Features of choice

A lot of cells in the "body" of gas silicate concrete are formed from the release of gas during the reaction of aluminum powder with a lime-silicon mixture. Depending on the density, the blocks are marked and have different applications - from insulation material to structural for the construction of partitions and load-bearing walls of low-rise buildings. It is advisable to know the block strength parameter in order to choose the right fastener. But even the most dense and durable gas silicate of the d700 brand remains cellular and requires not standard, but special solutions.

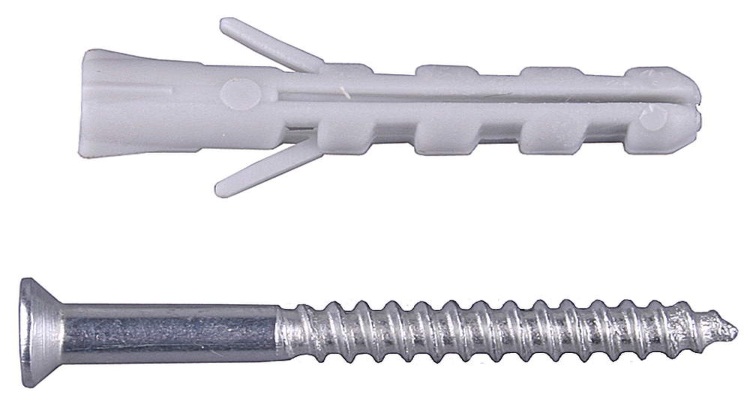

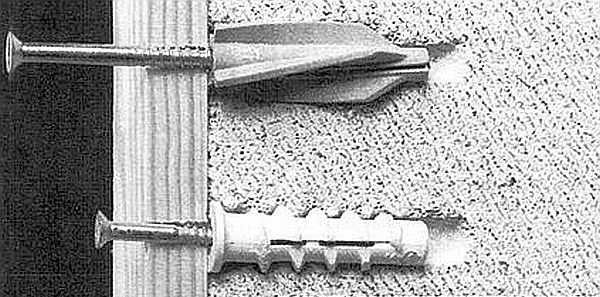

It is still possible to fix light decor items (photo frames, calendars, small posters without glass) on a wall made of porous blocks using the usual universal set "dowel-screw". And sometimes it is enough just to screw a large-threaded self-tapping screw for wood into the block.

Experts recommend:

- for pictures and not too massive shelves, switches, for installing skirting boards, it is enough to buy a set of polypropylene dowels of small diameters;

- nylon dowels with a diameter of no more than 12 mm will help to hang sconces or mirrors;

- installation of furniture structures, including heavy ones, should be performed with nylon dowels (8x55 mm; 14x80 mm);

- metal are recommended for the highest loads and for piping;

- frame are suitable for the installation of door frames and double-glazed windows;

- the profile batten for facade cladding must be fastened to universal facade dowels (nylon, stainless steel).

The selection takes into account such characteristics as:

- the value of the ultimate load on the fasteners (indicated on the package);

- overall dimensions - you need to choose a dowel of large diameter and length for a significant load;

- material - products that are not subject to corrosion are used for external walls and unheated rooms.

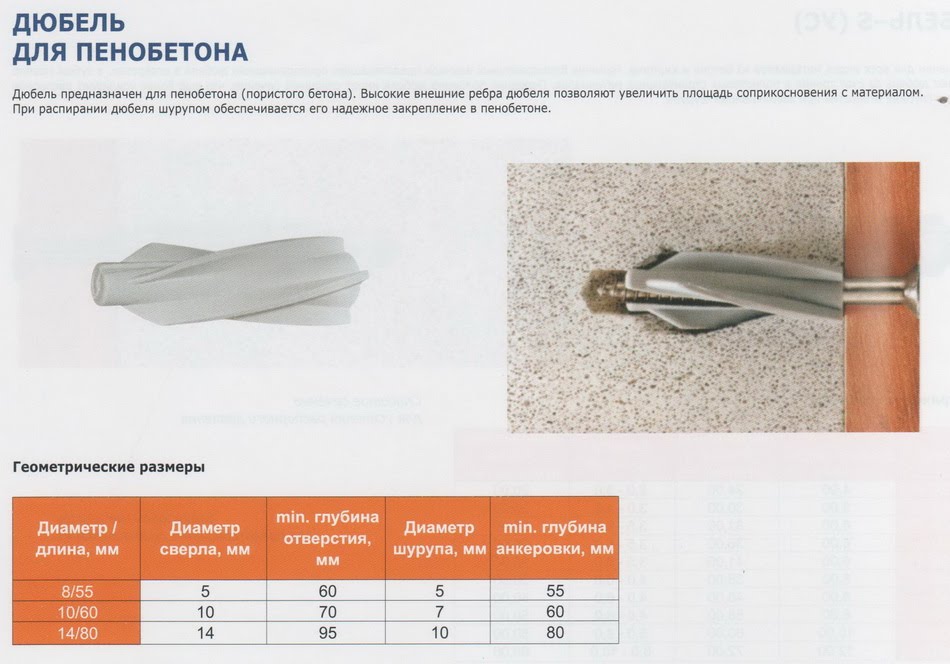

To select the correct gas silicate fasteners, you need to study the product label, consult the seller in the hardware department, or find a detailed description of the products of a particular brand on the Internet. For example, for a nylon screw dowel with a coarse thread 6x50 mm from Europartner (Russia), the approximate supported weight is indicated - 30 kg, and for a model made of 10x60 mm nylon with blades - 120 kg.

Selection criteria for facade dowels

All facade anchors are divided into two large groups:

- anchor fasteners;

- disc fasteners.

Anchor facade dowels

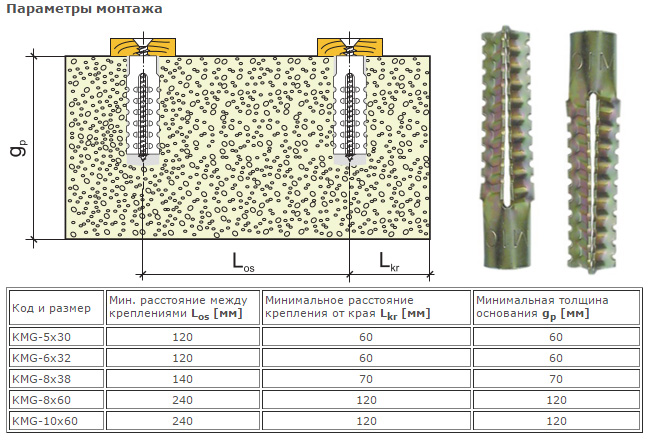

Anchor-type dowels (another name for dowel-screw) are mainly used for mounting the frame of the building cladding, fastening various brackets and other structures. Due to the need to hold heavy structures, all anchor dowels are different:

large size. The diameter of the fastener can be 10 mm or more, and the length of the dowel varies from 60 mm to 160 mm;

The dimensions of the anchor dowel are selected in accordance with the dimensions of the bracket or frame elements. For the strength of the fastening, the length of the anchor should be 10 mm - 15 mm longer than the corresponding parameter of the frame (bracket).

