Installation of cladding

There are two ways to decorate with stone or tiles: with jointing (a more decorative look) and end-to-end (a monolithic coating is obtained). Some types of decorative tiles can be laid only in one of these ways, it is worth asking in advance when buying, since the seam device requires special skills and devices. If the stone is of different sizes, then first they lay out some part on the floor, trying to achieve the maximum decorative effect by alternating parts of different sizes. Laying begins with openings and corners from bottom to top.

New technologies have made this process easier. Thermal panels appeared on sale - this is a finished insulation plate with a layer of decorative stone already glued on. The type, color and texture of the decor can be selected to your liking, thermal panels are glued directly to the facade

It is important that the surface of the wall is flat. For wooden walls, this material is not the best choice, since there is no ventilation of the wood

Modular types of cladding, siding, rail, lining are fastened with self-tapping screws to the crate or special locks from the bottom up. The first row is installed at a height of 10-15 cm from the ground for air circulation under the panels, if the plinth is not provided.

Decorative plaster is applied to the rough layer. It can be smooth or embossed. The relief helps to hide the irregularities of the facade. The optimum layer thickness for the facade is 1 cm. Choosing a plaster for finishing facade of a wooden house, it is necessary to be prepared for the inevitable appearance of cracks, since the tree has plasticity, and it deforms a little all the time.

Summarizing all the pros and cons of finishing materials, we get a scale of preferences for choosing the finishing of external walls in descending order:

- stone;

- brick;

- decorative rock;

- natural board, lath, lining, block house;

- siding;

- flexible ceramics;

- plaster;

- thermal panel.

Facing the bath with imitation wood under a bar

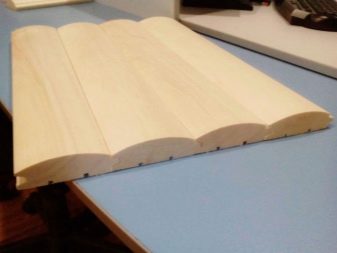

Imitation of a bar is a kind of lining, which is used for facing facades. Board dimensions: thickness - 1 cm, width - from 10 to 16 cm.

A distinctive characteristic of the material is the presence of a central groove to relieve stress in the wood, which helps to extend the life of the finish.

Imitation wood is made from various species, but coniferous wood is considered the best.

The main advantages of the finishing material include:

- environmental safety;

- affordable and quick installation;

- resistance to aggressive substances and damage;

- aesthetics;

- a variety of standard sizes - in width, length and thickness;

- high thermal insulation characteristics;

- long service life.

But even such a practical material is not devoid of significant drawbacks:

- the need for periodic treatment with antiseptics and fire retardants;

- susceptibility to fire and decay;

- the possibility of deformation due to insufficient drying or the use of low-quality raw materials for manufacturing.

The frame of the bathhouse is sheathed in the horizontal direction with a thorn outward. Such a mount is resistant to deformation and moisture penetration. The material is mounted on a flat surface using a wooden or metal crate. Before painting, the imitation wood is carefully sanded with fine-grain emery paper.

Types of wood facade cladding material

Decorating the walls of a house under a tree may seem quite costly for some.In the modern construction market, a huge variety of wooden facade material is presented, which differs in cost, appearance, its strength, thermal insulation, and operational characteristics. Before deciding, it is worth carefully studying all the options and choosing the most suitable one for the facade.

Timber imitation

House cladding with imitation timber

Practical and inexpensive, in comparison with others, type of facade decoration. The panel fastening system is simple, which allows you to cope with the installation yourself. In this case, the house will look as if it was built of wood. You can buy an imitation of a bar in various colors, so every lover of wood materials will be able to find a suitable one. This type of cladding is environmentally friendly and has a rather long service life - about 30 years. It can be considered universal, since it can be mounted on various types of surfaces: wood, brick, concrete, foam block and others.

Lining

Facade of a lining house

A special connection system eliminates the appearance of gaps and violation of the integrity of the facade. This material does an excellent job with heat and sound insulation and, in combination with insulation, will help to significantly save on heating. It is not difficult to mount the lining. The facade cladding should be started from the bottom up, with the spikes at the top. In order for the appearance of the lining to please for a long time and does not fade in the sun, it should be periodically treated with protective agents.

