Cellular polycarbonate: properties and characteristics

Polycarbonate is a viscous polymer that is 200 times stronger than glass. Cellular polycarbonate is used for roofing roofs, awnings or canopies, greenhouses. Given that the material is transparent, it is often used in construction.

Cut out the polycarbonate. Along the "honeycomb" polycarbonate is well cut with a knife along a ruler, across - with a hacksaw.

Since cellular polycarbonate is light enough, the cost of supporting structures can be minimized.

High temperature resistance of polycarbonate eliminates material deformation. It also indicates high safety, since it does not burn and does not support combustion. Due to the fact that polycarbonate sheets are covered with a special layer that absorbs ultraviolet rays, this material can be used in any climatic conditions.

Polycarbonate profiles do not transmit sound waves very well, therefore, using this material, you can achieve a sound insulation effect.

Polycarbonate has a low thermal conductivity. This helps to reduce the energy consumption required for heating or cooling by almost half.

Tool selection

There are some tips in the video:

The advantage of polycarbonate is that there are tools for cutting it in every home. It is easily processed, but the risk of accidental damage is also great. Therefore, all work must be done carefully, trying to do everything accurately and at one time. Let's take a look at some of the most recommended and widely used methods for cutting polycarbonate.

Electric jigsaw

With an electric jigsaw, you can cut sheet material of any type and thickness. Sharpened files with small teeth are used. Canvases that are intended for working with plexiglass, metal and plastic are suitable. The cut will be clean and smooth. It is better to use a jigsaw for cutting complex curved shapes and holes. If you work with sheets less than 3 mm thick, then they can be cut in a pack of several pieces at once.

Hacksaws and various saws

Saws and hacksaws are suitable for making straight cuts and cutting material into rectangular and square pieces. This tool is used only as a last resort, when there is nothing else at hand. It is not allowed to use hacksaws for wood, since they have too large, widely spaced teeth, which damage and tear the polycarbonate, leaving cracks, burrs and notches. You can only work with hacksaws for metal with fine and fine teeth.

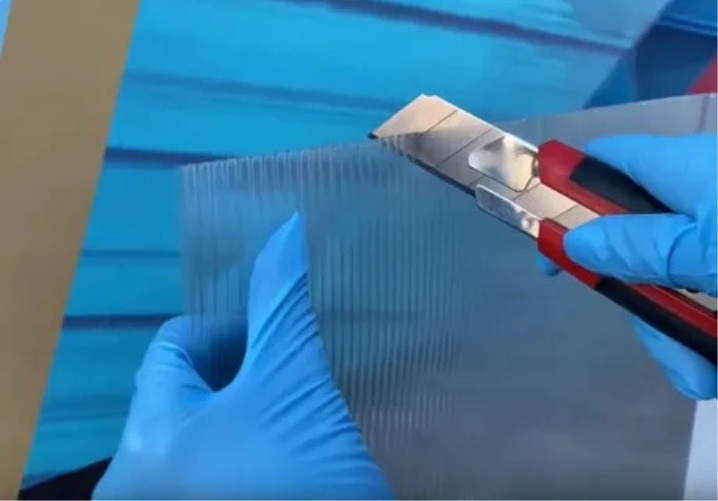

Stationery knife

When cutting sheets up to 6-8 mm thick, a clerical knife can be used. A special construction knife is better suited, since it has a more comfortable handle. It is best to use such a tool to work on small trimming and fitting of small pieces, since it is extremely inconvenient and long to handle large-area canvases. In addition, a clerical knife dulls quickly enough and often breaks. It is mainly used for cutting cellular polycarbonate.

Special scissors for plastic

Thin (up to 3 mm) sheets are cut with special construction scissors or plastic scissors. Thus, only monolithic canvases can be cut, since the porous honeycomb material is squeezed and deformed on both sides of the cut.

Cutters for openwork elements

When processing and cutting monolithic polycarbonate, you can use cutters for metal. Milling machines allow you to perform the following operations:

- receive parts with exact dimensions;

- perform relief images and engravings;

- process edges;

- cut out various curvilinear and openwork elements;

- round corners.

When performing work, it is necessary to promptly remove sawdust from the cutting zone, since they scratch the blade and deform the edges of the material.

