Manufacturers

The modern building materials market offers a fairly large selection of various mixtures and powders for certain tasks. It is worth choosing products from trusted manufacturers who guarantee high quality components and their creation in accordance with technology.

"Monolith"

A large manufacturer that creates and sells cement-sand mixtures at a plant in Kirov. The assortment is large enough, it includes reliable and high-quality compounds of the M150 brand, well suited for plastering, grouting, and masonry indoors and outdoors.

Also, reliable compositions of the M300 brand are implemented, which are relevant for the production of reinforced concrete structures.

Knauf

A well-known brand supplying to the market high-quality cement and plaster mixes in several lines (Sivener, Adheziv, Grunband, Unterputz). All products are distinguished by excellent thermal insulation performance. Suitable for a full range of finishing works - indoor / outdoor. In most of the manufacturer's mixtures, components are added to the composition to increase the positive properties.

"Real"

The manufacturer's products are popular, supplying high-quality cement mixtures of the M75 and M150, M100 and M200 brands. The assortment allows you to choose what you need for finishing and repair work. Most dry mixes are supplemented with components to increase frost resistance, which expands the possibilities of working with them and allows them to be used both inside and outside.

Dauer

A German brand that offers inexpensive high-quality DSP for indoor facades and walls, screed pouring, block and brick installation.

The manufacturer's dry mixes are very popular, since they have a low consumption, an affordable price, which in general can significantly reduce the cost of work.

"BaltPiterStroy"

A large Russian company supplying cement-sand mortars of any brands to the market. Also among the products you can find other components - rubble, gravel, crushed stone, sand, cement in bags and a variety of reagents (anti-ice, for example).

"Stroyservice-Novablock"

Previously, the manufacturer's cement-sand compositions were presented on the market under the Plita Milks brand. In addition to dry mixes, the range of products includes high-strength sand-gravel mix of M300 grade. All compositions are of very good quality, as they are produced on modern factory equipment on an industrial scale.

"Adamant SPB"

The plant offers a huge assortment of crushed stone, sand, cement, reinforced concrete products, high-quality concrete. DSPs are represented by various brands - the line includes both M100 and M400.

Types of cement grade 400

Binder with strength grade M400 can be produced based on different components, depending on this, the material is divided into several main groups:

- Portland cement (PC) is the most common type produced on the basis of calcium silicates (alite). These are metamorphic rocks. It is characterized by medium-term hardening and high technical characteristics.

- Alumina cement (HC or VHC) is produced on the basis of oxides of aluminum, calcium, iron and silicon in accordance with GOST 969-91. The material is characterized by accelerated setting and hardening. Suitable for urgent construction, including in winter.

- Magnesia cement (MGC) is a grinding product of clinker with a high magnesium content. The hardened stone is characterized by high wear resistance and density.

- Pozzolanic cements (PPTs) are made from volcanic rocks carefully ground to a pulverized state.Suitable for production are silica and aluminous minerals, some types of slag and fly ash, which have a high viscosity.

- Slag Portland cement (SPTs) is a binder made of clinker and blast-furnace or electrothermophosphoric slags with the latter amount not exceeding 20%. Such a binder is cheaper than the classic one, it is used when it is necessary to equip structures in aggressive environments and saline waters.

Specifications

Portland cement has higher strength characteristics in comparison with other types of cement, which is due to the peculiarities of the composition. These or those additives can enter into reactions, changing the technical properties of the material. The latter are associated with its mechanical resistance and operational capabilities.

It cannot be said that one of the technical characteristics is of higher priority. So, for example, strong, but too slowly hardening Portland cement can increase the construction time. A frost-resistant, but corrosive composition can only be used to solve a narrow range of problems.

Today, manufacturers strive to create universal formulations in which the properties most important for cement are manifested equally strongly.

At the same time, there are specialized formulations with a special purpose. This can be considered pozzolanic Portland cement, which has maximum corrosion resistance and moisture strength, but rather low strength indicators at the initial stages of work (in the first days of setting).

Technical

Among the technical characteristics should be highlighted:

- The specific weight of the product is 1100 kg / m³ for bulk mixtures, 1600 kg / m³ for compacted ones.

- The fineness of grinding is on average 40 microns (determined by the ability of the mixture to pass through a sieve No. 008), which ensures the required strength of the cement and its hardening time, and also affects its performance.

