Manufacturing and packaging

Production and packaging of cement is a long process that requires high-tech equipment and control. Its origin lies in limestone quarries. Two types of limestone are used. The first is located close to the surface, at a depth of several tens of centimeters. This is the so-called "second-rate" limestone, but it already contains iron, aluminum oxide, silicon and other minerals. They give unique properties to cement mixtures.

In production, both types are used, both pure and combined in different proportions with each other and additional components. The ratio of the first-class to the second-class substance, as well as the type and quantity of additives, determine the brand and cost of the cement. Limestone rock in its natural state is a solid monolith. It is broken into small fragments with explosives, laying them in layers of limestone in the quarry, and then collected by loaders. The sizes of the fragments can be of different sizes, from small pebbles to an entire building block. In this form, they go to cement plants.

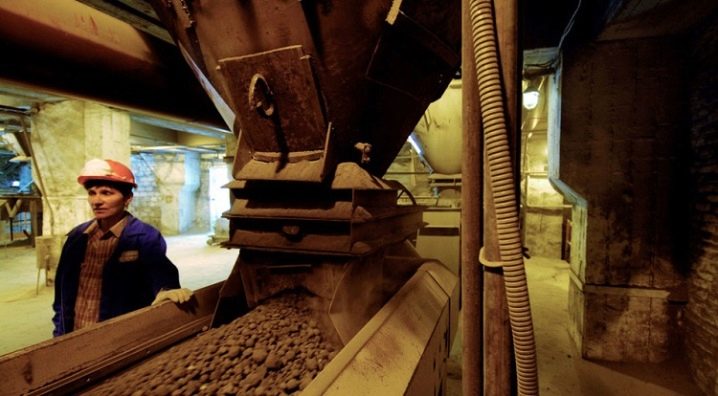

At the plant, the raw materials first of all go to the “primary crusher”. In it, large fragments are crushed to the size of a tennis ball. In the process of grinding large fragments, water enters the crusher so that dust does not rise, and together with it, the mass of limestone is not lost. The crushed stones are conveyed through a conveyor to a secondary crusher. In it there is a "grinding" of the rock to fragments the size of crushed stone. The first and second grades are crushed separately.

Then a raw mix is formed for cement of different grades. After mixing, the finished "heaps" are sent to the roller mill. In the process of grinding limestone, additives are used: powdered magnesium, silicon and aluminum oxide, if they are contained in the limestone rock in insufficient quantities. The mill grinds the rock to stone flour. This stone meal then goes to the preheater. In less than a minute, it heats up from 80 degrees Celsius to 800.

Unnecessary components are separated in the preheater, and lime, suitable for construction, remains. She goes to the cylindrical firebox. The bottom of the firebox heats up to 1700 degrees. The mass inside the kiln is melted into small "glass" balls called clinkers. When leaving the oven, they are quickly cooled with a flow of cold air to 70-80 degrees. Fast is key. If it cools slowly, the mixture is of poor quality. This is the raw material for quality cement.

The cooled "glass balls" go through the last stage of processing - the final crushing. In fact, this is the grinding of hard clinkers between steel balls of different diameters, of which there are about one and a half tons in one crusher. When grinding clinkers, lumpy gypsum is added to the stone flour. It slows down the hardening process of the slurry. The powder mixture leaving the crusher is cement. Some manufacturers add plasticizers to it to increase strength.

Cement bags rarely have a small volume of 10-15 kg. Usually the minimum weight is 25 kilograms, and the most running one is 50 kg. Bags of 50 kilograms are called slimbegs. Sometimes there are non-standard volumes of 30, 35, 42, 46 kg. The packing bag consists of several layers (2 to 5) of craft paper. Also common are packaging containers for construction on an industrial scale - big bags. These are soft containers made of high strength polypropylene or nylon with or without stiffening ribs and linings. The weight of cement in big bags is from 300 to 3000 kg.

