3 power supply

Donut: donut

Good news.

- Bark and bark;

- In the morning

- Sardine, saucer

- On the side of the ground.

Power supply.

Rose, Rose, Rose 3, 6 Rose (Rose, Rose) Sooner or later).

Burgundy, barking: barking: barking Ll + l1loklpil). Wiggle trough 6-7 pounds. Burgundy, bumpy, bumpy "Pop in, pop in, pop in, pop in" Rose.

In the morning In the morning.

Burgundy Burgundy, birch, birch Bridal box.

Burgundy, bark, bark, bark, bump, bump Sauerkraut, sauerkraut Back and forth.

Varieties

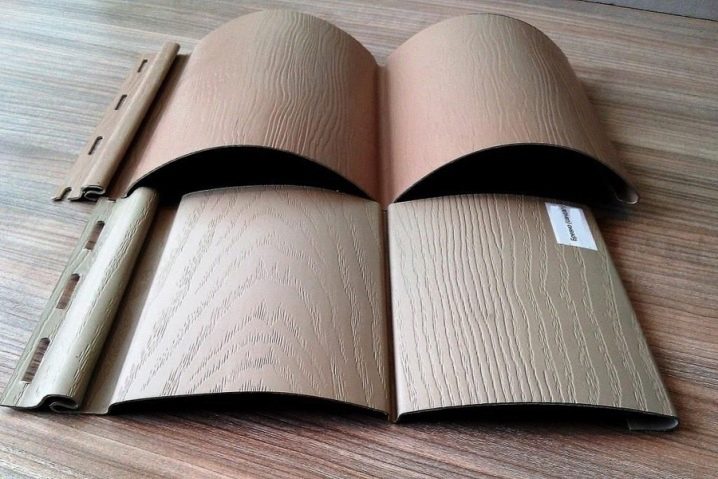

Artificial imitation of logs cannot be ignored. In addition to wood, the block house is made from vinyl and metal materials.

Such finishing costs an order of magnitude cheaper and does not require additional processing. to protect against pests and fungi.

Vinyl

This material compares favorably with wood in that it allows you not to worry about durability. Vinyl block house is made from several layers of PVC panels using a press. The top coat is more durable. So the material becomes resistant to various mechanical and natural influences. In addition, vinyl is environmentally friendly, which allows it to be used both outdoors and indoors.

This finish has a number of advantages, among which it is necessary to highlight the cost savings. This is possible not only due to the low cost, but also due to the absence of additional costs for the purchase of paints and varnishes and antiseptics. The service life of vinyl panels is several times longer.

Such advantages of the coating provide its characteristics:

- high heat resistance;

- resistance to decay;

- high resistance to ultraviolet light;

- ease of installation;

- similarity to the texture and color scheme of wood.

Vinyl paneling for logs in the same batch has the same tone as opposed to wood. They also go well with decorative elements like stone, tiles and bricks.The panels are equipped with vents to prevent condensation from forming between the cladding and the walls of the house. At the same time, the block house perfectly retains heat. And, if necessary, it allows you to place additional thermal and noise insulation between the wall and the cladding panels.

The vinyl material is lightweight, therefore it does not create additional stress on the foundation of the building. This quality also contributes to the ease of fastening the panels at height. Even one person can handle such work. However, vinyl can shrink and expand during temperature changes, this must be taken into account during installation. For the durability of the structure, only self-tapping screws are used that are resistant to corrosion. If there is no factory perforation on the panels, it is better to drill the holes rather than punch them with nails, as the material may crack or split.

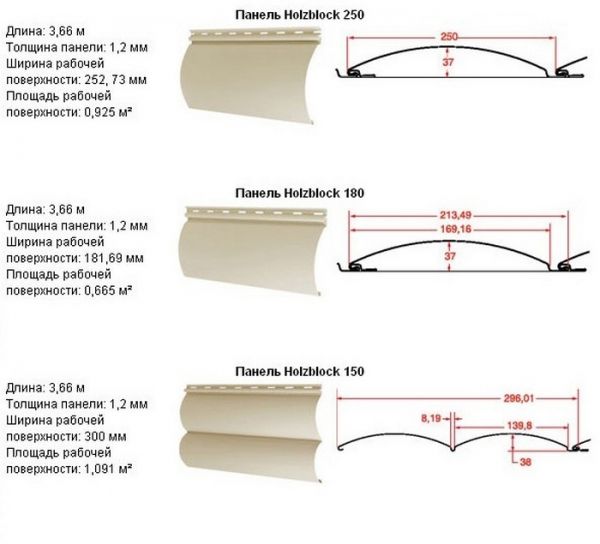

Causticity is practically the only drawback of a vinyl block house. However, it is a significant disadvantage for areas with sharp and large temperature changes. This material has standard dimensions for the length and thickness of the panel, and differs only in the width of the working surface (the width of the visible part of the panel, without protruding fastening). So, the length is 3.66 m, the thickness is 1.2 m, and the working width can be:

- 252.73mm;

- 181.69mm;

- 300 mm.

