Mixing methods

For the quality of the masonry, it is not only the characteristics of the brick that is used that are responsible, but also the method of preparing the mixture itself. Consider the most popular and effective methods for preparing cement mortar:

- The most popular recipe is a mortar to which sand and cement are added. It is quite durable, but when preparing it, it is necessary to strictly observe the proportions: even the slightest deviation from the norm can result in the formation of a large number of cracks.

- Lime-based mortar (lime). Its advantage lies in its high plasticity. The disadvantages include the fact that it is not moisture resistant, so if you intend to use it on the outside of the structure, be prepared for the fact that it will simply be washed off by rain.

- The next type is called mixed. And this is exactly the case when they took all the best and put it together. It has excellent strength combined with good ductility.

- Mortar with cement in the base and additives in the form of plasticizers. This composition is characterized by the improved qualities of the previous type, that is, a mixed solution. And thanks to the presence of plasticizers, it is much more convenient and faster to work with it.

But on what factors does the consumption of cement per 1 m2 of brickwork depend? The most important ones are presented below:

- Choosing a worker. This factor plays one of the most important roles. Indeed, how much mortar will be used for its intended purpose, and how much will be scrapped and how smoothly the brick will be laid, depends on his skill level.

- Brick. He plays an important role. For example, for a hollow brick, the material will take much more than for a solid one.

- And, of course, this is the seam thickness. This value should be between 10 and 12 mm.

Let us consider in more detail the consumption of the cement composition, depending on the type of brick used. So, when applying the mixture to a solid brick base, this parameter will have the following values:

- if the laying is carried out in half a brick (width -12 cm), then the consumption will be 0.19 m3;

- when installed in one brick, 0.22 m3 of mortar will be required;

- with a wall width of 38 cm, about 0.234 m3 of the composition will be needed for high-quality application.

In the case of solid brick, the consumption parameters will be different:

- when laying in half a brick, 0.160 m3 of cement mixture will be consumed;

- if the application is carried out on a base of one stone, you will need 0.200 m3 of solution;

- when laying one and a half bricks, the consumption will increase to 0.216 m3.

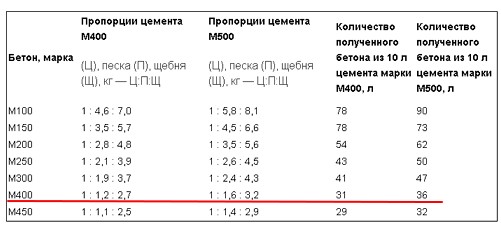

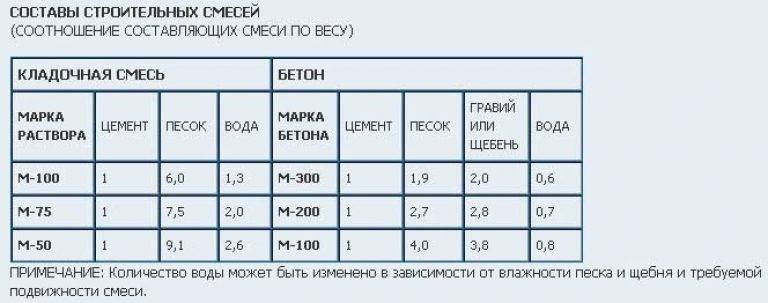

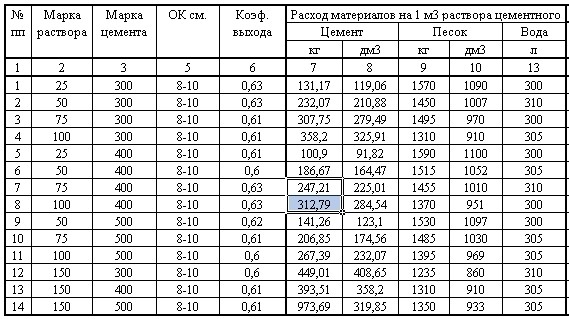

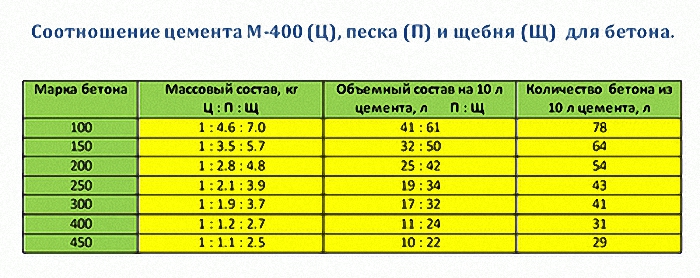

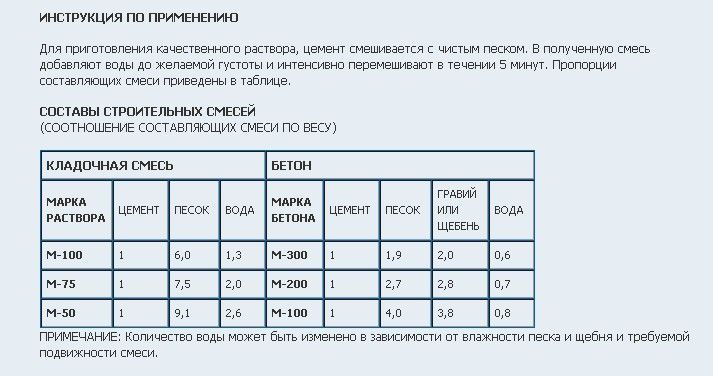

And now let's move on directly to the cooking standards. And for this, below is a table indicating the brand and ratio of all the components included in the composition.

|

Concrete grade |

Mass composition Cement: Sand: Crushed stone, kg |

Amount of concrete from 10 liters of cement, l |

|

M100 |

1: 4,7: 7 |

78 |

|

M150 |

1: 3,5: 5,7 |

64 |

|

M200 |

1: 2,8: 4,8 |

54 |

|

M300 |

1: 1,9: 3,7 |

41 |

|

M400 |

1: 1,2: 2,7 |

31 |

Do not make too much grout. After all, do not forget that the mixture freezes very quickly in air. Of course, if you want to save your time and effort, you can go to the store and buy everything ready, but it all depends on whether you can afford it.

