Reinforcement with tape

When puttying drywall seams, reinforcement is necessarily made using a special material.

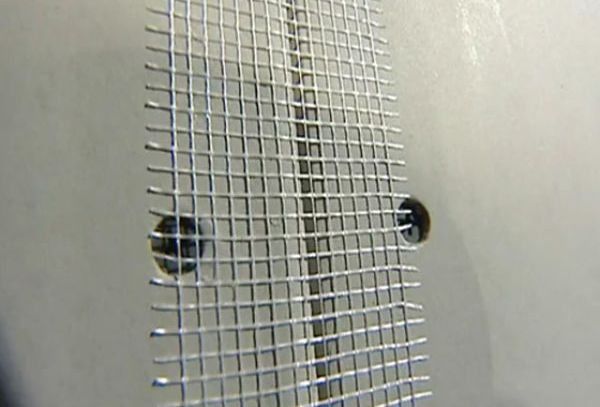

After filling the seams, a reinforcing tape is applied to them. It consists of non-woven tape, fiberglass mesh and fiberglass. The tape protects them from cracking. It is evenly distributed over the surface of the joints and, smoothing with a spatula, remove air bubbles.

In the process of reinforcement, paper banding tape is sometimes used. The use of paper tape for reinforcement gives the seams the necessary strength.

After that, you will need to sand the walls using a special tool or sandpaper. The last operations will give a holistic look.

Master class on processing joints:

Correct execution of the joint putty will help to level the ceiling and get a beautiful interior of the room. Careful adherence to the instructions will allow you to quickly achieve the desired result in the renovation of your premises.

Drywall is increasingly used in finishing works, displacing various types of plaster. In addition to wall mounting, such a finishing material is excellent.

Drywall is increasingly used in finishing works, displacing various types of plaster. In addition to wall mounting, such a finishing material is excellent.

If paint or whitewash is chosen for the treatment of the ceiling, then preparatory work must be done before applying them. Preparation and alignment.

Drywall tape called serpyanka has different sizes. The width of common specimens is 45 and 100 mm. Roll length varies from.

Drywall tape called serpyanka has different sizes. The width of common specimens is 45 and 100 mm. Roll length varies from.

To neatly glue the mesh at a corner, unwind a short piece of tape and place a piece of tape at one corner. Then, gently roll the remainder of the strip onto the other side of the corner and press the strip against the base. Before gluing the serpyanka to the drywall, carefully examine the assembled structure. Check the seams: there should be a distance of about 1-2 mm between the two sheets.

This is necessary so that in the event of surface deformation, the structure does not lose its previous appearance. Corner seams are made in the same way. Here you need to be very careful when working with the solution. You do not need to apply it a lot, then you will have to work for a long time to remove a flat surface.

After the work done with the seams and corners, the entire surface of the plasterboard product is leveled with the finishing putty.

- The room where the work is carried out should have a temperature from +10 to +25, as well as normal humidity.

- It is required to close window openings and doors to avoid air movement.

- Checking drywall products for strength. With “flimsy fastening of sheets, sealing of seams between sheets will be meaningless, since drywall is deformed and this will lead to undesirable consequences.

Manufacturers overview

There are currently several major brands on the market.

Knauf

A popular manufacturer of high quality mixes. To seal the joints are used:

- Fugen. Includes three groups of solutions: universal, ordinary and moisture resistant. The seam is covered in 2 layers, each 1–3 mm thick. The composition contains gypsum and special modifiers responsible for plasticity. During the preparation of the site, priming is mandatory.

- Uniflot. This blend from Knauf outperforms other types. Suitable for filling any edges, it is water resistant and elastic, which eliminates cracking. Naturally, such parameters increase the cost.

Among the Knauf products designed to work with gypsum plasterboard, the Uniflot mixture has recommended itself best of all, but when buying putty, you should be careful, as fakes are often found

Among the Knauf products designed to work with gypsum plasterboard, the Uniflot mixture has recommended itself best of all, but when buying putty, you should be careful, as fakes are often found

Volma

Quite a common option, distinguished by an acceptable price and good quality. The mixture consists of gypsum and various fillers. It stands out for its excellent adhesion, taking into account the life time of the composition of 35–40 minutes.

For work with gypsum plasterboard and gypsum plasterboards, a variety marked "Seam" is used. The process involves the obligatory priming of the joint and thorough drying. Laying is done in two layers, followed by sanding.