- Water consumption, the optimal liquid content in the composition should not exceed 25-28%, since this indicator affects the strength of the composition (with excess, the concrete dough delaminates, with a shortage, cracks appear on the finished product).

- The setting time after mixing with water does not exceed 40-45 minutes, further hardening depends on the characteristics of the composition and environmental conditions (in winter, the process slows down), but does not exceed 10-12 hours (measured using a Vic's device).

- A change in volume during solidification means a decrease in the cement body in volume by 0.5-1 mm / m in the open air and its swelling to 0.5 mm / m in water. An important point is the uniformity of changes throughout the volume of the solution.

Physical

- Corrosion resistance is achieved due to the introduction of hydroactive materials into the composition, which prevent the chemical activity of salts, as well as the addition of impurities that reduce the porosity of concrete.

- The storage period is no more than 12 months, provided that the original packaging is preserved (3-4-layer, hermetically sealed paper bags), since after 3 months of storage, up to 20% of the activity of the composition is lost, after a year - up to 40%. It is possible to return such cement to its former qualities only by secondary grinding.

- Compressive strength. In accordance with this characteristic, 4 strength classes are distinguished - 22.5; 42.5; 42.5; 52.5. This indicator is directly related to the setting speed of the solution.

Mechanical

The indicators of the mechanical strength of Portland cement are at least 42.5 MPa on the 28th day after pouring. The determination is carried out in laboratory conditions using a sample as an example. In accordance with the results obtained, the cement is marked (for example, M 500). The coefficient in this case indicates what pressure the sample can withstand (measured in kg / cm³).

Strength indicators, in turn, affect the degree of setting of the mortar (determined using a Vicat needle).

TOP cement М500

When choosing which cement is best for the foundation, you must definitely pay attention to this brand. It is characterized by high strength and is suitable for floors that bear loads, for laying load-bearing walls and pouring a foundation for a building.

Eurocement 500 Super

Such a product has many positive reviews, and cement is often used in the construction of houses. Recommended to use for pouring foundations, building walls, screeds. Specialists often buy it for quality reasons, the mixture meets GOST, the solution sets quickly, which helps to reduce the time of the main process. In addition, the consumer receives protection from moisture and frost.

Pros:

- High quality of composition.

- Strength.

- The durability of the poured solution.

- Fast drying.

- Wide scope of use.

No cons of this brand were found.

Holcim Tared 50kg CEM II / A-K (W-I) Class 42.5N

This option is considered one of the best for pouring the foundation for a house, since the solution can withstand heavy loads. This allows the mixture to be used for buildings of 2-3 or more floors. The hardening is optimal, the dry mixture includes minerals, excluding the appearance of cracks or flaking. The product is sold in 50 kg bags, which is convenient during construction.

Pros:

- Perfect for supporting structures due to its strength.

- Can be used indoors and outdoors.

- The maximum flexural strength is 78 kg / cm2.

- Includes mineral and plastic substances.

- Withstands loads within 433 kg / cm2.

- It has no blue tint, the color is gray.

- Affordable cost within 300 rubles per bag.

- Excellent adhesion.

- Optimal setting time, which helps to remove defects in the form of smudges or sagging.

Minuses:

- If you work in the cold, then seizure can occur with the formation of small voids.

- It is inconvenient to grasp the carrying bag.

EuroCement 500 Extra D20 CEM II

The product is characterized by optimal drying speed and durability. After preparing the solution, it is convenient to pour it into the voids, level the surface. The mixture is not afraid of frost, therefore it is used even in winter. Quality at a high level, but at temperatures below +10 degrees, hardening will be slow.

Pros:

- Excellent quality.

- Ease of use.

- Long storage period.

- No cracks appear during shrinkage.

Minuses:

- High price.

- In the case of a low temperature, the solidification process will be slow.

Stone flower М500 Д20

This is the best option for bricklaying, foundations and other important work. Cement is characterized by a high degree of strength, which is 500 kg / cm2. The composition contains polymers to accelerate solidification and eliminate cracks during drying. To increase adhesion, the manufacturer adds glue and other elements that also make the mortar insensitive to weather. Sold in packs of 40 and 50 kg.

