If the hat breaks off, how to get it

In the case when the cap is broken off, and the main part is in the wall, you can not get the dowel. It is hammered deeper. You need to take a thin, blunt object and hammer a dowel into the wall with a hammer. Place to putty.

You can remove a broken item with a drill. To do this, 3-4 holes are made around the nest, end-to-end with the dowel. It weakens, can be easily removed with pliers. The holes made are filled with putty.

When filling, a mesh is used so that cracks do not appear.

It is not necessary to remove the interfering object from the wall. It can be cut, hammered deeper. One has only to remember that metal objects give rusty spots. If you need to get the dowel off the wall, use self-tapping screws, drills, a corkscrew, a hammer.

It is not difficult to get an object off the wall, you just need to spend a little time and patience. And also have a good hammer and pliers on hand, you can have a nail puller. After removing the holes that have appeared, it is advisable to cover with a reinforcing mesh, putty.

Let's work with the tree

Today, most people use plastic dowels, but some prefer wooden caps. The difference in their extraction is not particularly great. The cap can also be pulled out using a self-tapping screw, which is screwed into a wood product, then the removal process is performed using pliers. If they are not at hand, then a nailer or other construction tool will do.

Another method is especially popular - pulling out in parts. This will require a chisel and a hammer, with which the dowel is split along the fiber. Then the resulting fragments are removed with a knife or screwdriver. A drill can also be used. This option is available for softwood dowels. The drill can be replaced with a hammer drill

Care should be taken to avoid large diameter holes in the wall.

In most cases, wooden dowels are used for mounting wooden windows. To do this, take 3-4 fasteners with which to fix the window sill, and several pieces for installing the window frame.

Metal dowels are not as widespread as plastic ones, because their use implies that special equipment is available. There are two options for removing such fasteners.

One way is twisting. The second is loosening with a hammer. If it was not possible to carefully unscrew the dowel, then you can try to loosen it with a hammer. When the fasteners are flush with the wall, they can be removed by making a few small holes around them. Then the extraction takes place directly.

Removing a dowel from a concrete surface is not an easy task, but using the right method, you can quickly pull out fasteners with minimal losses to the surface. To complete the procedure in the shortest possible time, you just need to prepare the necessary tools and choose the right way to pull it out.

How to quickly pull out a dowel from a concrete wall?

updated: Nov 11, 2016

author: Artyom

Few know how to properly remove the old dowel from the wall. The main thing is to try to choose a simple, reliable and economical way. The skills of installing and dismantling fasteners will help to achieve the result; experience in owning electric and hand tools will be useful.

Several types are produced specifically for concrete; a nail is always used as a rod in them. Reliable operation can be guaranteed if you are able to choose the right version based on the dimensions of the plane and the massiveness of the suspended structures, and perform high-quality installation.

Before starting work, it is necessary to assess the quality and thickness of the surface. The presence of hidden electrical wiring and metal fittings is the basis for a change in location. Sometimes it is not easy to hammer in the dowel carefully without damaging the adjoining part of the wall.

The most commonly used options are:

- Spacer, suitable for a solid wall.It will establish itself inside it due to the expansion of the plastic case. The plastic sleeve is made with a tapered metal core or threaded.

- Universal. The embedded nail fits snugly against the walls of the hole. Suitable for loose, hollow partitions.

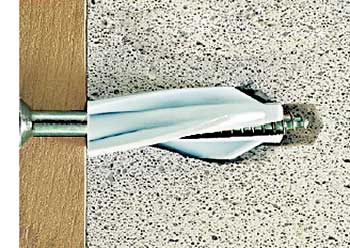

You can insert the dowel with a drill with the function of a hammer or punch, drill for concrete, hammer. Correctly perform work in the following sequence:

- using a punch, punch a hole with a diameter similar to the sleeve and a depth exceeding the length of the fastener by 0.5 cm;

- clean the resulting recess from dirt and dust;

- fix the dowel body with a hammer until its edge aligns with the wall surface;

- hammer a nail into the body until it stops.

If you follow all the installation rules, it will be difficult to get it.

Types of dowels

Today there are many types of concrete dowels, which can be listed for a very long time.

Therefore, we will highlight the most common:

- Conventional spacers;

- Butterfly;

- Universal;

- Dowels-nails;

- Facade (umbrellas);

- Chemical;

- KBT;

- GB.

Now let's take a closer look at their features and purpose.