A specialized mixture for joints is good in that the connection does not need to be reinforced, but in dry rooms you can use standard compounds, which are much cheaper, and for rooms with high humidity there is a special putty

A specialized mixture for joints is good in that the connection does not need to be reinforced, but in dry rooms you can use standard compounds, which are much cheaper, and for rooms with high humidity there is a special putty

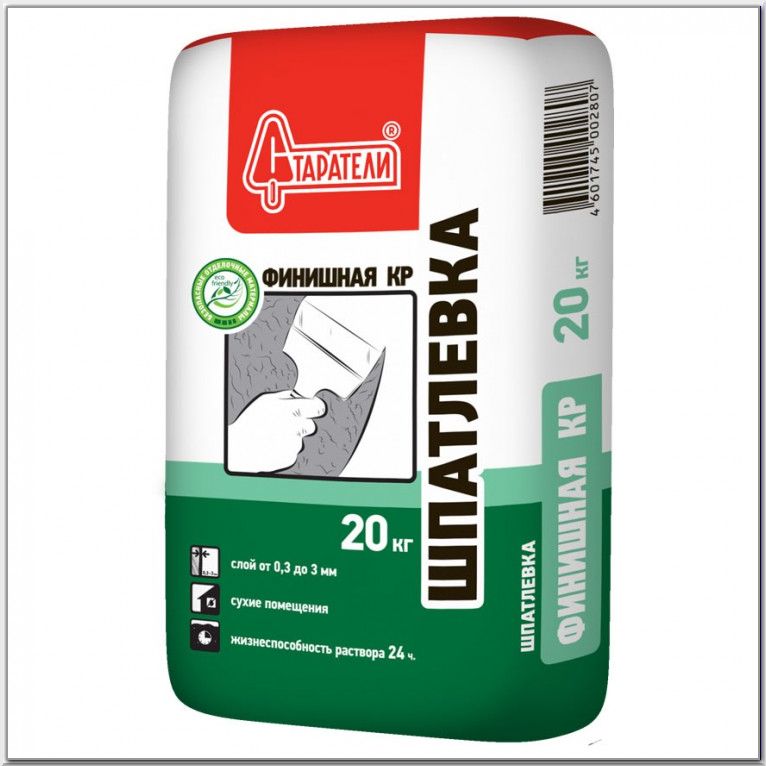

Prospectors

To seal the gaps between the plates, a finishing variety is used. A feature of the products is the need for laying in dry rooms with stable humidity. The mixture includes gypsum and polymer additives. It is produced in the form of a dry substance, the solution is suitable for use within 50 minutes. The manufacturer indicates the possibility of laying a thick layer, but it is recommended to divide the process into two stages with mandatory preparation.

Dry mixes from the Prospectors trademark have a good price-quality ratio, but a short setting time will become a problem for a home craftsman.

Dry mixes from the Prospectors trademark have a good price-quality ratio, but a short setting time will become a problem for a home craftsman.

Vetonit

A versatile variety that is also suitable for sealing joints in objects with constant humidity. Due to the fact that polymer glue acts as a binder, it is possible to achieve excellent adhesion, but this increases the drying time (at least a day).

To work with drywall, a superplastic dry mixture and ready-made putty for painting are usually used, with the second option it is easier to work

To work with drywall, a superplastic dry mixture and ready-made putty for painting are usually used, with the second option it is easier to work

Sheetrock

The products of this manufacturer are highly reliable. For do-it-yourself work, a polymer variation is used, which can be dry or ready-made, depending on the group. Great for dry rooms, drying time 24 hours.

High quality polymeric putty from Sheetrock

High quality polymeric putty from Sheetrock

For filling, it is better to purchase formulations made recently.

What are the putties

Paste formulations of putties consist of:

- conventional filler;

- special binder;

- different additives.

The putties can be completely dry, powdery, filled in bags or bags.

Dry plasterboard putties are convenient to transport and store, as they usually have a fairly long shelf life. The price of these mixtures is also lower than that of ready-made ones, but this does not affect the quality at all.

The most important thing in the use of such mixtures is the exact observance of technology and proportions when preparing a ready-to-use composition. The instructions for such putties will help you do everything right, the main thing is to follow it clearly.

In ready-made putty mixtures, everything is already diluted in ideal proportions, but their transportation is more difficult, and the shelf life is shorter than that of bulk ones.

According to the intended use, all putty compositions are subdivided as follows:

- leveling, they perform primary processing, correcting defects, seams, cracks;

- mixtures for the second layer must be compatible with the first layer and as a result of working with them, we must get a surface completely ready for finishing;

- specialized putty compounds, they are intended for specific purposes, as indicated by the instructions for their use.