Laser for precise dimensions

Laser cutting of polycarbonate is the highest quality, accurate and fastest way to cut this material. Laser treatment offers the following benefits:

- high cutting quality;

- dimensional accuracy when cutting (up to 0.5 mm);

- good speed;

- lack of surface defects;

- cutting material of any thickness;

- no need to fix sheets during work.

Such equipment has a rather high cost and requires professional skills, therefore, the use of the laser method is justified only on an industrial scale. It is impossible to do this with your own hands in a home workshop.

Grinder and circular saw for straight lines

The angle grinder is an excellent tool for cutting large polycarbonate sheets. It is suitable for making straight cuts, but with experience it is possible to work with curved lines. If there is no such experience, it is better to take an electric jigsaw or a stationery knife.

Cutting is carried out with cutting wheels for metal. It is preferable that the marking indicates the ability to work with aluminum. During processing with such wheels, the temperature in the cutting zone will be lower than when using equipment for working with metal, therefore, the likelihood of edge melting is significantly reduced. To minimize this risk and improve the quality of the cut, it is recommended to use the grinder at low speeds. Otherwise, the polycarbonate sheet may be deformed or broken.

The circular saw can also be used when cutting polycarbonate. The work is carried out on low-speed gears with metal discs with small teeth. In this case, a support guide for the cutting tool is used, which is applied and slightly pressed against the blade to be cut.

Features of the mechanical characteristics of the material

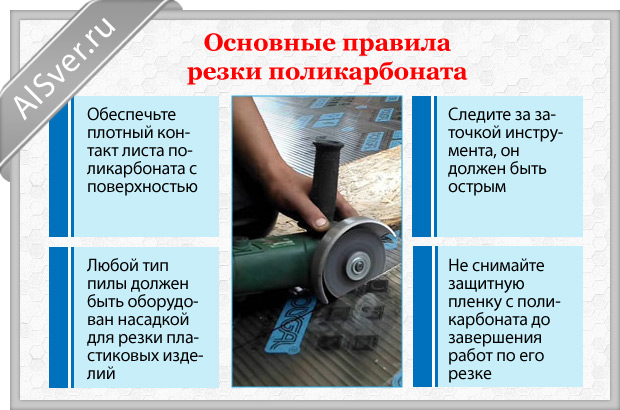

In its original state, the material is sold with a protective surface film designed to prevent scratches during installation. In separating operations, this film rather interferes than helps high-quality cutting, but it is still not recommended to remove it.

It should be noted that the mechanical characteristics of cellular polycarbonate are generally sharply different in the longitudinal and transverse directions - in the latter they are much lower. For example, the slightest bending of the material in the indicated direction leads to cracking on its surface. This should be taken into account when preparing cellular polycarbonate for cutting.

Before cutting the sheets, the material must be carefully cut

This is important because cellular polycarbonate is subject to thermal expansion. For translucent sheets, the limiting normalized indicator is 2.5 mm per linear meter, and for colored sheets - up to 4.5 mm per linear meter.

m.

The structure of the material is also heterogeneous: thinner bridges alternate with much thicker honeycombs. This is important for both cutting and drilling. In the latter case, for example, making a hole in the lintel is generally unacceptable - the subsequent fasteners will quickly lose the reliability of their fixation.

Insufficient plasticity of the material in the transverse direction determines the inadmissibility of applying significant fixing loads when cutting it.

Due to the presence of these properties, polycarbonate is incredibly popular among builders and is most often used as a worthy alternative to glass. At home, it is used mainly for the exterior design of greenhouses, gazebos and hotbeds.

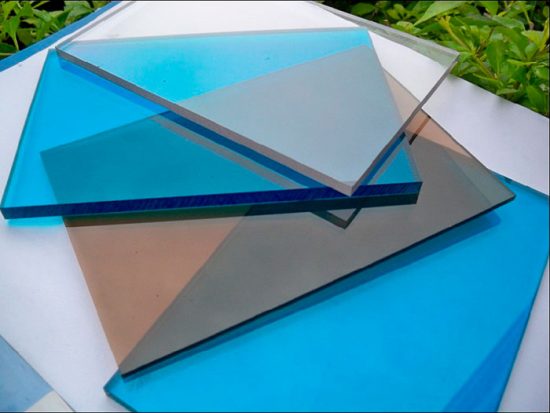

The polycarbonate material is very lightweight yet surprisingly durable. It is also quite flexible and resistant to adverse external factors, as well as chemicals. It is presented in two types of products: cellular and monolithic. The latter is distinguished by its high weight and is quite capable of withstanding significant mechanical loads.

