Types and applications of acrylic paint

Depending on the scope and types of additives used, acrylic solutions also have their own classification. Each species has its own technical characteristics and features.

Each species has its own technical characteristics and features.

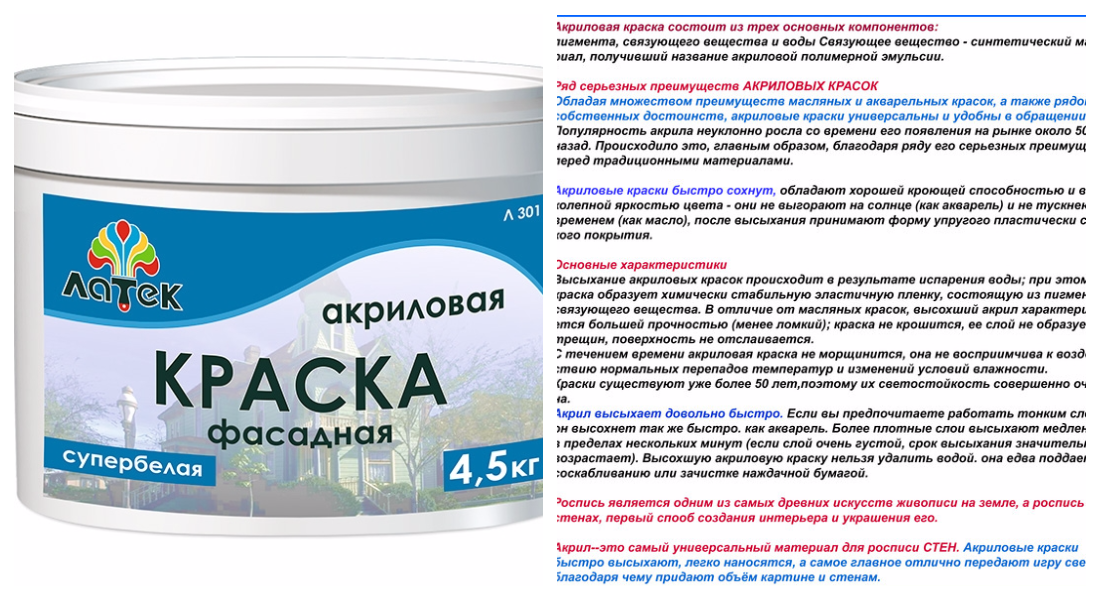

Facade paints

The name makes it clear that they were created to protect the facades of houses from the negative influence of the environment. In addition to facades, they are used for painting fences, gates, and backyard buildings.

The surfaces painted by them will be reliably protected from rain, snow, a sharp change in temperature indicators, and other harmful influences from the outside. Only the cheapest paints from the acrylic series require additional protective agents to be applied on top. The most durable and reliable are acrylic substances containing organic solvents.

Compositions for facade works, which are based on water, are considered to be faulty in terms of protective properties from natural factors, but when marble chips are added to them, these properties become more reliable.

Facade paints are created to protect the facades of houses from the negative influence of the environment.

When it is required to paint metal products, then it is necessary to choose compositions with elements designed to protect against rust formation on it.

It is necessary to choose formulations with elements designed to protect against rust formation on it.

Working with wood involves the addition of special components that resist fungal formations. Colorless acrylics can be used to preserve the natural grain of the wood. Acrylic paint is ideal for covering concrete, plaster, stone, brick surfaces.

Working with wood involves the addition of special components that resist fungal formations.

Interior paints

Acrylic formulations designed for indoor use differ from formulations for outdoor use in the absence of components to withstand environmental influences. But inside the building, they also show their durability, resistance (do not crumble or crack), and the ability to maintain the brightness of the color for a long period.

Since they are easy to apply, work does not require special skills, they are often chosen for painting walls and ceilings in a room, they are great for embodying the most daring design ideas. With them, you can create whole wall paintings in the room.

Interior applications are also possible for furniture, they are suitable for transforming windows and doors. The main difference in artistic use for interior design from oil products is that they do not have a pungent odor, so it is possible to work with them at any time of the year, because you do not need to open windows in the cold.

They are great for embodying the most daring design ideas.

Specialized paints

There are many variations of paints that are suitable for special applications, add components, and they are suitable for a specific application.

Their use for painting bathtubs can be noted, they can be used to refresh the enamel coating of an old bathroom.

To do this, first remove the old coating, and then cover the bath with a moisture-resistant acrylic compound, here it is important to create a thick layer of several millimeters, the surface of the bathroom painted in this way will serve for about 10 years

Their use for painting bathtubs can be noted, they can be used to refresh the enamel coating of an old bathroom.

Acrylic car blends are also popular, they create a beautiful decorative finish that also protects the car from corrosion.

They create a beautiful decorative coating that also protects the car from corrosion.

Acrylic varnishes, which are often used for manicure and pedicure in beauty salons, are widely known. They are easy to apply, you can create a beautiful nail design, such a nail coating lasts for a long time.