All formulations are based on one of three binding elements:

- cement, compositions based on it are resistant to moisture, but microcracks may appear on the surfaces treated with them;

- gypsum, gypsum-based compositions are afraid of moisture changes, it is not advisable to use them in wet rooms;

- polymers, these putties are superior to gypsum and cement in all respects, but their price is also much higher.

With such a variety of putty mixtures, it is very difficult to find the right one, not to be mistaken in the choice made.

Today we are interested in what kind of putty to choose for drywall. We advise you to carefully watch the video on our website that tells and shows about the process of plastering walls or plasterboard ceilings.

- How to putty drywall

- Sealing drywall seams

- Plasterboard putty

What KNAUF offers us

Now many manufacturers have established the production of materials for surface treatment from drywall, but Knauf drywall putty is the most approved product on this market.

Knauf Uniflott gypsum high-strength putty mixture.

For work on drywall sheets, the following KNAUF mixtures are most often used:

- Fugenfüller GV, used for sealing joints of gypsum sheets;

- Uniflot - also used for sealing drywall sheets;

- Fugenfüller hydro, intended for sealing the joints of moisture-resistant knauf sheets.

Putty Knauf Fugenfüller for sealing joints Knauf sheets.

Sealing screws and seams

For seams, there are special compounds Knauf-Fugen, Knauf Uniflot, Fugenfuller and their analogues. After the soil has dried, we dilute the putty to the consistency of thick sour cream

Please note that these putties dry quickly, so dilute a small amount at a time

We take a small spatula, apply the composition to the places where the screws are installed, remove the excess. There should be just enough putty in this place so that the surface is even. Thus, we go through all the screws. They can be sealed in parallel with the seams, or you can - in the first place

It does not matter

The principle of working with putty - a roller from the composition is laid on the edge of the spatula, then it is stretched in the right place

There are two types of drywall joints. Along the long side of the gypsum board, the edges are uneven - for easier sealing of this joint. But the sheets are also connected in height, where there are no ledges. You also have to cut the sheets and the connection is also end-to-end. Such connections require a special technology and more about it below.

Vertical joints

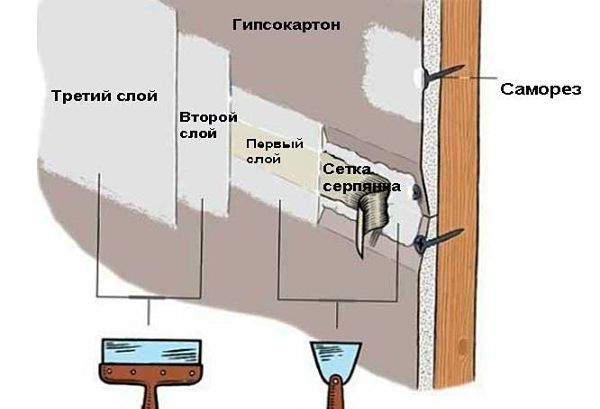

When puttying vertical joints of drywall with normal factory edges, they are first carefully filled, then glued.

After filling, while the composition has not yet dried, it is glued with a serpyanka mesh or paper reinforcing tape. This is necessary so that cracks do not form at the joints. If a tape is used, it is torn into the desired pieces, soaked in clean water for 10 minutes (while the seam is being filled).

The tape is recessed to the desired distance

After filling the seam, the tape is taken out, holding it between the fingers, remove excess water, stick to the seam. After that, they take a spatula 8 cm wide (necessarily this) and press the tape below the surface of the gypsum board. She "sits down" on one of the factory ledges. Start pressing in from the middle to the edges. When pressed, the putty is squeezed out from under the tape, we collect it. As a result, if you put a wide hard spatula (at least 20 cm wide) to the surface, you can see that the tape is below the surface of the cardboard. Then they again pass with putty, leveling the joint to the level with the surface.

Trim seams

It is better to putty drywall in the places of horizontal joints - where two plates are connected or on vertical ones, but without edges it is better after preliminary processing. First, the surface is moistened with water - dip the brush in water and grease the junction well. Walk several times to get the plaster wet. Then use a sharp knife to cut the grooves at an angle of 45 °. These joints can be treated prior to priming. It's even more convenient.

Preparation of joints for putty

We coat the prepared joints with soil. In this case, it is more convenient to use a brush. After drying, fill the seam with a compound for plasterboard joints. It is more convenient to work with spatulas 10 cm wide and 20 cm hard. Apply the composition with a small one, remove the excess with a large one.We fill it well by pressing the composition into the seam. If everything is done correctly, a small roller forms, slightly protruding above the surface.