Block house

Wooden facade decoration houses block house

The facades of houses made of natural wood, finished using a block house, look as if they were erected from rounded logs. In fact, one part of such panels is flat and has a tongue-and-groove system, due to which the individual elements are connected. This is a more expensive type of wood material compared to the previous ones. But its strength and external properties are also an order of magnitude higher. With the help of a block house, you can realize bold ideas and make even the most inconspicuous house attractive.

Wood siding

Example of a facade clad with wood siding

Comfortable, cozy atmosphere inside the house and an attractive view from the outside - all this is provided by the cladding with wooden siding. The panels are mounted on the crate, which allows for ventilation and eliminates the accumulation of moisture. Fastening the siding is simple, but at the same time, you should first calculate the required amount so that there are enough solid boards. The corner pieces are cut with a hacksaw. For corner sheathing, leave a gap between the corner panel and the main panel. At the end of the installation, it is necessary to treat this gap with a special mastic.

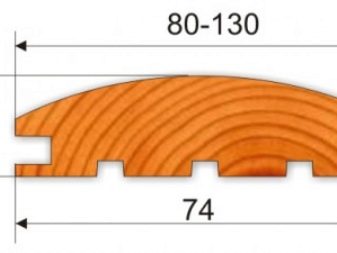

Planken

Façade larch planken and pines

Wooden boards with a thickness of 10 to 30 mm, which are placed at an angle to the surface, are called planken. Most often it is produced from Siberian larch. This material has excellent resistance to external factors, as well as a low level of thermal conductivity. In addition, the price of this breed is affordable, so such facade cladding will be relatively inexpensive.

To mount planken, you should take into account the recommendations of specialists so that the result meets expectations. Leave a small gap between the boards, as in wet conditions the wood can swell, leading to swelling. This is possible thanks to the rounded edges. At the same time, there are no gaps in which additional moisture can accumulate.

Thermal panels

Thermal panels are a material that performs two functions at once - cladding and external insulation of houses. A layer of decorative coating is applied to the thermal insulation layer at the factory. It looks like marble or natural stone, does not burn, and has low water absorption characteristics.

It is possible to cover and insulate the house with one material at the same time using thermal panels

This finishing material is made on the basis of foam, mineral wool or extruded polystyrene foam. Depending on the type of insulation, the installation method is selected: expanded polystyrene and expanded plastic are glued to the appropriate composition. The joints are closed with a special aluminum strip or rubbed with paste.

Facade cladding panels on the basis of mineral wool, they are mounted only on a special system of profiles, the joints are also sealed.

A very attractive idea is to immediately insulate the house and veneer it. Excellent appearance, and the characteristics of such a cladding are impressive. It's just a pity that there is little operating experience and there are no reviews yet: it appeared quite recently.

There are also clinker thermal panels. Clinker tiles are glued to the insulation. The material is not cheap, but the performance is impressive, as is the variety of finishes.

Another option for thermal panels - with clinker tiles

The choice of materials that can be used to sheathe a house at any time - in winter or summer - is considerable. There are expensive options, there are cheaper ones. In any case, besides the cost, be sure to consider vapor permeability. Then you don't have to deal with mold and dampness.

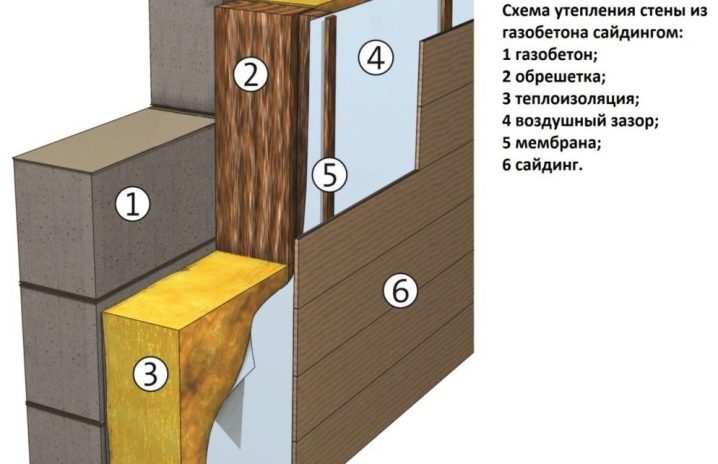

Features of cladding with siding (or metal block house)

Before starting work on insulation and siding, the walls of the house are strengthened, the cracks and cracks formed are closed. The design of such a facade depends on the quality and external characteristics of the material.