They are easy to apply, you can create a beautiful nail design, such a nail coating lasts for a long time.

There are special paints for painting. They are available in tubes, cans, and other types of containers.

They are available in tubes, cans, and other types of containers.

It is not for nothing that acrylic paints are so popular, they have a number of advantages, and can be used to implement many design ideas, and simply as a protective coating for surfaces. Their main plus is environmental friendliness and safety against the background of good practical properties. A wide variety of species makes it possible to choose the best composition suitable for a specific purpose.

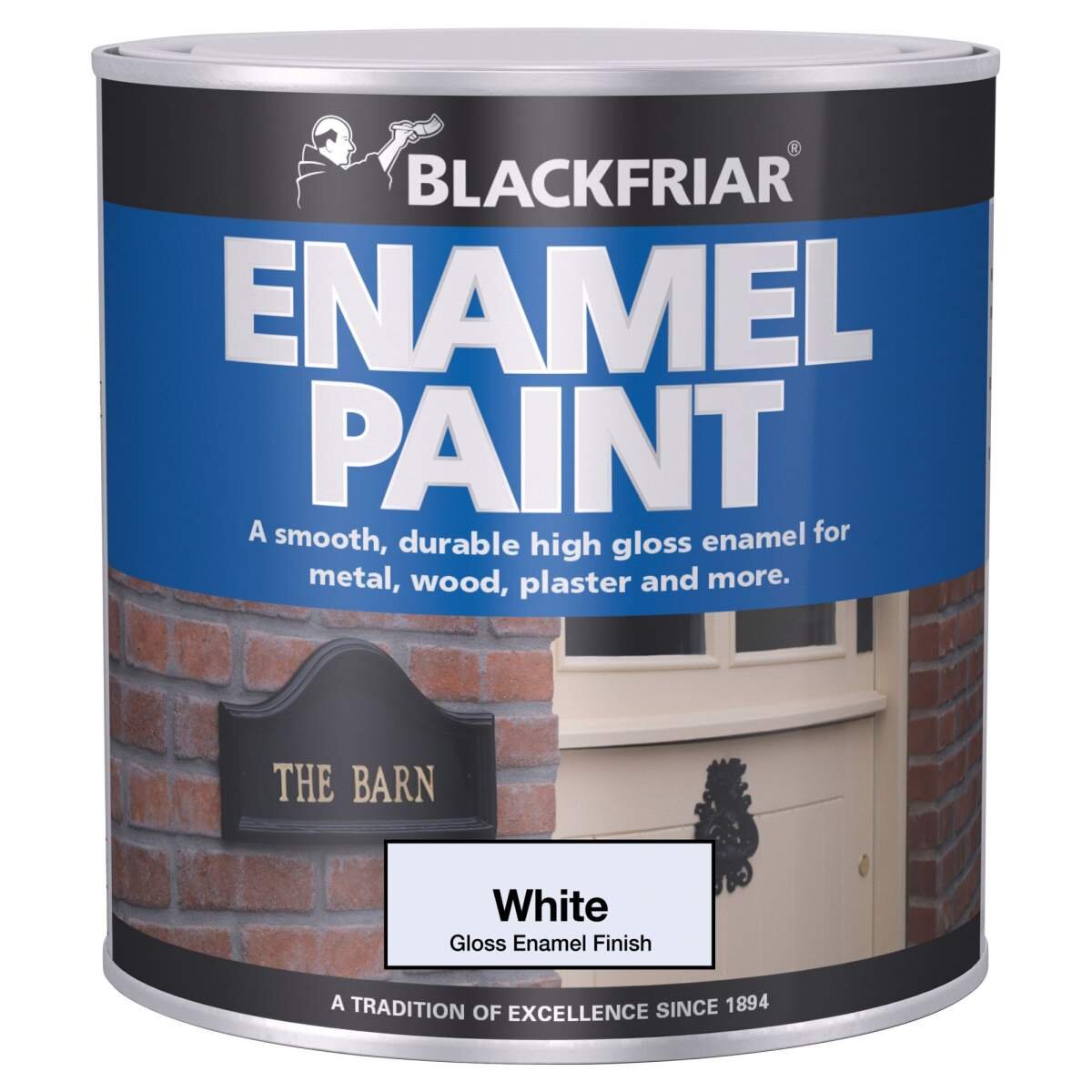

Areas of application of enamels and paints

For the exterior, enamel is better, but for the interior - paint

- External coatings. If your plans are to paint outdoor areas, then it is definitely worth stopping at enamel. The paint tends to crack on condition of constant contact with moisture.

- Windows and benches. However, enamels are not resistant to sunlight. For the elements mentioned, it is better to use conventional paints and varnishes.

- Interior decor and cosmetic repairs. In this case, it is also better to use paint, since it has a suitable loose texture. The choice of enamel can be fraught with the fact that the coating "cracks" some time after application.