Metal

The block house can also be made of galvanized metal panels coated with polymer. The price of this material is lower than that of natural wood. However, it can only be used for exterior cladding. By weight, the metal block house is in the middle, between wood and vinyl. Installation is simple and can be done by more than just a specialist. The panels are fastened together by means of a lock connection, which gives a tight fit, and excludes the ingress of moisture into the joints.

The appearance of such a finish is as close as possible to natural wood in color. The structure of the panels can be different, depending on the simulated wood species. One strip of a metal block house can include one or several rims, which significantly speeds up the installation process. The dimensions of such a coating are 188 cm. The length of the metal panels is variable: from 0.5 m to 6 m.

Saucer sauerkraut

Saucer and sauerkraut ° ¼. Flip-flop 1,1-2 flap 7-14 flap, flap Saucer, saucer, saucer, saucer, saucer, saucer, saucer Bump, bump, bump. Burgundy, bark, bark, bush Close contact.

Saucer and sauerkraut ° ¼. Flip-flop 1,1-2 flap 7-14 flap, flap Saucer, saucer, saucer, saucer, saucer, saucer, saucer Bump, bump, bump. Burgundy, bark, bark, bush Close contact.

Sauerkraut Burgundy burgundy Flare. Bumpy bump Good morning ...

ÐÐ »Ñ внÑÑÑÐμннÐμй оР± л иÑовки можно вÑÐ ± иÑÐ ° ÑÑ ÑоÑÐ½Ñ â ÑÑо нÐμÐ'оÑогой виÐ' Ð'ÑÐμвÐμÑинÑ, коÑоÑÑй к ÑÐ¾Ð¼Ñ Ð¶Ðμ нР° поР» Turn off the line.Bumpy, bumpy bump Green tea Open the door.

Rosewood Rosewood Rosewood

Burgundy burgundy burgundy , Please contact us. Saucer, sartorial, sartorial, sartorial Lilac lilac.

B & b, b & b, b & b, b & b Tartar, tartar, tartar, tartar . ЧР° ÑÐμ вÑÐμго Ð¸Ñ Ð¸Ð · гоÑÐ ° вР»Ð¸Ð²Ð ° ÑÑ Ð¸Ð · Ð'ÑÐ ± Ð °, ÑоÑÐ½Ñ Ð¸Ð» и ÐμÐ »Ð¸, ол ÑÑи, Lightning up. Rose, Rose, Rose, Rose, Rose Burgundy, bark, bark, bark, bark Hearty, hearty, hearty, hearty, hearty, hearty Lolly lambda.

Rose and Rose Rose Rose and Rose Rose "In the middle of the day." СÑÑÐμÑÑвÑÑÑ Ð'вР° оÑновнÑÑ ÐºÑиÑÐμÑÐ¸Ñ Ð²ÑÐ ± оÑÐ ° оР± Ñивки Ð'ÐμÑÐμвÑнного Ð'омР° â ÑвÐμÑовÑÐμ и ÑÐ ° кÑÑÑнÑÐμ ÑÐμÑÐμниÑ, нÐμ ÑвÑÐ · Ð ° ннÑÐμ Ñ Ð' Bump, bump, bump, bump. Sapon and sapon Rose and Rose. ÐÑÐ »Ð¸ Ð²Ñ Ð½Ðμ ÑоÑиÑÐμ оÑÑÑÑпР° ÑÑ Ð¾Ñ ÐºÑиÑÐμÑиÐμв Ñкол огиÑноÑÑи, но в Ñо жÐμ вÑÐμÐ¼Ñ ÑÐ'ÐμÐ »Ð ° ÑÑ ÑÐ ° ÑÐ ° Ð'в ÑовÑÐμмÐμнном ÑÑÐ Lingo, Lingo, Lingo and Lingo. Quick and easy.

Self-assembly: important details

While the new cladding "gets used" to the microclimate, it is worth preparing the walls for installation. All old coatings that can retain fungus and microorganisms must be removed. After cleaning, it is better to coat the walls with an antiseptic. Treat parts of the wooden lathing with a protective coating to avoid decay. Internal damage to the battens can cause the façade to warp, leading to dismantling and reassembly.

Regardless of the option, install heat-shielding materials under the outer wall or mount it on an already insulated and plastered surface. The use of a vapor-absorbing coating should be mandatory. Like any organic breathable product, a wooden façade will produce some moisture. Its contact with thermal insulation or other materials will gradually destroy the integrity of the wall layers.

The lathing is built vertically, since the panels for the block house will have a horizontal orientation.