Modern manufacturers offer a huge selection of panel types, various colors and textures for any taste. Many people wonder what is better block house or siding?

The modern facing material of the blockhouse is made of galvanized steel with a special coating, it imitates the construction of wooden logs.

These panels differ from conventional siding precisely in that they are an exact imitation of a timber frame.

Blockhouse is a good material that is ideal for indoor and outdoor decoration.

Manufacturers offer a wide range of panel colors and shades, which in turn allows you to create a unique exterior at home.

If there is a question of siding or corrugated board when choosing a material for facade cladding, it is most rational to give preference to the first option.

Siding for exterior wall decoration of the house has the following set of advantages:

- excellent soundproof and heat-insulating properties;

- the construction of the frame for the installation of the panels provides natural air movement, thereby allowing the walls to “breathe”;

- fire safety;

- simplicity and high speed of panel installation;

- for facing in this way, preparatory work is not required;

- no need for maintenance;

- resistance to weather and seasonal changes.

Summing up, it is worth noting that both finishing options have the right to occupy the first positions in the list of high-quality and effective facade materials for arranging the facades of private houses.

Convex or rectangular outer surface is an individual choice according to your taste and aesthetic expectations.

What, unambiguously, pleases, is the same cost of finishing with siding or metal block house. The same quality of the facade structure and durability in operation.

Peculiarities

The block house is a type of lining. On the one hand, the surface of the panels has a convex shape, which visually resembles a log house or a rounded beam. There are special spikes and grooves for fastening to the material.

The block house is used for interior and exterior decoration. The building material can be used to cover rooms of a small area, since the thickness of the panels is not very large.

The products have a number of advantages.

- Safety for human health.Since the panels are made of natural wood, the block house is a completely environmentally friendly material.

- The panels do not create a large load on the walls due to the fact that they have a low mass.

- The material provides a good level of sound insulation.

- The coating has thermal insulation properties. Of course, the panels do not provide absolute heat retention, but they minimize the influence of cold surfaces on the microclimate.

- The material is easily attached to the surface of walls and ceilings. The work is not difficult even for beginners.

- The block house made of valuable species of trees fills the room with a pleasant aroma, which creates a special mood and has a beneficial effect on the health of households.

- Wood panels do not have to be used to decorate the entire room. The block house goes well with other materials; it can decorate only one wall or part of it.

Siding baths

Siding - decorative panels of a standard size: width - 22 cm, length - 125 cm. The material can be metal and vinyl, it has more than 10 colors.

To sheathe a timber bath with siding, it is first necessary to install a profile frame or a wooden crate on self-tapping screws. All installation work can be done independently. The surface of the walls is carefully treated with antiseptic compounds to prevent the formation of mold and harmful microorganisms.

The siding is installed in a horizontal position with an indent of 20 cm from the foundation of the building.

Bath siding has the following advantages:

- protection of the facade from atmospheric precipitation;

- resistance to temperature extremes and fading;

- inertness to deformation and mechanical damage;

- Fire safety;

- lack of toxic elements;

- good air permeability;

- low level of moisture absorption;

- availability of installation.

However, the material has some drawbacks:

- high cost of individual fixing elements of the structure;

- the appearance of deformations and backlash in case of violation of the installation technology;

- the need to create a flat surface for fixing the panels.