The answer to the question of how enamel for painting differs from ordinary paint is ambiguous. Several factors must be taken into account, including the method of manufacture, the presence of additives, the nature of the smell, etc.

In order to navigate the variety of paints and enamels, choose them correctly, select auxiliary material for them, it is useful to get acquainted with the accepted marking.

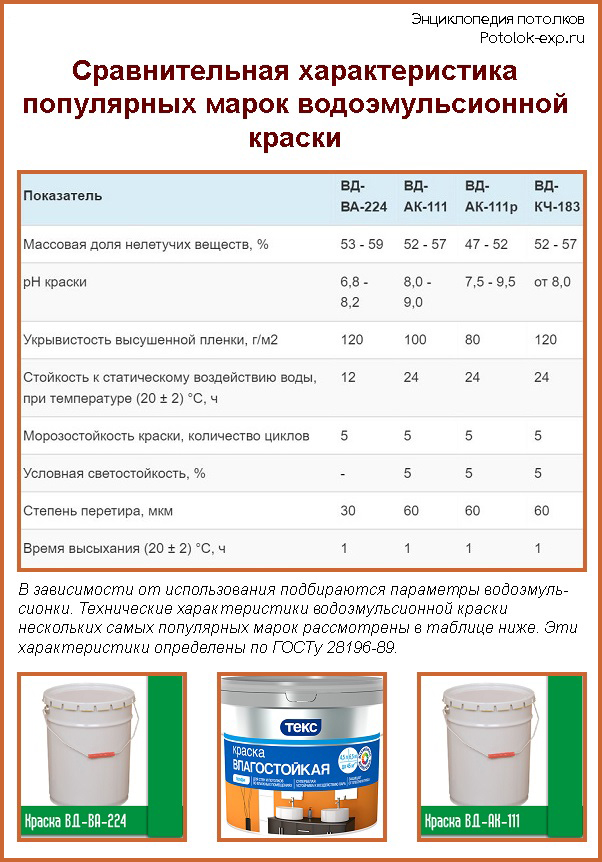

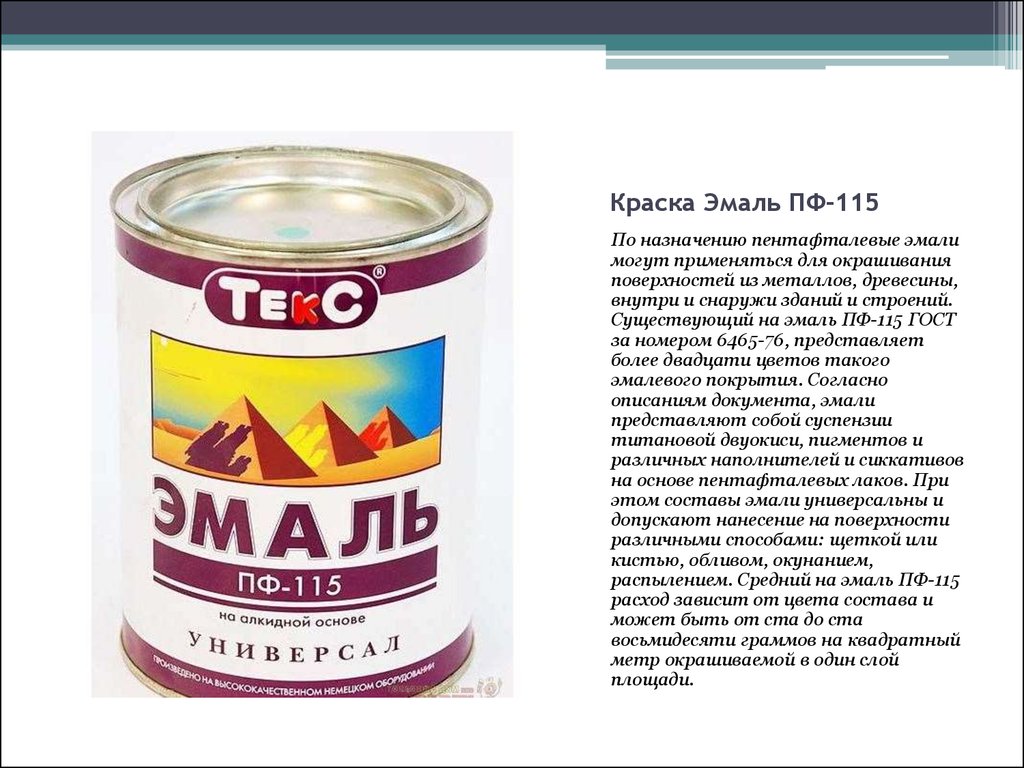

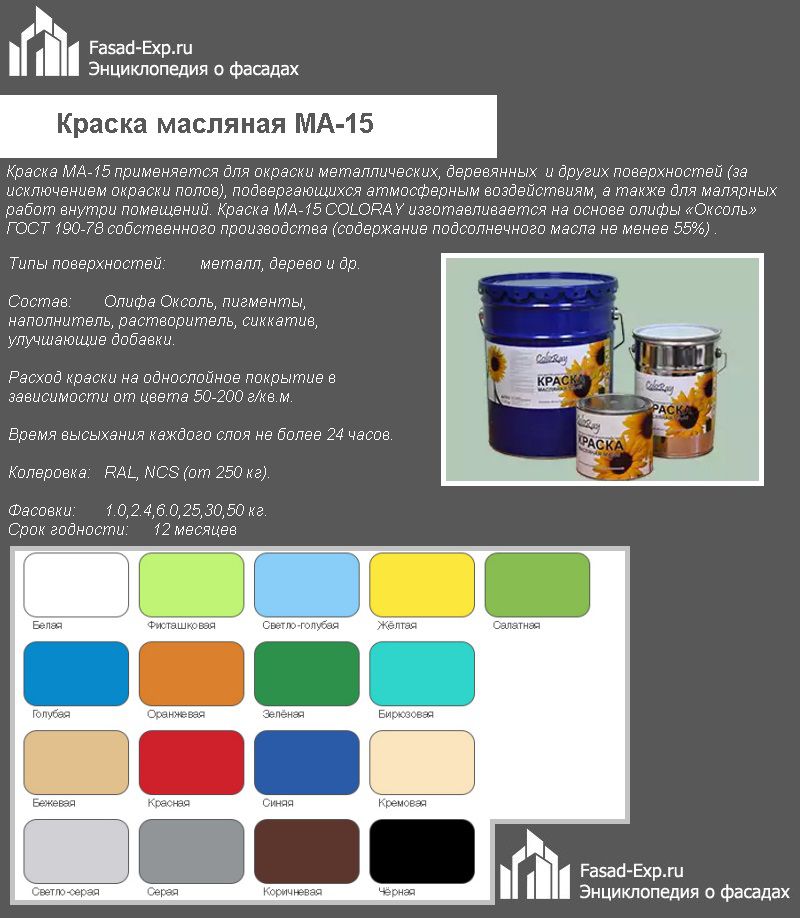

In the name of the paint or enamel, and it is necessarily indicated on the packaging (label), designations have been introduced that help to find out the composition of the paint (enamel), its purpose. Paints are obtained on the basis of drying oils, varnishes and enamels - on the basis of synthetic resins. The binder on which the paint or enamel is made is indicated by the index of the letters behind the name. The letters MA denote paints on drying oils from vegetable oils, PF - enamels on pentaphtalic varnishes, GF - on glyphtal varnishes, YES - on oil-phenol varnishes, ML - melamine alkyd resins, MCh - on urea-formaldehyde resins, PVA - based on polyvinyl alcohol, BG - based on polyvinyl alcohol bitumen, AK - based on polyacrylates, MC - based on melamine styrene resins, PE - on polyester resins.

The letter is followed by a numerical designation. By the first digit, you can judge the purpose of the paint. The numbers 1 and 5 say that the paints are suitable for external and internal work, number 2 - only for painting indoors, 0 - primer, 00 - putty.

Paints based on drying oils (MA), glyphthalic (GF), pentaphthalic (PF) and oil-phenol (FA) varnishes belong to the group of alkyd paints. They are compatible with each other, they can be mixed in various ratios (proportions).

Paints suitable for outdoor use should be prepared with fade resistant pigments and weather resistant binders. Some pigments - zinc white, ocher, red lead, chromium oxide - do not fade even in bright sunlight.

High-quality oil formulations are obtained only on natural drying oil. They are used to paint surfaces for protective and decorative purposes.If the main purpose of painting is to protect the surface to be painted, painting is performed with compounds that form a glossy film. When decorating surfaces indoors, as a rule, matte coatings are used, which soften the tones of the color and make the defects of the surfaces prepared earlier for painting less noticeable.