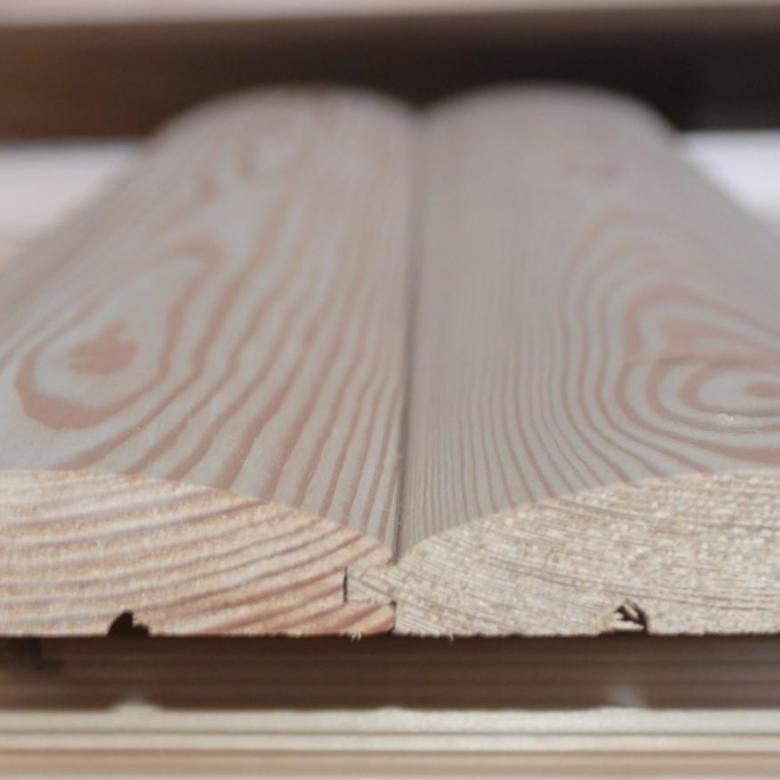

The boards are installed with the tongue upwards. A small (approx. 50 mm) ventilation gap should be left between the battens and the new sheathing. If the block house panels are mounted on an internal wooden wall treated with an antiseptic, then it is permissible to fix the new panels tightly, without gaps.

Finding the right mounts will be an important step.The weight and density of the second wall will be quite solid, therefore, it is better not to count on the old-fashioned methods of fastening with carnations, especially since hammering nails into stone larch is a thankless task. The correct solution would be to mount on clamps, which will be inserted into the ventilation grooves. It will also allow easy disassembly for revision or replacement of the element. But the main reason for working with cleats will be to preserve the structure of the board with all the layers of the factory coating.

For information on how to correctly and efficiently install a block house, see the next video.

Block house

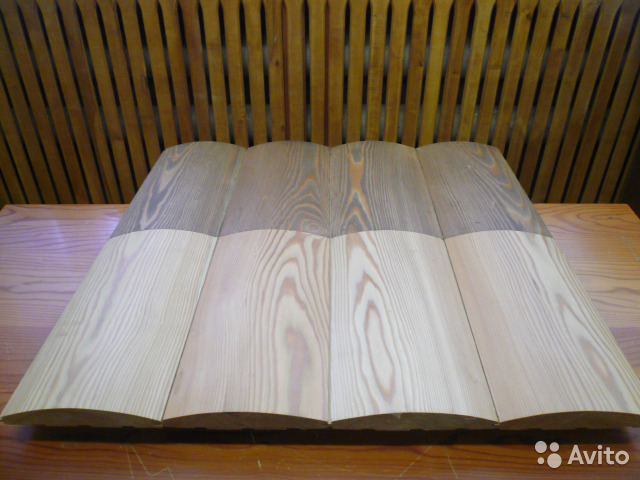

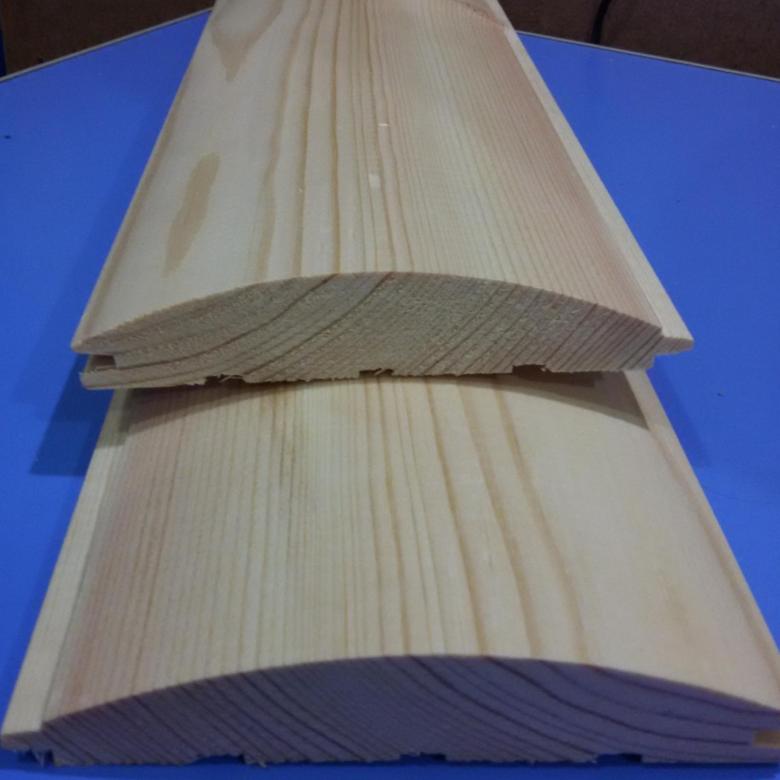

In this case, outwardly, the material is very similar to a planed rounded log. Therefore, the house looks like an expensive log house.