Materials for wood finishing of the walls of the facade

Decorating a private house with wood will be of high quality and durable only if you choose the right material and carry out its installation using high-quality consumables strictly according to technology. Among the most common wood species are oak, beech, ash, pine, cedar.

| Breed | External characteristics | Durability | Peculiarities |

| Oak | A wide variety of colors is characteristic. Shades can be either golden or dark brown. | The service life is about 100 years. | Hard and very durable wood. Under the influence of the load, it is able to deform, but after the cessation of exposure, it restores its shape. |

| Beech | It has a beautiful pattern in the form of heart-shaped and shiny lines. | With proper care, it will last more than 50 years. | Differs in good flexibility. It is susceptible to moisture and rots if stored and maintained improperly. |

| Ash | Available in various textures and shades: light brown, pink, yellowish. | In terms of service life, it is equated to oak, but it is advised to renew it every 50 years. | Very durable and flexible. Has excellent resistance to physical impact. The cost of such material is quite high. |

| Pine | A varied range of colors, a pronounced pattern. | It is short and is 10-12 years old. | It differs in a low price, but at the same time it is less resistant to mechanical stress, but has a low level of thermal conductivity. It is resistant to decay, due to the presence of a large number of resins in the composition. |

| Cedar | Has a yellowish tint, presented in various colors. | Can last over 25 years with proper care. | It is resistant to pests, has good thermal insulation properties, practically does not rot and mold. |

Varieties of material

At a modern building market can be found many types of block house, which differ in some parameters and characteristics. The main classification implies the selection of several types of material, depending on its quality.

- "Extra". "Extra-class" panels do not have significant defects, are of excellent quality and high cost.

- Category "A". Panels in this category are of good quality. A small presence of healthy knots, resin pockets and traces of pests (wormholes) with a width of no more than three millimeters is allowed.

- Category "B". The material may have more significant surface defects. However, flaws should not spoil the performance and decorative characteristics of the panels.

- Category "C". Products of this class are distinguished by low cost and the worst quality. The material has an unpresentable appearance and needs additional processing. Panels of this class can be used to decorate the walls of utility rooms.

The operating characteristics of a block house are influenced by the type of wood from which the material was made.

- Pine. On such a surface, there are usually traces of knots, which create an interesting pattern. The material can be used for both interior and exterior decoration of houses.

- Siberian fir. This material stands out among other conifers with the smallest weight. Fir contains little resin, so such wood is prone to decay and requires additional treatment with an antiseptic.

- Spruce. This material has a nice texture. Unlike pine, spruce has a lighter shade.

- Cedar. Such wood has a pleasant aroma and has a good effect on the indoor microclimate.

- Larch. This material is highly durable. Larch contains a large amount of resin, which protects the material from decay.

- Alder. This type of wood is considered one of the most durable and moisture resistant. The performance of alder panels only improves over time.

- Linden. Such a coating is practically not exposed to high temperatures. Most often, a linden block house is used for cladding bath rooms.

- Birch. The wood has a homogeneous structure and is easy to process with paints and varnishes. With the help of birch panels, you can create an imitation of almost any expensive wood species.

- Aspen. Such panels are not subject to decay, they tolerate moisture well and are highly durable.

Wooden panels can be of different lengths, widths and thicknesses. Standard material thicknesses are 20, 30 and 36 millimeters. The width can vary from 90 to 190 millimeters. The intermediate values of the width of the released material are usually 120, 140 and 160 millimeters. The panels are usually two or six meters long.

Cladding process

Let's proceed to the process of the cladding itself. It consists of several stages.

First step

Vapor barrier can be carried out using several materials (polyethylene, aluminum foil). The main purpose of this process is to create ventilation thanks to the film. How to do it: we fasten narrow slats (about two and a half cm) at a small distance from each other. Using a stapler, we attach a vapor barrier and make small holes (from the bottom between the slats).

Second phase

We build a medium-sized structure from boards for thermal insulation. We attach to the wall in a vertical position, with a distance for insulation.

Fourth stage

We attach a special film (waterproofing) on top of the thermal insulation. This film serves to prevent moisture ingress. We also lay it in several layers, like the previous one.We attach the first layer with a stapler, and the joints with tape.

Fifth stage

We fasten the frame to the boards of the previous frame, on top of all the insulations. We leave gaps between the frame and the waterproofing to remove condensation. I advise you to attach a mesh to the bottom to protect it from rodents and insects.