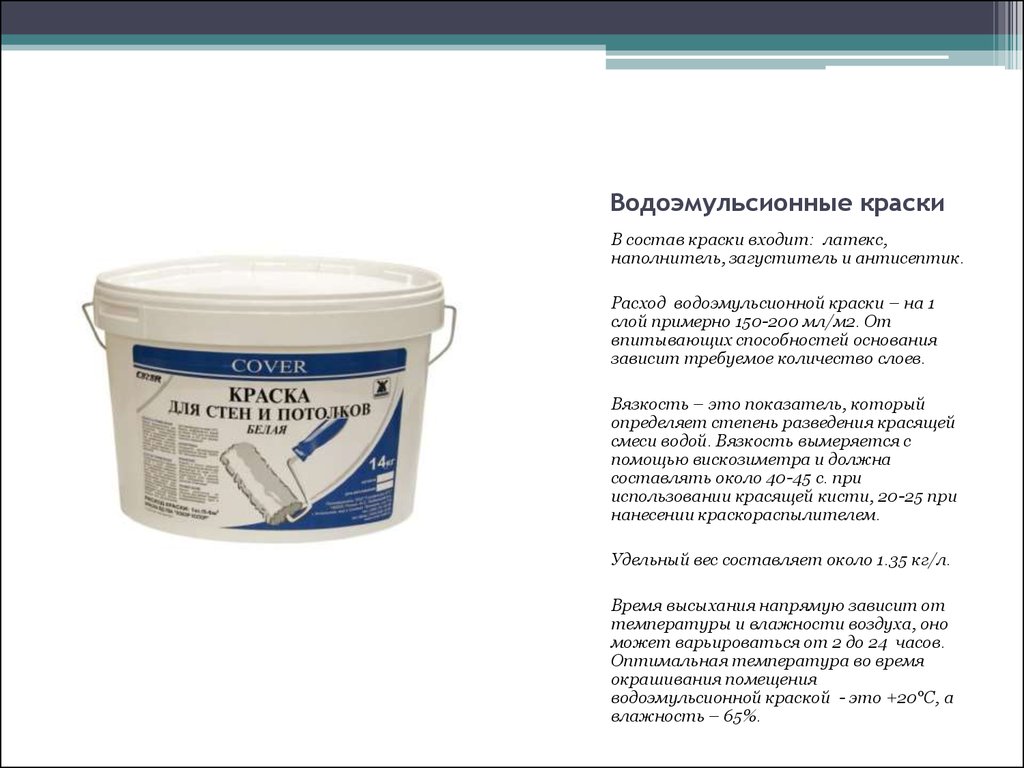

Matte coatings are obtained by reducing the amount of binder in the film, replacing it with an evaporating solvent, and introducing matting additives into the formulations - waxes diluted in a solvent. Such coatings are beautiful, but their strength is low. When preparing for painting with matte oil paints, the surfaces are primed with linseed oil or paint and painted at one time with a greasy oil composition to gloss. In this case, the appearance of the prepared surface should be uniform. All alkyd paints and enamels are applied by brush or roller, usually in two coats. Paint consumption per 1 square meter of surface (in one layer) is on average about 150 g. Paint consumption depends on color and hiding power; for whitewash - not less than 200 g / m².

Those who are professionally engaged in painting know the answer to this question. These are painters, people who sell varnishes and paints, as well as those who certainly work with these substances. Ordinary people do not understand the differences and think that enamel and paint are the same thing. Many people think that paint has a decorative matte finish, while enamel has a shine. But all these judgments are wrong. And there are a lot of differences.

Composition

In fact, the only similarity is that both are colors. In terms of their composition, they are completely different.

The alkyd type can be called a more modernized version of oil paints. They are characterized by a similar mechanism of hardening and the formation of a surface film (which, by the way, is somewhat stronger, but less elastic). Alkyd paints consist of polyhydric alcohols (for example, glycerin) in combination with orthophthalic acid. Actually, the word "alkyd" comes from a combination of the words "alcohol" (alcohol) and "acid" (acid).

Unlike alkyd paints, acrylic paints are made on the basis of acrylic, a polymer better known as plexiglass. The composition of paints may include various additional components designed to improve certain properties (add elasticity, accelerate drying).

Basic properties

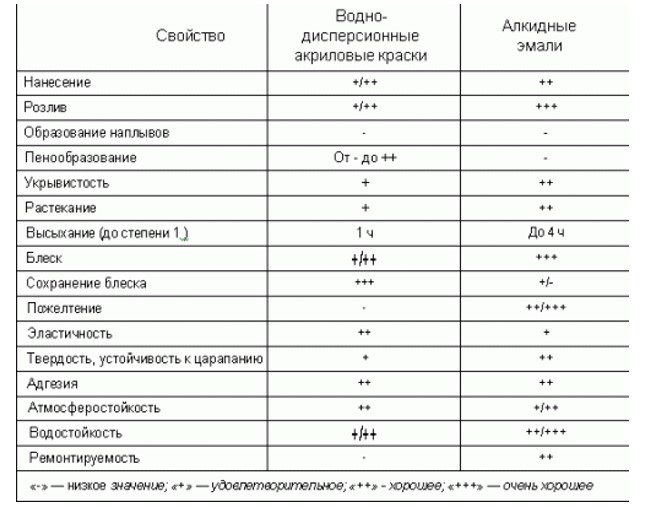

- Life time. Unlike alkyd paint, acrylic paint retains its original appearance much longer. It is advisable to renew alkyd paint about once a year, since oxygen and ultraviolet light intensively destroy the surface layer of the paint. Acrylic coating, subject to the technology of surface preparation and paint application, can last from 8 (wood) to 20 (plaster) years.

- UV resistant. Acrylic practically does not change the properties of the surface film under the influence of sunlight, that is, it does not fade, does not turn yellow and does not acquire a "matte" appearance. Alkyd compounds are not so reliable in this regard.

- Drying process. But the alkyd film dries relatively quickly, and after a couple of days it fully fulfills its protective and decorative functions. The acrylic film completes its formation approximately one month after application to the surface. In this case, the coating should be protected from mechanical stress until it is completely dry.

