How to buy M100 solution

You can order this building material in several ways:

- make an application directly on the site, through the purchase form;

- by phone from managers;

- make a request for a call to your company;

- in the sales office of our company.

The price for M100 masonry mortar is negotiated additionally in each specific case. Transportation conditions are strictly agreed with the customer. Payment can be made in a way convenient for your company. Manufacturing facilities allow delivery to your site even on the day of order. The building material is completely ready for use and can be used immediately in construction work.

If you have any questions, please call / 8-967-593-17-23 (Anna) or use the feedback form. Our experts will help you! We are waiting for your applications!

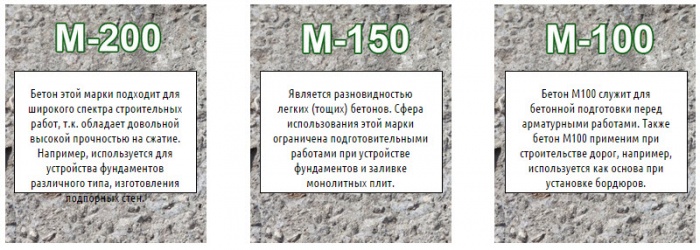

Other grades of concrete

Do-it-yourself solution preparation

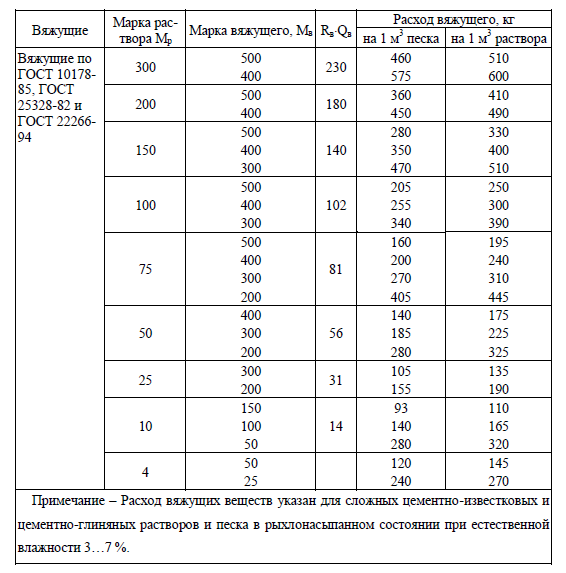

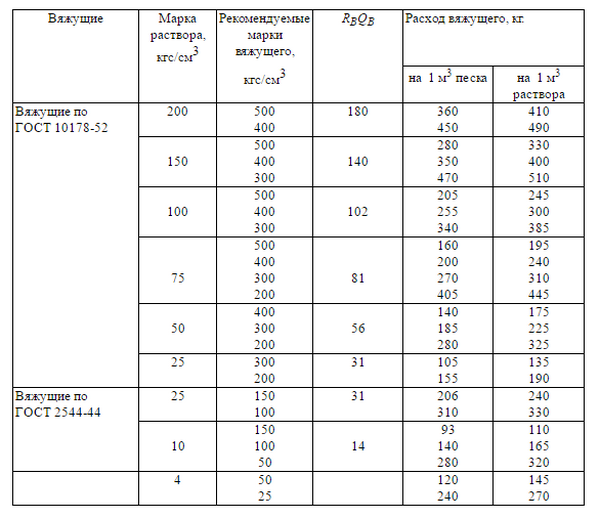

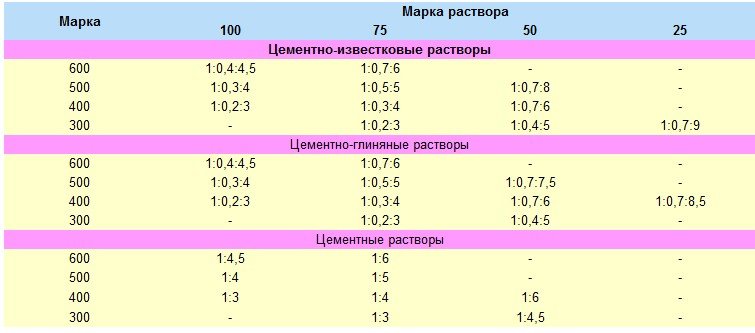

In addition to ready-made production options, it is possible to make the lime mortar yourself. Buy all the necessary high-quality elements and carefully observe the proportions to achieve a high-quality result while saving money. The main ingredients used are cement, sand, lime and water.