And now a small digression for those who work with solutions in the cold seasons. Many are faced with the fact that when all the norms have been observed and preparatory work has been completed, the structure of the composition is still violated. The thing is that the water used for kneading froze and broke the entire structure. Therefore, to avoid such adverse effects, salt or other antifreeze additives are added to the solution.

We have analyzed all aspects related to work, but there are still many useful tips that can make your work not only easier, but also of high quality, and maybe even financially not too expensive.

What mortar is needed for bricklaying

Correctly formulated masonry mortars must comply with the following standards:

- Competent choice of recipe for mortar for masonry, proportions of sand and cement and volumes of raw materials.

- The use of quality components.

- Thorough preparation of materials.

- Compliance with production technology.

- Optimum plasticity of the mixture. This parameter contributes to the effective filling of recesses in masonry layers.

- Curing time. Large volumes of mortar that harden quickly are unusable. To eliminate this phenomenon, you need to add lime to the composition.

- Increased strength. When the mixture hardens, the strength characteristics of the cement layers will be increased, and the brick wall will become resistant to deformations and other negative factors.

To ensure the effective formation of solid CPL, it is necessary to correctly select the proportions of the solution. In the process of the reaction of the components with water, the strength indicators increase, and the binder component combines the building materials into an integral structure.

Regardless of the formulation used, the masonry mortar and the proportions of sand and cement must include the following ingredients:

- Knitting part. In most cases, masonry cement is used, which begins to harden when interacting with the liquid, combining with the rest of the mortar.

- Filler substance. Designed to improve the performance and increase the volume of the mixture.

- Liquid. The water is used to react with the astringent part of the additive and aids in normal hydration.

The role of a substance with astringent properties can be played by the following types of raw materials:

- Portland cement.

- Lime.

- Lime-cement mixture.

When figuring out which cement is best for laying bricks, it is necessary to take into account the type of tasks for which it will be used and the characteristics of the brand.

Cement mortar for brickwork must also contain additional components, including:

- Additives for increasing frost resistance. Their task is to prevent crystallization of the liquid under the influence of frost and to normalize hydration.

- Plasticizing additives. They contribute to the workability of the working composition and facilitate its operation.

- Hardeners. They improve the process of polymerization of binder additives and reduce the period of a set of strength indicators.

- Dyes. With the help of colored pigments, you can change the range of materials and improve the aesthetic properties of the wall.

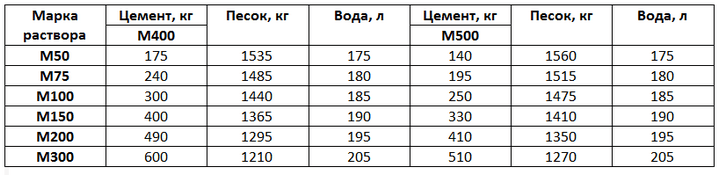

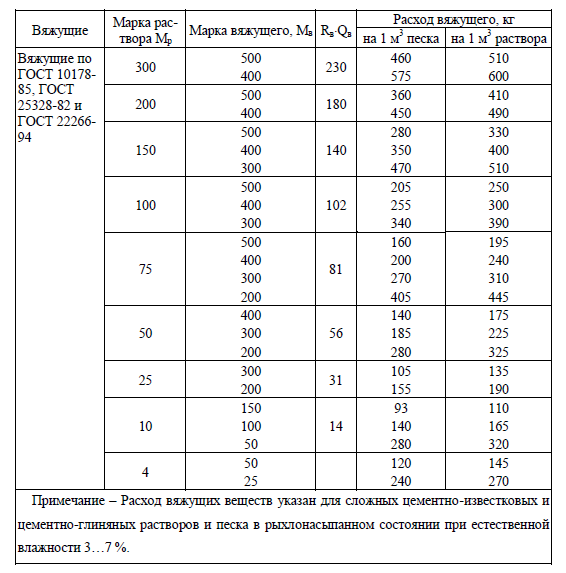

The final grade of the composition is determined by the proportions of sand and cement for brickwork. As the content of sand increases, the grade decreases, and as the proportion of cement increases, it increases. For mixing mortars, different brands of cement-sand mixture are used for brickwork, but the most common is M75. In this case, the proportions of cement and sand for brickwork are selected in a ratio of 1: 5: 0.8.

The masonry mortar can differ in a different ratio of ingredients. They are selected taking into account the purpose and scope of application.

Lime

For the construction of brick fences and wall structures, it is customary to use mortars for brickwork with high plasticity. Therefore, lime combined with sand is added to their composition. Dry additives are thoroughly mixed, and then filled with liquid. Then the ingredients are mixed again until a creamy consistency is formed without lumps and solid impurities.

The optimal proportions are chosen at the rate of 1 part of lime to 2-5 parts of sand.