Conventional spacer fasteners

Spacer

Expansion dowel for a concrete wall allows the installation of various rigid structures. This type of fastener may differ in the type of screw heads. Most often they are made "in the back" and under the Phillips screwdriver.

However, screws with large diameters are sometimes found on a wrench with a hex head. As a rule, they have a slate-like thread, due to which the dowel is hammered into the concrete during installation.

In the case of dismantling, before pulling the dowel out of the concrete wall, you just need to unscrew the screw. After that, the sleeve can be easily removed from the hole.

I must say that the liners themselves may differ. They are two or three-spaced. They often have spikes and locking tabs to help secure the fastener in the hole.

The dimensions of the concrete dowel can be very different. Therefore, you should choose depending on the type of structure that will be mounted.

In the photo - fasteners "Butterfly"

Butterfly

Used for hollow or thin-walled structures. The sleeve of such an attachment is inserted into the through hole. After screwing in the screw, its reverse side is folded, as a result of which fixation occurs.

Universal fasteners

Universal

This fastener in solid walls is identical to the spacer. In hollow walls, when the screw is screwed in, the sleeve is wrapped in a knot, as a result of which fixation occurs according to the "Butterfly" principle. Thus, the same fastener can be used for different surfaces.

Dowel nail

Nail

This fastener is a metal dowel for concrete, designed for non-removable fastening of various thin-sheet materials and profiles to concrete. It can be used for through fastening of the profile.

The "nail" has such a design that it is fastened in the wall by hammering. As a rule, for installation, a gun is used to drive dowels into concrete, however, this procedure can also be performed with a hammer.

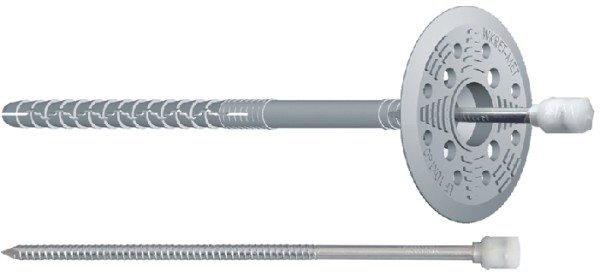

"Umbrella" with a metal rod

Façade

Facade fasteners can be attributed to a separate group.

It is intended for the installation of thermal insulation:

- Expanded polystyrene;

- Fiber boards;

- Mineral mats.

In fact, this is the same expansion dowel, but elongated and with an enlarged head. The sleeve itself is made of impact-resistant polypropylene, and the rod is made of fiberglass-reinforced polyamide. Sometimes there are "umbrellas" with a metal rod. (See also the article Self-tapping screws for concrete: features.)

Chemical dowel

Chemical

Another unusual type of fastener is the chemical foam concrete dowel.

It consists of two elements:

- Chemical composition capsules;

- Metal screw.

Installation instructions for such a dowel are as follows:

- First of all, a hole of the required length is drilled in the foam concrete.

- Then a capsule with a chemical composition is inserted into the hole.

- Next, a screw is screwed in. In this case, the capsule breaks, and the chemical composition penetrates into the pores of the foam concrete.

- After that, you need to wait until the substance hardens. Depending on the type of composition, this may take from several hours to a day.

KBT fasteners

Kwt

KBT is specially designed for installation in aerated concrete. It features a wide thread located on the outside of the sleeve. Thanks to it, a reliable adhesion to the porous base material is obtained. (See also the article Sanding concrete: how to do it.)

When screwing the sleeve into aerated concrete, it does not destroy its structure, but cuts a thread in it. Depending on the grade of the material, the KBT lightweight concrete dowel can withstand 400-600 kg.

GB fasteners

GB

The GB fixture is a dowel for polystyrene concrete blocks. In fact, it is a spacer sleeve with spiral blades.

Thanks to this design, the GB polystyrene concrete dowel is able to withstand heavy loads, therefore it is used when installing wall cabinets, heating radiators, shelves for household appliances, etc.

How to drive a nail dowel

In order to fix technological and decorative elements on concrete and brick surfaces during repair work, in many cases, dowel-nails are used, in other cases, ordinary self-tapping screws can be used. Due to their high frictional force, they provide a high degree of connection reliability. Driving in the dowel-nail can be carried out by performing only preliminary preparation of the mounting hole for it.

To drive a dowel-nail, you will need a dowel-nail, a drill for concrete, pliers, a hammer, a hammer drill or a drill.