Big bags have a number of advantages over conventional packaging:

- wholesale purchase of cement reduces the price for 1 kg of the mixture;

- soft containers have slings for loading;

- They are heavy-duty, reusable and recyclable;

- polypropylene shell extends the shelf life, since it protects the cement from the negative effects of the external environment;

- containers can be completed with liners for heat resistance, anti-static, waterproof, UV protection.

Mixing proportions

There is a classic version of the mixture, which is determined by the ratio of 1: 3 - 1 part of cement and 3 parts of sand. Both components are first mixed dry with each other, and then water is added in portions to this mixture. All this is thoroughly mixed until a solution is formed, similar in consistency to thick sour cream. Be sure to give the finished mixture 15 minutes to thicken, and then mix again.

By the way, the cement-sand mortar “lives” no more than 1.5 hours. After which it begins to lose moisture and dries out. So a small batch is a justified decision.

For mixing the components, it is recommended to use a construction mixer or a drill with a special attachment. If you require a large amount of material, for example, for pouring a foundation, we recommend that the cooking process be carried out in a concrete mixer.

The main ingredients of the solution:

Cement is an astringent component. It must be in paper bags. It is recommended to buy it before starting construction processes. That is, it must be "fresh". Indeed, during long-term storage, this material cakes, which means it loses its qualities. Sand is a filler. There is one quality issue here. There should be no foreign materials in the sand. This is especially true for clay. Therefore, it is recommended to purchase river sand

The coarse fraction is not used for the preparation of plaster, although it works great in foundation solutions. Water is the basis, so it must be clean. The main requirement for it is the absence of acidic and oily impurities.

Features of choosing a brand of solution

Now you can move on to the proportions and deal with such an indicator as the brand of the solution:

- The masonry composition has the M100 brand. It is used in the construction of walls and protective structures made of bricks or blocks based on different materials. This will require M400 cement and sand, which are mixed in a 1: 4 ratio.

- To increase the strength of the masonry, you can take a solution of the M200 brand. To do this, you will have to reduce the amount of sand by 2 times.

- To level the floor bases, the M300 solution grade is used. To do this, you can use cement M400 or M500 with the addition of water and sand in a ratio of 1: 3: 0.5.

- For plastering the walls, use exactly the same mortar as above, only with a slight increase in the amount of cement. For example, it could be 1.2-1.5. Plaster solutions are often made with the addition of milk of lime. This reduces the strength of the material, but increases its plasticity. In this case, the ratio of cement-sand-milk will be 1: 5: 2.

Standard proportions

There are certain technological standards that regulate the ratio of the components of the building mixture. Here are three examples:

- To prepare a solution for screed, use a ratio of 1: 2-1: 6. In this case, the amount of water is not indicated, but only the cement-sand ratio is indicated.

- In low-rise construction, 1: 3 or 1: 4 solutions are most often used.

- For structures under construction - from 1: 3 to 1: 6.

Why is water not specified in the standards? The fact is that it is easy to make a mistake with the volume of water. After all, the sand can be wet, and the degree of moisture cannot be determined at home. At the plant, however, this indicator is strictly controlled. What can you offer to those using handcrafted solutions? To do this, it is better to double the batch if the first one turned out to be liquid. Just add cement and sand to it according to the standard, but reduce the amount of water.

Today, facing tiles and stone are placed on ready-made adhesive mixtures, which greatly simplifies the process of preparing the composition. But since we are considering all cement-sand mortars, this masonry material should not be ignored. Let's just designate the proportions - 1: 2.4: 0.4. Here is such a non-standard ratio.

Features of production

As soon as people began to build houses, they had a need for such a composition that could hold together stones and other building materials. At first it was ordinary clay, but such dwellings were short-lived, and the building itself looked very unpresentable.

A little later, the builders discovered that the lime mortar also has some binding characteristics - this discovery was made by the ancient Greeks and Romans, and the latter noticed that if volcanic ash is added to the lime, the masonry becomes truly monolithic.