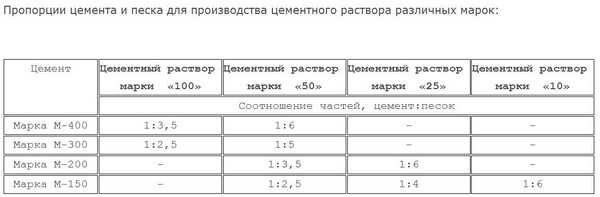

Cement

Interested in how to prepare a mortar for laying bricks, the proportions of sand and cement must be chosen taking into account some requirements.Depending on the brand of the second component, the ratio of the ingredients is determined: for example, 1 part of cement can account for 3-6 parts of sand.

Cement-lime

The composition of a masonry mortar based on a cement-lime mixture is created from the following ingredients:

- Slaked lime, diluted in water to a thick state. The lime mass is carefully filtered.

- Dry cement for masonry and sand.

Each part is thoroughly mixed. The presence of lime in the composition of cement increases the plasticity of the mixture and allows it to be used with any kind of bricks.

Simple mix

A simple mixture is created on the basis of a binding agent and sand. Clay can be used as the first, but this option is in demand only for narrow-profile tasks.

Complex mix

Complex kneading is a formulation of various additives and an astringent base. These include cement-lime-clay and other solutions. The presence of clay in the composition contributes to easy and neat styling.

Mortar for brickwork: composition and proportions

During the construction of a building, a variety of mortars are used for masonry, because everything here depends on the number of storeys of the building, the mobility of the soil and the type of structure that is being erected. Let's find out which mortar for brickwork is applicable in this or that case.

First, let's figure out the types of mortars for brickwork. There are only three of them: lime, cement-lime and cement. Mortar due to low strength, they are rarely used, although to improve the qualities of cement - yes.

Lime-cement mortar consists of slaked lime, which is diluted with water to the thickness of milk, cement and sand. To prepare such a solution, cement and sand are thoroughly mixed, after which strained lime is added. This simple technique allows you to increase the plasticity of the solution, so it is much easier to work with it. This mortar can be used for almost any type of brickwork.

Normal cement mortar also very often used in construction. It consists of sand and cement. The amount of sand in the cement slurry depends only on the quality of the cement purchased. Cement mortar is inferior to cement-lime in terms of mobility, therefore it is more difficult to work with it.

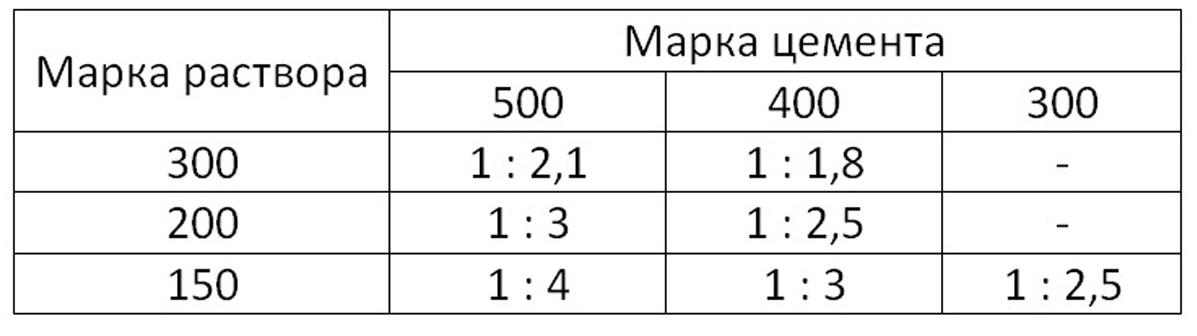

Now let's look at the brands of solutions. which are used in construction

The brand is very important to know, since the proportions of the mortar for laying bricks directly depend on it

M50 solution usually use for sealing gaps and seams indoors during renovation. M75 used for partitions and walls indoors. For outdoor masonry, this solution is used only for the construction of temporary structures.

M100 brand solution used to fill the seams of panels, floor screed, masonry (from solid and large bricks). It is allowed to use mortar for laying the underground part of the brick foundation.

M150 brand solution used for filling seams of structures made of heavy concrete and screeds. This solution has a very high strength, therefore, in it, as well as in higher grades, it is unacceptable to use components that provide greater elasticity (lime, gypsum, clay).

For masonry work, they are almost never used solution M250... since it is used mainly for the manufacture of especially strong screeds and for the installation of monolithic unloaded floors.

Now let's deal with the proportions of the components for the solution... Usually, for the preparation of a solution, the following ratio is used: from 1: 3 to 1: 6 (cement-sand). The amount of sand depends on the quality of the cement. The higher the quality of the cement, the more sand will be required to prepare the mortar.

For preparing M100... as one of the most popular mortars for masonry, a simple ratio of 1: 4 (if cement grade M400) or 1: 5 (cement M500) is used.To make the solution more elastic, lime can be introduced into it, in this case the proportions for M100 will be as follows: 1: 3: 0.2 (cement M400, sand, lime) or 1: 4: 0.3 (cement M500, sand , lime).

When preparing a good solution, you should take optimal amount of water... For a conventional cement mortar, the optimal amount is considered to be 0.8 parts of water per 1 part of cement. To prepare the mixture, use only cold and clean water!

In many ways, the quality of the solution depends on the sand. It must be clean, without various stones. For masonry mortars use construction sand with a grain size of 2 to 2.5 mm... Before preparing the solution, sand must be sieved, because this way it mixes much better with cement.

Never do not prepare a lot of solution... after all, after only 30 minutes, it becomes unusable. Also keep in mind that the finished solution should be stirred from time to time. When heavy particles settle to the bottom, the solution becomes heterogeneous and stratifies. It is impossible to make masonry with such a solution.