Pros:

- The optimal hardening time, which is suitable for mixing mortar, laying with further leveling.

- The solution is easily prepared using technology or by hand.

- Affordable price.

- The presence of mineral additives.

- Suitable for outdoor or indoor use.

- High strength.

- Ecological cleanliness.

- Complies with GOST.

- Resistant to frost and moisture.

- The ready-made and hardened solution serves for a long time and retains its properties.

- High degree of adhesion to materials.

Minuses:

- Shelf life up to six months.

- The corners of the bags are smooth, so it is inconvenient to carry and take goods.

Manufacturers

Cement production facilities are located in almost every region of Russia. The proximity to the manufacturer will significantly reduce the cost of transporting large quantities of cement. In addition, at regional factories, various substances are added to cement that improve the physical and mechanical properties of structures, taking into account the peculiarities of the weather and water conditions of the area.

Here are some examples of businesses located in different regions:

- Association "Yakutcement" - Republic of Sakha.

- Podolsk Cement Plant - Podolsk, Moscow Region.

- Teploozersk Cement Plant - Jewish Autonomous Region.

- Novotroitsk Cement Plant - Orenburg Region, Novotroitsk.

- Verkhnebakansky cement plant - Krasnodar Territory, Novorossiysk.

There are dozens of similar enterprises. There are also large manufacturers on the market, known throughout Russia and even in Europe. For example:

- Mordovcement offers the 400D20 brand in 40 kg bags. This product has increased corrosion resistance and is more frost resistant. The average price is 200-230 rubles.

- "Eurocement" unites a group of manufacturing enterprises, therefore, offers a wide range of products. Cement M400 can be bought in packages from 25 kg to 1 t. Price - about 220 rubles. for 50 kg.

Cement M500 - application

Scopes of cement grade M500 (GOST 23464-79):

- The main purpose is for the preparation of concrete of strength classes B30 and B35 or B22.5, B25, B27.5 (with increased tempering strength).

- It is allowed to use in the production of concrete of classes B15, B25, B27.5, B40.

Strength kinetics of M500 cement.

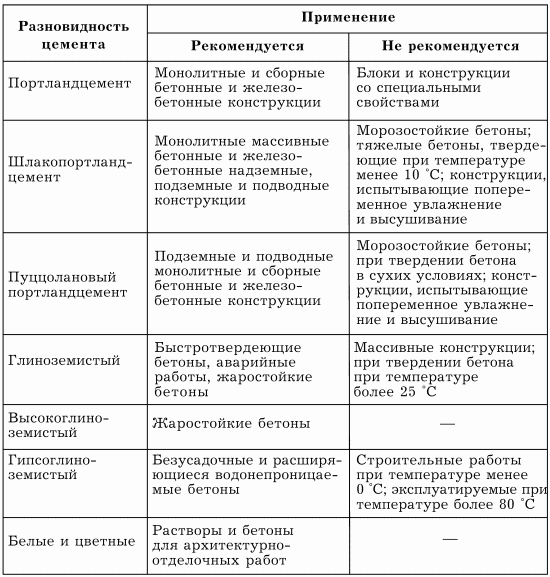

Scopes of cements from various types of clinker (GOST 23464-79):

- Portland cement (including with additives up to 20%) - for all types of concrete and reinforced concrete structures without special requirements.

- Slag Portland cement - for prefabricated concrete and reinforced concrete products subjected to steaming; monolithic, used in conditions of constant exposure to water. Slag Portland cement is unsuitable for structures subjected to alternating moistening and drying, as well as for the preparation of frost-resistant concrete.

- Pozzolanic cement - for underground and underwater structures exposed to soft fresh water, with an increased risk of sulfate corrosion. It can be used for the construction of aboveground structures operated in high humidity conditions. This variety is unsuitable in the same cases as slag, as well as when concreting in winter or in hot dry weather.

Fast-setting cement of class 42.5 is used for the preparation of concrete intended for the installation of monolithic and prefabricated structures (with increased tempering strength). It can be used in the production of mixtures for precast concrete products and concrete structures. You cannot make mortars from it.

When choosing a construction technology, it is necessary to take into account that the production of cement and mixtures based on it is harmful to the environment. It is better to minimize their use in all cases, whenever possible, to replace them with natural materials or geopolymer concrete.