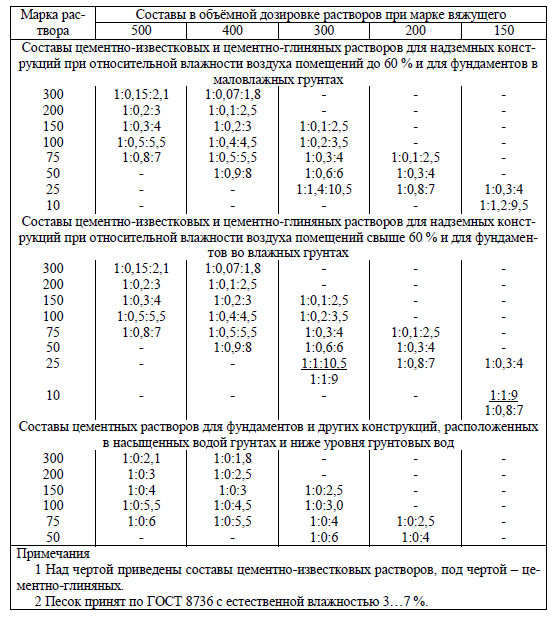

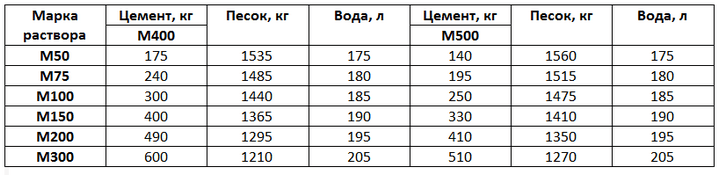

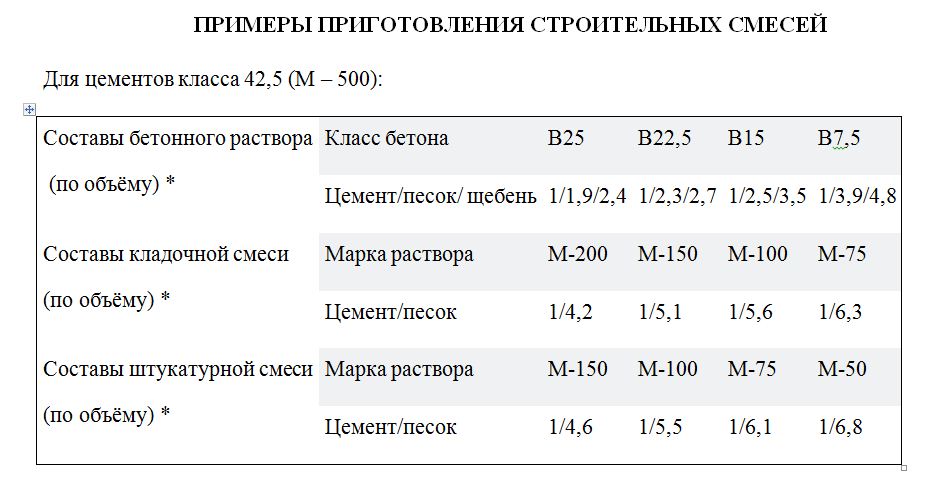

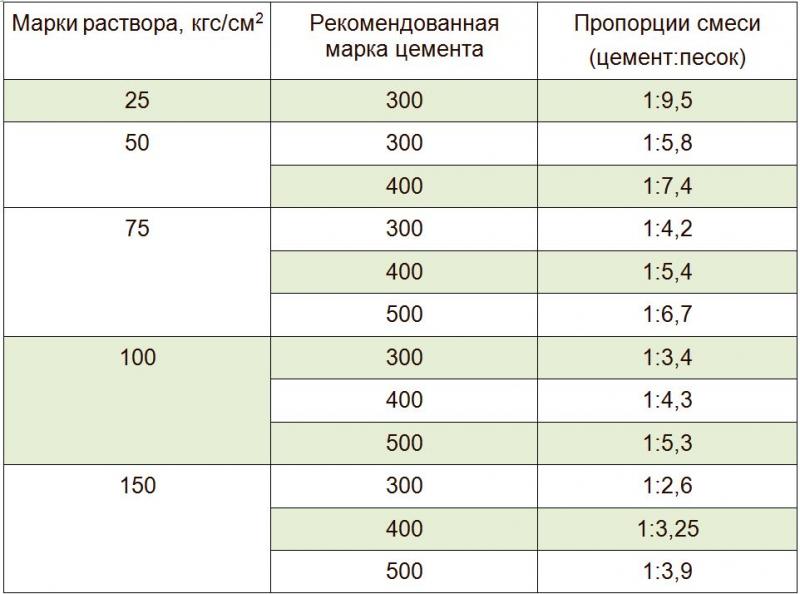

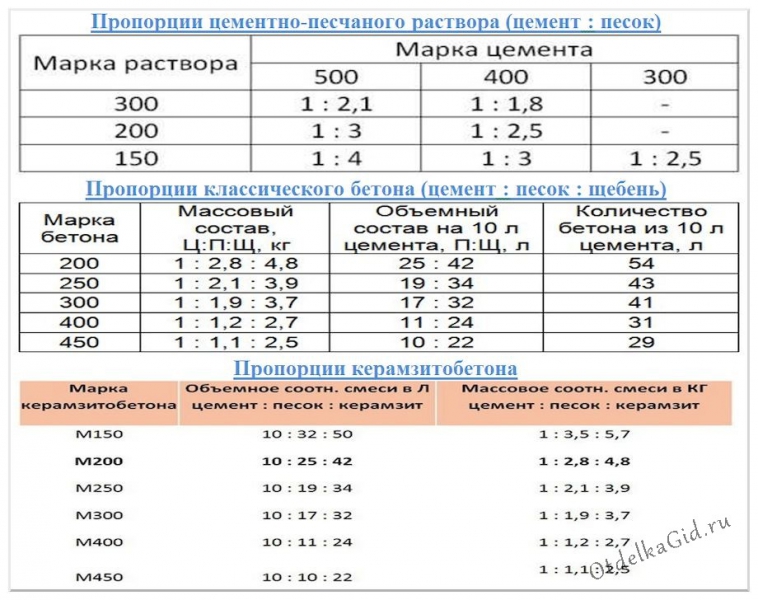

The ratio of ingredients determines the brand and specifications.

| Cement grade for preparation |

Lime composition brand |

||||||

| M200 | M150 | M100 | M75 | M50 | M25 | M10 | |

|

Proportion of components - cement-lime-sand |

|||||||

| M500 | 1:0,2:3 | 1:0,3:4 | 1:0,5:5,5 | 1:0,8:7 | — | — | — |

| M400 | 1:0,1:2,5 | 1:0,2:3 | 1:0,4:4,5 | 1:0,5:5,5 | 1:0,9:8 | 1:1,9:12,5 | — |

| M300 | — | 1:0,1:2,5 | 1:0,2:3,5 | 1:0,3:4 | 1:0,4:5 | 1:1,3:10 | — |

| M200 | — | — | — | — | 1:0,2:3,5 | 1:0,7:6,5 | 1:2:16 |

| M150 | — | — | — | — | — | 1:0,3:4,5 | 1:1,5:10,5 |

| M100 | — | — | — | — | — | 1:0,1:3 | 1:0,8:7 |

The water consumption during preparation is usually 0.8 parts per hour of cement. In practice, the amount of liquid is determined visually by the consistency of the solution - normally the mixture should resemble thick sour cream.

Lime, as a building material, is used only in a quenched form, otherwise, as a result of a chemical reaction, the finished material may swell or burst altogether. You will need a separate container for preparation. The process differs depending on the quenching speed.

1. Fast-extinguishing lime is poured into a barrel with water until it is completely immersed. After the appearance of steam, more water is added and mixed. Extinguishing takes an average of 8 minutes.

2. The medium-quenching lime is poured into a container and filled with water in a double volume. When vaping, water is also added and mixed. The process takes about 25 minutes.

3. Slow lime is only moistened with water. The reaction is accompanied by a threefold increase in volume and an increase in temperature. Takes over 25 minutes.