- durability. The material for the manufacture of anchor dowels for facade work is ordinary or stainless steel. To increase strength and protect against corrosion, the fastener is treated with a layer of zinc or other anti-corrosion material;

- durability.

Anchor bolts are divided into the following types:

standard products with a spacing of the bottom, which are used for walls made of brick, wood and other durable materials;

Standard anchor for facades with expansion at the bottom

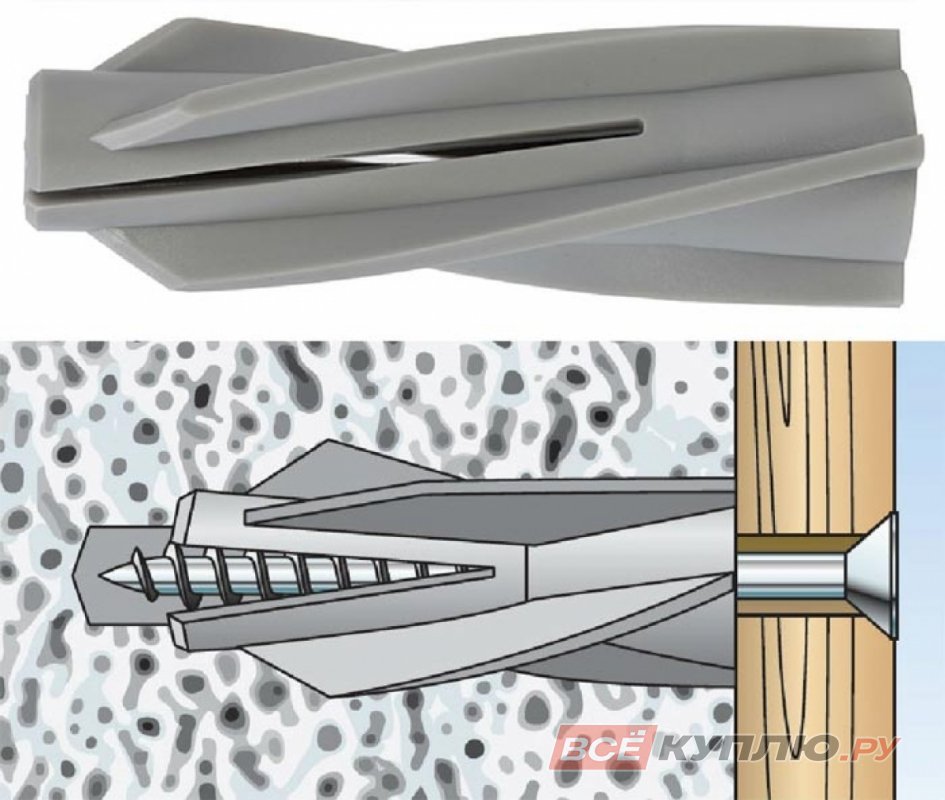

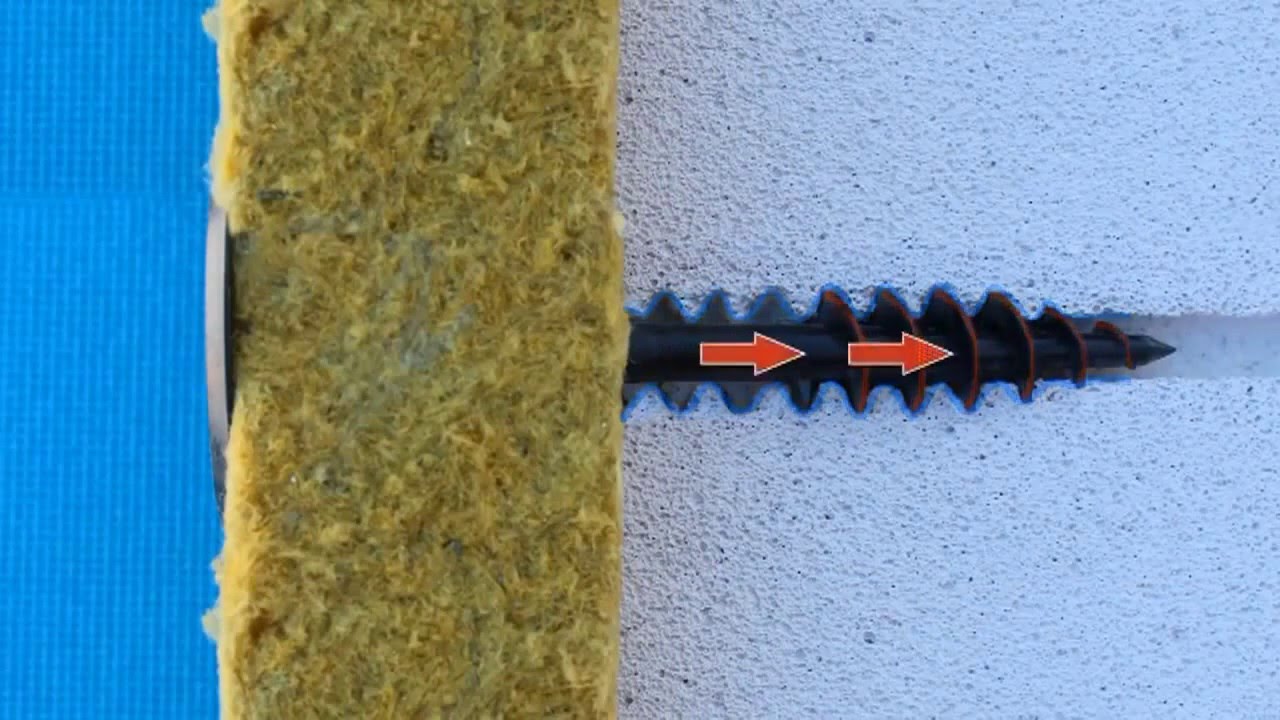

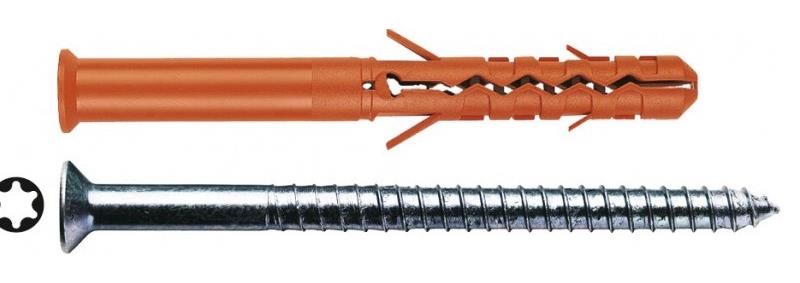

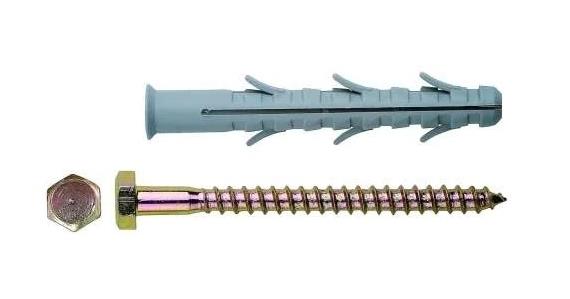

products with "antennae".Dowels with side lobes are used for aerated concrete and other porous and brittle materials, as they provide a higher level of adhesion of fasteners to the facade surface.