Lime was also used in Russia, mixing it with clay and water. At the beginning of the 19th century, a building mixture was experimentally created, which in its parameters is close to modern compositions.

So, cement is the definition of a material consisting of clay and limestone components. They are mixed with each other and subjected to prolonged heat treatment, after which the resulting mass is ground to a powdery state.

The mixture has a gray tint and, when interacting with water, forms a solution, which, when dried, becomes solid like a stone. Its exclusive feature is that the mass hardens only under conditions of high humidity, and this process can occur even under water. This, by the way, is the main difference between cement and many other binders.

For example, gypsum and air lime gain strength only in air. And in the composition of concrete, it hardens not so much because the water evaporates, but due to its reaction with the powder: at this moment heat is released and solid or crystalline substances are formed. That is why the process of mixing the mixture itself is often called a gate, and not at all dissolution.

A monolithic mass is formed due to the hydration of cement, concrete should not be dried in the scorching sun - it will simply "break", it will crack and begin to crumble very quickly.

Let's dwell a little more on the features of production.

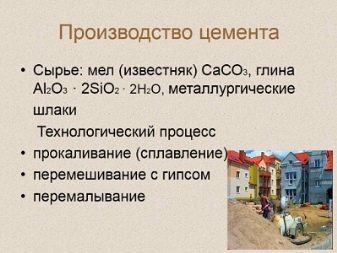

At the first stage, limestone is harvested, chalk, marl, as well as limestone tuffs are considered the best, but all kinds of gypsum and dolomite are not recommended - strength cement based on them leaves much to be desired. Then the raw material is mixed with clay in a ratio of 3: 1 and the resulting mixture is sent to a rotary kiln heated to 1400-1500 degrees.

After 3-4 hours, the composition leaves the furnace, at this moment it is a set of different-sized lumps - this is cement clinker, then it is crushed to particles less than 100 microns in size, at this stage 6% gypsum is added to the composition - this is necessary for cement did not absorb moisture from the air.

In addition to gypsum, other active components are introduced into the composition, which improve the performance characteristics of cement and allow it to be used in a wide variety of construction industries: all additives give cement certain parameters, for example, water-repellent or fast-hardening building materials, and in conjunction with ASG they produce concrete.

Manufacturers

The modern building materials market offers a fairly large selection of various mixtures and powders for certain tasks. It is worth choosing products from trusted manufacturers who guarantee high quality components and their creation in accordance with technology.

"Monolith"

A large manufacturer that creates and sells cement-sand mixtures at a plant in Kirov.The assortment is large enough, it includes reliable and high-quality compounds of the M150 brand, well suited for plastering, grouting, and masonry indoors and outdoors.

Also, reliable compositions of the M300 brand are implemented, which are relevant for the production of reinforced concrete structures.

Knauf

A well-known brand supplying to the market high-quality cement and plaster mixes in several lines (Sivener, Adheziv, Grunband, Unterputz). All products are distinguished by excellent thermal insulation performance. Suitable for a full range of finishing works - indoor / outdoor. In most of the manufacturer's mixtures, components are added to the composition to increase the positive properties.

"Real"

The manufacturer's products are popular, supplying high-quality cement mixtures of the M75 and M150, M100 and M200 brands. The assortment allows you to choose what you need for finishing and repair work. Most dry mixes are supplemented with components to increase frost resistance, which expands the possibilities of working with them and allows them to be used both inside and outside.

Dauer

A German brand that offers inexpensive high-quality DSP for indoor facades and walls, screed pouring, block and brick installation.

The manufacturer's dry mixes are very popular, since they have a low consumption, an affordable price, which in general can significantly reduce the cost of work.

"BaltPiterStroy"

A large Russian company supplying cement-sand mortars of any brands to the market. Also among the products you can find other components - rubble, gravel, crushed stone, sand, cement in bags and a variety of reagents (anti-ice, for example).