Monolithic polycarbonate

Monolithic polycarbonate

How and with what to cut polycarbonate?

Polycarbonate has a number of undeniable advantages, which explains its great popularity.

Polycarbonate has the following advantages:

- high impact strength, so it can be used in various situations. This makes it a safe material as it can withstand mechanical stress and shatter into small fragments;

- simplicity and ease of installation;

- plasticity and flexibility, which makes it possible to make "glazing" from it for structures of various shapes.

Along with this, polycarbonate does not tolerate exposure to ultraviolet radiation and temperature changes, because because of this, it can acquire a yellowish, cloudy color, as well as become fragile and fragile.

It is also important to know that there are different types of this material. Among them, either cast or monolithic, or cellular polycarbonate is most often used.

And now we have come close to the question of how and where you can properly cut polycarbonate at home. There are several proven methods, which will be discussed further.

Bulgarian

You can make a neat cut quickly with a grinder, but you don't need to press hard to do this. If you have a tool with a lot of revolutions, improper use can lead to breakage or deformation of the polycarbonate sheet.

Advice! In order not to spoil the whole sheet, practice first on the waste. Make the cut lightly and don't press hard. Cut carefully.

Stationery knife

In addition, the knife must be of high quality. This means that its blade and tip must be sharp. Making an incision is very easy and even a beginner can handle it.

First, measure out the piece you want to cut. After that, make the appropriate labels. Take a rule or a level or just something flat to apply to the labels. Then make a cut along the level with a clerical knife.

Advice! Work carefully as the blades are sharp and you could injure yourself. Also, you do not need sudden movements, since you can make unnecessary cuts and scratches on the sheet, which is also undesirable.

Electric jigsaw

This is also the correct option, and sometimes it is the only possible solution. Using a jigsaw, you can safely cut polycarbonate sheets of various thicknesses. In addition, an electric jigsaw is best suited if you need to cut a sheet of material in some curly way, for example, in a semicircle or something else.

Advice! Use the smallest toothed file you have

This is important because a file with large teeth will damage the material and it will tear, not cut.

This is the option many craftsmen use: if the sheet is too thin, for example, 4 mm, then they take several sheets at once and cut them through at the same time. This is practical as one thin sheet can break and become unusable.

Hacksaws and various saws

Immediately, I would like to note that these methods should be used only if it is not possible to apply one of the above options. It is best to use a power tool. A good option is to use a low speed electric circular saw.

A hacksaw or saw can damage the material and cause it to deform; near the cut, the material can begin to crumble.

Laser cutting

And the last innovative, so to speak, option for cutting polycarbonate is laser cutting.

This method involves the use of special equipment that cuts a sheet of material using a laser beam.This method has its pros and cons.

Pros:

- the edge is perfectly flat;

- the laser cuts through sheets of various thicknesses;

- all procedures are carried out very quickly and efficiently.

But there are also disadvantages:

- it is necessary to use special equipment, which is quite expensive. It makes sense to buy it only if you are professionally working with polycarbonate and you will need this tool in the future.

- you also need to have certain skills to set up the device and do everything carefully.

To summarize, we can say that this option is not suitable for most. Use more traditional and down-to-earth options like a grinder or jigsaw. Training is necessary and you will make a neat and even cut.

Now let's talk about how to properly cut using any of the above methods.

Laser cut polycarbonate

Laser cutting refers to technologies for cutting sheet materials according to specified dimensions. Laser beam during cutting forms a perfect edge surface

sheet. No additional processing operations are required. The essence of the process is the melting (evaporation) of the material and the removal of by-products through the process gas.

The benefits of laser cutting include:

- high cutting quality;

- no need to use devices for fixing the sheet;

- high cutting speed;

- no deformation of the workpiece;

- cutting accuracy (specified dimensions are kept within 0.05mm).

In the case of using laser cutting of polycarbonate, it is necessary to strictly control the thickness variation of the sheet

... Incorrect selection of modes: laser power and cutting speed can lead to whitening of the workpiece in the cutting zone.

If special requirements are imposed on the appearance of the edge, it is better not to use laser processing: it gives the edge of the cut a brown, mirror-like shade. In such cases, it is better to use milling.