Once again we go through the seam, applying a fresh putty about 0.5 mm thick, take the soaked reinforcing tape and glue it to this compound. We take a spatula 8 cm wide and press the tape well to the surface, squeezing out the excess putty from under it.

Putty of cut seams on gypsum board

In this case, a wave of paper is formed (in the photo you can see), we make sure that it does not wrinkle, we catch up with it to the end, where it straightens out. We remove the excess solution in the tape and the adjacent area of the sheet. And the last stage - again we take the putty and coat the glued tape on top with a thin layer. We make this layer as thin as possible, as they say - "for sdir". Actually, stretch the remaining putty with a very thin layer.

Second technology: first tape then putty

There is a second technology - a serpyanka or paper reinforcing tape is first glued onto gypsum, then it is putty. It turns out this way faster, but the drawback is the voids that remain under the tape. In these places, the wallpaper can wrinkle or the putty, decorative plaster can crack.

This is how they stick the serpentine on drywall

Also, instead of paper tape, a serpyanka mesh is used. Serpyanka is more difficult to work with - it is tough and its edges often stick out of the solution. To make it a little easier, the mesh is pre-glued, after the glue is completely dry, putty. In order not to think about glue and speed up the work, use a self-adhesive serpyanka (there is one).

An example of a seam putty with serpentine

But, all the same, it is more difficult to putty drywall - its surface is uneven, the spatula "jumps" on the fibers and a small wave is obtained, which is not at all easy to smooth out.

Preparation of putty

The putty process begins with the preparation of the putty. In order for the composition to have all the necessary qualities, it is worth adhering to the manufacturer's recommendations regarding the proportions of the dry mixture and water. Each manufacturer's preparation methods and proportions may differ, so you need to carefully look at the instructions on the back of the package.

In addition to the dryest mixture, a number of tools will be needed to carry out the process:

- container for mixing the solution. The optimal volume of the container is 20 liters, while it is worth making sure that the bottom is flat and the edges are round.

- spatulas of different widths and lengths required for sealing joints and filling a flat surface;

- corner spatula, for leveling internal corners;

- special mesh (serpyanka) for seams. With its use, the risks of cracking are minimized.

- construction mixer or drill with a screw attachment.

To prepare the mixture, a set volume of water is poured into the container, after which, with the mixer turned on, a certain amount of dry material is added, necessary to achieve the desired consistency. After complete mixing, it is advisable to leave the mixture for a few minutes to bind the components. However, do not forget that gypsum compositions solidify very quickly, therefore, such a solution must be mixed in a small amount, since it cannot be mixed again.

Which putty is best for drywall

The choice of plasterboard putty is quite a responsible matter, so you need to listen to the opinion of experts. Which putty is best for sealing drywall seams?

Types by type of binder

For different purposes, different types of putty are used. In addition to dividing into finishing, starting and universal, putty is divided into several types, based on the substance that is the binder and does, in fact, all the main work. Usually putty mixtures are used based on three substances:

- Gypsum plaster for drywall

- Cement plaster for drywall

- Polymer plaster for drywall

Plaster putty

Experienced builders consider gypsum-based putty to be the best option for drywall. This material is environmentally friendly, and it significantly improves the most important characteristics - strength, reliability, durability. Advantages of the gypsum mixture:

- Fast drying without loss of strength

- Plasticity that prevents the putty layer from collapsing when changing the sheet size under the influence of temperature

- It is very easy to apply and level

- Excellent adhesion to the plasterboard surface

The plaster putty has only one drawback - it is afraid of moisture, so it is not possible to use it in the kitchen or bathroom.

Cement putty

This type, on the contrary, is used most often on facades, in kitchens and bathrooms, because the cement, which is in the base, is not afraid of moisture. It protects drywall from various vapors and water

The main advantage is high strength after drying, but it is very difficult to correct defects after application, so everything must be done very carefully and correctly. A huge drawback is shrinkage after drying

This leads to cracks and the need to putty several times. For interior decoration of a house, such a putty is not very suitable, but for a rough finish it is quite.

Polymer putty

It is considered the most convenient to work with. Its scope is very wide. The advantages are:

- Moisture resistant

- Polymer putty does not shrink after the composition has dried

- It is easy to apply

- Possesses high strength

The only drawback is the high cost compared to the previous options. This is especially noticeable in large rooms. But it's worth it, this putty is versatile and can be applied on almost any surface. Most often it is used as a finishing putty. A layer with a thickness of only 1 mm is able to smooth out all roughness and unevenness, which makes the polymer putty the most economical. Repairs carried out with this type of putty will not require updating for a long time.

