall

Nails are widespread dowels. The expander of this product is made of nylon and consists of 3 sections. There is a through hole in the tail of the product, which makes screwing easy and gives the necessary axial travel to the screw.

With the help of dowels, nails are attached:

- Reiki.

- Cornices.

- Door frames.

- Skirting boards.

- Window frames, etc.

There is also a steel dowel, but it is used very rarely, only for the device of plasterboard sheathing. The dowel-nail provides quick, through-mounting, it is easily hammered into the hole drilled with a drill with a hammer.

Self-tapping dowel DRIVA - fast and convenient!

Plasterboard is used to level the walls, level the ceilings, make niches, this material is so firmly entrenched in the construction industry that without it we no longer think of a decent repair. It's just not for nothing that it is also called dry plaster, you always need to remember that this is just a facing material that is not able to hold a lot of weight on itself. But as for quite acceptable things, such as lamps or shelves, with the help of special dowels, they can be safely attached, including to drywall. If you want to hang a photo frame or a very light shelf for 1-2 items, then it is quite possible to use, including for drywall, an ordinary dowel-nail, but for more weighty things, butterfly dowels of different designs and other types of fastening are suitable.

Self-tapping dowel - such a fastener fully justifies its name, since a thread is applied on its outer surface for screwing into drywall. Nylon self-tapping screws, numbered TT22, are screwed into an already finished hole, but metal fasteners with the international designation DRIVA, in addition to the thread, also have a drill at the end, which makes it possible to screw them into the surface on their own using a conventional screwdriver or screwdriver. This saves a lot of time with large volumes of work. However, for sheet thicknesses over 15 mm, it is still recommended to drill a hole.

Such a dowel is the best suited for fixing in a single-layer or multi-layer drywall with decorative or insulating material on the other side. Due to the large number of sizes, the dowel can be selected in such a way that it does not come out on the other side of the partition. DRIVA dowels can also be used for stronger gypsum fiber boards.

How to mount on unstable surfaces

Very often it becomes necessary to fasten objects on unreliable surfaces, which include plasterboard walls, building structures in old brick houses, etc. When fastening on such surfaces, the following recommendations should be followed.

- It is better to choose dowel elements from nylon, while their diameter should be 10–12 mm. The diameter of the winning drill, with which the hole for the fastener will be made, must be 2 mm smaller than the transverse dimension of the selected dowel.

- Drilling must be performed in one step, without changing the drill, and the impact mode should not be used in order not to destroy the walls of the hole being formed.

Securing items to plasterboard walls with a butterfly dowel

To perform reliable fasteners, it is important to take into account the condition of the surfaces, choose the right cutting tool and competently carry out the drilling process itself

Important parameters that should also be taken into account are the dimensions and weight of the object to be fixed.In addition, it is necessary to choose the right screw for the dowel in order to ensure reliable fastening of the object to the surface of the wall or any other building structure.

Types and characteristics

Butterfly

The butterfly fastener is made of metal or polypropylene and has two wings "straightened" in opposite directions, which prevent the screw from spinning. It is used to fix objects with light weight: paintings, lamps. Disposable - not reusable. There is a possibility of dismantling the element.

To install the butterfly dowel, it is necessary to press the side elements to the center and carefully hammer them into the drywall sheet with a hammer. At the time of installation of the dowel, the wings "straighten" on the other side of the gypsum board, evenly distributing the weight of the suspended element over the surface. After that, you can screw in the screw.

The standard sizes of this dowel are 8/28 and 10/50. For the first option, a 3.5 / 35 mm screw is suitable, for the second - 3.5 / 55 mm. Butterfly size 10/50 mm is capable of supporting up to 24 kg. For full disclosure, you will need a self-tapping screw with a length of no more than 55 mm.

Made of plastic. Sold folded.

Umbrella

Designed for heavier objects: due to its shape, it is suitable for fixing the chandelier to plasterboard ceilings. Cannot be dismantled.

When mounted, it looks like a regular umbrella. A closed dowel is inserted into the drilled hole. Thanks to the built-in spring, reaching free space, it opens up inside the gypsum board.

Able to withstand up to 35 kg.

Molly

One of the most expensive options for the dowel, which belongs to the category of "expandable". Suitable not only for drywall but also for suspended ceilings. When installed, the dowel clamps the plasterboard between the front and rear. This dowel can hold up to 35 kg. There is a possibility of dismantling.

Its advantage is that there is no need for a self-tapping screw: all the necessary parts are included. To fix it, you need to drill an 8 mm hole, insert a dowel and press down on its side so that both teeth tightly closed in the gypsum board. Then you just need to tighten the top element of the dowel so that the back part is tightly pressed against the sheet.

Made from metal only.

Driva

The easiest to use, therefore ideal for beginners who are just starting to get acquainted with a material such as drywall. Driva looks like a snail and is screwed in with a regular screwdriver until it stops. To facilitate screwing in, it is possible, but not necessary, to drill a 6 mm hole. Due to tight screwing into the core of the sheet, it can withstand loads of up to 25 kg. For the driva dowel, it is necessary to choose the correct length of the self-tapping screw, which will subsequently also be screwed into the dowel with a screwdriver. Such a screwdriver, falling into the void, twists into a knot, allowing you to hang on it something similar in weight to a kitchen cabinet.

It can be either metallic or nylon.

Legs

This fastener is made of metal. It has two pointed ends with triangular plates, which are called "legs" in professional language. The kit includes a screw.

Dowel nail

The second name of this element is DBM (quick mounting dowel). Does not require special skills and additional effort for installation. Has no screw. Does not involve subsequent dismantling. The dowel is inserted into the hole corresponding to its size, and then driven in with a nail until it stops. Suitable for curtain rods and skirting boards. It is reliable due to the fact that during installation it expands in three directions at once.

Nails are divided into two subspecies: with a cap in the form of a fungus and a secret cap. They differ among themselves in the height of the side. The dowel with a fungus presses the elements more reliably. Using the example of fastening heavy skirting boards, it can be proved that the countersunk head will not provide the necessary fixation of the dowel.

Chemical anchor

It is a capsule with an adhesive liquid.The complex has a mesh sleeve that allows even a non-professional to fix the element.

Dowel for double drywall

For double drywall, special mounts are used. They have a drill bit that allows them to be easily screwed into the double sheet.