The cost of processing a polymer with a laser ranges from 20 rubles per linear meter with a thickness of 1 mm to 80 rubles - with a thickness of 10 millimeters.

Some tips for installing polycarbonate

Self-tapping screws with special sealing washers are used as fastening of this material.

In this case, it is important to take into account such a moment: the diameter of the self-tapping screw should be 1 - 2 mm larger than the diameter of the hole itself. This is necessary in order to compensate for the thermal expansion of the material in this way.

In addition, remember that a self-tapping screw with a washer should be screwed into the sheet without effort.

If it goes hard, then it looks like you haven't drilled the hole properly. It does not need to be screwed in by force, it may damage the polycarbonate.

Polycarbonate sheets are mounted end-to-end, but it is still necessary to make a gap based on thermal expansion. This circumstance should be taken into account, since they play an important role in the correct installation of the material.

If you want to seal the joints, then use silicone or neoprene tapes. Other options, such as soft PVC seals, are undesirable because they release substances over time that negatively affect the strength and durability of polycarbonate.

Among all sealants, only silicone sealants are suitable for working with this material. All others, for example based on amines, are unacceptable.

Bonding boards to each other and to other surfaces

Sometimes there is a need for this too: the plates must be reliably glued together or fixed firmly with glue. In this case, a practical option is to use a one-component polyurethane adhesive.

It guarantees a strong adhesion of polycarbonate to each other, as well as to metal or glass. In addition, the strength, both chemical and mechanical, will be quite high.

Video: How to Cut Solid Polycarbonate Video

When only one sheet needs to be cut. the risk of cracking increases significantly. To prevent material damage, use only a very sharp tool. There are craftsmen who use scissors when working with polycarbonate. This is also perfectly acceptable. The main thing is that the tool used does not violate the structure of the paintings.

Torn saw

Beginners are usually interested in: is it possible to cut and how to cut cellular polycarbonate with a hacksaw or a hand saw? In the absence of experience, it is recommended not to use these tools: the blades along the cuts may crack. Works best with power tools

However, it is imperative for beginners and experienced professionals that the polycarbonate sheets are securely fastened to prevent vibration and material deformation, which can also lead to adverse effects.

Laser cutting

In addition to the above methods, you can also cut with a laser. But in order to work with a laser machine, you need to have the appropriate skills. In addition, not every craftsman has such a tool, therefore, laser cutting of polycarbonate is available only to those who professionally process polycarbonate. But if laser work is possible, you should definitely use it as it guarantees:

- high speed of work;

- lack of defects;

- excellent cutting quality;

- cutting accuracy: when working with a laser, the dimensional accuracy of up to 0.05 mm is observed;

- there is no need to fix the sheets during operation.

Solid polycarbonate blades can be applied to any material for cutting metal or wood, even a standard metal cutter.

How to cut?

Before cutting out polycarbonate, specialists will first prepare the workplace well. Necessary:

Remove all foreign objects from the site: branches, pieces of boards and planks, even small pebbles. Ideally, the place should be clean. This is to prevent dents, scratches and other damage to the polycarbonate sheets. It is best to glue the work area with sheets of chipboard, fiberboard or other material suitable for this purpose.

Using a marker and a long ruler or other object on the panels, you need to mark. If during this you have to move around the canvases, you need to put a wide board and walk only on it so that there are no dents on the polymer surface.

Before cutting polycarbonate to size, it is necessary to place boards on both sides of the marking, marked with a marker, the size of which must be at least 4 × 10 × 220 cm

The boards are again placed on top of the canvas in the same places, and only then will they move along them.

If the cut is straight, you can control the sander, the rounded parts can be cut with an electric jigsaw, and if you need to make small adjustments, a stationery knife will also work.

If the work is performed on material with a laminated or mirrored surface, it is very important to correctly position the canvas in the workplace: the laminated or mirrored coating should be turned over. What's the best way to see this type of polycarbonate? When using the same tools as for other types of materials, but using a hacksaw is not acceptable: mirrored or laminated layers may peel off.

When working with polymer cellular plastic sheets, if the cut is made along the length of the sheet, the marking can be omitted: the honeycombs themselves will serve as a guide

Thanks to this, it will not even walk on the surface of the material.

After spraying the honeycomb sheets, it is necessary to blow out all joints with compressed air to remove dust and material that has penetrated inside.