What putty to use for drywall, depending on the type of work

The putty is used for various purposes - to close seams, level the surface. Therefore, there are several types of putty, depending on the purpose:

Starting

It is used only for primary processing (elimination of irregularities and defects). It is a mixture of large grains, most often white, gray, brown.

Finish

It is used for the final leveling of the wall or ceiling, giving smoothness, in order to prepare for the final finishing - gluing wallpaper, laying decorative tiles, painting. Small white grains.

Universal

It performs the functions of both starting and finishing putty - filling cracks and seams, final leveling. Sold as a powder or mixture, it is usually white in color.

Work order

Each master has his own secrets of how to putty drywall under the wallpaper. Nevertheless, the work is carried out according to the technology in several stages:

- All joints and defects are carefully leveled.

- External and internal corners are formed.

- The filled areas are sanded.

- The entire surface is dedusted and primed.

- Putty is applied.

- Grinding and priming is carried out for subsequent finishing.

You can control the quality of the base using the directional light of a lamp or flashlight. If defects are noticeable, you need to apply the next layers until the desired result is achieved.

Sealing seams, holes and defects

All recesses on the surface of the wall must be tightly filled with putty. Professional craftsmen recommend using a Knauf-Fugen mixture for this. It is flexible, easy to use, fills the joints well.

The putty is rubbed into the defects with little effort until a bead of material forms on the surface. Self-tapping screws are recommended to be processed with Knauf-Fugen 2 times to avoid shrinkage.

To strengthen the seams, reinforcing paper tape or serpyanka are used. They protect the filler from cracking and destruction.

Seam sealing is carried out in the following ways:

- Pre-wet the paper tape in water for better adhesion to the surface and prevent the formation of bubbles. Fill the joint with putty and glue the tape, pressing it lightly with a narrow trowel. The tape must be completely immersed in the solution.

- Apply a finishing filler to the seam. Glue the wetted tape on PVA glue to the joint. After drying, putty the entire surface.

- When using a seam, the seam is also first filled with putty. Remove excess mortar from the middle with a narrow spatula, then smooth the tape strictly in the center of the joint with your hand, pressing slightly. Cover with putty with a wide spatula.

There should be no voids in the seams and holes, and bubbles under the tape or serpentine. Grinding is started after the solution has dried (10-12 hours).

Plasterboard corners

The processing technology for external and internal corners is different. For the outer corners, special perforated profiles made of galvanized steel or plastic are used. They allow you to strengthen the joint of two sheets and give the corner the correct geometry.

The area is pre-covered with fresh putty. The profile is applied to the corner and pressed slightly. A portion of the putty is applied on top and smoothed so that the corner disappears completely under it. You can pre-fix the profile with self-tapping screws.

A paper tape is used to reinforce the inner corners. The joint must be well coated with putty. Place the tape over the mortar and press firmly. Smooth it out with a narrow trowel, then cover with a small amount of putty.

Finishing plaster of plasterboard walls for painting

The substrate for painting should be almost perfect. The task of the finishing putty is to level out even the smallest defects.

Before puttingty drywall for painting, the entire surface must be covered with a starting mixture, dried and sanded. Clean the walls from dust, prime. After drying, get to work:

- Stir the composition for finishing putty thoroughly. If it is prepared from a dry mixture, you need to achieve a uniform and smooth consistency, reminiscent of sour cream.

- Apply the mixture with a trowel to a long trowel and spread over the wall.

- Then, in a circular motion, rub over the surface with the thinnest possible layer.

- Sequentially putty each area with an approach to the adjacent one, so as not to leave rough marks from the spatula. Movements must be done with uniform pressure.

To speed up the work and improve its quality in the corners, it is recommended to use a special angled spatula. It copes well even with hard-to-reach places.

The air temperature in the room should not be lower than 10%. Drying time - 8 hours. After complete drying, start sanding. This is a laborious process, but the final result will depend on the quality of the work done.

Remove dust and primer before finishing. If necessary, repeat the putty-sanding-priming cycle several times until the desired surface quality is achieved.

Plaster of seams (joints) of drywall

The joint filling technology is as follows:

- Carefully inspect all irregularities in the area of joining the sheets. If any of the screws protrude, then they will need to be screwed in.