"Stroyservice-Novablock"

Previously, the manufacturer's cement-sand compositions were presented on the market under the Plita Milks brand. In addition to dry mixes, the range of products includes high-strength sand-gravel mix of M300 grade. All compositions are of very good quality, as they are produced on modern factory equipment on an industrial scale.

Views

There is no official classification for cements. In the most general terms, several groups of compositions can be distinguished, the criteria of which are based on various parameters.

So, depending on the purpose of the composition, general construction and special compositions are distinguished. If the composition is taken as a basis, then you can designate options with min. additives and clean cement.

If you classify cement depending on the rate of hardening, then the following options are most common:

- quick-setting mixtures - those whose setting speed is less than 45 minutes;

- normally setting - harden within 45-120 minutes;

- slowly hardening - harden for more than 2 hours.

Stressed, refractory, self-expanding cements and many others are also distinguished.

Let's dwell on the most popular types:

- White cement is a material that is made from low-iron clinker, which is bleached. It is a material with unique properties, it can be used not only for bonding surfaces, but also for the manufacture of sculptural elements and columns, as well as for cladding the facade of a building. Due to its color, the use of white cement can improve the aesthetic component of the surface. By adding certain pigments, colored cement can be obtained.

- Waterproof expandable cement is a substance with a high setting and hardening rate. It is produced in the process of simultaneous grinding of cement, gypsum and calcium hydroaluminate. Such cement begins to set after 4 minutes from the moment of mixing, and finally dries up after 10 minutes.

- Waterproof non-shrinking cement - the main composition of the components of such cement is the same, however, the processing and production technology makes the hardening rate even greater - it takes no more than 5 minutes for the composition to dry completely. Such a composition is used to form a waterproofing shell of concrete goods.

- Fast hardening Portland cement is a cement that is finely ground, making it more intense than standard Portland cement. The material gains special strength in the initial stage of hardening - after 1–3 days. Most often it is used when carrying out repair work.

- Plasticized Portland cement is a composition, during the production of which 0.25% mash on a sulfite-alcohol basis is introduced into the grinding of clinker, due to which the frost resistance of the mixture and its plasticization significantly increase.

- Hydrophobic cement - made by joint grinding of Portland cement clinker and gypsum, as well as by introducing axilol or another hydrophobizing additive into the composition. The water absorption of such cement is low, therefore it can be stored for a long time even in conditions of high humidity and this will not in any way worsen its physical and technical characteristics. Such a mixture does not form lumps, and concrete based on it does not crack over time and does not delaminate.

- Alumina cement is a hydraulic binder made from raw materials rich in alumina, usually limestone or bauxite. The material hardens in low temperatures, therefore it is widely used for repair work in the winter season.

- Magnesia cement - obtained from raw materials rich in magnesium oxide. It has found application in the arrangement of magnesia floors.

- Portland cement - is obtained by grinding Portland cement clinker with gypsum and special additives, the firing technology is built in such a way that the resulting product retains a high content of calcium silicates.

- Pozzolanic Portland cement - these building materials include components of volcanic origin in their structure. This composition quickly hardens both in the open air and in water, while mixtures based on such cement do not give any efflorescence and are highly hygroscopic. As a rule, such material is used in the equipment of swimming pools.

- Acid-resistant cement uses quartz sand and sodium silicofluoride in the manufacture, such a composition is resistant to most mineral and organic acids, it does not change its characteristics in water. However, when it reacts with alkalis, it begins to break down.

Preparation of the solution

So, after all the materials and tools are prepared, you can start making the solution with your own hands.

- 1 layer of cement is poured into the container, then a layer of sand, after which all layers alternate. The number of such layers should be at least 6. Thus, all components can be diluted more efficiently. Sand and cement should be poured into a bed. The total height must be no more than 300 mm.