The prepared material is diluted with water in a 1: 1 ratio to the state of milk of lime. Often, for final extinguishing, it is poured into a special pit, sprinkled with a layer of sand and earth and kept in this way for 15-20 days. The composition acquires a creamy consistency and is now called lime dough or paste.

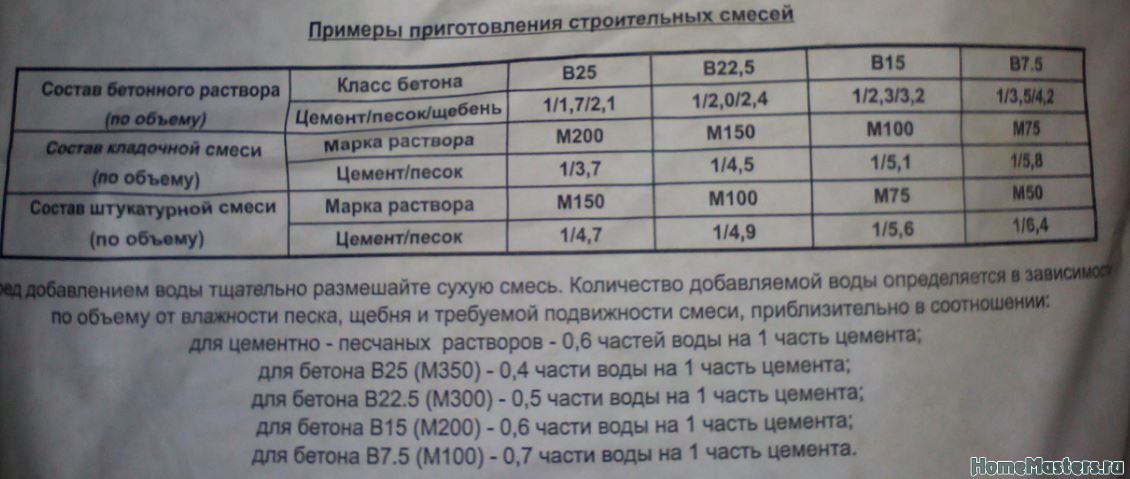

For cement-lime plaster mortar, the most commonly used binder cement is:

- Type I Portland cement with a minimum amount of additives and a high setting rate;

- Portland cement type II, grades M500-400 with an additive content of up to 35%.

As practice shows, three-layer plastering is most often used on construction sites. The proportions of the mortar (water-sand-lime-cement) in this case will depend on the layer of plaster.

- rough layer - spray - 2.2: 6.7: 1.5: 1;

- middle layer - soil - 2.8: 9: 2.2: 1;

- finishing layer - cover - 4: 13.5: 3: 1.

For the preparation of masonry cement mortar, it is more expedient to use a concrete mixer, since in practice it requires more than plaster.The latter, in turn, is prepared in improvised containers using a construction mixer.

In the case of manual cooking, there are two types of procedure:

1. The lime dough is passed through a sieve with a mesh diameter of not more than 3 mm. Then sand and cement are added in portions to it, everything is thoroughly mixed until the required fat content of the solution is obtained.

2. A dry mixture of sand and cement is prepared in the desired ratio. Lime milk is gradually poured into it, if necessary, diluted with water to achieve the required consistency.

To increase the stability of the solution to environmental factors, slow down the hardening process, the following is added to the finished mixture:

- plasticizers;

- frost-resistant additives;

- retarders and others.

Portland cement used in the composition also brings a number of positive characteristics to the material:

1. in combination with the action of hydraulic additives, it provides resistance to leaching, and therefore to prolonged exposure to ground and sea waters;

2. Applies a high level of anti-corrosion protection to the cement;

Specifications

Let us consider in detail what technical characteristics modern cement-sand mixtures have in accordance with GOST.

Density

The thermal conductivity and strength of the cement-sand layer largely depend on the level of its density. In pure form (without additional components), such solutions are quite heavy. They are distinguished by high density, amounting to 1600-1800 kg / m3 in solid state.

Heat conduction properties

Due to the high density, the thermal conductivity of such finishing materials is very high. In a room with such a design, a comfortable temperature and sufficient warmth will always be maintained. A similar effect cannot be achieved with a lighter gypsum with a porous structure.

Vapor permeability

This characteristic is very important for any finishing material. Without it, condensation and excessive dampness will accumulate in the room. Over time, this will lead to the formation of mold and mildew.

Drying time

The drying time of the cement coating directly depends on the thickness of the layer. So, in conditions of temperatures from +15 to -25, a layer of 2 cm will dry out for 12-14 hours. The thicker the layer of the applied solution, the longer it will harden. Experts recommend not to touch the finished surface for another day after all work has been done. Of course, this rule is not categorical, but this way you can avoid damage to the freshly applied cement layer.

How to stir

To create a solution, the amount of sand has already been determined, now you need to be puzzled by the tool. For large quantities of the required mixture, a concrete mixer is best suited, which independently mixes all the components.

Concrete mixer

When small volumes of the mixture are required, it is enough to have a drill with a mixing nozzle, it will quickly and efficiently bring the solution into a homogeneous state. Do not set a high RPM initially, as the cement is very volatile.

Drill with mixing attachment

In extreme cases, make sure you have trowels, a spatula, or any other tool for mixing the mixture.

For the correct dilution of the solution, the basic recommendations should be followed:

- initially water is poured into the container. Usually the amount of water is calculated from a 1 to 1 ratio with cement. When the sand contains a certain moisture, this coefficient can be slightly reduced;

- immerse half of all the sand in water;

- all cement is poured one-time at once. Now you need to thoroughly stir the mixture, about 2 minutes for the procedure will be enough;

- the sand that remains must be added to the solution. Mix again in the way you have chosen;

- check the consistency and, if there is a need for a thinner mass, add more water. The consistency is highly dependent on the purpose of the solution.

Experienced builders point to several main factors that are characteristic of a properly prepared cement mortar.

First of all, it is important to make sure that the mixture adheres to the trowel, and does not have a layer of water, because of which everything disappears, which is characteristic of poor mixing.

It is necessary to mix the mortar thoroughly, otherwise areas with a high cement content and a low amount of sand, or vice versa, will crack instantly. It should also be remembered that cement is added to the water, not vice versa.

For more information on how to mix the cement mortar correctly, see the video:

Scope of cement mortar grade M-200

These mixtures are used for the installation of vibro-brick panels, for filling joints in structures made of heavy concrete, as well as for plastering these buildings.