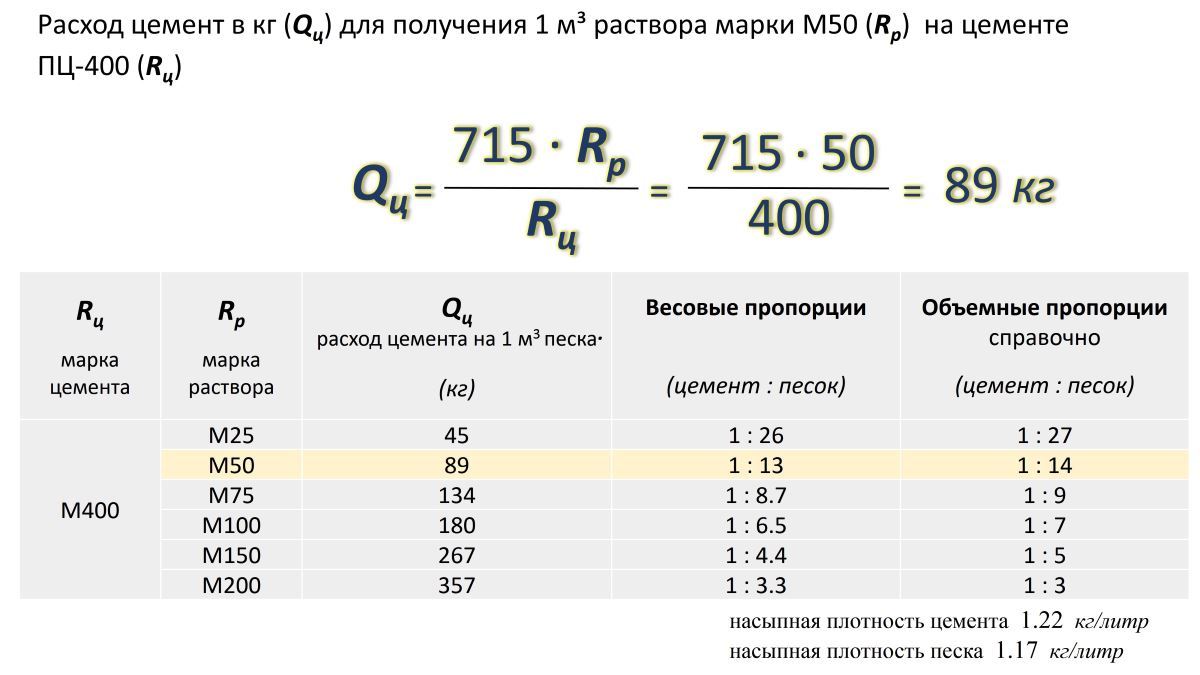

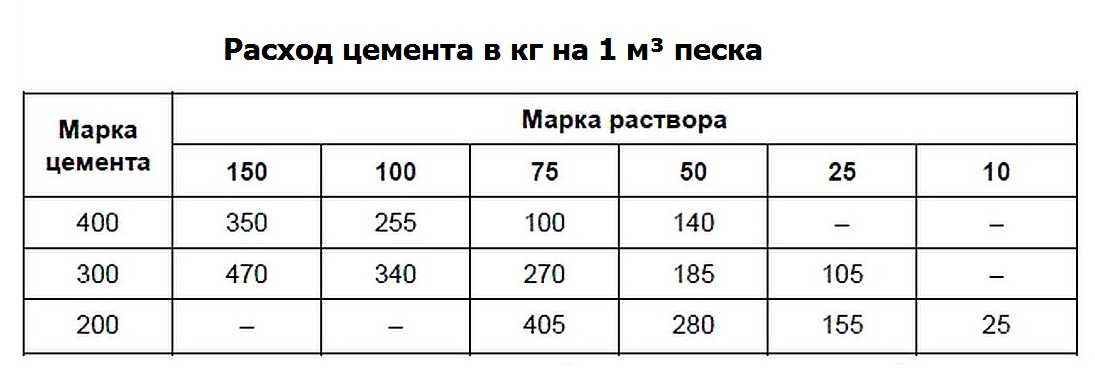

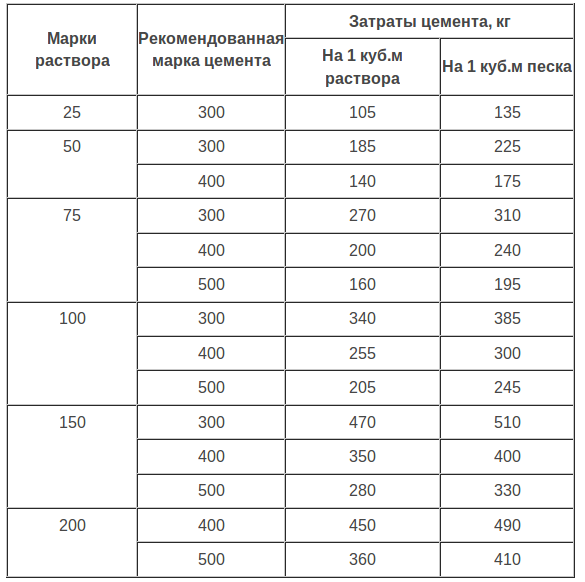

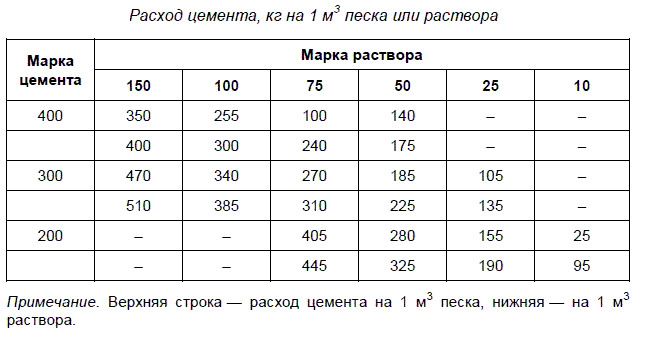

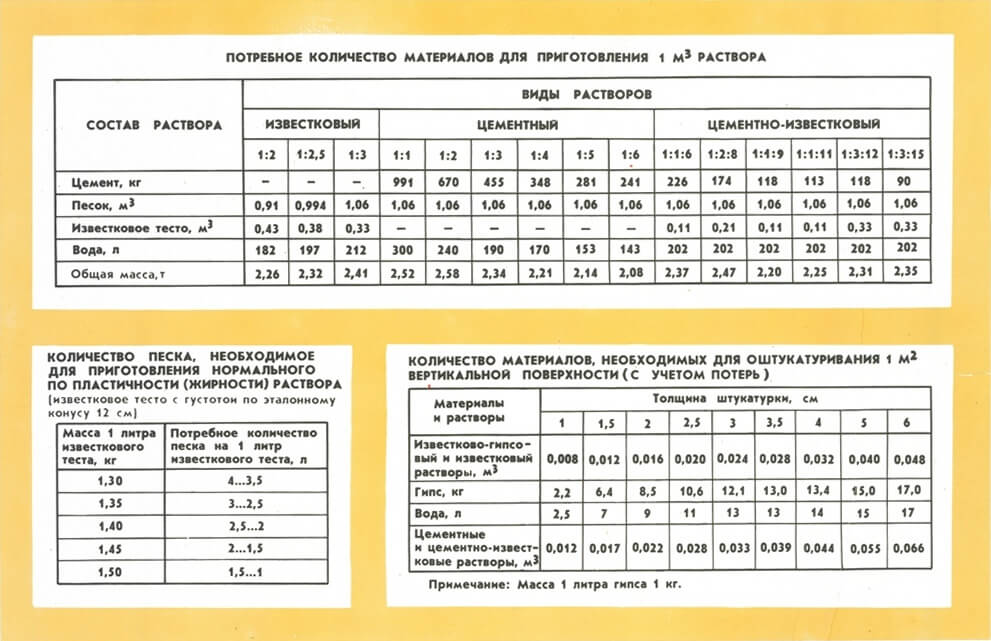

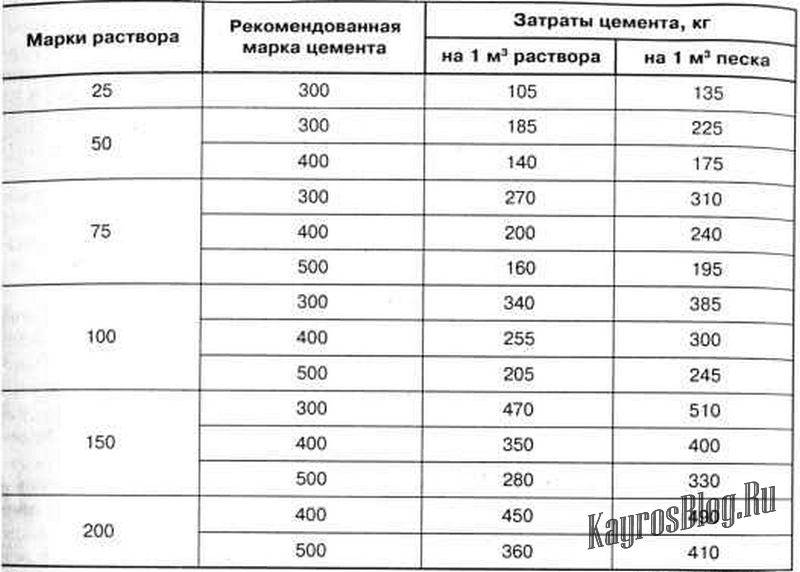

Consumption rates for different solutions

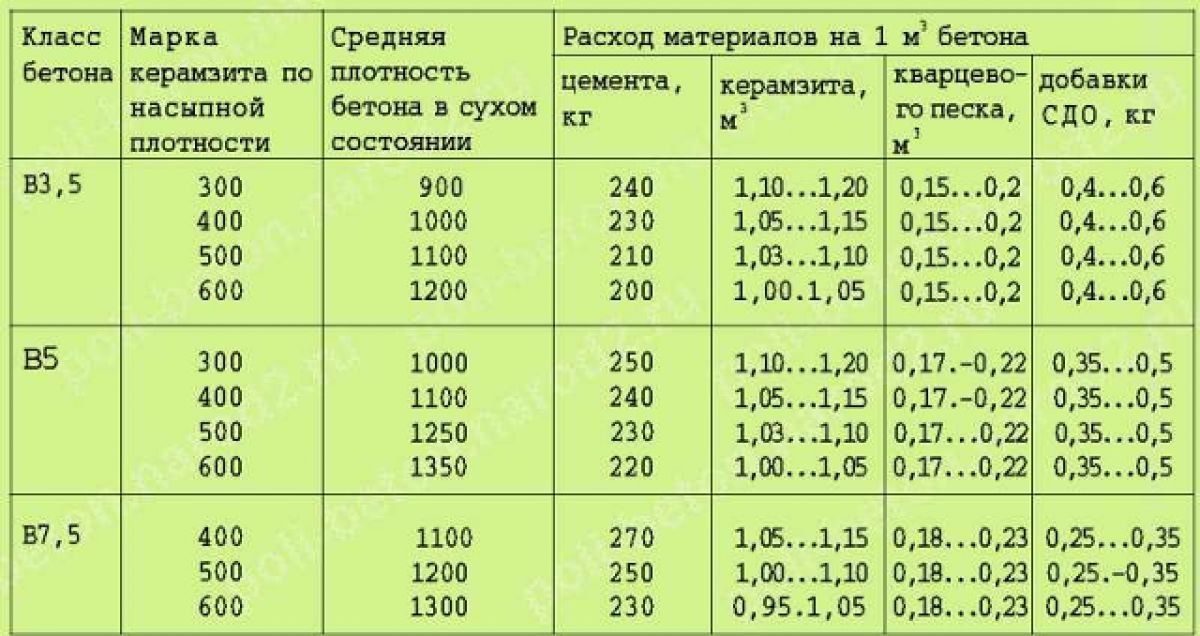

Depending on what the concrete is for, 1 m3 of mortar may contain a different volume of cement. In modern construction, concrete solution is used to implement four tasks: pouring the foundation, laying building blocks, pouring the screed and making plaster. For each of these types of work, it is assumed that a certain type of solution is prepared with a specified volume of cement.

The largest consumption of cement per cube of mortar is obtained in the preparation of a mixture for masonry or plaster. For pouring a foundation or screed, it is important to use large fillers (gravel, crushed stone, slag), which reduces the consumption of cement. The brand indicates the purpose of the solution (the properties of concrete and the main characteristics depend on it).