You need to select and prepare all the necessary tools that you will use in order to hammer in the dowel nails. If the work will be carried out on concrete, you can use a hammer drill or electric drill with a bump stop. If you intend to hammer dowels into a brick surface, you can use a hand drill or a rotary wheel. For both cases, you will need a concrete drill. It must have a diameter (stuffed on the shank) corresponding to the same parameters of the dowel, the length of the working part (where there is a groove) must be at least five mm longer than the full length of the dowel. In addition, you need to prepare a center punch with a hammer.

You must choose the place where the dowel-nail will be driven in. Check if the wall (floor, ceiling) is thick enough for you so that it does not pierce through during drilling. You must make sure that there is no electrical wiring in this place hidden in the grooves and channels located inside the boards. When drilling a concrete surface, you need to try to choose a place in such a way that it does not hit the metal reinforcement. When working with brick structures, you need to avoid the cement areas of the masonry, so the dowel will not hold so well here. You need to mark the selected place.

Drill the dowel hole. To prevent the drill from moving away from the intended location at the beginning of drilling (especially when working with a hammer drill or concrete drill), you need to knock out a small hole in the surface using a center punch and hammer. Next, you need to place a drill in it and start working at low speeds. After deepening the drill by 5 mm, you can increase the rotational speed of the drill. Be careful when drilling bricks, do not use the chipper mode.

Next, you need to hammer in the dowel-nail, but before that you need to get rid of the dust accumulated in the mounting hole.Next, you need to insert the end of the dowel there and, using light hammer blows, hammer it to its full length. If the dowel is damaged during the driving process, you need to remove it using pliers and use a new one. If you need to attach heat-insulating materials, then for this there is a special dowel for thermal insulation.

Removing the fasteners

When renovating an apartment, high-quality wall decoration is required. To prepare the room for wallpapering, applying any other decorative coating, it is required to align the walls, having previously freed them from the old fasteners.

It is often necessary to remove unnecessary dowels through which screws are attached. To do this, there are several simple ways to remove the dowel from a concrete wall.

For dismantling, you will need:

- Self-tapping screw;

- Sharp knife;

- Corkscrew;

- Awl;

- Hammer;

- Punch;

- Soldering iron;

- Nail puller;

- "Bulgarian".

Dismantling method:

- To remove a regular plastic dowel, you can use a self-tapping screw of a suitable size. In this case, the self-tapping screw is screwed two-thirds into the dowel, for a reliable connection with the part to be dismantled. The head of the screw is clamped with pliers and, together with the dowel, is pulled out. Sometimes you can use a regular table corkscrew;

- The head of a self-tapping screw screwed into a dowel is pushed off with a nail puller. With this lever, the dowel is removed with less effort. But the main condition is a tight fit of the working part of the self-tapping screw in the hole;

- A wooden homemade dowel is dismantled from the nest in parts. To do this, the element is crushed into several pieces along the grain of the wood with a chisel with a thin blade and a hammer. After destruction, the dowel is carefully pushed off with a nail, the tip of a sharp knife or an awl, and pulled out;

- If the dowel is firmly in the wall, it is not always worth pulling it out. In this case, with a sharp knife, you need to cut off the part of the dowel that protrudes above the surface of the wall, and cover the resulting depression with plaster of paris and carefully align;

- A heated soldering iron is used to remove the dowel in which the screw fragment is stuck. The plastic base of the dowel is melted with the tool, then the fragment of the fastener is pryed off with nippers or round-nose pliers and pulled out of the socket;

- A metal dowel-nail driven into concrete with a construction gun should first be processed with frequent, sufficiently strong hammer blows on the protruding part of the part from different sides. Most often, the dowel loosens, and then it is relatively easy to pull out with a nail puller;

- If you cannot immediately loosen the metal dowel, you need to make a recess in the wall next to it with a drill with a carbide tip or a metal punch. Such a circular funnel reduces the area of adhesion of the product to the wall material, which makes dismantling much easier. If this does not help, the protruding part of the dowel must be cut off with a grinder and the recess must be leveled.

To determine which dowel is best for concrete, you need to get acquainted with their types, advantages and disadvantages. In addition, it is worth understanding the technology for installing the product, and carefully following the basic building rules when performing work.

Product classifications

When choosing a mount, 5 main factors are taken into account:

- load value - on the dowel, on the surface, on the structure;

- the nature of the load - stationary, dynamic;

- type of fixation;

- the nature of the material - stone, concrete, brick, drywall;

- surface construction - wall, ceiling.