What does the characteristic depend on?

Specific gravity is the ratio of the mass of a substance to the volume it occupies.

Bulk is an indicator applicable to a material after grinding, which is a pulverized substance. It is a variable characteristic. True is a characteristic of a frozen composition. Is a constant number.

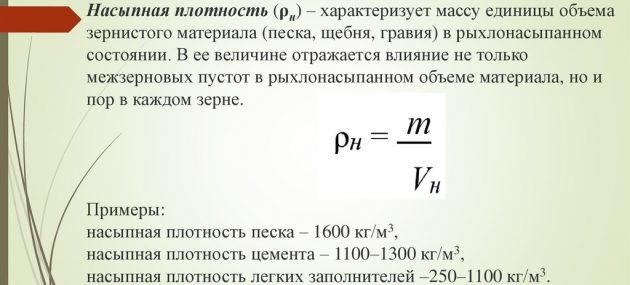

Bulk density

The value of the true density of cement varies in the range of 2700–3500 kg / m3. Its exact figure depends on the brand of cement. This is a reference number that has no serious practical use.

The bulk density of cement is necessary for the practical determination of the quantitative and qualitative structure of building mixtures and mortars. This parameter can vary widely. This is due to the composition of the crushed building material, which as delivered is a mixture of grains with an air gap between them. The more air the powder contains, the lower its density.

Density of cement slurry

Immediately after grinding, particles magnetized by intense friction are repelled from each other according to the laws of electrostatics. Air-filled gaps between particles are large. The density of freshly ground cement will be about 1100–1200 kg / m3.During further transportation, transfer, storage, storage, the charge of the particles decreases, the repulsive force disappears, and the powder settles, displacing the air. The cement mixture is compacted, increasing the specific cement weight up to 1600 kg/ m3.

Factors influencing the parameter

The following factors influence the value of cement density:

- type of building material;

- particle size reduction;

- production technology;

- method of drying in a silo (a specialized tank for storing ground material);

- time elapsed after grinding (the parameter increases over time);

- storage conditions (placement in a silo does not increase the indicator as intensively as storage in bags and similar packaging).

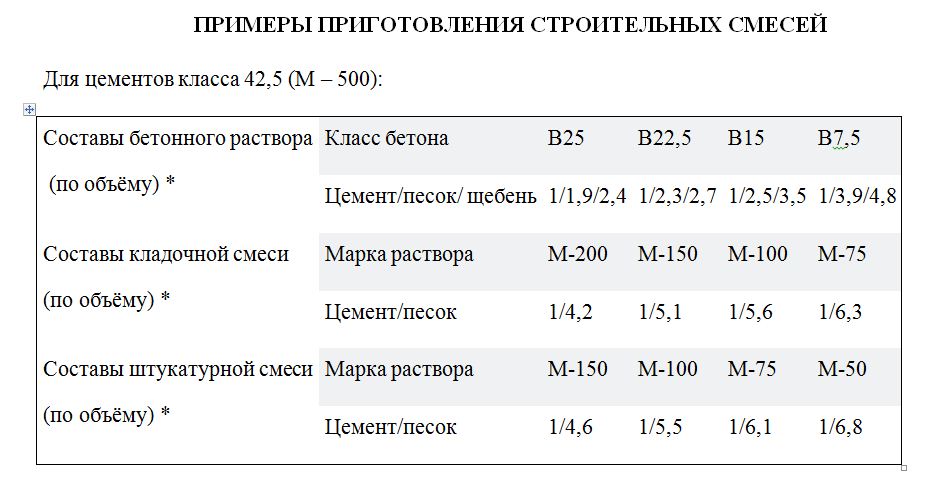

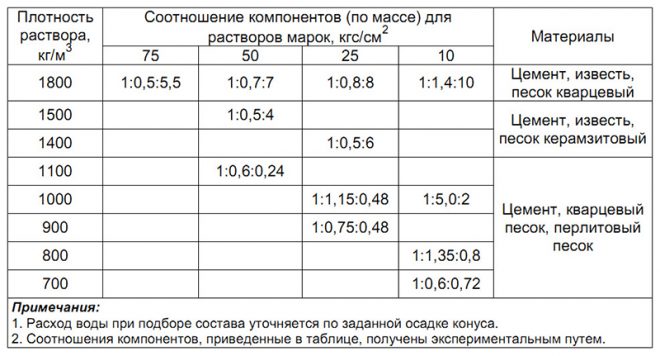

Cement mortar application table

Varieties

This cement brand is also divided into several types:

- with the presence of additional impurities and additives, but not more than 20%;

- complete absence of additives in the dry mix. A similar building material is indicated by marking D0.