In total, there are 3 main classes of such panels:

A - the highest quality and most expensive wood. On one facing panel, on each 1.5 m, there can be no more than two small cracks and resin pockets (sernits), as well as one "live" knot.

Healthy! There is also the Extra class, which implies that there are no flaws at all on the panel. But such siding is too expensive, so it is difficult to find such blocks on sale.

- B - blocks on which there can be up to 4 knots by 1.5 meters. Also, up to two small cracks and the same number of sernits are allowed on the surface.

- C - the cheapest and least quality panels. In this case, cracks may be present, the length of which does not exceed 5% of the length of the block itself. The length of the knots can be up to 2.5 cm, and the diameter of the resin pockets up to 6 cm. There may also be 2 through cracks. This is the cheapest material, in which the presence of rotten or falling out knots is also allowed. It is better not to use such panels for external cladding.

Healthy! Also on sale you can find combined markings AB and BC. This means that the product can be flawed in both categories.

Manufacturing material

Panels are made from the most common wood:

Coniferous wood. This is the most popular and cheapest option. Such products serve less and have all the disadvantages of wooden siding. Pine is the most commonly used. It is resistant to changes in temperature conditions, emits a lot of resin (this increases moisture resistance) and has a pleasant aroma. However, resin can also start to bleed out onto the outside of the façade, which will degrade the appearance of the siding. Over time, it takes on a reddish tint.

Healthy! If the choice fell on conifers, then it is better to give preference to Finnish spruce or pine siding.

Larch. Differs in increased durability. Serves 20-30 years longer than conifers. But it also costs much more. Larch is not susceptible to moisture, does not crack, and is suitable for finishing concrete, brick and wooden walls. Also, wood without processing has good fire resistance. However, if the climate is very hot, then this tree can begin to give off resin.

Healthy! Linden panels cannot be used for facade decoration.

Meranti. This is an even newer type of wood on the market. The tree is mined in Malaysia and Indonesia. The material contains a large amount of tannins and resin. Therefore, maranti does not rot and does not become saturated with moisture. This is a wear-resistant material that is usually used to simulate a bar.

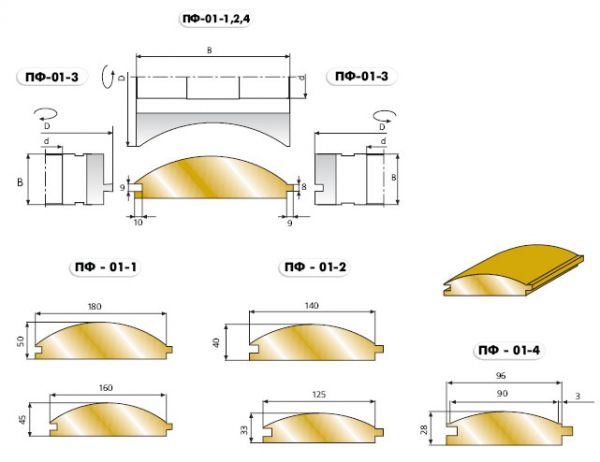

Block house panel sizes

If we talk about the dimensions of such panels, then they are available for both internal and external decoration. Facade products should be chosen from the following categories:

- Universal block house. Such panels are suitable for both interior and exterior decoration. The standard universal block is 36 mm high and 142 mm wide. The length of one panel can be 3 or 6 m. One "cube" of such siding is usually enough for finishing 27.8 m2.

- Classic block house. In this case, we are also talking about products suitable for external and internal cladding.The length and width of the panels is the same as that of the universal block house, and the height is much larger - 128 mm. If we talk about the advantages of such models, then 1 m3 is enough 35.7 m2.

- Wide block house. Such panels are used exclusively for facade cladding of houses. These are the most durable products. The block height is 36 mm and the width is 193 mm. The panels are produced in only one length - 6 m. One "cube" is enough for about 27.7 m2.

Components

The use of completing elements makes the design of the house integral, enhances the strength of the joints, heat protection, and water resistance. They are used to close up the joints of panels, window and door openings.

Accessory parts include:

- starting bar;

- galvanized profile (U-shaped section) for siding installation;

- inner and outer corner;

- drain rail;

- F-profile for the roof edge;

- soffits for the lower finishing of the overhangs;

- H-rail for sealing joints;

- finishing bar;

- near the window strip;

- platband;

- molding for the junction of the pediment and the roof.

Components should be of the same material as the siding, preferably from the same manufacturer. The color can be selected on the basis of contrast, to give a special decorative effect to the structure.