Actually, there are several types of fasteners for different methods and materials.

The video below tells about the rules for choosing dowels:

By type of installation

The dowel, or rather, the nail, can have a slightly different structure, due to which you need to work with it with different tools.

Manual assembly - that is, using mechanical tools. Nails for such work are divided into 2 types:

- without thread - the nail is hammered in with a hammer, there is no way to unscrew it;

- threaded nail - driven in or screwed in. Its main advantage is the possibility of dismantling.

Installation using a construction and assembly gun - the nail has a restrictive collar, but does without a spacer body. This option provides a much faster installation and, moreover, is designed for a higher load.

By surface material

More interesting from the user's point of view, as it allows you to determine which fasteners are suitable for which wall or ceiling.

- The most common are threaded or non-threaded nylon plugs with diameters ranging from 2 to 16 mm. They are used for fastening to standard building stone - brick, concrete, and can withstand from 200 to 450 kg of stationary load.

- Dowel for aerated concrete - the material is considered to be relatively low-porous, so such an attachment is quite acceptable. The dowel is held by spiral ribs and wedging when driving a nail.

- Frame - have a great length, from 60 to 360 mm. They are produced in 2 types: for solid solid material and for hollow slotted material. The expansion part of the dowel is lengthened and is designed so that when passing through the slotted base, the dowel will hook several jumpers, which will provide fasteners.

- Distance dowels allow you to fix elements - lathing, for example, at some distance from the wall. The distance can vary from 1 to 30 mm. The distance plug is divided into 2 parts - one for the rail, the second for the material, and connected with a screw of a special design. In this way, numerous irregularities in the wall can be compensated for and a perfectly flat surface can be obtained.

- Universal - able to "independently" determine the presence or absence of voids. When fixed in solid material, the spacer body expands and is tightly fixed, and when it enters the voids, it bulges and adheres to the support.

- Metal dowels behave in the same way, that is, with a metal case. They are designed for attachment to thin-walled surfaces, but at the same time they hold a sufficient load. When the screw is screwed in, the metal dowel bulges and presses against the thin support.

- The nail dowel provides quick installation of battens, skirting boards, battens and other things, when it is necessary to strengthen a large number of elements. The nail here is knurled in the form of reverse cones. It is inserted together with the dowel into the drilled hole through the rail and hammered in with a hammer. Cannot be dismantled.

- Products with spring-loaded folding strips - butterfly dowels, are used to fix objects to a hollow surface - to false ceilings, for example, when installing a chandelier. Having passed the hard layer, the dowel opens under the action of the spring, rests against the skin from the inside. Typically, the model is sold with hooks or threaded rods.

- For fastening structures with a large weight to concrete and solid bricks - garage doors, sun-protection awnings, and so on, metal dowels with threaded rods or bolts are used. The fasteners are designed for a very heavy load - up to several tons.

- Dowels for drywall and aerated concrete - both metal and plastic, have a tip in the form of a pinned drill and a large thread on the spacer body. For such dowels, the hole is not drilled, but the entire structure is screwed in with a regular screwdriver.

- Insulation holder - a special dowel for fixing a heat insulator or solid foam material. Holes for it are drilled in brick and concrete, but the dowel itself is hammered in without a nail.

- A very specific type is the injection dowel. A mesh anchor is inserted into the hole for the fasteners, then a dowel is driven in and a quick-hardening compound is injected through a protective sleeve with a syringe. Under its pressure, the anchor mesh inside the material expands, forming an anchor in the form of a ball.When fixing in a slotted brick, it is allowed to use a dowel without a grid.

The length, thickness, weight of the dowel-nails are discussed below.

Types of dowels for drywall profiles

Dowels for profiles - fasteners used in the installation of guide profiles and hangers for the frame under the gypsum board.

Distinguish:

- dowel nail;

- dowel-wedge (anchor);

- butterfly;

- Driva;

- Knauf-Hartmut;

- Fischer Pd ";

- umbrella;

- chemical anchors.

The main types of dowels used in the installation of the frame base

To understand which dowel should be used in a certain situation, all options are considered below.

Dowel-nail for drywall profile

The most common fasteners for mounting the GKL frame. According to the method of fastening, two types are distinguished: manual driving and with the help of an assembly gun.

The second type is a fastening element consisting of a nail and a washer. They are used for mounting heavy massive structures to a concrete base.