- Mechanical stability. A longer process of forming an acrylic film is compensated by a higher level of resistance to mechanical stress (deformation, scratches).

- Decorative properties. Alkyd compositions are distinguished by a more diverse range of shades and halftones, as well as generally brighter colors. On the other hand, acrylic paint lasts longer and does not require regular renewal.

Are acrylic and alkyd paints compatible

Can alkyd compounds be applied to acrylic or vice versa? Neither one nor the other is recommended, especially if the painting of the substrate has occurred relatively recently or it is a metal surface. The fact is that the specific composition of paints may not be completely clear to us. Alkyd formulations may contain components that will show dark spots through the acrylic layer. If alkyd paint is applied over acrylic, then it may not adhere to it, that is, peel off.

Nitroenamels. From gunpowder to paint

More than two hundred years ago, in 1800, the French economist and politician Pierre Dupont immigrated to America with his two sons and their families. Once there, the Du Ponts decided to open a gunpowder factory. One of the sons, Eleuther Dupont, was supposed to do this, since he was familiar with gunpowder firsthand: in France he worked at the state gunpowder factory under the leadership of the great Antoine Lavoisier.

No sooner said than done. In 1802, in the state of Delaware, near the city of Wilmington, work began on the construction of a new powder factory, soon after which boxes with the inscription “DuPont. Explosives "(explosives).

For a long time, the Du Ponts were engaged only in gunpowder, but at the turn of the 20th century, they decided to start manufacturing other goods. To do this, they built a large laboratory and hired several dozen chemical scientists. This is how the era of revolutionary discoveries began, among which: the first synthetic rubber (neoprene), the first artificial fiber (nylon), cellophane, Teflon, Lycra, Kevlar and many others. The name DuPont thundered all over the world.

The history of the development of car paints almost coincides with the history of these discoveries. In 1923, when processing cellulose fibers, chemists received the world's first nitro paint, which made a real technological revolution in the automotive industry. Unlike oil paints, which were applied with brushes and dried at a snail's pace, nitro paints could be applied using pneumatic spray guns, and their drying was almost instant. All this led to the hegemony of nitro enamels in the automotive world.

But these colors also had disadvantages. Due to the low gloss, the coating required frequent polishing (in the twenties, linen rags and polishing pastes were used for this). And the painting process itself was long and laborious. Due to the low solids content, the nitro enamel film was too thin and brittle, so 5 to 11 coats of enamel were required to obtain a durable finish.

By the way, this is how the government “Seagulls” and “Zilas” were painted during the Soviet Union times. The coverings of these "members" consisted of up to 12 layers! Moreover, in the process of painting, the carrying of each subsequent layer of enamel alternated with a thorough polishing of the previous one, and the last layer was necessarily processed with wax polishes.

Needless to say, the cars painted this way looked great. There was absolutely no shagreen on their surface, paintwork gave exceptionally beautiful, clear highlights and reflections. In the future, however, the whole thing had to be tinted and polished almost constantly - it was good for someone ...

The same technology was used to paint relatively old models of Rolls-Royces and Cadillacs. This, for example, looked like a 1938 Cadillac 60 Special painted with nitro paint.

Let's talk about the mechanism of film formation of nitro paints. What do you think is the reason for their polymerization? A trick question - no polymerization in nitro paints actually occurs. These paints cure, or rather simply dry out, solely due to the evaporation of solvents. That is, due to a purely physical process.

The film obtained after drying turns out to be reversible, hence another disadvantage of nitro paints: the coating has low resistance to aggressive influences, for example, to gasoline and sunlight.

The disadvantages of nitro paints forced paint and varnish manufacturers to look for ways to obtain new, more durable and more convenient materials to work with. Although, despite all the disadvantages of nitro paints, you should still give them their due - for their time they were very good.

By the way, nitro paints are still produced (you can identify them by the NC marking). Of course, they are almost never used in auto repair. Basically, they are used either by restorers of vintage cars or by owners of old special equipment such as tractors and bulldozers.And then only in order to prepare such equipment as cheaply as possible for the passage of technical inspection.

Differences in composition, characteristics

To find out exactly how acrylic enamel differs from alkyd, you need to consider their composition. Their only similarity is that they are used to paint a wide variety of surfaces. However, there is a big difference between acrylic and alkyd enamel. First of all, the difference between acrylic enamel and alkyd enamel lies in their composition.

Alkyd enamel is a more modernized version of oil paints. It is characterized by similar solidification mechanisms, as well as the formation of the so-called surface film. However, unlike other types of oil products, the surface film that forms after it is applied to the surface to be painted is slightly stronger, but significantly inferior in terms of elasticity.

These paints and varnishes contain polyhydric alcohols. Quite often, they are made from glycerin and orthophthalic acid. In addition, the very name alkyd owes its origin from the phrase of two words - alcohol and acid.