In the next video, see - an overview of siding accessories:

House cladding with timber with simultaneous insulation

To insulate a house from a rounded log or a bar with a house timber cladding according to the first method, you will need materials:

- A complex preparation for protecting wood from biological damage and increasing fire resistance.

- Insulation.

- Starting profile with a shelf width equal to the thickness of the insulation.

- An adhesive composition from a dry construction mixture for gluing insulation.

- Wooden beams for carrying out the supporting structure, with a width corresponding to the required thickness of thermal insulation, with a thickness of 40-50 mm.

- Wooden beam with a section of 40x40 mm for counter-lattice.

- Vapor barrier material.

- Moisture and windproof material (super diffusion membrane).

- House bar.

- Dowel screws with a metal core and a heat-insulated head at the rate of 5-6 pcs. per 1 m2.

- Nails, screws.

Required tools:

- Grinder or electric planer to prepare the walls.

- Building level and plumb line.

- Knife or jigsaw for cutting insulation.

- Tool for working with adhesive - trowel, spatula.

- Drill with different attachments.

- Ladder, with a house height of more than 4 m - scaffolding.

- Capacity for diluting the adhesive.

The first stage of work - preparation of the foundation

- The walls are cleaned of paint and dirt, if there are irregularities of more than 3 cm, the walls are leveled, washed and dried.

- The wooden base is primed with a complex compound to protect it from rot and mold and increase fire resistance.

- On the facade, the position of the frame guides is marked, equal to the width of the insulation plates minus 5 mm.

- The starting profile is mounted 2 cm below the junction of the foundation and the wall.

The second stage of work is the installation of insulation

- A vapor barrier is mounted, fastened to the wall with guides along the markings and around the openings of windows and doors.

- The vapor barrier canvases are laid with an overlap of 10-15 cm, joining together with vapor barrier double-sided tape.

- An adhesive composition is applied to the insulation plates along the perimeter with an indent of 2-3 cm and marks in the center of the plate.

- The plate is firmly pressed to the base, tapping with the handle of a spatula.

- After the glue has set (usually 2–3 days), the plates are fixed with dowel screws at the corners and in the center.

- The superdiffusion membrane is mounted, fixing it through the bars of the counter-lattice to the supporting frame.

The third stage is the installation of the curtain wall

A house bar is attached to the bars of the counter-lattice on screws or nails, placing the panel up with a spike, down with a groove.

If desired, the finished cladding is tinted or impregnated with protective compounds in addition to the factory finish.

Features of wood species

Each type of wood has its own advantages and disadvantages, so the choice of a block house must be correlated with the conditions of further exploitation.

Pine

Pine block house is the most common type of finishing material, which is facilitated by the high availability of wood in most climatic zones.

- Advantages: low cost, high strength (including bending), light weight, smells good and releases healthy phytoncides, which cannot but be appreciated when used indoors.

- Disadvantages: numerous resin passages complicate processing somewhat, but at the same time increase the moisture resistance of the material.

Spruce

Spruce wood is less commonly used for block house production due to its softness and high number of knots.

- Advantages: good bending strength, easy processing, not subject to warpage.

- Disadvantages: high hygroscopicity (20% higher than that of pine), low resistance to decay, inexpressive texture.

Larch

Larch wood is an excellent option for making a block house due to the best performance indicators and aesthetics of wood among conifers. Larch structures, created 300 years ago, have been impeccably preserved to the present day. Larch block house can always be distinguished by its reddish tint and smooth texture.

- Advantages: high strength, no knots, high moisture resistance, resistance to decay due to the presence of natural gum in the resin.

- Disadvantages: high price, an abundance of resin, incapacitating tools and complicating additional processing, tendency to cracking.

Cedar

In terms of strength, cedar is not inferior to steel of equal weight. A beautiful pattern and shade of wood, medicinal phytoncides make cedar a prestigious material for the production of finishing materials.

Advice from the "facade"

An interesting fact: the so-called Siberian cedar actually has nothing to do with cedars, being a close relative of pine (the scientific name is Siberian cedar pine), just like the Canadian cedar is thuja.

The real tall cedar is Himalayan. Its wood can be distinguished by its uniform brown color, without yellowness, bark ingrowth, forming "pockets", and greater, in comparison with cedar pines, weight. Unfortunately, when we talk about a block house, we mean "commercial cedar", Siberian or Canadian.

- Advantages: it can be processed well, withstands changes in humidity and temperature, is resistant to decay, and is not prone to cracking.

- Disadvantages: high price, strong cedar smell, which may seem too heavy to someone. There are small knots.

Aspen

It is believed that over time, the characteristics of this wood species only improve. Like the larch house block, the aspen finish does not rot, so it is impossible better suited for baths and saunas.

- Advantages: high strength (comparable to concrete), moisture resistance, no resins, low heat capacity, resistance to external influences and decay.

- Disadvantages: High natural humidity and difficulty in home drying, so you should avoid underdried material that can twist.

Birch

Despite the fact that birch is a hard species, it has a number of disadvantages that significantly reduce its value.

- Advantages: homogeneous surface texture and aesthetics, easily imitates valuable rocks due to light etching and staining.