This type of fastener is not applicable to work with gypsum board

I mark the products by size. Dimensional specifications indicate the diameter of the base and the length of the nail. When working with a drywall profile, the best option is 6/40, 6/60 mm, where 6 is the diameter, 40 and 60 is the length. They fix the guide profiles to the rough base, and also fix the direct suspensions.

Dowel-wedge

A wedge or anchor wedge is a reliable fastener. Dowel for fixing profiles on concrete and solid brick walls. Withstands heavy loads. Fastening is possible even at a small distance from the edge of the base. Anchor wedge is produced in sizes from 8/45 mm to 16/150 mm.

Fasteners are used for through and pre-assembly

Butterfly dowel

According to dimensional characteristics, there are:

- 8/28 mm. The smallest, suitable for attaching light objects. Self-tapping screws are not included. Must be purchased separately, size 3.5 x 35 mm.

- 10/50 mm. Self-tapping screws with a size of 3.5 x 55 mm. Withstands loads up to 24 kg. Suitable for fixing furniture shelves and cabinets.

- Metal dowel-butterfly. The second name is Molly. Suitable for use on walls made of hollow materials. Sizes range from 4/21 to 6/80.

Observing all the rules for fastening, "butterflies" serve as durability for a long time

You can find out more about the sizes and types of butterfly dowels on our website.

We advise you to watch a video about the process of attaching the "butterfly".

Driva

They produce two types of hardware: with and without a drill, from nylon, metal. For hanging heavy objects on a plasterboard surface, a galvanized part is used.

The shape is a conical cylinder. The thread pitch is large. Flat hat with cross recess. They are used for the installation of small-sized, lightweight structures. Sizes 12 x 38, 12 x 42, 14 x 38, 15 x 29.

Knauf-Hartmut

The fastener consists of:

- U-shaped profile;

- plastic antennae and bushings;

- screw with dimensions 5/60 mm.

Principle of operation:

- drill a hole in the wall;

- insert the profile plate into the hole using the guiding antennae;

- break off the antennae;

- screw in the screw.

Withstands loads up to 55 kg.

Fastener for mounting heavy objects

"Fischer Pd"

Fastening device for working with drywall and profile. Plastic cylinder with sleeve and side blades. Principle of operation:

- drill a hole, the diameter is equal to the dimensions of the sleeve;

- insert a phisher;

- fix with a screw.

The mount can carry up to 16 kg. Sizes - 10/28.

When fixing, the side blades should be opened and pressed against the base from the back.

Umbrella

It got its name from the principle of operation. After fixing in the hole, the side blades unbend and the fastener looks like an open umbrella. This contributes to the distribution of the load, the ability to withstand heavy weight.

Chemical anchors

It is a cartridge with a capsule containing an adhesive liquid. Under mechanical stress, the capsule bursts, the glue enters the hole.

Due to its properties, it is a monolithic fastener that can withstand heavy loads

4 Installation of dowel nails using a special gun

All the previously described options for driving the dowel-fastener imply that the nail is driven into the dowel. But there is another way to mount the fastening in question, which involves the use of a construction gun. Such a modern mounting device allows you to "target" the structure to be fixed to the base using a dowel-nail.

In this case, a special dowel-fastener is used, which by and large does not imply the use of the dowel itself. The presence of a special washer on the nail guarantees a tight fit of the fastener into the solid material. The essence of the pistol operation technology lies in the fact that after the dowel-nail is fired, the washer at its tip moves to the head of the fastening element and is tightly fixed there.

Such a dowel-nail is used for fastening metal structures to solid foundations made of natural stone, concrete, steel with a low carbon content, brick. The gun and the described type of fasteners are very often used when installing canopies on balconies of buildings. They produce "nails with a washer" with a length of 30 to 80 millimeters, a section of 4.5 and 3.7 millimeters from steel coated with zinc. It is extremely rare to find on sale nails with a cross section of more than 4.5 millimeters.

How to use the dowel-nail, I think you already understood. A person does not have any particular difficulties with this fastener.

In this case, it is very important to choose the right type of fastener, since the dowel-nails, which, for example, perfectly connect the surface and the concrete base, are absolutely not suitable for fastening chipboard or drywall slabs

It is enough to contact the consultants (sellers) of a hardware store, where various types of fasteners (for example, slate nails or finishing nails) are sold, in order to obtain comprehensive information on the types of dowel fixtures. They will also advise you on how to use the dowel-nails. However, this information, after carefully reading the article prepared by us, for sure, you will no longer need. You can easily mount fasteners to any type of surface without any help!