Since the cement mortar of the M-200 brand is resistant to water, it is often used as a waterproofing. These mixtures must be made using cement M400 or higher. Materials based on such an expanding, waterproof binder are able to withstand a hydrostatic pressure of 5 atmospheres 24 hours after pouring. If the structure will be constantly exposed to chemically aggressive waters, then a mixture containing a certain type of binder should be used - sulfate-resistant pozzolanic cement.

In private construction, ready-made mixtures of the M-200 brand are used for floors made of mosaic, ceramic and granite tiles, clinker bricks, paving stones, concrete slabs, cast iron perforated slabs, and so on.

Preparation

If home renovation involves the use of a small part of the cement mortar, then it is better to buy a ready-made option, which will speed up the process itself, but in the case of a large scale of work, it will be cheaper and more economical to buy the necessary ingredients and mix them yourself.

To obtain a good result, the most important criterion will be the use of the correct proportions of the components that make up the composition.

When preparing to knead the solution, it is necessary to prepare a metal or plastic container in which all the ingredients can be mixed. With the help of a shovel, it will be convenient to pour all the components into the container and mix them.

Using a trowel will allow you to apply a ready-made solution to the surface, but you can also knead a small amount of the substance with it if you need to cover up only a few cracks.

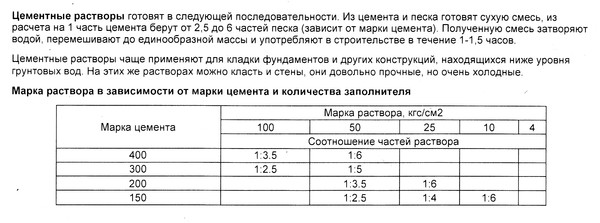

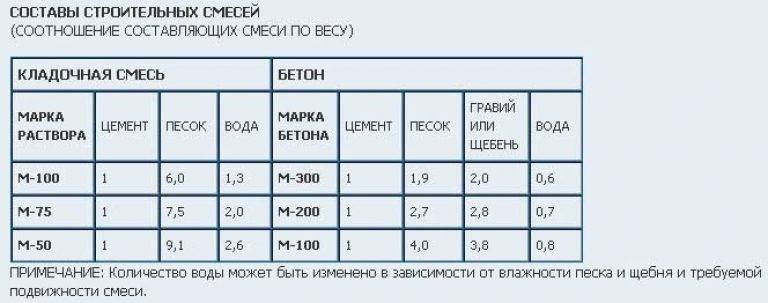

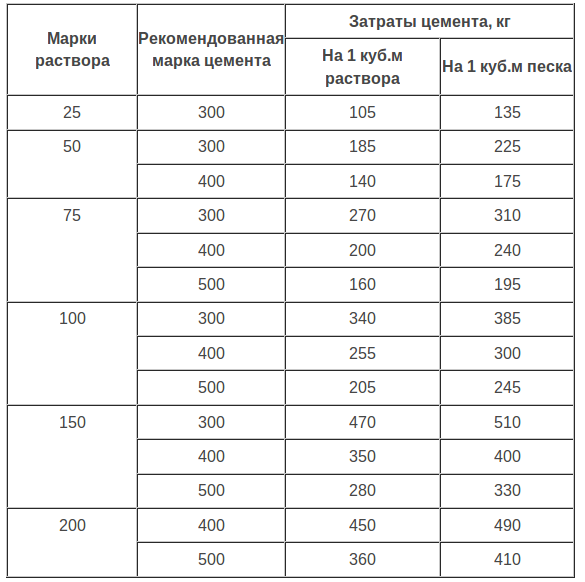

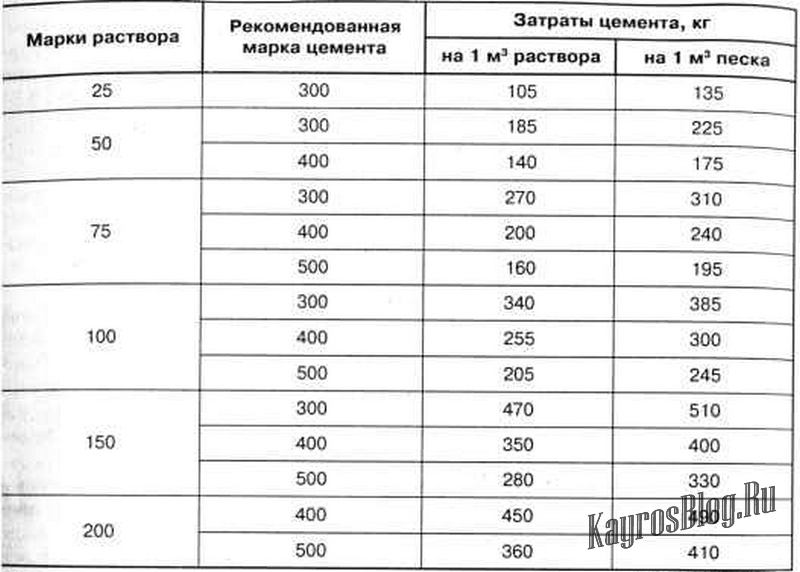

At the first stage of preparation, it is necessary to work only with sand and cement, which must be well mixed with each other. The choice of proportions in this case depends only on the brand of cement that will be chosen.