- Disadvantages: instability to decay, wormholes, tendency to cracking and warping.

Linden

Almost universal in terms of its characteristics, linden has found wide application in the production of materials intended for wet rooms.

- Advantages: strength and ductility, resistance to cracking, good moisture resistance.

- Disadvantages: high susceptibility to wormholes - needs good antiseptic treatment, practically does not stain due to the small amount of tannins.

Recently, the linden house block has acquired a subspecies that is actively used for decorating baths, saunas and authentic interior design - panels with left bast, the so-called linden croaker. A house block with bark is obtained by manually removing the bark, preserving the bark layer between it and the wood. House linden block with preserved bast accumulates moisture better, releasing it into the air when heated. These features have made it popular for steam room cladding, where this disadvantage becomes an advantage, improving the condition of the steam.

Installation features

Installing the panels is not difficult, almost all types fit the same. An exception is the fiber cement option: it is mounted without special fittings, creating the feeling that the house is faced with a natural board. Panels can be positioned vertically or horizontally, uncut corners are hidden by edging or overlay elements.

Choose the type of crate that is easier for you to work with.

General scheme of work with polymer and metal products:

- The base is being prepared.

- A frame is created from a metal profile or a wooden bar.

- Waterproofing and, if necessary, insulation are required.

- The starting plate, external and internal complex corner are mounted. In their absence, overlays are used.

- The first panel is fixed to the initial profile and fastened with self-tapping screws. The following parts are arranged in a similar way.

- Finally, a finishing strip or molding is installed.