Bolt with additional fastening in the form of "antennae"

They can be equipped with a screwdriver head (pictures above) or keys (hex dowels) to facilitate the installation process.

Dowel with hex head

Disc-shaped facade dowels

Dowel-type dowels are mainly used for fastening insulation. The main distinguishing feature of this type of fastener is the presence of a round-shaped spacer element, which increases the strength of the fastening.

The main components of the plate dowel

Dowel-shaped dowels or dowels-nails are made of the following types:

plastic dowel-nail. The fasteners are suitable for thermal insulation with light materials (polystyrene, expanded polystyrene, low density mineral wool, and so on). Materials such as nylon, polypropylene and polystyrene are used to make the dowel. Fasteners are available in a standard diameter of 10 mm and in various lengths (from 70 mm to 200 mm);

Facade plastic dowel

In order to achieve maximum fastening strength, it is not recommended to use plastic dowels with a spacer size less than 50 mm.

dowel with metal nail. A distinctive feature of this fastener from the above type is the manufacture of a fixing nail from metal. Such a fastener can be used to fix any kind of insulation, regardless of its characteristics;

Universal facade dowel

a dowel with a metal nail and a thermal head, which protects the heat-insulating material from stains resulting from metal corrosion. Such fasteners are more expensive;

Fastener with added rust protection

Any disc dowel can be supplemented with an expansion washer for fixing loose or easily deformed insulation materials.

You can find out about the choice of dowels by watching the video.

How to use?

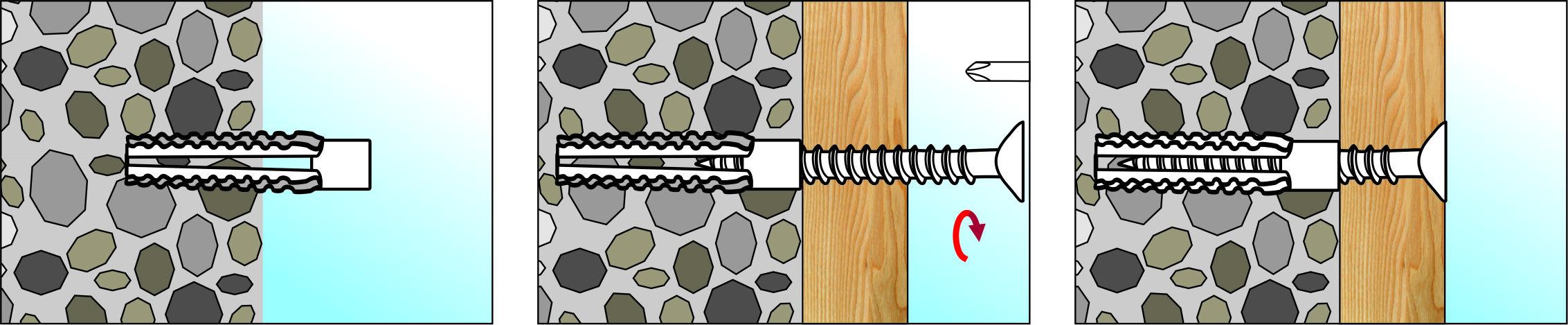

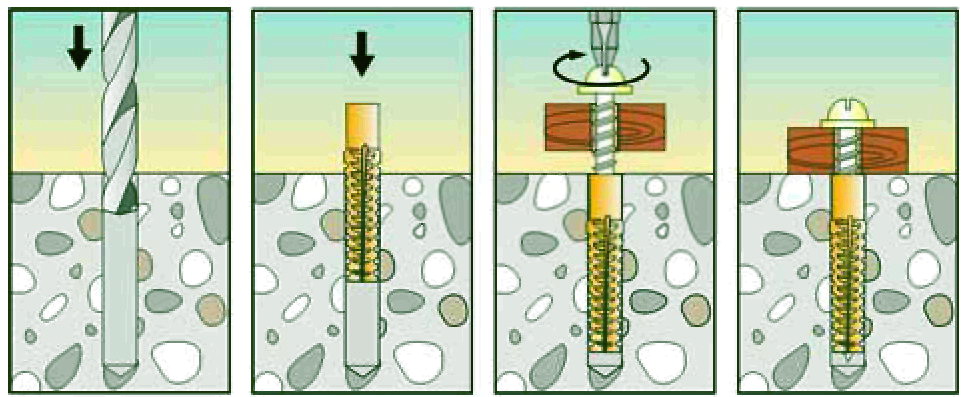

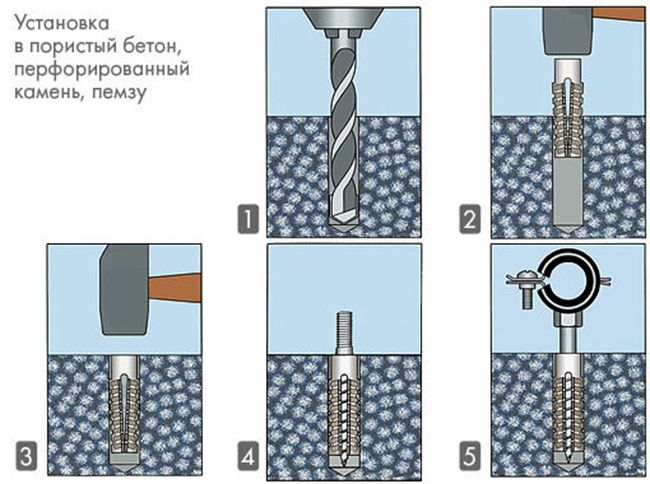

The principle of installation of dowels is the same as for other types of fasteners. You need to act in the following order:

- first you need to prepare holes for the dowel, which should be smaller than the diameter of the attachment; for example, for fasteners of 8 mm, you will need to use a 7 mm drill;

- if you take a tool such as a punch, then you need to turn off the impact mode in it, of course, it is advisable to use a drill in this case, since it is more effective;

- plastic fasteners must be carefully screwed in using a screwdriver; if metal parts are used, then they should be driven into the bore hole with a hammer;

- when doing work, it is imperative to make sure that the products do not touch or are crooked;

- when the cuff is installed all the way, you can proceed to screwing a self-tapping screw or a universal-type bolt;

- it is necessary to screw in the self-tapping screw with a screwdriver, adhering to the required depth.