Without additives

There is a big difference between these two types, and therefore they are used in certain types of buildings. First of all, this is the composition of the cement.

Cement m500 d0 is made from the purest clinker, and contains a small proportion of gypsum, therefore, the mortar made from this building material sets much faster than its competitors. If this particular cement marking is present in the concrete composition, then the finished structure will serve a considerable period of time.

Cement sand with the presence of additives loses in characteristics without additives. And although the setting time is the same, due to the presence of additional components, it is not used for the construction of monolithic structures, therefore the cost of cement m500 d20 is slightly lower than d0.

But it is good to use it when decorating the external facades of buildings, floor screed, brickwork and foundation pouring. This material is less susceptible to corrosion.

Floor screed

The use of this brand guarantees high strength of the finished structure, capable of withstanding significant pressure. Perfect for office buildings.

The range of cement m500 includes the following compositions:

Portland cement;

Portland cement М500

with the presence of additives that increase the resistance to sulfate. Allows you to apply the solution even in aggressive conditions;

М500 with additives

with the presence of plasticizers that increase the speed of hardening.

With plasticizer

Determine the brand of cement mortar

Sometimes it happens that the cement brand information stamped on the bag is damaged or poorly visible. In this case, do not rush to despair. You can also experimentally recognize the capacity of the bag.

To do this, you need to take a hammer and hit the concrete surface or with a hammer on the chisel, which must first be fixed perpendicular to it.

If it crumbles and shatters into tiny pieces or when it hits the side of the structure, huge debris breaks off or the chisel breaks into the concrete by about 5 mm - this is the M100 brand; a decent imprint is preserved from above, from which narrow flat-shaped pieces can fly off.

Sharp such pieces are also separated from the surface, then you are dealing with the M100-M200 brand; there is an almost imperceptible or shallow trace on the cemented surface, but the pieces do not separate - М300-М400.

when struck near the side of the structure, it splits off - M400 - M600.

Specifications

Cement mortar of the M400 brand has individual technical characteristics:

- the solution consists of 97 percent of inorganic components, the main of which are oxides of calcium, magnesium, titanium, aluminum, iron, silicon;

- physical condition - solid;

- the construction of cement is able to withstand a pressure of at least 400 kg per 1 cm² of the total area;

- bulk density in an unconsolidated state is from 1100 kg to 1500 kg per 1 m³;

- temperature range is from -30 to +300 degrees Celsius;

- partial solidification of the solution occurs after 4 hours, and a full set of strength occurs after 1 month;

- water resistance is no more than 25 percent;

- maximum adhesion characteristics appear after full curing;

- the period of operation is at least 100 years;

- has high resistance to organic and inorganic solvents.

Cement manufacturers distinguish several groups of the mixture, depending on the components in its composition:

- Portland cement (PC). It is made from calcium silicates and is characterized by a wide range of applications. Has an average speed of hardening and high technical parameters.

- Alumina cements (GC). They are made from aluminum, calcium, iron, silicon and their oxides. Quality standards are established by GOST 969-91. They have a high speed of solidification and complete hardening. They are used for the construction of facilities in regions with low temperatures.

- Magnesian cements (MGC). Contains a high percentage of magnesium. Structures made from this solution have a high percentage of density and a long period of operation.

- Pozzolanic cements (PPTs). They are made from small inorganic compounds of volcanoes. In production, substances with a high viscosity are used (silica and alumina mineral components, slag and fly ash).

- Portland slag cement (SPC). It is produced from blast furnace slags. It has a low price and is used in aggressive environments and mineral waters.