The resulting cement plaster will be subdivided into the following grades:

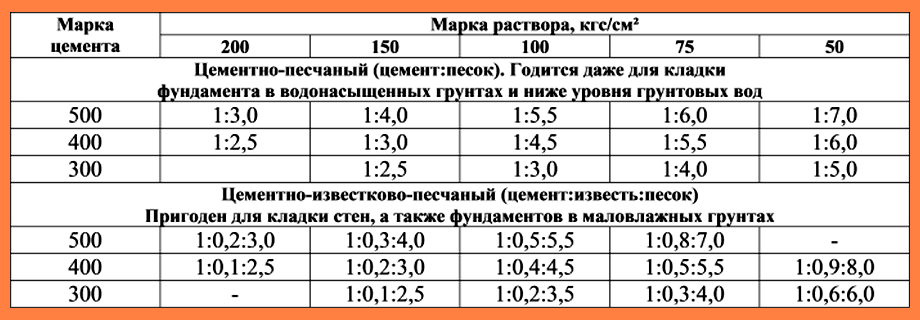

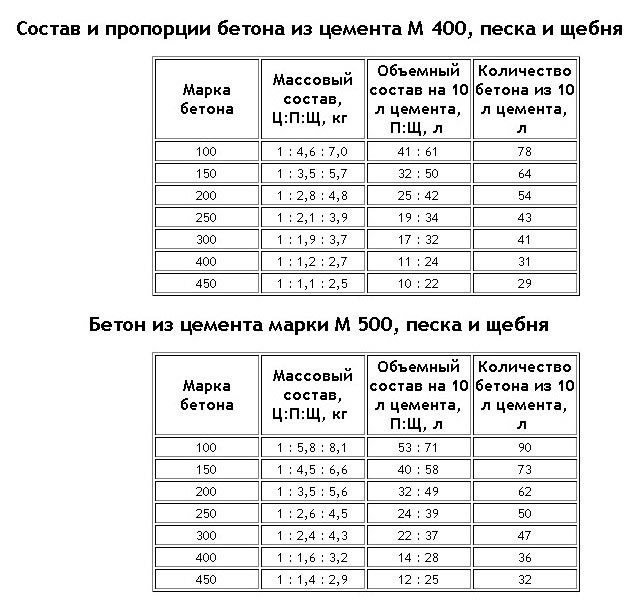

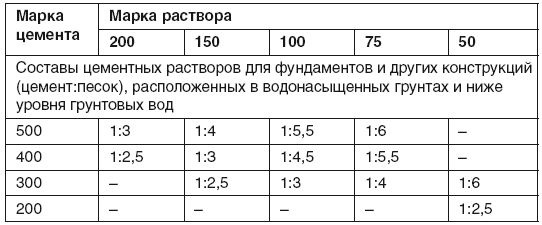

- M200 with grade 200 will have a ratio of sand and cement of 1: 1, with grade 150 it will be 1: 2.5, for 100 it is 1: 3.5, and for 75 - 1: 4;

- M400 with a grade of 200 will have a ratio of sand to cement of 1: 2, at 150 it will be 1: 3, at 100 - 1: 4.5, and at 75 it will be 1: 5.5;

- M500 with grade 200, the ratio of sand to cement will be 1: 3, for 150 it will be 1: 4, for 100 - 1: 5.5, and for 75 - 1: 7.

In order to make a high-quality solution, the first thing to do is to deal with sand. It is sieved through a sieve to eliminate any inclusions. The cement should be relatively fresh, as it can be problematic to work with stale residues. If there is no choice, then it is sieved, like sand, so that you can remove the hardened areas and leave only a one-component composition. In this case, the proportion of sand is reduced by ¼ due to the atypical characteristics of the cement.

In order to dissolve such a mixture, only water is not always enough; often it is necessary to add a plasticizer to it.

There is another option, how you can make a cement-sand mixture, but it involves the reverse sequence of actions. First of all, water is collected, the amount of which in the container should be 4/5 of the required volume.After that, liquid soap or other is added detergentwhich foams as much as possible. Only after that, half the volume of sand and all the necessary cement should be poured into the working container. All contents are mixed until a homogeneous mass is obtained.

The next step is to add the remaining sand, after which the solution must be stirred until it becomes completely homogeneous.

It is very important that the cement and sand mix very well, otherwise the result of work with it will be disappointing. Using this option, you can mix the components much more efficiently and obtain an optimal composition than with dry stirring.

It is important to add part of the water during the final mixing process, which will make it possible to obtain a solution of the desired consistency.

How to cook?

It is quite possible to make a cement-sand mixture on your own. To do this, you should adhere to the correct proportions and not waste time in vain, so that the composition does not begin to dry out. Consider several options for preparing such a solution.

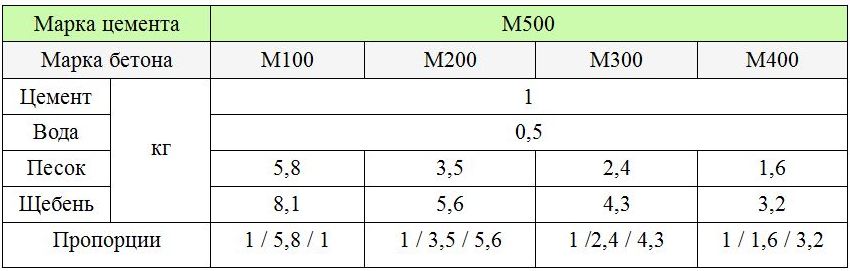

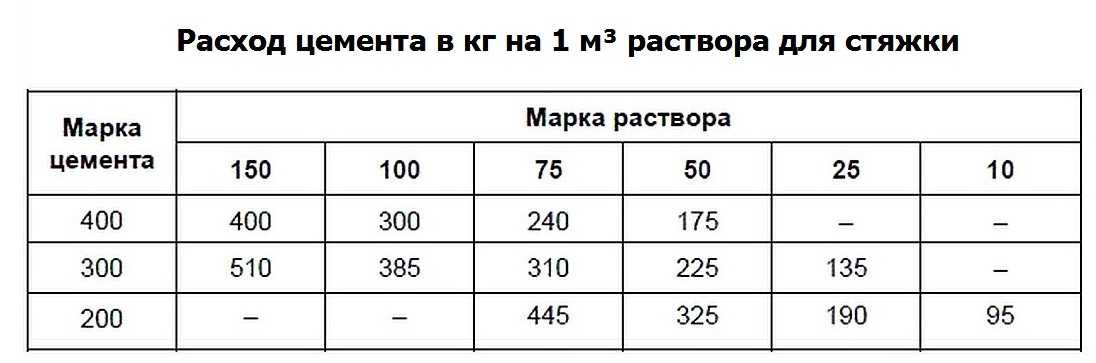

For screed

For such work, cement marked M400 or M500 is most often used. If you chose the 400 grade, then you need to adhere to the proportion of 1 to 2, and in the case of the M500 - 1 to 3.