Anchor

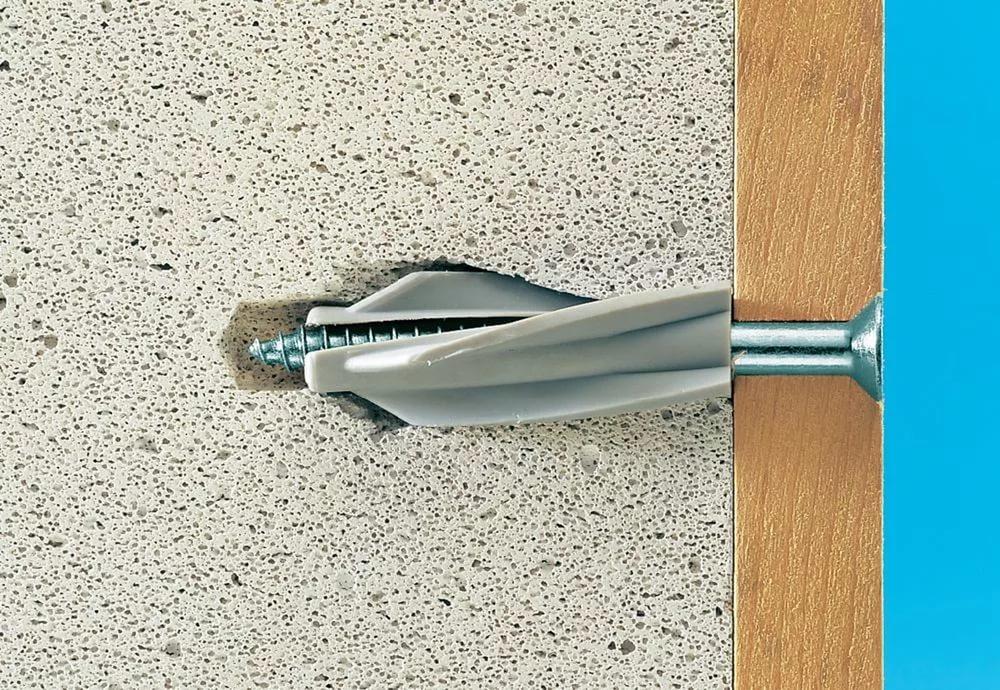

Manufacturers for cellular blocks produce special anchors. It is worth noting that a regular anchor will not work here, it simply will not withstand the load. In order to withstand certain loads, such a consumable must have a certain solution. Some anchors are hammered into special plastic dowels. Thus, friction is created between the anchor and the porous structure of the blocks.

To create a strong connection, installation is carried out in the following sequence:

- A hole is drilled in the block.

- The hardware is inserted into the prepared hole.

- The anchor is twisted and unclenched.

With this fastening, a sufficiently strong connection with foam concrete is obtained.Metal and plastic bolts have a similar type of fastening, the installation of a foundation anchor bolt is similar.

Foam concrete anchor

The anchor bolt is used when working with high density foam concrete. Such fasteners are able to withstand any, including quite weighty structures. A plastic anchor, as a fastener for aerated concrete, is used for a more fragile material than foam concrete. It is suitable for gas silicate blocks.

The foundation bolt has found its application in the installation of heavy structures. This is a double-sided consumable, one end with a threaded thread, the other has a device that is able to hold the foundation bolt itself in the base. The foundation should not deform further.

Types and features

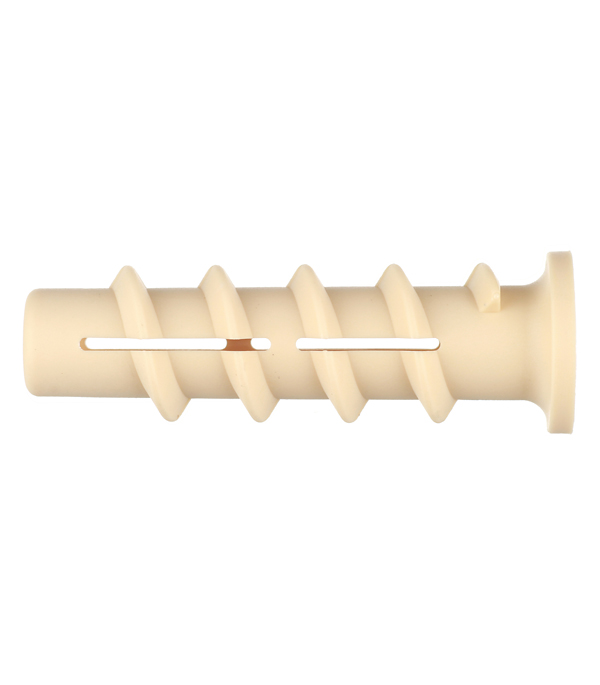

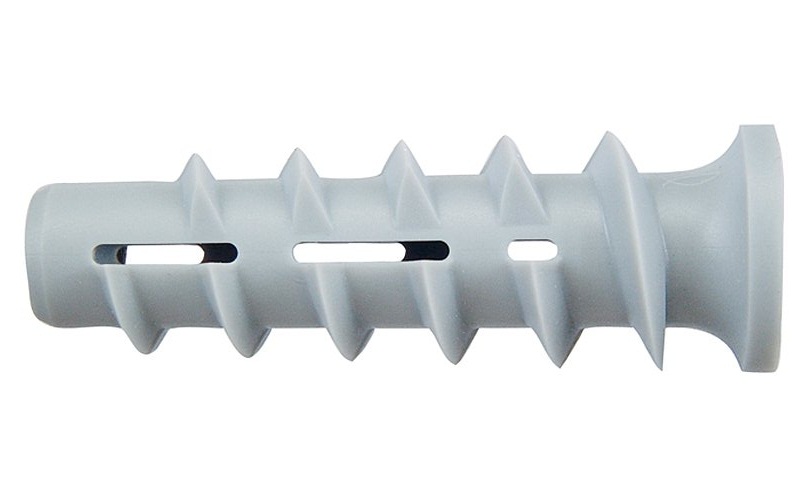

The dowel fastening device is a bushing with four petals and a rough surface. When twisted or clogged, they begin to expand in the porous structure of aerated concrete. The teeth and incisors in such a device contribute to a secure fixation. They can be especially secured when the teeth move in a spiral and the tip of the screw does not protrude beyond the dowel.