Acrylic enamels, in contrast to the same alkyd paint, are made on the basis of a substance called acrylic. This substance is a polymer that is also known as plexiglass. They may also contain a variety of additional substances that are necessary to improve its characteristics or properties (increasing the level of elasticity, improving drying performance, surface tension).

Purpose and application

Alkyd enamel, due to its versatile properties and characteristics, is widely used during repair and construction work. It is used to paint almost any surface or material. Alkyd paint can be used to paint the surface, both during interior and exterior construction or renovation work.

Most often, it is used to paint structures made of metal or wood. In addition, it is perfect for painting concrete, perfectly protects metal structures from the harmful effects of an aggressive external environment, and also actively prevents the formation of rust on metals. Therefore, it is most often used for painting structures in industrial buildings, as well as in a variety of household facilities. For example, quite often it is used as the main tool for painting heating radiators.

take care of good ventilation inside the rooms. During work, it is recommended to use gloves, as well as to protect the respiratory system - a respirator.

Acrylic enamel is a versatile product that is perfect for painting almost any surface. Typically, it is used when painting surfaces made from:

- metal;

- concrete;

- wood.

It has increased resistance to low as well as high temperatures. Therefore, it is perfect for both interior and exterior decoration of premises. Thanks to its use, any surface on which it has been applied becomes immune to the harmful effects of moisture or pests (in the case of staining wooden surfaces).

Despite the wide range of applications, these enamels are most often used for painting surfaces made of metal. It should be noted that they are not applied directly to the metal itself. Before using them, the surface to be painted is pre-treated with a primer. As a rule, cars are painted with acrylic car enamels. Also these paints use for dyeing batteries heating, because, as you know, they are able to perfectly tolerate temperatures up to 120 degrees Celsius.

Consumption indicators for 1 m?

To find out what kind of enamel is better than acrylic or alkyd, you also need to consider the indicators of their consumption per 1 m2. The standard consumption rate of acrylic enamel can only be taken into account when painting smooth surfaces (walls, ceilings). When painting rough surfaces, the consumption may be slightly higher than the standard value. The traditional consumption rate for painting is no more than 200 grams per 1 m2.

Alkyd enamel consumption rates primarily depend on the type of surface to be painted. For example, consumption values for wood and metal surfaces may vary slightly from each other. On average, its consumption for painting 1 m2 is 130 grams.

Features of enamel and paint

Various types of paints are common and widely used materials. Nevertheless, even professionals do not always understand what is the essential difference between enamels, enamel paints and ordinary oil paints and varnishes.

It is widely believed that enamel is about the same as paint. The confusion is added by the fact that the first material is shiny, and the second has a matte surface. However, the main difference goes much deeper.

In fact, there is nothing in common between these types of coatings. The enamel is a specially designed vitreous formation, which includes quartz, metal oxides, as well as a large set of additional components. In the process of applying a thin layer to the surface, a subsequent heat treatment occurs, as a result of which the components are actually sintered.

Paints are inherently a much broader concept. Quality paints and varnishes are based on chemically modified olive. Conventional paints and varnishes are made on the basis of linseed oils, which have been subjected to high temperatures and additional processing.