- The components poured into the container must be mixed several times with shovels until a homogeneous mass is obtained. Do not forget that the quality of the finished mixture and further work will depend on the mixing process. After everything is mixed correctly, experts recommend sifting the composition through a sieve with 3x3 mm cells again. The homogeneous mass must be absolute.

- After mixing the dry components, you cannot immediately add water or other components, for example, water glass. The addition of liquid should be done gradually and carefully. Water must be added very slowly, so you can control the process of acquiring the desired consistency density. If the supply of liquid is large, it is the gradual addition that will not allow the mass to become too liquid.

An equally important indicator for cooking is the temperature of the liquid: it should not be either low or high. Try to use water that is close to the ambient temperature. An important role is played by the ambient temperature: it is necessary to dilute ready-made cement mixtures at an air temperature of at least +5 degrees.

As for the consistency of the cement mortar, everything here will depend on the area in which it will be used. For example, a thick material is required for masonry, and liquid material for filling.

For screed

The rules for preparing the solution depend on the purpose for which it will be used. For example, it is easier to prepare a mixture for a screed than for organizing a foundation. Crushed stone is not required here, and the proportions of the remaining components will be as follows: cement of the M400 brand and sand in a ratio of 1 to 3.

To properly prepare the consistency, follow the steps in the following order:

- lay a sheet of metal on the floor;

- pour 1/3 of the sand and 1/3 of the cement onto the surface, mix until smooth, repeat this action until the ingredients run out;

- make a pile from the resulting dry mixture, and in it a notch;

- Pour some water into this "container" and mix everything well.

For the foundation

As for the preparation of the mixture for the foundation, the process is more complicated here, and the best solution would be to use a device such as a concrete mixer.

Begin the kneading process by adding water. Determine the required amount at a ratio of 1: 4. Experts recommend initially pouring less water, since you can add it at any time

During the preparation of the cement mixture for the foundation, it is very important to monitor the consistency. It is better that it is liquid, but water must be used carefully

If there is a need for density, this indicator can be achieved after the kneading process is completed.

For finishing

The cement mixture is also used for interior decoration. The need for it appears when it is required to carry out high-quality plastering of the surface.

The use of the components that are in the composition of the cement makes it possible to obtain the required consistency

Note that more solution is needed for this to work. If there is a need to sand a small area, you can use manual mixing, but in any case, the concrete mixer will make this process faster.

Application

With the help of cement, many construction and repair tasks are solved. In some cases, it is effective on its own, and in some it forms a symbiotic substance with additional components or itself becomes part of the building mixture.

Common uses for cement:

- Pouring the foundation for a private house or garage. It is not used in its pure form due to its too large weight. To do this, it is introduced into a concrete composition in which there is dry alluvial sand, stone or crushed stone, ASG, water. Cement here plays the role of a binder and elastic component.

- Filling the floor screed. It is essential in almost any room. With a relatively flat surface of the subfloor without defects and large differences in height, a thin cement screed of 30-40 mm can be dispensed with. For more problematic areas, it is used in two layers. Also, with the help of cement, you can make an inclined screed in rooms where a drain is needed, or fill in the contour of a water-heated floor in order to avoid damage to the system from temperature differences inside the pipes. It is important to use acid-resistant cement and cement-sand mixtures for screeds.

- Production of reinforced concrete structures and prefabricated foundations, floors and wall elements of the house. Stressing cement is needed here.

- Construction of structures in water, road construction, construction of bridges, tunnels, multi-storey residential buildings.

- Brickwork.In this case, liquid cement plays the role of mastic, connecting bricks, blocks, natural and decorative stone, and other laying materials. Masonry is used not only for the construction of partitions and walls in the room, but also for the construction of fireplaces and stoves. In the last two cases, refractory cement is needed, not lower than M400.

- Plastering and leveling of ceilings and walls inside and outside the premises. A solution of finely dispersed limestone with the addition of gypsum cements problem areas, making them suitable for decorative finishing. Since the process is long, PVA glue is added to the finished composition, which slows down the evaporation of moisture and improves adhesion to the working surface.