Fasteners, depending on the material used, can be:

- metal - stainless steel, galvanized, brass, aluminum, with the addition of an anti-corrosion compound;

- plastic (polyethylene, polypropylene, nylon).

The first type is considered the most reliable in operation. They are perfect for push-through and complex installations. However, such fasteners have a significant drawback - they begin to oxidize under prolonged exposure to moisture. Equip them with supporting elements to minimize the risk of cranking, falling through heavy hardware inside aerated concrete blocks.

Fasteners made of plastic are appreciated for their lightness, versatility and resistance to corrosion processes. Of all the varieties, nylon dowels are considered the best.

All these fasteners are divided into hammered and screwed in, depending on the installation method. They are suitable for installation without pre-drilling the blocks and are also threaded into a pre-drilled hole.

By the type of thread and fixing of the elements, the bushings can be standard with the same section length and a helical spiral. There are cone-shaped hardware, which diverge to the sides with blades when twisted. Some begin to expand when the structure is pulled apart.

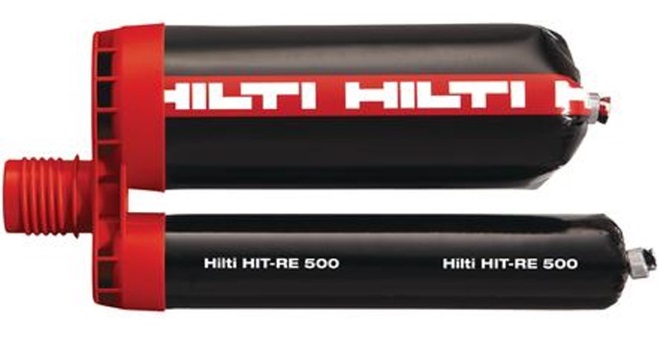

A separate group includes chemical anchors. Their fixation occurs due to the polymerization of a special composition. They are very convenient to use, since it is enough just to put the capsule in the prepared place.

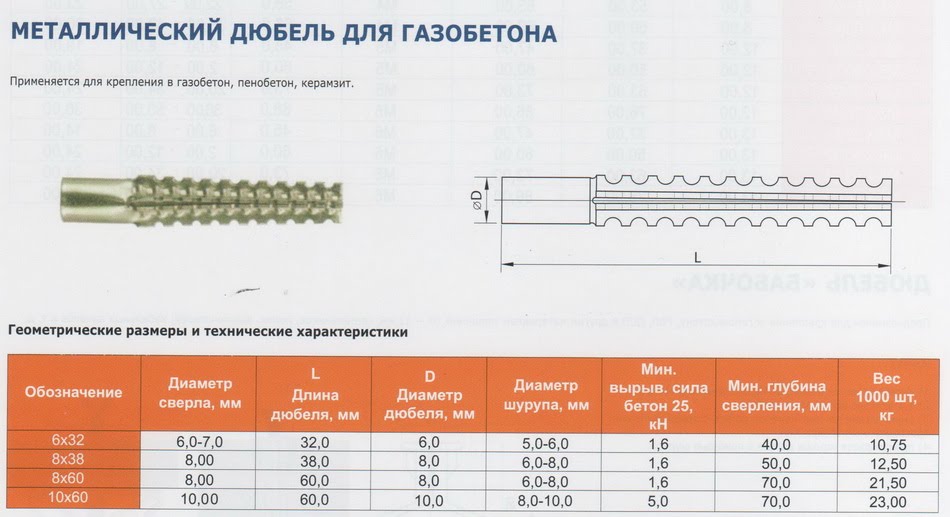

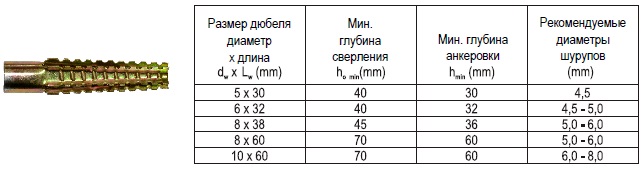

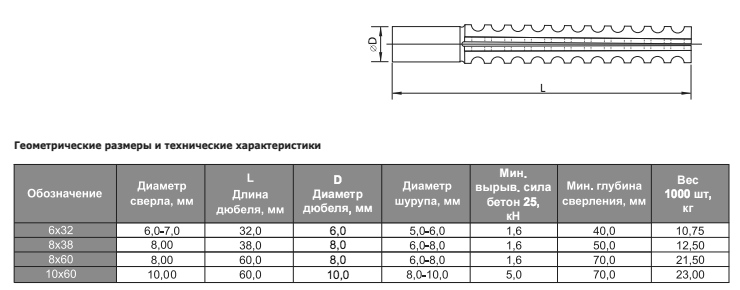

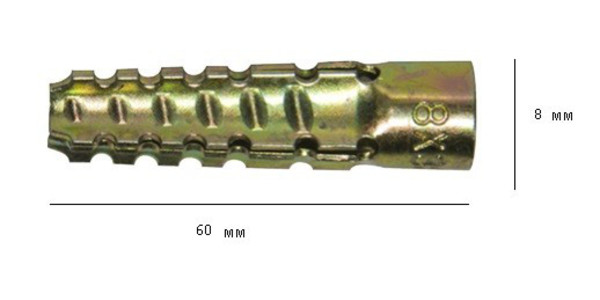

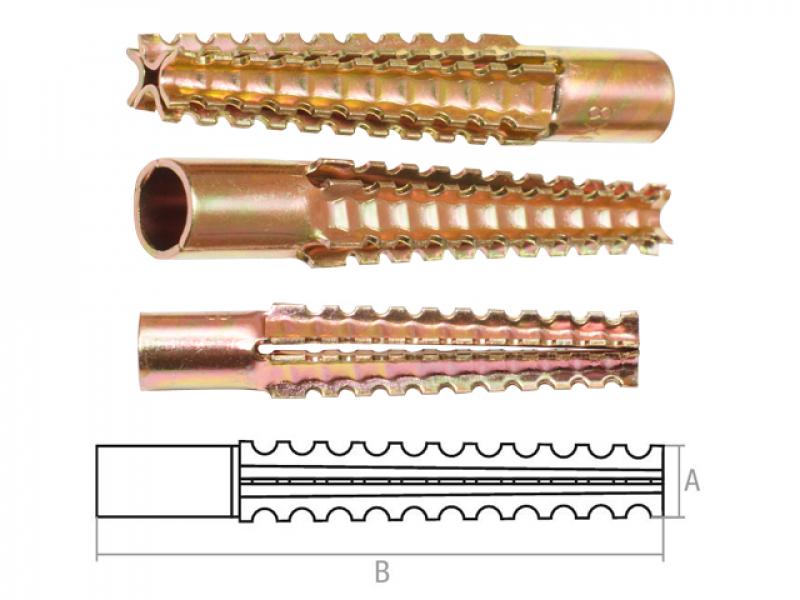

Metal dowels

These fasteners are fire resistant and are therefore often used in installations where there is a risk of fire. Metal dowels have a stopper collar, which is also called a "collar". At the moment of twisting, it prevents the sleeve from turning around its axis and prevents it from falling into the wall. Most often they are made from galvanized steel.