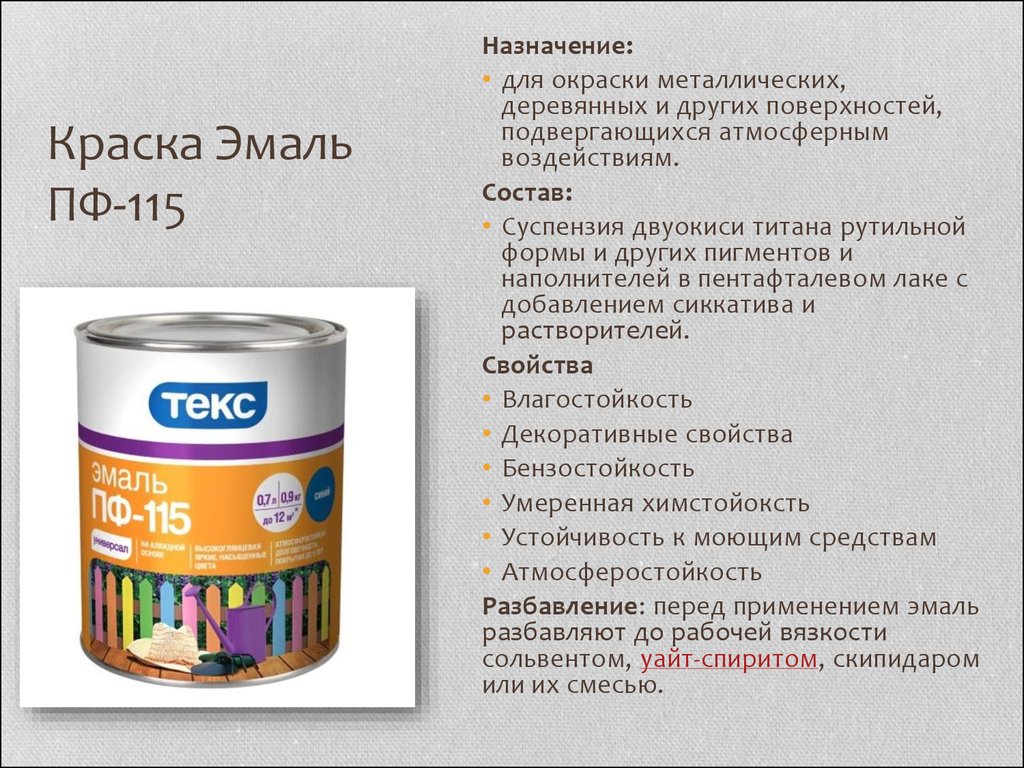

The difference between enamel and plain paints is contained in the presence of alkyd resins in the former. In fact, enamel paints are indexed with the abbreviation PF, which stands for pentaphthalic component. Enamel paint, due to special polymerizing components, is much more stable, the formation of a glossy coating.

Enamel dyes are a solution of liquid or paste-like pigment components, in which film-formers and additives are also dissolved. Dye alkyd resins function as a top film.

Enamel is characterized by a rather pungent odor. Conventional formulations do not always include this characteristic. Water-based paints are especially clean in terms of volatiles. The reason for the pungent odor of enamel paints is the complex chemical processes occurring on all layers of the applied composition.

The effects of polymerization with subsequent strengthening require the release of various organic and inorganic vapors into the environment. That is why the application of enamel should be carried out exclusively in well-ventilated rooms or outside.

Despite their excellent aesthetic qualities, indicators of durability and preservation, enamel paints are not always the only and best choice. Here comes the question of the expediency of using certain materials.

It is better to paint door and window openings with a reliable and durable substance that ensures stable preservation of the internal structure. At the same time, park benches are best painted with polyurethane dyes.

With regard to mechanical factors such as hardness and general elasticity, enamel paint types come first here. The increased resistance to moisture and even water jets compared to any other type of colorant also works in favor of this modern type of coating.

Although the principle of film formation is similar in all enamels, there are several different formulations depending on price and consumer needs.

Organosilicon types of enamel compositions can be applied to almost any type of surface, regardless of the properties of the material. The increased resistance to moisture, combined with wear resistance, makes this type of coating extremely popular in production and construction.

Pentaphthalic enamel paints are based on an oil component combined with synthetic resins and modified alkyd components.

All acrylic enamels are latex-based water dispersions. Suitable additives help to slow down the drying time and speed up the polymerization.

Comparison of two groups of paints and varnishes

The similarities and differences are as follows:

- Acrylic materials are more expensive than oil materials, but they do not have to be renewed every year, spending additional money and time.

- Both groups allow you to carry out work both indoors and outdoors. They are resistant to high humidity and protect well the material they cover.

- Unlike acrylic paints, oil paints are highly toxic.

- Oil paints take much longer to dry than acrylic paints.

- The color palette of acrylic is much wider (compared to oil). However, the colors of oil paints after drying are usually brighter and more expressive.

Paints have a completely different composition. The advantage of acrylic paints is that their solvent is water. Even an allergic artist can easily create masterpieces with them. Oil-based paints and varnishes may also be available for artists with allergies, but only if diluted with linseed oil, which is expensive. Most often, such paints are diluted with turpentine, white spirit and other strong-smelling solvents.

Comparison of compositions

The basis of acrylic paint is a polymer emulsion - acrylic mixed with pigments. The solvent is ordinary water, so the material does not have a pungent odor

... Acrylic is known as water glass and is used as a binder in other building mixtures. It also includes improving additives that affect the viscosity, temperature stability of the solution, the finished coating.

Alkyd, or oil, enamel consists of alkyd varnish, coloring pigments, kerosene solvent (white spirit). Additional additives may be included: antiseptics, anti-fungal, fire-fighting additives. This enamel is often used to cover wood products. During work, careful ventilation of the premises is required: the composition has a pungent specific smell.

Features of alkyd paint

You can find varnishes and paints.

The varnish is made on the basis of alkyd and solvents. It contains no pigments. The mortar is used as a primer for other finishing coatings, as a wood preservative.

The paint contains pigments. Can perform surface protection function. It happens glossy, matte, this does not affect the quality of the coating.

Varnish and primer on the same base have good compatibility. They can be applied on the same surface, mixed.

Dignity

- Wide color range.

- Ease of application, good distribution over the surface.

- The layers dry quickly.

- Resistance to cleaning.

- Suitable for interior and exterior use.

- Affordable price.

disadvantages

- Strong smell.

- Low UV resistance. The coating fades quickly in the sun.

- Hardness negatively affects the service life. Dried enamel is inelastic, does not withstand linear surface expansion. After a few years, it cracks, requires updating.

If you need to use alkyd paint outdoors, you should choose a composition with additives. It is better to place the painted product in the shade.