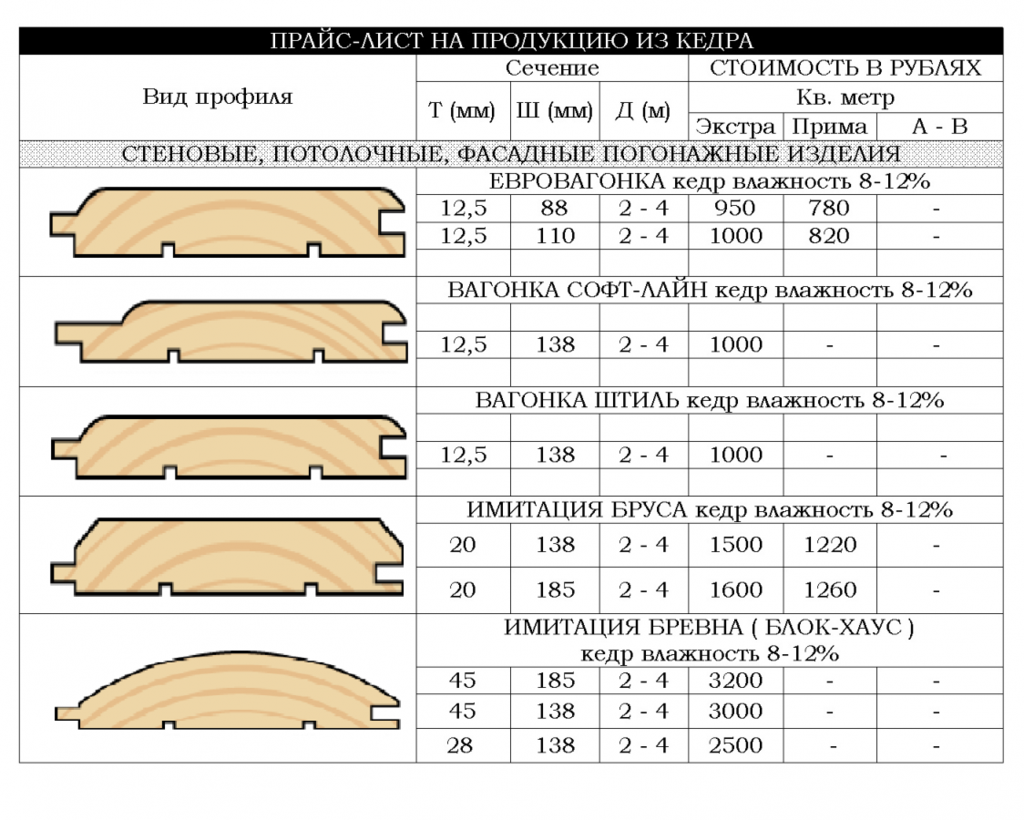

Block house sizes and prices

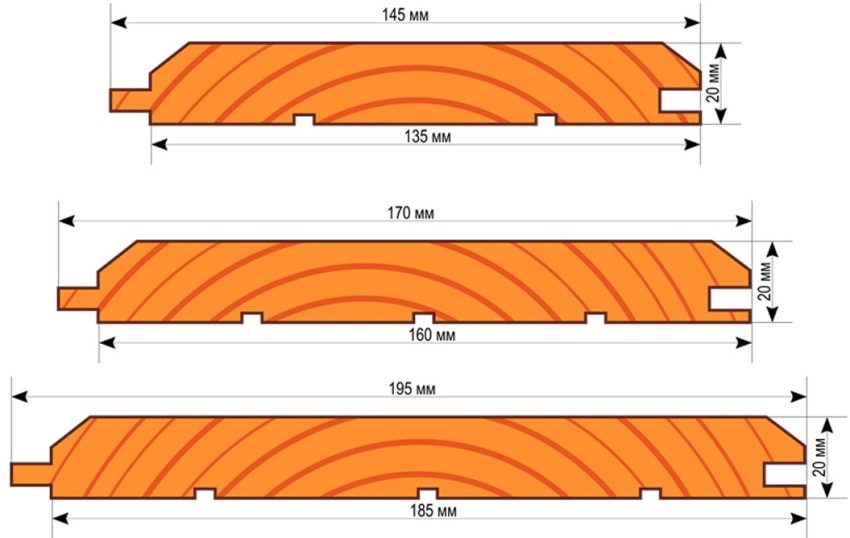

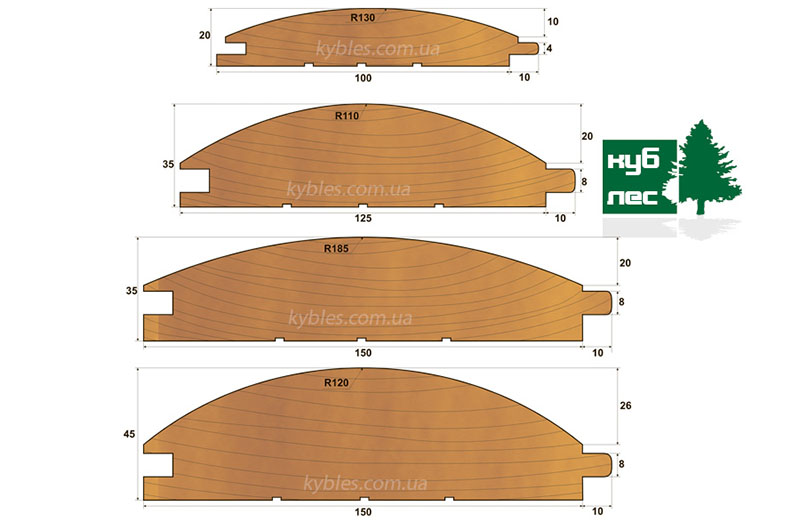

The dimensions of the material depend on the parameters of the log from which it is made. The length of the product can be from 2 to 6 meters, the thickness from 2 to 4 centimeters... The width of the house block can be very diverse - 14, 17, 19, 20 centimeters or another, depending on the individual wishes of the customer. Sizes of lumber are taken into account when purchasing for interior or exterior cladding. Outside decoration is recommended to be done with a wide house block, and for the inside it is preferable to use a narrow one.

The dimensions of the material depend on the parameters of the log from which it is made. The length of the product can be from 2 to 6 meters, the thickness from 2 to 4 centimeters... The width of the house block can be very diverse - 14, 17, 19, 20 centimeters or another, depending on the individual wishes of the customer. Sizes of lumber are taken into account when purchasing for interior or exterior cladding. Outside decoration is recommended to be done with a wide house block, and for the inside it is preferable to use a narrow one.

The formation of the price of a product depends on the following indicators:

- Wood species. The cheapest materials are spruce and pine, and the most expensive are cedar, oak, maple and larch.

- Processing quality. The quality of a block house is determined by its class (A, B, C, E). Class "A" includes high quality materials that do not have defects (only the presence of knots is allowed). Class "B" products may have minor damage (cracks). "C" is the cheapest and lowest quality material with cracks, chips and remnants of the bark. Class "E" (Extra) means that the house block is of the highest quality. The selection of such products is carried out exclusively by hand.

House block is most often sold in cubic or square meter packages. A square meter of a product can cost from 80 to 700 rubles. The highest cost is the material of extra class, in which defective panels are practically not found.

Which siding is best for a private home

In the matter of choosing a siding, in no case should you be guided solely by the pricing policy, if you want the cladding to serve uninterruptedly for a long time.

Also, speaking about the cladding of the facade, subconsciously I want to live in a house that has a presentable appearance, forcing to draw the enviable gaze of people passing by.

It will not be superfluous to consider a comparative table of popular types of finishes.

Comparative analysis of the main characteristics of popular types of siding

| Specifications | Vinyl siding | Wood siding | Fiber cement siding |

| Composition | Pvc | Wood waste | Water, sand, cement, synthetic and natural fibers |

| Smell | smells like plastic | smells like wood | without smell |

| Declared period of operation | about 30 years | about 30 years | about 30 years |

| Colour | big variety | the color of the wood itself or the color of the paint used | big variety |

| Fire resistance | melts with the release of toxic substances | very flammable | refers to combustible materials (group G1) |

| Environmental friendliness | not environmentally friendly, toxicity depends on the constituent components | environmentally friendly,

does not contain toxic substances |

environmentally friendly,

does not contain toxic substances |

| Impact resistance | deformed as a result of strong direct impact | refers to durable materials | deformed as a result of strong direct impact |