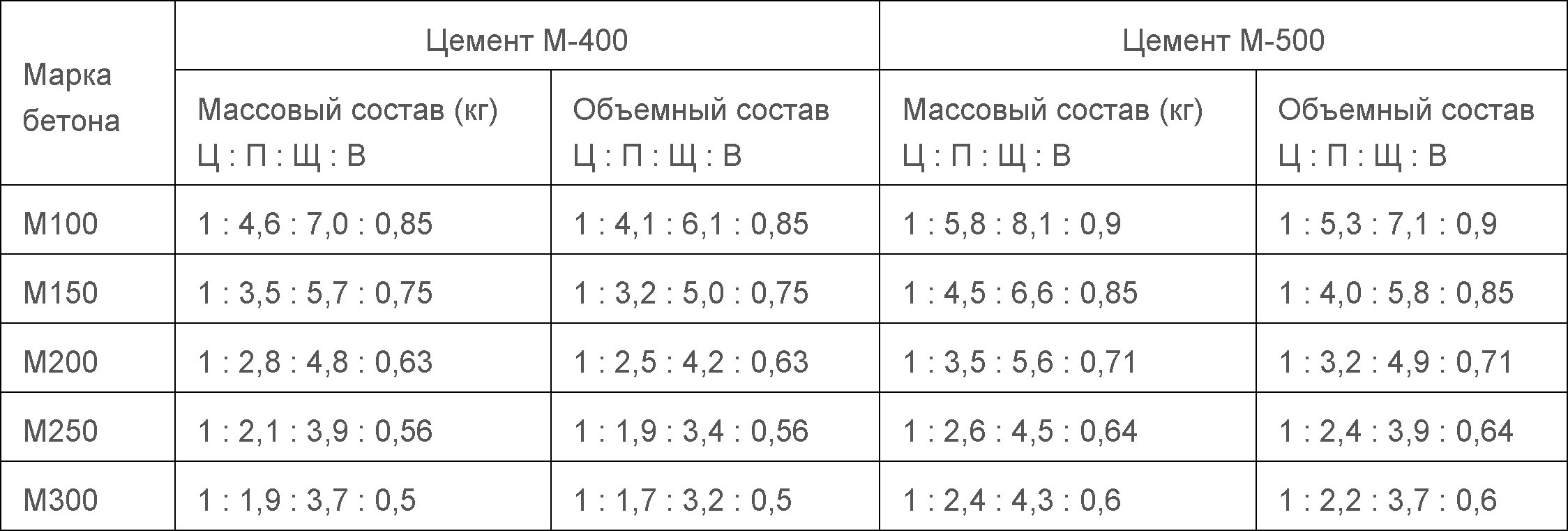

To obtain a high-quality concrete solution, it is necessary to strictly observe the proportions of water, cement, crushed stone and sand. Violation of technological standards when diluting and mixing components will result in poor quality concrete. To prepare 1 cube of M200 grade concrete, it is necessary to use 500 kg of M400 grade cement.

Features and Benefits

Portland cement is one of the subtypes of cement. It contains gypsum, powder clinker and other additives, which we will indicate below. It should be noted that the manufacture of the M400 mixture at each stage is under the strictest control, each additive is constantly studied and improved.

Today, in addition to the above ingredients, the chemical composition of Portland cement includes the following components: calcium oxide, silicon dioxide, iron oxide, aluminum oxide.

When interacting with a water base, clinker promotes the formation of new minerals, such as the hydrated constituents that form cement stone. The classification of the compositions occurs according to the purpose and additional components.

The following types are distinguished:

- Portland cement (PC);

- fast-setting Portland cement (BTTS);

- hydrophobic product (HF);

- sulfate-resistant composition (SS);

- plasticized mixture (PL);

- white and colored compounds (BC);

- slag portland cement (SHPC);

- pozzolanic product (PPT);

- expanding mixtures.

Portland cement M400 has a lot of advantages. The compositions have increased strength, do not react to changes in temperature and humidity, and are also resistant to adverse external environments. This mixture is resistant to severe frosts, which contributes to a longer period of preservation of the walls of buildings.

Portland cement ensures the resistance of reinforced concrete structures to the effects of even critically low or high temperatures. Buildings will have a long service life in all climates, even if no special ingredients are added to the cement to counteract frost effects.

Mixes made on the basis of M400 set very quickly due to the addition of gypsum in a ratio of 3-5% of the total volume. An important point that affects both the speed and the quality of setting is the type of grinding: the smaller it is, the faster the concrete base reaches its optimal strength.