The metal dowel for aerated concrete is used when performing the following works:

- for the installation of equipment and furniture with an impressive weight;

- fixation of pipelines, including the most complex ones;

- fastening guides designed for the installation of sheets of gypsum board.

Plastic and nylon retainers

Such fasteners are good because they are not affected by corrosion processes. The plastic dowel for aerated concrete has special spiral ribs. This part of the part is responsible for maximum adhesion to the cellular structure of the material. The main advantage of plastic mounts is environmental friendliness. The advantages also include resistance to aggressive environmental influences.

They are distinguished by their low cost, which makes them irreplaceable and always in demand when working with aerated concrete. Despite all the positive characteristics, they are not suitable for use on the facade surface. Their significant disadvantage is poor resistance to sub-zero temperatures.In winter, during frosts, such a fastener can easily burst.

The nylon versions are also non-corrosive. However, they are more durable than plastic counterparts. They are often used when doing outdoor work. A nylon dowel for aerated concrete is considered much stronger and more durable. At cost, they are much more expensive, so they are rarely bought by consumers.

The high price is fully justified, since the characteristics of the clips allow them to be used for many jobs. For example, with their help they make installation of window and door openings. This is a great option for mounting mirrors and installing lighting fixtures, if you use fasteners with a diameter of less than 12 mm.

Chemical anchor

Often, massive objects have to be fixed on the aerated concrete surface. In this case, chemical anchors are used. Metal dowels, in comparison with anchor bolts, will not be able to withstand very heavy weight. They are sent to a prepared place using a special adhesive.

Scope of application

Chemical anchor in aerated concrete are used less often. They are used in cases where it is required to provide a reliable fastening for massive objects. Mechanical anchors cannot support, for example, the weight of massive equipment.

Epoxies are used mainly on solid substrates. They are used for fastening:

- wall structures;

- beams;

- fences along the roads;

- creation of noise-insulating screens;

- when installing reinforcement outlets;

- when installing mounted equipment.

Such a composition can be applied:

- in a humid environment;

- under the water;

- both outside the building and for interior work.

Its composition:

- does not create stresses in the structure of the porous wall;

- does not contain styrene;

- creates fasteners with smooth reinforcement.

The solidification of the mass depends on the air temperature. The time can last from 7-180 minutes. or 7-48 hours

Polyester anchors are used to create:

- enclosing structures;

- when installing facade elements;

- for installing translucent elements;

- when installing engineering communications.

> Typically threaded rods are used with polyester compounds. The polyester anchor contains no styrene. Therefore, it can be used on both indoor and outdoor fasteners. Polyester anchor takes 2 to 30 minutes and hardens from 25 to 180 minutes.

The anchor bolt for aerated concrete can be smooth or threaded if a vinylester anchor is used. It is used to create fasteners in wet substrates. It does not create unnecessary stresses in the structure of aerated concrete. This adhesive solution is safe because it does not contain harmful substances. It is used to perform internal and external fasteners. Does not create stresses after installing fasteners in the structure of the aerated concrete block. Hardening is observed after 15 minutes, or after a day.

Epoxyacrylate anchoring composition has gained wider application due to its qualities. The period of setting and hardening of the composition is 2-24 and 15-180 minutes, respectively. Epoxyacrylate retains its properties when the temperature drops to -5 ° C, and also provides resistance to fire in case of fire for up to 2 hours. Epoxy acrylate anchoring compound is suitable for anchoring floor slabs in an aerated concrete house.

Types of fasteners and the use of dowels

The nylon look is a design that resembles a miniature, made of plastic, meat grinder screw, or as it is also called, the Archimedes screw (named after the ancient Greek inventor). An axis is a lengthwise section of a hollow tube. For different mounting options, it is better to use a different helix pitch and blade width. Sometimes you can find a tapered look, made in the same style. It is installed in this way:

- a hole is drilled to the required depth in the block along the outer diameter of the axial tube;

- using a flat or Phillips screwdriver, the dowel is screwed into the body of aerated concrete with effort;

- for fastening inside the dowel, a self-tapping screw of the corresponding diameter and length is screwed with an interference fit.

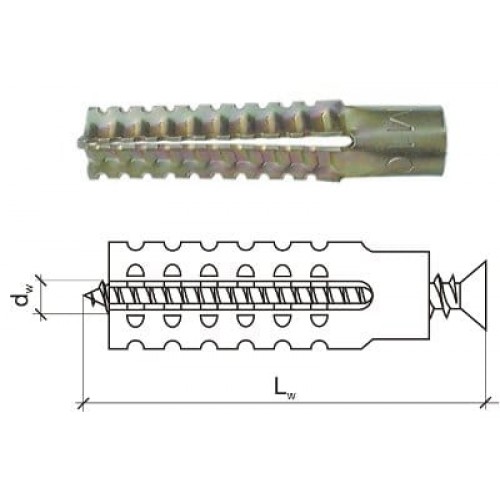

Another plastic nylon type of dowel, it is also called frame dowel, despite the fact that it is very similar to the usual one, differs from it by the presence on the lateral sides in the lower expanding part of special sharp spikes, cutting into the block, "mustaches" and other parts, design which, when screwing in the screw, restricts the plastic dowel to rotate around its own axis, breaking the hole-socket for installation.

Metal dowel nails are available with or without a head. The principle of operation is similar to the operation of a collet pencil, in which the expanding collet-grips hold the lead well and securely as soon as it gets out of the hollow tube located above into the gripping zone. It is necessary to insert it into a pre-drilled hole in the gas block. Then, with a sharp and precise blow of the hammer, drown its protruding element to the required depth. The opened metal collets from the recessed side will cut into the concrete, securely grip and fix the inner movable part (in fact, the nail), providing strong fasteners.