If some turned out to be recessed by more than 5 mm, then they should be unscrewed and screwed in again at a distance of up to 50 mm from the previous place. Alternatively, you can replace such a self-tapping screw with a longer one and not make another hole in the sheet. Trim the cut edges of the drywall at a 45-degree angle to a width of 3-5mm. If in the area of the joint there is “the native edge of the sheet, then it is not necessary to cut it off. This is done to increase the adhesion of the surface to the putty.

Don't forget to prime the cut edges! Drywall putty begins after this layer has dried.

On top of it, another layer of putty is applied with great pressure on the spatula. It should be recessed into the material so that it does not jump out as unnecessary during grinding. For the last layer of putty, it is better to use a ready-made pasty mass.

It is more plastic and the result of its application is much more attractive. The final layer of putty should be applied clearly at the level of the sheets themselves.

Apply only with a wide, straight-edged trowel. Working at this stage with an old tool is simply barbaric: it will leave scratches that you tried to avoid during all the previous stages.

The next, final stage begins in 4-6 days, when all layers of putty are dry. Grinding of the putty joints (seams) is done first with sandpaper, and then with a softer version of it - sandpaper.

Instructions: how to putty drywall joints (video)

Additional Information: Putty plasterboard seams how to putty plasterboard seams

Also, for filling the joints, you will need a reinforcing tape - serpyanka. It is a fiberglass-based construction mesh. One side of it is treated with an adhesive that fixes the tape to the surface. The width of the serpyanka is different - from 4 to 23 cm, length from 2 to 18 m.

Internal corners are most often trimmed with paper and serpyanka - the joints of walls, as well as walls and ceilings. The technology is similar to the sealing of seams. A certain amount of putty is applied to the corner, paper or serpyanka is glued onto it, the reinforcing strip is pressed into the composition with a narrow spatula, the excess putty is removed.

After that, go through the corner again, applying a thin layer of putty on top.

Sealing drywall seams is not difficult, but it requires enough endurance and accuracy, since there can be a lot of seams, and everyone will have to seal them up, and if they are also located on the ceiling, then the master will be very tired. We advise you to take small breaks so that the quality of the work does not fall, and so that the putty does not fall from the ceiling, you need to press harder on the spatula, so it will more densely penetrate deep into the seam.

The main reason for the formation of cracks at the joints of drywall is the properties of the material of which the gypsum board consists. Gypsum absorbs and releases moisture well from the air and, depending on the season, the sheets either expand or contract. And if mistakes were made during the installation of the GKL and during the puttying of its joints, then their result will be the appearance of cracks.

To begin with, you can walk with a sharp, even spatula, cut off all the most protruding irregularities. Next is the grinding process. Since the corners and seams at this stage do not need to be cleaned to perfect smoothness, they take a mesh for grinding with a 180-200 mesh and a wooden block.

A mesh is attached to the bar (you can use staples from a construction stapler, but the staples should not stick out). With this device, the surface is leveled. When working, it is desirable to highlight with an oblique light - this way all the irregularities are more visible.

But you can not putty drywall under the wallpaper so carefully.

One of the possible defects is bubbles at the joints of the gypsum board. We cut the bubbling areas with a painting knife. Small bubbles can be removed completely. Next, we tape the area around the bubble and cover the defect with putty.

We level the surface with a spatula. How to properly putty plasterboard walls for painting video? A day later, we process the area with a finishing compound and clean this place with a fine-grained abrasive.

What are the mixtures for bathrooms

There are many different putties on the market today, which differ in their composition and are suitable for wet rooms. It depends on the presence of different components what qualities the mixture will have.

Based on the required properties, two types of materials can be distinguished:

| View | Properties |

|---|---|

| Waterproof cement-based mixture |

For this composition, I use the highest grade cement, which only strengthens its properties from exposure to high humidity. The following are used as additional additives:

sand - very fine fraction; marble chips; clinker chips; hardener; plasticizer; modulator.

All this makes it possible to use the putty even outside the building.

Advice! If it is supposed to paint the walls, then it is better to pay attention to the pigmented compounds.

Moisture-resistant mixtures based on various polymers (latex, acrylic)

Modern materials that have many positive qualities. They contain a large amount of synthetic and mineral additives, which give the desired properties. They have excellent plasticity and elasticity, are easy to apply, and have a long service life. Great for wet rooms.

However, there is one significant drawback that does not apply to quality. Namely, the high cost.

Advice! If you do not want to understand the names and compositions of putties for a long time, then it is better to pay attention to mixtures for facades.