Calculation of cement per cube of concrete according to GOST:

- М100 - 170 kilograms of cement

- M150 - 200 kilograms

- M200 - 240 kilograms

- M250 - 300 kilograms

- M300 - 350 kilograms

- M400 - 400 kilograms

- M500 - 450 kilograms

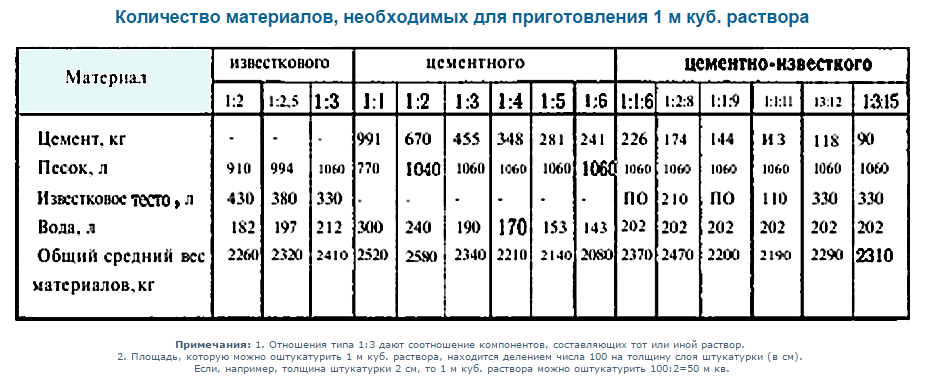

On plaster

A standard plaster mortar is prepared from 3 parts sand and 1 part cement. If the layer is made with a thickness of no more than 12 millimeters, then 1.6 kilograms of M400 cement and 1.4 kilograms of M500 cement are weighed per 1 square meter of plaster. The volume of solution per cubic meter of masonry can be calculated as follows: 1m2 x 0.012 m = 0.012 m2 = 12 liters.

On masonry

For a square meter of brickwork one brick thick, you will need at least 75 liters of M100 mortar. The proportion of cement grade M400 and sand is 1: 4. Thus, the consumption of cement for laying bricks is 250 kilograms per cubic meter of sand. How many cubes of solution will be needed in general is considered by the size of the building.

Water is taken in the volume of half the weight of the cement. So, if you knead the solution using buckets, it turns out like this: 1 bucket of M500 brand cement, 4 buckets of sand, 7 liters of water.

For the foundation

To prepare a solution for pouring a foundation, everything must be calculated correctly. Usually, a solution of the M100-M300 brand is used. The strength of M100 is sufficient for low-rise buildings, M150 and M200 are suitable for a building with several floors. The higher the grade, the stronger the structure will be. For mixing, take cement M300 / M400 (1 part binder and 3 parts sand) or M500 (1 part binder and 5 sand).

Cement consumption per cubic meter of solution:

- M50 (based on M400 cement) - 380 kilograms

- M100 (based on M300 cement) - 214 kilograms

- M200 (based on M400 cement) - 286 kilograms

- M300 (based on M500 cement) - 382 kilograms

Such calculations are relevant if the mixture is prepared according to the proportion: 1 part of cement, 2-4 parts of sand, 3 parts of crushed stone / gravel.