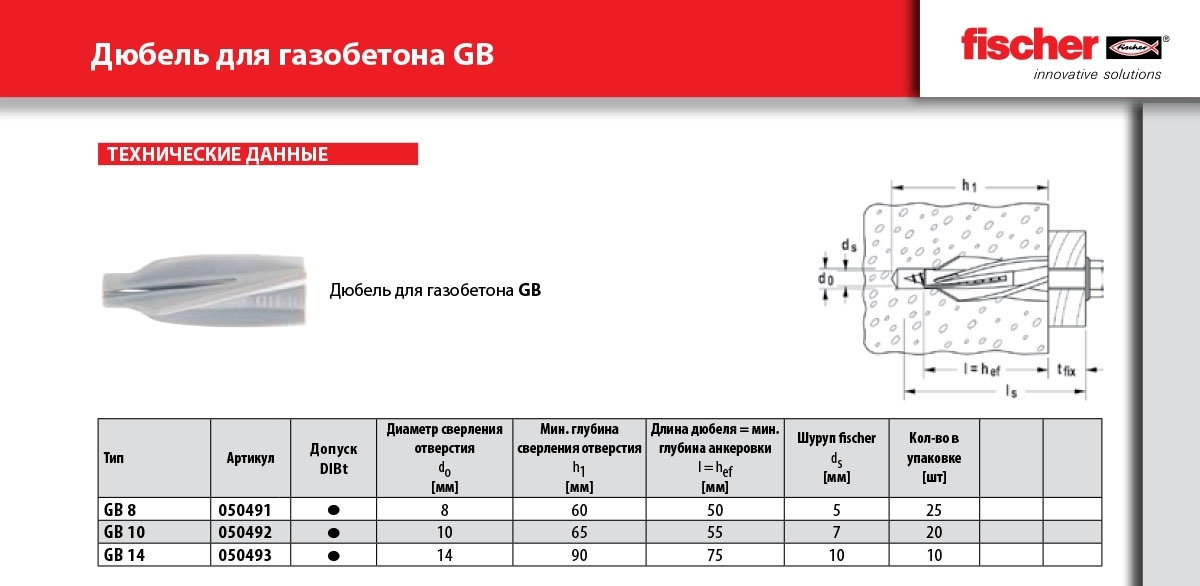

After installation in the hole, the HPD HILTI anchor is fixed with a special device, the impact of which pushes through the slots in the lower part of the anchor a kind of metal "mustache", cutting into the block, preventing rotation and pulling out of the fastener, which is a hollow tube. It is good and convenient to attach a structure that requires suspension through a threaded stud and a mounting nut. Most often, the HILTI HPD anchor is used to fix wooden or metal frames to aerated concrete facades under cladding with various sheet, panel or tile materials.

The cost of the most common dowels

Fasteners differ in cost, determined based on the purpose, principle of operation, overall dimensions, material from which they are made. The price depends on the size (length), diameter, the number of pieces in the package (it can be from 25 to 400 pieces), the seller, and also the manufacturer.

The approximate cost of HILTI nylon and metal dowels for a gas block of common standard sizes is shown in the table.

| Material | nylon | the size | — | — | — | 8X55 | 10X60 | 14x80 |

| price, rub / pc | — | — | — | from 31 | from 40 | from 55 | ||

| metal | the size | 5×30 | 6×32 | 8×38 | 8×60 | 10×60 | — | |

| price, rub / pc | from 22 | from 23 | from 33 | from 40 | from 50 | — |

The price of the HILTI HPD anchor depends on the diameter of the working thread and the length.

| HPD anchor HILTI | metal | the size | М6х86 | М6х106 | М8х88 | М8х98 | М10х90 | М10х110 |

| price, rub / pc | from 110 | from 115 | from 130 | from 135 | from 200 | from 220 |

Dowel

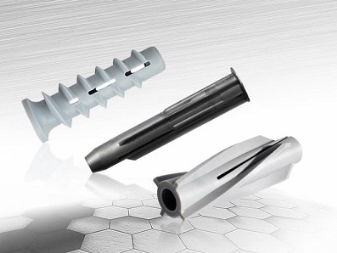

The part is a spiral bushing with ribs on its surface. At the moment the screw is screwed in, they expand, due to which they firmly enter the soft surface of the base. Such fasteners can be made of galvanized steel or plastic.

The first option is the most common and is considered the most expensive. It is used for the installation of profiles, installation of hinged equipment and furniture, fixation of various pipelines. Such fasteners are widely used in fire-hazardous areas.

They produce a metal dowel for aerated concrete in 2 modifications, which differ in design features and installation methods. Parts can either be screwed into the base or hammered into it. The latter option is used if the aerated concrete floor is planned to be equipped with a collet.

According to the shape of the fixation ribs, fasteners with a classic helical spiral and cone-shaped dowels equipped with spiral blades are distinguished. The design of metal elements also provides for the presence of a stopper flange or cuff, due to which the part will not rotate.

Corrosion resistance is the main advantage of plastic products.The materials for them are polypropylene and polyethylene. The positive characteristics of parts include their efficiency, environmental friendliness, and immunity to aggressive environments. Such dowels are not intended for outdoor work, since with the onset of cold weather, plastic can burst.

A separate group is made of nylon aerated concrete fasteners. They are more wear-resistant, so they can be used for facade cladding. Together with them, galvanized screw elements with 2 types of heads are used - countersunk or hexagonal. The disadvantage of this type of mount is the high price.

Depending on the scope of application, there are several types of dowels:

- Universal. It can be mounted on any concrete surface. On a solid basis, fixation occurs in a standard way. In a cellular covering, the product is rolled up into a stop unit. However, the load-bearing capacity of universal dowels is lower than that of spacers.

- Dowel-nail, which has a wide range of applications. At the time of fixation, a nail is inserted into the fastener, and the screw is not screwed in. In order to avoid scrolling the part, use a sleeve.

- "Pancake-like" structure of frame dowels allows to reduce the load on the porous surface of the block.

Types and scope of application

As a mass, which is used to fill a hole for an anchor or chemical-type dowel, substances based on the following types of resins are used:

- epoxy;

- epoxyacrylate;

- polyester;

- vinyl ester.

Resin for chemical anchors can be in capsules or tubes

Certain types of adhesives (for example, those based on vinyl ester resin) can be used to form anchoring joints that are operated at low temperatures. The convenience of using glue based on such a resin also lies in the fact that it can be used to fix even in wet holes, while no internal stresses are created in the material of the building structure. Such anchors can be equally successfully used for mounting threaded and smooth rods in aerated concrete.

It is also important that there is no styrene in vinyl ester resins - a substance harmful to human health.

Adhesives based on epoxy resins are very popular among specialists. Such compositions are used for fixing anchor bolts in aerated concrete, the class of which exceeds C20 / 25. The most common areas of their application, in addition to the device of reinforcement outlets, include installation:

- various objects on walls, beams and road barriers made of concrete blocks;

- screens performing noise protection functions;

- technological equipment for various purposes.

A two-part epoxy adhesive capsule is intended for use with a dispenser when installing threaded rods or fittings

Distinctive features of epoxy based adhesive are:

- the ability to use in conditions of high humidity and even under water;

- application for the installation of anchors both inside the building and on external building structures;

- the ability not to create internal stresses inside the building material;

- no toxic styrene;

- the possibility of using for the installation of both threaded and smooth fasteners.

For professional use, it is recommended to purchase a special kit that includes everything you need to install chemical anchors.