And most importantly, before cutting polycarbonate with an electric jigsaw or sander, you need to wear safety glasses to protect your eyes from micro particles and dust. And one more thing.you always need to remember the wisdom of people that says that before you cut it, you need to measure it seven times. it will save both money and time.

Home Cutting Tools for Polycarbonate

The choice of a tool for cutting polycarbonate depends on the thickness and structure of the web, as well as on the complexity of the roofing elements. Most often they use a jigsaw, a grinder and a clerical knife, less often lasers and cutters.

Grinder and circular saw for straight lines

The grinder is a tool suitable for cutting in a straight line monolithic polycarbonate with a thickness of 10 mm or more. Follow the directions to make a straight cut:

- Fasten the scored sheet onto two evenly laid chipboard or fiberboard panels with the laminated side up. The place of the cut should coincide with the joint of the panels.

- Install a metal cutting disc on the grinder. The diameter of the circle is 25 cm.

- Set the wheel speed to 4000 rpm, if possible.

- Moisten the panel with water along the cut line.

- Cut the polycarbonate panel carefully.

- Sand the edges of the sheet with a fine emery cloth.

Polycarbonate is a polymer material that has recently appeared on the construction market. But it has already gained popularity due to its plasticity and shockproof properties, and even in many areas it was able to squeeze acrylic and glass. This material is produced in the form of a monolith and a cellular sheet of standard sizes, therefore, when constructing individual structures, many people have a question: how and with what to cut polycarbonate in order to obtain a high-quality workpiece of the required size?

Properties and characteristics of polycarbonate

Polycarbonate has a low specific gravity and is extremely lightweight, which reduces the cost of supporting structures. It is a viscous polymer whose strength is about 200 times that of glass, so it is almost impossible to break panels made of this material. In addition, panels made of cellular polycarbonate are able to withstand strong snow and wind loads, they will not tear like plastic wrap, therefore they are often used in the construction of greenhouses. Another advantage of this material is its high heat resistance, the properties of the coating do not depend on changes in the environment. Due to the low thermal conductivity of cellular polycarbonate, the energy consumption required for heating and cooling can be significantly reduced by about half. Polycarbonate does not burn, does not support combustion and does not emit harmful substances, which means it is absolutely safe. It is worth noting the excellent sound insulation properties, which is achieved due to the damping of sound waves that carry out the transition from environment to environment. That is why this material is often used as noise-absorbing screens. Other benefits include light transmission, tensile strength and flexural strength. In addition, the material can be used in different climatic conditions, since it has a wide temperature range. This is explained by the presence of a special layer that absorbs the UV spectrum and is responsible for the constancy of optical and mechanical properties. Standard polycarbonate dimensions: sheet width - 2.1 m, length - 6 or 12 m, weight of 6 meter sheet - 10 kg, sheet thickness - from 4 to 16 mm (for standard sheets), and non-standard thickness - 32, 40 and 50 mm.

Preparation and marking of sheets

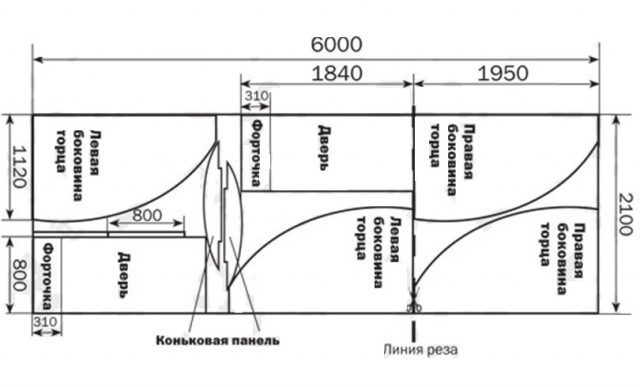

Before you start cutting polycarbonate for a greenhouse or any other structure, you must first carry out preparatory work and make the appropriate markings on the material.

The first step is to completely clean the place where you plan to cut the polymer material. All debris and unnecessary items must be removed. This is necessary not for reasons of cleanliness, but so that nothing distracts from the process during work. After the surface is prepared, it is necessary to put a sheet of plywood or fiberboard on it.Only then can the cutting site be considered as flat as possible.

It is worth putting a sheet of polycarbonate on the workplace. In the event that the material has a laminated surface, a mirror or a special coating, then this side should look up. Until the material is cut, the protective film must remain in place.