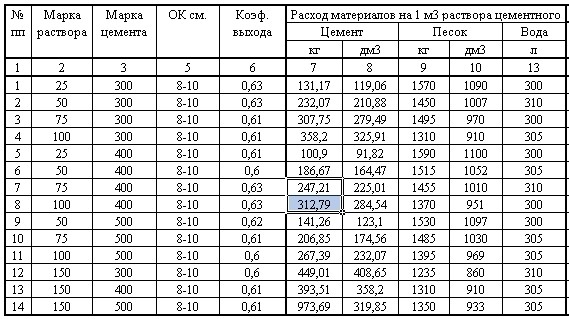

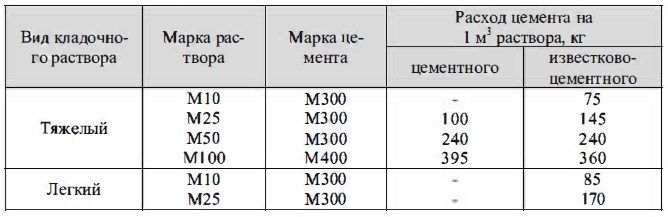

For masonry

In this case, the thickness of the seam determines the quality of the finish. Much depends on how the sand was prepared. It must be carefully sieved and dried. As a rule, 3-5 parts of bulk material are taken for one part of the cement component.

Experts recommend making masonry mixes in moderation. First, you should check the quality of the resulting composition on a separate surface, after which it will be much easier to calculate the proportion of binders and the sand itself. At this moment, the approximate consumption of the cement-sand mixture for the masonry becomes clear. Thanks to such actions, you can avoid significant waste of material.

For plaster

The preparation of such formulations is quite simple. In this case, it is necessary to knead all the components in a 1 to 3 ratio.

The preparation of a high-quality and durable solution depends not only on well-selected components, but also on thorough mixing. It is almost impossible to achieve the desired effect by manual method, even if you use a ready-made composition.

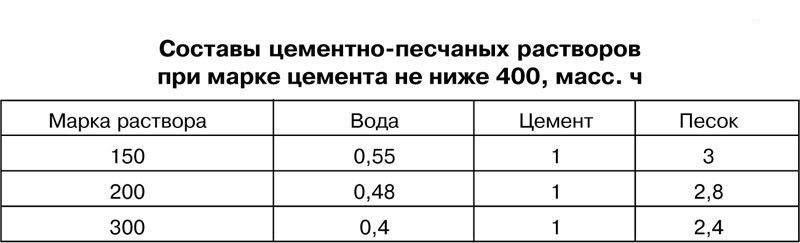

Cement mortar brands M-150 and M-200.

Grades of cement mortar M-150 and M-200 are used, as a rule, in the manufacture of screeds, vibro-brick panels, as well as for filling seams in structures made of heavy concrete and plastering walls.

Scope of cement mortar grade M-150

This brand of mortar has high strength. The difference between this brand of cement mortar is that it cannot be mixed with other brands that have lower binder values. Ready-made commercial solutions starting with the M-150 brand do not contain clay, lime, gypsum and other binders with low strength.

For brick and masonry, mortar M-150 is usually not used. Since it has improved characteristics, it is quite expensive to use it in masonry work.

Cement mortar M-150 is usually used for the construction of foundations on weak soils or wet types of soil. In addition, it is actively used for equipping hydraulic structures as masonry or plastering material (water parks, swimming pools, underground utilities, sewer mains, and so on).

In civil and residential construction, using the ready-made solution, the following works are carried out: laying the facing layer of the floors, pouring the screed and laying ceramic tiles. Online calculation of the composition of the cement slurry.

To use M-150 cement mortar as a plastering material, structures must be cast from concrete of the same brand.

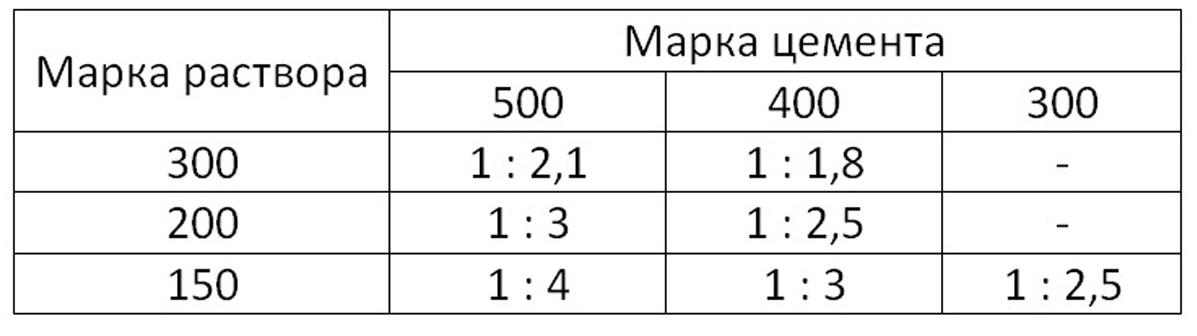

Sand to cement ratio

If you choose a ready-made brand of cement, then you need to remember some information:

- The type of mortar is determined by the load on the future foundation.

- The mark indicates the degree of compressive strength of the solid composition. The higher the number in the name of the composition, the higher its strength and cost.

- For finishing and preparatory work without a heavy load on the surface, cement grade 100 can be used. However, for the most robust structures, it is necessary to choose grade 300-500.

- The ratio of sandy, concrete and crushed stone components should be in a ratio of 1: 3: 5.

For brickwork

For work with such material, the most common version of the proportions is suitable, for which you need to take 1 part of cement and 3 parts of sand. Choose sand with medium sized particles.

In the process of preparing the mixture, you first need to mix the dry components until a homogeneous mass, then dilute it with water

Now we will consider other options for the ratio of the components of the cement mixture for brickwork with the use of various additives:

- Cement grade 500 with sand - 1 part of cement to 3 parts of sand, for grade 400 - 1 to 2.5.

- Cement with the addition of lime - 1 part of cement grade 300,400 or 500 to 2.5-4 parts of sand and 1.3-2 parts of lime.

Water is added in a volume of 8/10 to 1 part of a mixture of cement and sand. 1 part of a 100 grade product requires 1 / 2-7 / 10 parts of water.