Advantages and disadvantages

A variety of fastening systems are used in construction. However, for specific cases and types of structures, the most suitable options should be selected. For example, for roof construction work, screw roof nails are best suited.

The important advantages of using are the following factors:

- due to the rotary movement during installation, the surface of the wood is not damaged;

- high adhesion strength is ensured;

- fastening remains reliable for a long period of time, excluding extrusion from the material;

- resistance to dynamic, vibration and other types of load;

- the possibility of fastening using more flexible materials, such as chipboard.

The design features can be seen in the photo of screw nails. But at the same time, they have several disadvantages. First, they are more expensive than their sleek counterparts. Secondly, the presence of a thread makes it difficult, and sometimes simply excludes, the possibility of disassembling the fastened structure and reusing the nails. Just like other metal products, they corrode, which leads to damage to the wood.

What do self-tapping screws for aerated concrete look like?

Self-tapping screws are fasteners that are made in the form of rods with heads. They have a special external thread with which they are screwed into the surface. That is, self-tapping screws are rod screws that have been threaded using a special variable method.This method helps to ensure anchoring and good adhesion to concrete structures. The self-tapping screws resemble a long rod with a pointed end on one side and a round cruciform head on the other.

For concrete structures, special hardware products are needed. Manufacturers took this fact into account, and on store shelves you can always see self-tapping screws for aerated concrete and ordinary concrete. To screw in any other hardware, you first need to drill the required hole diameter, in concrete structures this can only be done with the participation of a hammer drill or an impact drill.

We offer you to familiarize yourself with the Hanger with your own hands made of wood

Masonry dowel installation rules

Considering the fact that it is somewhat more difficult to install the dowel fasteners designed for bricks than fixing the dowel used for concrete work in the wall, you should understand this procedure in more detail. In this situation, it is very useful to take advantage of the experience of specialists who are often faced with the need to reliably fix objects that have even a very significant weight on brick building structures.

During installation, the distances from the edges and between the dowels must be observed, depending on the size of the dowels and the depth of anchoring.

If in order to fix a dowel for work on concrete in a building structure, which is hammered in like a simple nail, it is enough to use a minimum set of tools, then for a neat and reliable fixation of fasteners in a brick wall you will need:

- a hammer drill or drill needed to drill the bore hole;

- drill of the appropriate diameter;

- glue designed for laying ceramic tiles;

- a set of rubber spatulas of different sizes.

Dowel installation procedure

The very procedure for installing a dowel into a brick wall consists of the following steps.

The first thing to do is to carefully drill a bore hole for mounting the fastener. This can be done using an electric drill or a hammer drill, on which the drilling-only mode (no impact) is enabled.

It is important that the diameter of the drill used to perform this procedure exactly matches the diameter of the dowel itself.

After drilling, the hole must be thoroughly cleaned of construction dust and pieces of material that has crumbled into its internal cavity. You can check how thoroughly you cleaned the hole using the dowel itself: it should enter without difficulty and obstacles.

When the hole is thoroughly cleaned, you can start working with dry tile adhesive, which must be diluted with water in the proportion indicated by the manufacturer.

After the glue mass is ready for use, it is necessary to fill the hole drilled for the dowel with it. You can use a rubber spatula for this, and you can push the glue mass into the depth of the hole using the dowel itself or a regular pencil. When the hole is completely filled with adhesive mass, you can insert a dowel into it, which should go into it until it stops. After that, it is necessary to allow the adhesive composition to completely solidify, which is quite enough 24 hours.

After the tile adhesive has completely hardened, you can screw a threaded element (stud or screw) into the dowel

In this case, be sure to pay attention to the fact that screwing in occurs with some effort. This means that your dowel is firmly anchored in the brickwork.

Fasteners obtained using such a simple technology are highly reliable and can withstand even significant weight loads.

You can also use this method if you need to install fasteners in a porous material (the use of concrete dowels for such structures is also prohibited). Such materials, in particular, can be gas or foam concrete, porous bricks, etc.Given their high popularity in the modern construction market, the choice of fasteners that could ensure reliable fastening of objects fixed to such structures is a rather serious problem.

In conclusion, we suggest you watch a couple of videos that highlight some of the nuances of installing dowels into bases made of various materials.