Along with all the advantages of the listed types of adhesives, materials based on epoxyacrylate resins are also distinguished by a high fire resistance limit - R120. This parameter indicates that even if there is direct exposure to fire on a fastener fixed with such an adhesive, nothing will happen to it within 120 minutes.

Adhesives also differ in the period required for their setting and complete hardening.So, the setting / hardening time is for compositions:

- epoxy - 7-180 minutes / 7-48 hours;

- based on polyester resins - 2-30 minutes / 25-180 minutes;

- vinyl ester - 2-60 minutes / 15 minutes - 24 hours;

- epoxyacrylate - 2-24 minutes / 15-180 minutes.

If you wish, you can make glue for installing a chemical anchor in aerated concrete with your own hands, the main thing is to strictly observe the proportions of all its components.

Fasteners for aerated concrete

Only very light objects such as photo frames can be attached to ordinary wood screws to aerated concrete. In all other cases, special fasteners will be required.

Fastener requirements

When choosing which fasteners to use for aerated concrete, you need to consider the following points:

The density of wall blocks, indicated in the marking of products by numbers after the letter D. The higher it is, the less pores in the material, and the stronger it is. The load limit when pulling out fasteners depends precisely on this indicator, and the instructions from the manufacturer on the packaging contain this information.

The numbers show how many kilograms in a cubic meter of material

Fastener parameters - its length and diameter. The larger they are, the more load it can withstand. The load-bearing capacity must also be indicated on the packaging or on the certificate.

Chemical anchors have the highest load-bearing capacity

Corrosion resistant. This parameter is especially important when fastening to aerated concrete is carried out from the outside walls or in unheated rooms. Steel hardware must be covered with a protective layer.

Aerated concrete punch

Mounting options

Let us consider in more detail which aerated concrete fasteners are used most often.

Let's start with the traditional views:

| Image | Application |

|

Dowel nail |

When a smooth steel nail enters the sleeve, its base opens and enters the material at an angle. Suitable for all types of concrete. |

|

Facade dowel universal |

Allows you to attach the profile to aerated concrete for attaching facade panels and hang wall cabinets and shelves. |

|

Expansion dowel universal nylon |

It is used only for light loads: fixing light shelves, curtains, skirting boards, switches, cable ducts, etc. |

|

Frame dowel |

Helps to carry out fastening of window and door frames, wall cabinets to aerated concrete. |

|

Nylon dowel for aerated concrete |

Specially developed for aerated concrete. It is used with ordinary self-tapping screws for the installation of wooden and metal facade subsystems, windows, doors, suspended ceilings, sanitary equipment, pipelines. |

|

Zinc coated steel dowel for aerated concrete |

Designed for any aerated concrete, wide range of applications. |

|

Steel anchor for aerated concrete |

Solves the problem of how to attach heavy objects to aerated concrete: water heaters, air conditioners, hanging pipes, heavy wall cabinets, etc. |

All of these elements may have other varieties than the images shown in the table. For example, turbo dowels with self-tapping threads are made from nylon.

Turbo dowel FTP K

And from galvanized steel - spacer four-blade toothed dowels. Their segments at the moment of screwing in the screw move apart, reliably biting into the cellular materials.

Steel expansion dowel

As already mentioned, one or another hardware and method of fastening are chosen depending on the expected load.

If you need to mount the shelves, you need to carefully drill aerated concrete at a right angle, insert a dowel into the hole and screw a screw into it.

Shelves with covered fixing on aerated concrete wall

- And for hanging a light picture or mounting an electrical switch, a simple self-tapping screw screwed at an angle of 45 degrees to the wall is enough.

- If you need to securely secure heavy equipment or install a metal front door, it is best to use chemical anchors.

In the installed form, they are capsules of synthetic resins and organic polymers, which embed holes in the aerated concrete wall, firmly holding a metal rod or threaded rod in it.

The advantages of such fastening include exceptional reliability and durability, non-susceptibility of the adhesive base to thermal expansion and resistance to aggressive media.

No special qualifications are required for fastening with chemical anchors, everything can be done by hand.

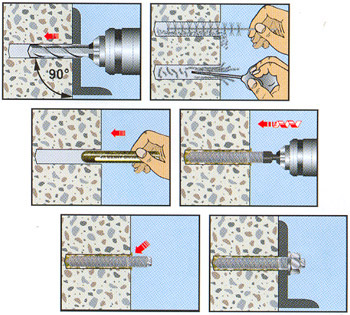

For this:

- A hole of the required depth is drilled in the wall, its bottom is slightly expanded by the oscillatory movements of the drill;

- Construction dust is blown out of the hole, and a sleeve is inserted into its neck;

- The cavity is filled with an adhesive solution using an assembly gun;

- An anchor rod is immediately installed in it;

- After the solution has hardened, fasteners can be carried out.

The price of such fasteners is higher than that of other types, but the reliability does not raise the slightest doubt.

Installation nuances

To avoid errors, the following sequence is followed:

- Using a drill or perforator operating in a non-impact mode, a hole is prepared in aerated concrete with a depth of 10 mm greater than the length of the anchor itself. When installing plastic varieties, it is recommended to use a drill with a diameter of 1 mm less, when screwing in metal - 2.

- The cavity is purged and cleaned of debris.

- The fasteners are carefully screwed in with a screwdriver or an installation tool, or hammered in with a hammer. At this stage, distortions are avoided, the dowels and anchors are usually located perpendicular to the base.

- Final fixation with screws or self-tapping screws. For maximum reliability, the tip of the fastener should protrude slightly beyond the edges of the dowel, but if necessary, they can be tightened to any desired depth. To expand the product inside the gas silicate, it is not recommended to use powerful power tools, an overly intense effect simply turns the thread, crushing the porous structure.

At all stages, the integrity of the gas blocks is checked, if necessary, they are cleaned of dust. The important nuances include the choice of the correct drilling depth, it depends entirely on the type of dowel and the length of the installation part, which must be indicated by the manufacturer. A stock of 10 mm eliminates the risk of being pushed out by dust (cleaning does not drive out the crumbs of the block to the end, new ones are formed during the fastening process). With high requirements for the reliability of fixation, it is advisable to use chemical anchors; in extreme cases, the products are additionally sealed with polyurethane foam.

Dowel cost

| Type and material | Manufacturer | Length, mm | Diameter, mm | Packing, pcs | Price, rubles |

| Plastic | Crepe-Comp | 80 | 14 | 100 | 700 |

| Nylon SX | Fischer | 50 | 10 | 25 | 150 |

| Metal, with anti-corrosion coating | Crepe-Comp | 32 | 6 | 30 | 120 |

| Steel anchor FPX I with female thread, for pre-installation and push-through installation. | Fischer | 75 | 10 | 1 | 180 |

| Frame dowel KAT N, plastic | Sormat | 160 | 50 | 1240 |