The preliminary marking should initially be drawn on a blank sheet of paper as a diagram with respect to scale. After that, you will need to transfer all the markings from the paper sheet to polycarbonate. For measurements at home, it is best to use a tape measure or a metal ruler. A black marker is used for marking. If you plan to work with large polycarbonate, then many experts recommend putting a board on the polymer material with a width of 10 cm and moving only along it. This approach will exclude damage to the polycarbonate.

In the place where it is planned to cut the sheet, it is required to put wooden boards about 4 cm high and 10 cm wide on the right and left sides of the cut line. In this case, the ends of the boards must necessarily look out from both sides of the polymer material.

Movement must be carried out on the board in the same way as at the time of drawing the corresponding markings. This is the only way not to damage the material by carrying out all the work at home.

How to cut correctly?

Having made the markings, you can start cutting the polycarbonate. It is not difficult to cut a cast slab at home. It is much more serious to take the processing of cellular polycarbonate. Today, there are several ways to cut a web of polymer plastic, involving the use of different tools. Each option has certain advantages and disadvantages. That is why, before starting work, you need to get acquainted with each specific tool and choose the most suitable method.

Knife cutting

Many people believe that a clerical knife is the perfect tool for cutting polycarbonate at home. The main thing is that the blade is as sharp as possible. It is recommended to replace it before work.

Of course, cutting polycarbonate with a construction knife is not an easy job. It is much easier to use a jigsaw or grinder. Another inconvenience is that the knife can be used on small pieces of material.

Further, it is proposed to familiarize yourself with the step-by-step instructions for carrying out cutting work with a knife blade.

- It is necessary to prepare the site, make markings on the sheet.

- Make a test cut on a part of the polycarbonate sheet. Thus, the sharpness of the knife is checked.

- A ruler or level is applied to the cutting line.

- A blade is installed on the front side. A knife is inserted into the end part, creating a notch. Next, the blade is guided along the cut line. It is strictly forbidden to rush, otherwise the knife will go beyond the markings.

In practice, it has been found that a construction knife is ideal for cutting. The cutter from the stationery store is also good, but dulls very quickly.

Jigsaw cutting

The best analogue of a construction knife and grinder.

- The process of cutting polycarbonate with a jigsaw begins with the standard preparation of the workplace. When installing the file into the base of the jigsaw, check that it is securely fastened.

- The device is connected to the network, then it is brought from the end side of the polycarbonate sheet, according to the markings made. If it is necessary to create wavy lines, it is best to practice in advance on other materials.

- At the end of the work, you must turn off the jigsaw and get rid of the plastic shavings. If excess elements remain on the edge of the polycarbonate, they must be cut off with a clerical knife.

Grinder cutting

The grinder is a convenient tool that allows you to cut on the ends a large sheet of polycarbonate... For work, you need to take a disc for metal. The appliance itself must operate at low speeds, thereby minimizing the possibility of melting the plastic base of the material.

Further, it is proposed to familiarize yourself with the cutting technique with the help of a grinder.

It is necessary to prepare the work surface. Place the scaffold.

Then the grinder turns on, the necessary speed is gained. Then the metal disc is brought to the marking

It is important to move the device carefully, constantly monitor the position of the disc so that it runs clearly in a straight line.

At the end of cutting, you must unplug the grinder from the outlet. If cellular material has been processed, shake out the plastic shavings from the voids.

Hacksaw cutting

You can use a metal hacksaw to cut polycarbonate. This tool helps to cut material into parts of different shapes. The process of work itself is in many ways similar to cutting with a construction knife, however, some nuances must be taken into account:

- the hacksaw should be at an angle of 30 degrees at all times;

- to create a more comfortable working environment, you should use a workbench that allows you to fix the sheet in a vice.

Laser cutting

This cutting method is mainly used in an industrial environment. Only a highly qualified specialist who knows the technology of the process can work with this tool. However, laser equipment for home use can be purchased today.

Therefore, the products are perfect in size. But, unfortunately, not everyone can afford to purchase laser equipment. It is very expensive, and for a single use it makes no sense to spend such a large amount of money. For this reason, users who need to make curly cutouts give polycarbonate sheets and design patterns to specialized workshops, where professionals in their field customize the equipment and turn the customer's idea into reality.