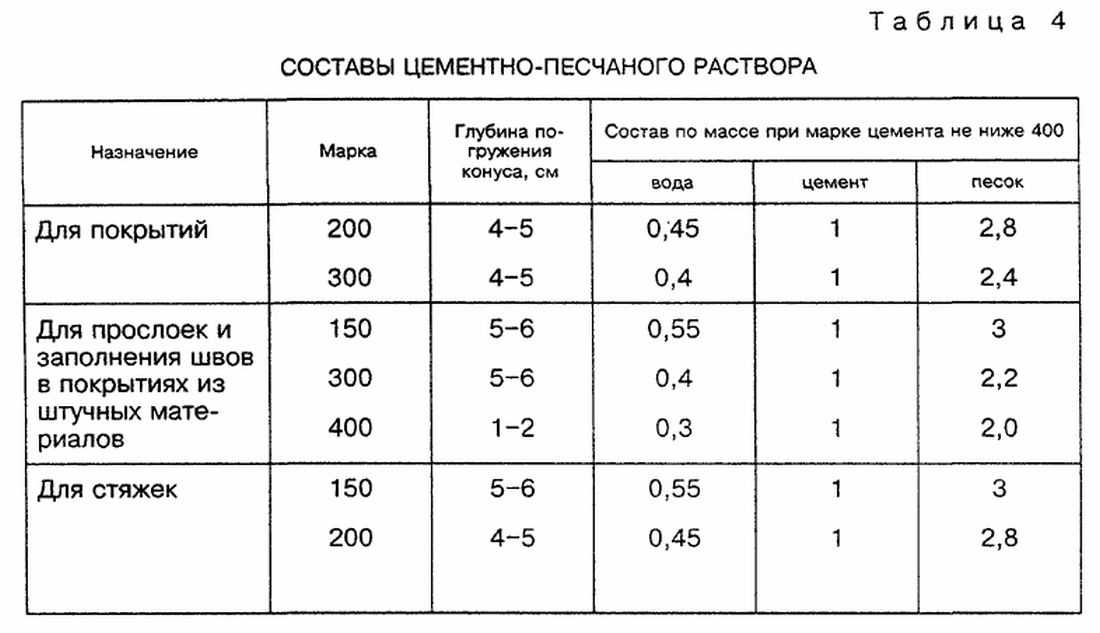

For screed

The proportion for mixing is as follows: 1 part of cement and 3 parts of sand. Here is an example of correct calculations. So, you need to fill the surface of 3 by 4 square meters (12 turns out) with a layer thickness of 30 millimeters.

Calculation stages:

- Determination of the required volume of concrete solution: 12 m2 x 0.03 m = 0.36 m3.

- Choosing a concrete grade - we take M200, we prepare it from M500 cement, which needs 410 kilograms.

- Counting the number of bags of cement: 410 kg x 0.36 m3 = 148 kg / 50 = 3 bags (almost).

- How much sand is needed: 1600 kg / m3 (weight of a cubic meter of the mixture) x 0.36 m3 (the required amount of the mixture) = 576 x 0.75 (proportion of sand in concrete) = 432 kilograms. A cube of sand solution will take about 1200 kilograms.

Quantity per brick laying

The quality of the masonry is determined not only by the characteristics of the brick, but also by the mixture used. You can prepare such a composition according to various recipes, we will consider only the most popular ones:

Sand and cement based

The resulting solution is characterized by high plasticity, however, it is unacceptable to use it for outdoor masonry, since it is simply washed out by rain.

A mixed type of mortar, which involves the use of both cement and lime. Thanks to this combination, it is possible to obtain a durable and plastic composition.

Cement-based mortar with the addition of plasticizers. Thanks to the introduction of additional components, it becomes possible to improve the quality of the solution, to give it strength, plasticity, and most importantly, it is very easy to apply.

If you are going to decorate the facade, then you can apply various colored pigments to the solution. Then the seams and the masonry itself will have a spectacular look.

The video shows how to calculate the cement consumption:

When making a mortar for brickwork, the same requirements are always presented: stir thoroughly so that the mixture does not contain lumps. As a result, you should get a solution of a homogeneous structure. To achieve this effect, you must first mix the dry ingredients, and then add the liquid. It is not worth preparing the mixture in large quantities, since under the influence of air it begins to set quickly.

For the laying of load-bearing walls, it is necessary to use cement, the grade of which is higher than in the construction of self-supporting structures. The proportions are determined taking into account which brand of cement is used. Let's consider all this with an example:

- For the M500 binder, it is worth using the proportion in which the cement relates to sand, like 1: 4.

- For the M300, the ratio is 1: 2.5.

- For M400 - 1: 3.

Of course, you can not waste your time preparing the solution, but go to the store, where all these products are presented in finished form. In this case, information about the consumption will be present on the package.

As for the consumption of cement per 1 m3 of masonry, this parameter depends on the following factors:

- seam thickness, which can take a value of 10-15 mm;

- the qualifications of the worker, whether he puts a large amount of mortar on the brick, how much of the mixture becomes unusable;

- type of brick: for ceramic or silicate stone, more mortar is required than for laying facing, hollow requires more consumption of the mixture than corpulent.

If the construction process is carried out using solid bricks with different wall thicknesses, then the mortar consumption will be:

- when laying in a half-brick, the width of which is 12 cm, 0.19 m3 of mortar will be needed;

- when installed in one brick, the consumption will be 0.22 m3 of the mixture;

- with a wall width of 38 cm, the mortar consumption will be approximately 0.234 m3.

When the construction process is carried out using a thickened or one-and-a-half stone, the mortar consumption will be:

- the width of the wall is 12 cm, the amount of mortar will be 0.160 m3;

- when installing in one stone, you will need 0.200 m3 of the mixture;

- when laying one and a half stones, the consumption will increase to 0.216 m3.

.

How much powder and sand to take

The proportion of the constituents is largely determined by the grade of the starting materials. Sand, cement are the leading ingredients. The higher the brand, the more cement powder will be needed, and the better the mixture will be. As for the brand, it is selected individually, depending on the type of construction work.When forming foundations and building serious objects requiring high strength, it is recommended to use a solution of higher grades.

Types of cement mortar.

There are 3 types of solutions: for masonry, plaster and cladding. In the latter case, grades M-200 and M-300 are suitable. For masonry work, it is preferable to take mortar of the M-150, M-300 and M-400 brands. Often there are situations when it is necessary to carry out a cement floor screed. For this, a mixture based on cement and sand of the M-150 and M-200 brands is suitable.

The proportion of cement and sand depends on the grade of the cement powder itself. In most cases, powder grades 400 and 500 are taken. To make a solution of the M-100 brand, the ratio of sand and cement should be 1: 4, provided that 400 powder will be taken. This proportion is determined in mass equivalent of the substance. In the event that the cement powder is grade 500, then the proportion is 1: 5. No gravel or crushed stone required. If you need to get a mixture of the M-200 brand, then the amount of raw materials will be different. Here, for 1 kg of cement, only 2 buckets of sand are needed. Everything suggests that the higher the required grade of the solution, the better the cement needs to be taken, and the more its consumption will be.