The specific gravity of cement under the M400 brand varies depending on the stage of its readiness.Freshly prepared Portland cement weighs 1000-1200 m3, materials just delivered by a special machine have a similar specific weight. If the composition has been stored for a long time on the shelf in the store, then its density reaches 1500-1700 m3. This is due to the convergence of particles and a reduction in the distance between them.

Despite the affordable price of M400 products, they are produced in fairly large volumes: 25 kg and 50 kg bags.

Density

To make a mortar from M400 and M500, which are used in construction, it is necessary to take the correct proportion of all components. This is why builders need to know the density of cement and other materials. This information is placed in a special reference book, in addition, it can be read on the packaging.

Solution proportions

Basically, the low density is characterized by Portland cement or cement 400, which was recently mixed. This can be explained by statics, because at the stage of transportation and unloading, cement particles begin to magnetise, and, accordingly, are repelled.

When the material is stored for a long time, its structure becomes as dense as possible, and the particles themselves become heavy.

It is influenced by the following indicators:

- production technology. Here, the indicators of the degree of fineness of the granules should be taken into account, because their size and the total volumes of the voids that have formed depend on this. Choosing cement 400, this indicator is quite difficult to determine, so you need to focus on the figure of 1300 kg / m3;

- the date the material was produced. If the cement was made a few days ago, its strength values will differ from what came off the assembly line a few months ago;

- the reason is hidden in the cooking process: all available fragments receive their energy. As a result, a force is formed that pushes the particles away, and this becomes the cause of the formation of many voids, which are filled with N2 and O2;

- the conditions in which the material was stored. If the role of a warehouse was played by a room with an increased percentage of humidity, then as a result of such storage air was displaced from the voids of the cement, as a result of which the weight of the material began to increase;

- a funnel, a volumetric flask, and a balance are used to measure the density of cement. To carry out the measurement process, it is worth doing the following manipulations: the material in question is placed in a volumetric flask with a capacity of 1 liter;

- the composition is leveled, excess is eliminated, and then weighing is carried out. But during all the above manipulations, it is forbidden to shake the cement, and also to ram it in some way.

Density of the cement mixture M400:

- just made - 1.100-1.200 kg / m3;

- the one that is lying on store shelves - 1.500-1.600 kg / cubic meter.

For concrete goods of organizations, the bulk density of cement m400 should be at least 1300 kg / m3

At the same time, manufacturers draw the attention of buyers to the real density of cement - 3000 kg / m3

M-400

This difference between actual and bulk values is easy to explain: air voids appear in the gaps between the cement grain. It is worth noting that even in the material that is stuck, almost 1⁄2 of the volume of the mixture is N2 and O2.

The indicators described above play an important role at the stage of producing dry-type building materials (sand concrete).

The density of cement 400 is also influenced by the crushed degree of clinker, the drying itself and the methods used for this, as well as the volumetric grain surface.

Clinker

During the mixing phase, builders pay a lot of attention to the absorption of liquids. If the composition is liquid, the quality indicators will decrease significantly.

For more information on how to mix concrete correctly, see the video:

Main properties

Cement is considered an astringent building material, which includes clay, limestone, marl, gypsum and other mineral additives. In its pure form, cement is rarely used - the solution is diluted with sand and water.

The main properties that you should pay attention to when buying are:

- The rate of solidification of the solution is responsible for the strength and uniformity of the surface layer. The fineness of the dry composition is considered to be an interrelated parameter.

- Strength is responsible for the load that the finished material can withstand. According to mechanical parameters, cement is divided into 4 grades: 400, 500, 550, 600.

- The time and volume of heat transfer during the hardening of the mixture is regulated by mineral additives. The characteristic is responsible for the uniformity of the coating and the absence of cracks.

- The grinding fraction plays an important role in the density of the future material. The finer the grains, the stronger the fill will be.

- The frost resistance of the mixture determines where it is advisable to use the material - indoors or outdoors.

Specific gravity: characteristic of the indicator

The specific gravity indicator makes it possible to determine the mass of 1 cube of cement.

The parameter depends on a number of factors:

- Weight and density proportionally depend on the brand of dry composition.

- A method of making a mixture. The coarse fraction retains some voids between the components of the material, which reduces the mass ratio by 1 m³.