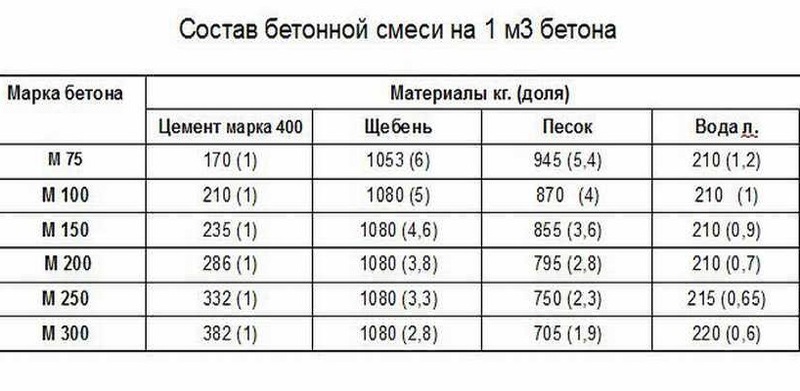

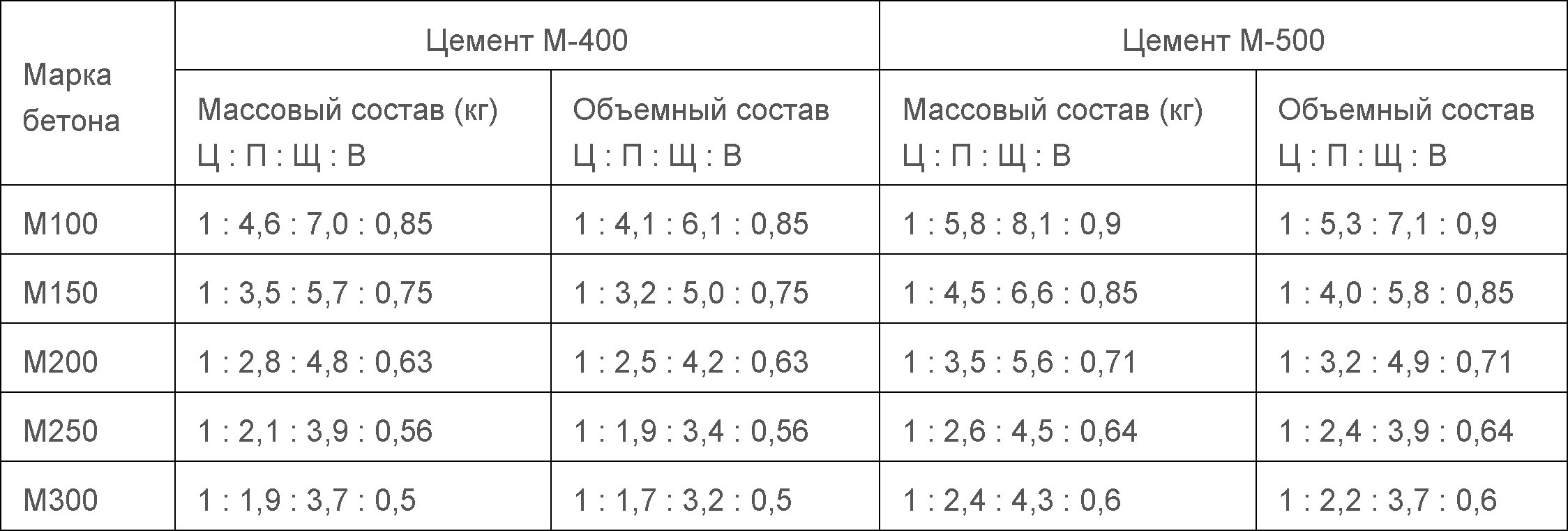

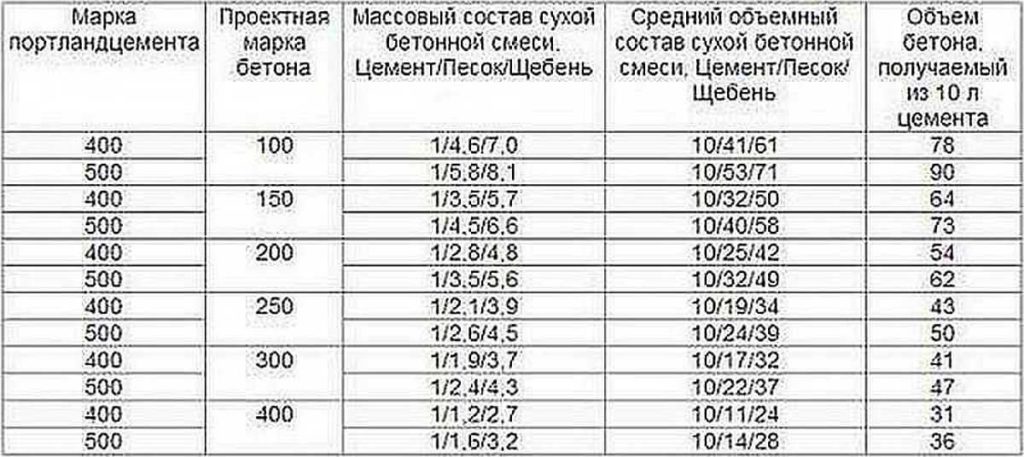

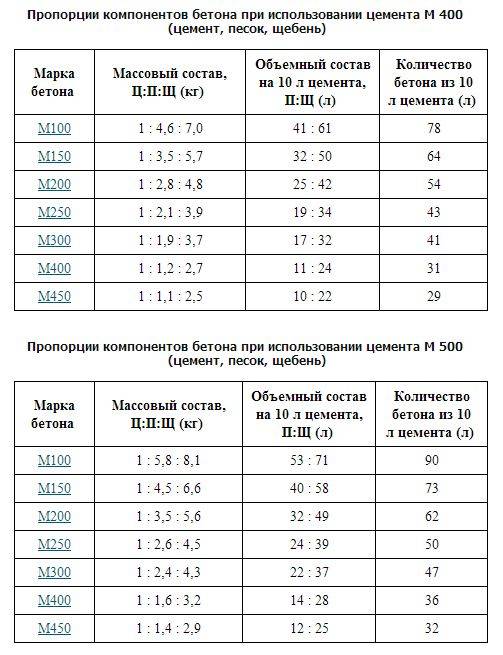

For concrete

To determine the appropriate grade of cement for working with concrete, it is also worth focusing on the operating conditions. The composition of the solution for such a material includes not only cement, sand and water, but also crushed stone, gravel and other elements. The ratio of the number of components depends on the end goal.