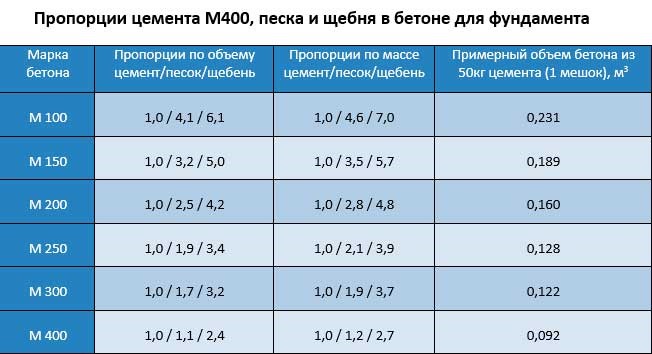

Mixing proportions for concrete

To knead a cubic meter of concrete, you need to stock up on raw materials. Not everyone knows how much rubble is in a cube of concrete. Crushed stone is a coarse-grained raw material that gives strength and rigidity to the structure when solidified.

Concrete mixing scheme.

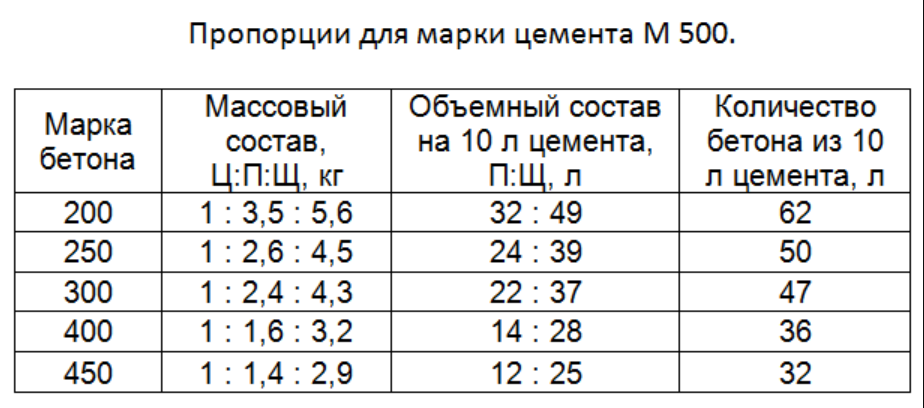

To obtain reliable concrete, for example, of the M-300 brand, you will need cement, sand and crushed stone in a ratio of 1: 1.9: 3.7. This rule only applies when 400 cement is used. If grade 500 powder is available, the proportion will be 1: 2.4: 4.3. In the construction of critical structures requiring special strength and wear resistance, it is preferable to use concrete M-400 and higher. To get a cube of concrete, you need a lot of raw materials. In this case, the ratio of the three main substances is 1: 1.2: 2.7, taking into account the fact that concrete grade 400 will be obtained (in the presence of powder 400).

It is also important that when mixing concrete, the following factors must be taken into account:

- size of sand and coarse material (crushed stone or gravel);

- the quality of the future concrete;

- density of raw materials.

Don't forget about water. The latter is the link between all bulk components. If there is a lot of it, then the solution will turn out to be liquid and less durable.

It is also important to mix the raw materials correctly. In this case, concrete or cement-based mortar will have a homogeneous structure, reminiscent of sour cream.

If you plan to mix a large volume of components and get a cube of concrete or more, then you cannot do without a concrete mixer.

A situation may arise when it is required not only to calculate the consumption of raw materials, but also to determine the brand of the resulting solution. This will require accurate data on the mass of the raw materials used. If it took 1 bucket of cement 400 and 4 buckets of sand to make the mixture, then you need to divide the brand by 4 (400/4 = 100). As a result, it turns out that there is a grade 100 solution available. The same is true if there is a grade 500 cement and 5 buckets of sand.

Peculiarities

Cement has long acquired the status of the most demanded material used for construction. With its help, concrete is obtained, which is used for the foundations of future structures. The cement composition is the main binder for obtaining a concrete mixture.

Powder is made by grinding clinker and further adding minerals and gypsum. Thickened cement can be adversely affected by aggressive media and plain water. To improve the characteristics, a hydroactive material is added to the cement composition, which prevents the penetration of salts. Corrosion resistance increases with the addition of a special polymer additive to the initial composition of the raw material, which significantly reduces porosity and prevents adverse physical and chemical effects on the environment.

All kinds of cement compositions absorb different volumes of water. The grain size of the material has a fairly high density, three times the density of water. As a result, when a large amount of water is added, part of the cement will not dissolve, but will end up on the surface of the prepared solution.Therefore, the material will settle, and the top of the structure from the resulting cement mortar will turn out to be an unstable and cracking structure.

To determine the grain size composition, the material is sieved through a sieve with meshes of less than 80 microns. With a high-quality cement composition, the largest part of the mixture is sieved. But at the same time, do not forget that fine grinding is of better quality, but in the future it will require a larger volume of water. Therefore, it is recommended to give preference to a composition with both small particles (up to 40 microns) and large (up to 80 microns). In this situation, the cement mixture will have all the necessary and acceptable properties.

The possibility of thawing and freezing is one of the main characteristics of the cement mixture. The water in the porous areas of the cement structure expands in volume up to 8% at low temperatures. When this process is duplicated, the concrete cracks, which contributes to the destruction of the constructed structures.