- Waterproofing. A sheet of insulating material can be "planted" on the cement mortar so that it does not float when the screed is poured.

- Manufacturing of paving slabs and other decorative items. Colored cement with high aesthetic qualities is used here.

- Organization of garden paths using a reinforcing mesh.

- For the blind area. This structure plays the role of removing liquid sediments and melt water from the building. In this case, 30-40% of the components of the bulk fraction of the type of expanded clay, broken brick, slag are added to the cement mixture.

- "Ironing". It works as a protective "shell" on the concrete surface. A thin layer of liquid cement mixture is applied, and after hardening, it is rubbed to smoothness.

- Decorating. Cement perfectly replaces gypsum for creating sculptures, park and garden decor in the form of flower beds, pots and flowerpots.

For information on how cement is produced, see the next video.

Conclusion on the topic

As you can see, cement-sand mortar is not just a common mixture of two ingredients. There are several types of it, each of which is intended for specific construction work. At the same time, it is not only the quantitative ratio of the main ingredients that matters, but also the content of water and special additives that increase the qualitative characteristics of the material. Mortars based on cement and sand are most often used in construction and repair work. Therefore, everyone who is going to build a house or renovate his apartment should know their composition and proportions of components.

One of the main components of mixtures for plastering surfaces, or for concrete solutions, is cement. Cement is currently considered a very popular material, because it has sufficient strength and ductility.

I must say that in the process of construction or the production of repair and construction work, cement is almost never used in its pure form. It is expensive, and the hardened clean cement is very fragile, so the brickwork on it does not differ in strength. Therefore, at construction sites, it is customary to use a cement-sand mortar. Moreover, the ratio of the components depends on the purpose for which such a mixture will be used.

In other words, if it is necessary to lay bricks, then one type of sand-cement mortar must be used. For plastering surfaces - other types, etc. I must say that complex and simple solutions are used in construction. Although they differ, first of all, in the number of components used. Those. if a simple solution can be easily prepared from water, a certain part of cement and sand, then complex solutions consist of more ingredients.

Brickwork is usually laid on lime or complex sand-cement mortar. Lime mortar is a cheap and convenient type of mortar, which is why it is used most often. However, it should be noted here that its strength in some cases leaves much to be desired, therefore it is not recommended to use this type for strong masonry. For this, cement-sand mortar m100 or m150 is more suitable.

M100 is the most popular among all other mixtures of this kind and is often used in the construction of houses and in repair and construction work.It can be used for masonry, masonry of concrete blocks, slag and foam blocks, as well as for arranging screeds on concrete bases.

Even more popular is the cement-sand mortar m150. It contains a fine filler, and as for crushed stone or large fractions of filler, they are not in it at all. The main components of this solution are sand and cement, and a little more cement is taken than in the manufacture of concrete of the M150 brand. It is usually called mortar, cement mortar, plaster mortar. Moreover, in the latter case, a certain part of lime is necessarily added to its composition. In some cases, clay can be added to the cement-sand mortar to give it elasticity.

Special building codes have been developed that determine the correct ratio of sand and cement for the preparation of such mixtures. It must be said that the strength of the solution, due to the addition of sand to it, increases, but at the same time its plasticity also decreases. Most often, 3 parts of sand and one part of cement are added to the solution. This solution is considered classic and is used most often.

In order for the mixture to be of high quality, you must first mix the components dry, but as for water, it should be added in small portions to the dry mixture. It is necessary to add water until a creamy consistency is obtained. After receiving such a mass, the solution should be left to thicken for 15 minutes, then again mix well. In principle, cement filled with water is capable of setting in an hour or two, therefore, large volumes of mortar should not be prepared in order to avoid waste of materials.

In conditions of high humidity or frost, special additives are usually introduced into the sand-cement mortar.