- Date of manufacture. In the process of manufacturing the material, frictional energy arises between its particles, which increases the bulk density of the cement. Over time, the energy weakens, and the indicators change.

- The presence of mineral additives increases or, conversely, decreases the value of the parameter.

- Storage conditions. The increased air humidity in the room where the dry composition is stored contributes to an increase in density, which accordingly increases its mass.

In the specialized literature, there is another name for the parameter - the specific density of a substance.

Share of various brands

People who use building material for private purposes are wondering how much does the cube weigh ... This is due to the fact that the density of the building material, purpose and mechanical characteristics directly depend on the brand of the cement mixture.

The approximate ratio is as follows:

- the specific gravity of M400 cement in compacted form is 1400-1600 kg per 1 cubic meter;

- the mass of the mixture in 1 m³ of the M500 brand is 1500-1700 kg, or, if translated into tons, 1.5-1.7 tons.

When constructing large objects, builders often use the concept of "bulk density". The specific gravity is influenced by the degree of compaction of the material, therefore, when calculating the weight of 1 m³ of M400 cement in bags, it can exceed 3 tons.

It should be remembered that the specific gravity indicator for one brand may differ from manufacturer to manufacturer. Therefore, it is not recommended to use materials of several brands on one object.

Varieties

Depending on the composition, the following types of mixture are distinguished:

- lime;

- sulfate-resistant (characterized by increased frost resistance);

- marly;

- clay (highly waterproof);

- hydraulic;

- backfill;

- stressful.

Various grades of solution are obtained by increasing the percentage of mineral additives and components that can affect the characteristics of the material.

For example, the sulfate-resistant type is highly resistant to low temperatures, which makes it used for the construction of non-residential buildings and outdoor work. But such a solution dries out longer than others. The grouting type is used for concreting oil wells, and in municipal construction the material is used extremely rarely.

Preparation of concrete mortar

General trend: the higher the binder grade, the more durable the concrete will be when used. Portland cement M500 is suitable for mixing concrete mortar M100 ... M450. Moreover, the lower the grade of the working solution, the lower the consumption of the binder occurs. If you count, you can save money this way! It is enough to know the correct proportions of the preparation of the material.

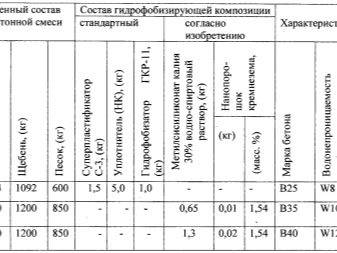

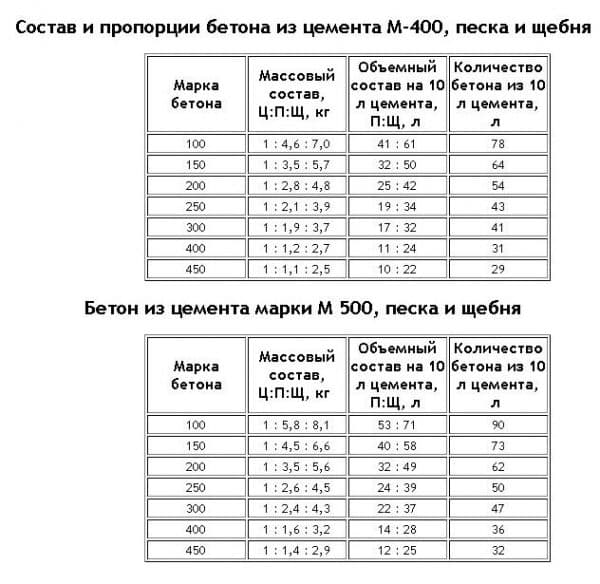

In addition to the binder, you will need cleaned crushed stone, river sand and water. Technological table of proportions of concrete from cement m500:

In order to obtain a mortar with respect to the proportions and in the future a structure with the expected characteristics, it is necessary to take into account the shelf life of the binder. In impermeable polyethylene bags, it can be stored for 12 months, in multilayer paper bags - 6 months

It is noteworthy that every 3 months there is a weakening of the dry binder by 1 position, that is, M500 turns into M400 2 months after release. It is clear that the proportions indicated in the table for such a component are no longer relevant. For this reason, it is necessary to choose cement directly from the manufacturer or a direct supplier.