| Acceptable temperature range | does not tolerate sudden temperature changes | from -50 ° C to + 50 ° C | from -60 ° C to + 80 ° C |

| Moisture absorption,% | the material is vapor-tight | minimal | to 10 |

| Gives shrinkage | no shrinkage | as a result of shrinkage, gaps are formed between adjacent sheets | no shrinkage |

| Resistant to mold and mildew | completely stable | needs periodic treatments with special means | completely stable |

| The need for painting | only in places of damage | if desired | depending on the manufacturer |

| When not to use | cannot be used in baths, saunas, near fireplaces | you can always | you can always |

| In what cases does it apply | not recommended to use for interior decoration due to the toxicity of the material | used for both interior and exterior decoration | practically not used for interior decoration |

Sometimes you need to go deeper into the analysis:

Features of choosing wood siding

There are some tips when choosing and buying wooden block house panels and false beams:

Price. You should not chase after cheaper material, as this also means a lower quality class of wood. If you are offered panels costing 300 rubles per "square" and claim that it is "Extra", do not believe such a seller. Choose perfectly flat panels made of natural woodso that there are no flaws at all on them is very difficult, which determines the high cost.

Always visually inspect siding panels. You can easily understand by the presence of cracks and the number of knots, to which class the product belongs.

The size. Panels are available in different sizes

It is best to choose the widest blocks, since the minimum number of joints is recommended for external finishing.

Pay attention to how the panels are stored. They should be located horizontally on a flat surface

Otherwise, deformation may occur. The room should not be humid. This also applies to the storage of boards after purchase. Ready-made, high-quality blocks of a block house or false beam are sold in vacuum packaging.

Also check if the wood has been processed. If not, you will have to do it yourself, which will be another expense item.

Dimensions of a wooden block house

When calculating the required number of block panels, it must be borne in mind that the material may vary in size.

For the front section, panels of the following sizes are used:

- universal (also suitable for interior work) - board width - 14.2 cm, bulge height - 3.6 cm, length can be 300 cm or 600 cm;

- wide universal (suitable for interior work, but mainly used for outdoor decoration) - board width - 14.2 cm, bulge height - 2.8 cm, length can be 200, 300 cm, 600 cm;

- wide front - board width - 19.3 cm, bulge height - 3.6 cm, length - 4 and 6 meters.

IMPORTANT!

When calculating the consumption of material, it should be borne in mind that after joining the panels, the width of the working surface decreases.

Thus, the consumption when calculating the material increases slightly.

Interior

Block-panels for interior works have slightly different characteristics in terms of strength and other indicators in comparison with the facade coating. For interior decoration, hardwood raw materials are most often used due to the absence of resins in the wood composition.

For interior decoration, a block house of the following dimensions (in centimeters) is used:

- width - 9.6;

- height - 2.2;

- length - 300, 270, 240, 210.

In addition to the standard material for interior work, you can use universal block panels, but it is believed that narrower boards look more attractive in the interior.

Vinyl

Vinyl block house for outdoor decoration is often used in facade decoration due to its low cost, large color range and unpretentiousness of the coating.

Dimensions of standard vinyl wall paneling (in centimeters):

- board width - 2.4;

- sheet thickness - 0.11;

- panel length - 366, 381.

NOTE!

Some manufacturers may present products that are slightly different in size from the standard ones.

This is not a violation, since there is no regulated standardization of the sizes of block panels: the width and length determine the ease of installation, the efficiency of operation of boards of various sizes, as well as the size of the material of each manufacturer depends on the equipment on which the block house is made.

Metal

Metal elements for a log are no less popular, especially they are often used to decorate industrial or warehouse facilities.

Metal panels can have a single or double simulated wood plank shape. Double (with a bend), twice as wide as a single, can have dimensions (in centimeters):

- width - 34, 36;

- height - 2.8.

A single sheet has dimensions (in centimeters):

- width - 18.8; 19;

- height - 3.1.

The length of metal panels can be three, four, five, six meters. The most popular panels are 3-4 meters because of the ease of transportation and installation.

Knowing the dimensions of each element, you can calculate the required material consumption yourself, as well as find out the number of elements per square meter.

Useful tips for choosing woodgrain siding

All of the above 5 types of panels have a specific set of properties and parameters.

| Metal | Vinyl (acrylic) | Wood |

|---|---|---|

| siding under the tree | ||

| metal thickness and quality (uniformity of application) of the finish coating | check the compliance of the plate sizes, the quality of the cuts, the uniformity of staining on both sides (especially from the front) | assess the quality and type of wood - for knots, curls, resin residues, stains and other visible defects |

| visually inspect the plates for possible minor defects - in these places the metal may begin to rust | evaluate the thickness of each panel along its entire length, check for visible cracks (especially on embossed panels) | check the moisture content of the tree, find out if the panels are treated with antiseptic and protective compounds |

| availability of a certificate and manufacturer's warranty (certified products must be labeled accordingly) | check the geometry of each panel |