Most often, the proportions are as follows: for 1 part of cement, 4 parts of crushed stone, 2 parts of sand, 1/2 part of water are taken.

For plaster and screed

The cement mixture for such work should consist of diluted cement and sand in a ratio of 1: 5

Therefore, the optimal grade of concrete here will be M150.

This material has a strength index of 12.8 MPA, which meets the requirements. Also, when choosing the composition of the cement slurry, the following parameters should be taken into account:

- the presence of any communications and the possibility of their concealment;

- the need to align or change the height of the surface.

For each grade of concrete used in mortars for floor screed, there are requirements for the proportions of sand and cement:

- M100 - 1 to 3;

- M150 - 1 to 2;

- M200 - equal parts;

- M150 - 1 to 3;

- M300 - equal parts;

- M400 - 1 to 2.

For the foundation

The composition of the mortar for the construction of the foundation includes not only water, sand and cement, but also crushed stone. The components must be taken in the following ratio: 1 part of cement, 2 parts of crushed stone and sand. If you need to prepare a more durable structure, then you can increase the amount of crushed stone added. And to increase the elasticity, you should knead a solution with a high clay content.

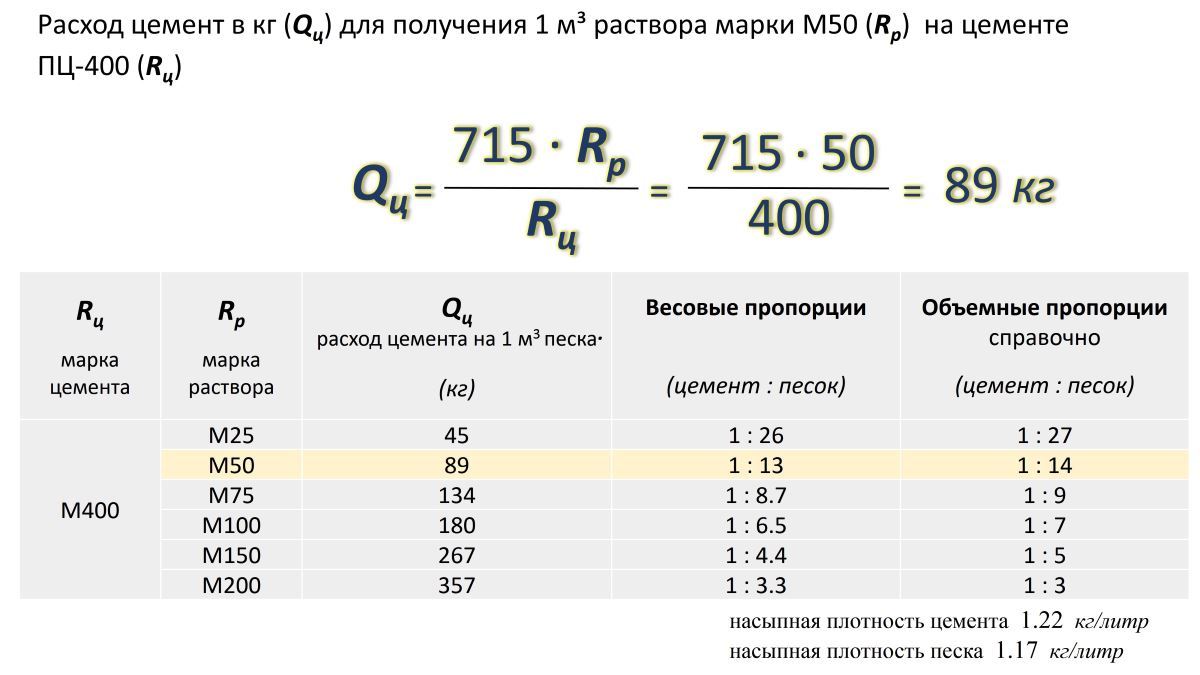

Basic proportions

When preparing solutions, the working measure is the mass or volume fraction of the binder; the most common and convenient ratios include 1: 3: 5 (cement, sand, gravel, respectively). The regulated proportions, depending on the required concrete strength, are:

The final grade of the solution

In private construction, it is inconvenient to determine separately the mass of all the ingredients to be poured; a bucket is usually used as a measuring instrument. In this case, all fillers are pre-weighed dry. The W / C ratio largely depends on the moisture content of the sand, experienced developers introduce no more than 80% of the recommended proportion of water when mixing, and then, if necessary (insufficiently plastic consistency), fill it in portions. Fiber, PAD and other plasticizers are added to the concrete at the very end along with the liquid, their share usually does not exceed 75 g per 1 m3.

Component requirements

To prepare a cement mortar for pouring a foundation, the following are used:

- Fresh Portland cement, ideally the date of issue does not exceed 2 months before the start of concreting. The recommended brand is M400 or M500.

- River sand with particle sizes in the range of 1.2-3.5 mm with silt or clay admixtures not exceeding 5%. It is advised to check its purity (fill with water and track the change in color and sediment), sift, rinse and dry if necessary.

- Pure crushed stone or gravel with a size of fractions from 1 to 8 cm, with a flakiness within 20%. When preparing concrete for the foundation, screenings of hard rocks are used; limestone is not suitable due to its low strength.

- Water: tap water, free of impurities and foreign particles.

- Additives: anti-freeze, plasticizing, reinforcing fiber. The introduction of such impurities is carried out with strict adherence to proportions.

A mixture for a foundation without crushed stone is prepared only when it is erected from separate blocks or slabs, sometimes for quick pouring of pile supports.

The recommended proportions of cement and sand for masonry mortars are 1: 3 or 1: 2. The first ratio is considered universal, the second is chosen when building foundations on unstable soils. In practice, this means that for one bucket of cement with a grade of at least M400 (M500 at increased loads), 2 or 3 sifted quartz sand and no more than 0.8 parts of water are taken. A properly prepared mixture resembles toothpaste in consistency; to increase workability per 1 m3, 75-100 g of plasticizers (liquid soap or other PAD) are introduced.

How to make a foundation grout?

The process begins with the preparation of components and a concrete mixer, the presence of the latter is mandatory when mixing concrete for underground structures. The amount of building materials is calculated in advance according to the volume of the foundation and is purchased with a small margin

After filling in a new ingredient, the drum turns on for 2-3 minutes, no more than 15 minutes later, the finished solution is unloaded.