And the last, sixth step

We proceed to clapboard facing. We start at the bottom. The first lining sheet is located with a spike down, it is necessary to check with a level. It is worth fixing with nails. Subsequent boards must be tightly installed in the groove of the previous one and secured. After the work done, it is necessary to fix the boards in a vertical position at the corners of the building, overlapping one another. Next are the trims for windows and doors.

After all this, it can cover the lining with a special compound that protects it from any damage.

With this brick cladding, it should be remembered that there must be a space between the building wall and the brick itself.

Views

The main criterion based on which the classification of a block house is carried out is the raw material used for the production of such panels. Products are made from wood, metal or vinyl.

For the production of wooden products, preference is given to coniferous and deciduous types of wood, among which pine, spruce, cedar and so on can be distinguished.

The production of such panels is carried out using the following technology:

- the log is cut according to a special method, during which four elements are formed;

- the resulting products go through a drying process that can last about 14 days;

- after which the material corresponding to the required properties is given the appropriate configuration, which allows them to finish the buildings.

Taking into account the quality of wooden lamellas, there are several categories of wooden block houses:

- category "A" - products of this group may contain defects in the form of 1 knot, 2 cracks and resin pockets for 1.5 m of material;

- products with up to 4 knots and 2 pockets are categorized as "B";

- category "C" includes products on the surface of which there may be defects that make up no more than 5% of the panel length.

The positive qualities of wooden products include the following material properties:

- high level of resistance to mechanical stress;

- maintainability of individual components of the structure;

- ease of installation and low weight of products;

- environmental friendliness of products;

- panels allow the bases to "breathe" and provide thermal insulation;

- aesthetic appeal.

The metal block house is notable for several positive qualities.

- The raw material for production is zinc-coated steel sheet.

- The inside of the panel is primed and painted. A certain pattern is applied to the outside, which imitates wood.

- The material stands out for its durability and resistance to temperature extremes. In addition, unlike wooden counterparts, the products are not subject to deformation from contact with moisture.

Metal gives the panels high strength, and the cost of metal products is always an order of magnitude lower than a block house made of wood. In addition, steel panels do not need to be processed and are not classified as fire hazardous construction products.

Vinyl products contain special additives that provide them with high quality and durability. Products on the market today are distinguished by a wide range of colors and low cost.

Vinyl panels perfectly imitate wood finish, among the advantages of the products it is worth noting the following characteristics:

- the material does not require specific maintenance - there is no need for processing or painting over time;

- according to consumer reviews, a vinyl block house has a long service life, which exceeds that of wooden products;

- products have a minimum weight, which eliminates the presence of additional load on the foundation of the building after the facade cladding;

- panels have a high level of UV resistance.

The disadvantages of vinyl products include the heterogeneity of the structure, as well as sensitivity to temperature fluctuations, due to which, according to experts, they should not be used for all types of buildings, including frame-type houses or buildings made of aerated concrete.

Peculiarities

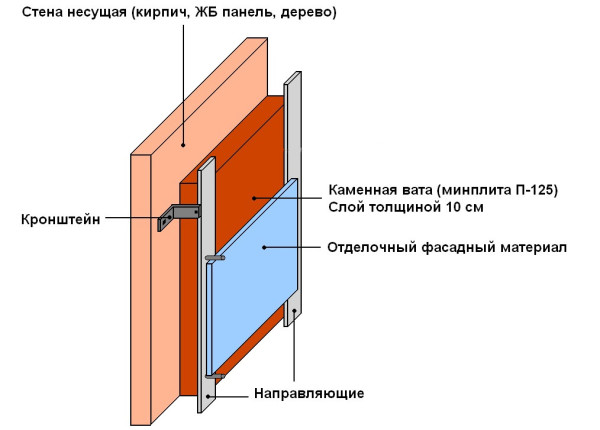

There are two types of cladding: with and without insulation.

Let's analyze the first, more popular option.

All structural elements are equally important. If you neglect the vapor barrier or wind barrier, it will have to be repaired much more often. The layers are listed away from the wall.

The block house is mounted in the same order:

- A layer of vapor barrier is needed to protect the insulation from moisture vapors from the side of the wall.

- Lathing - the frame of the facade, creates a space between the wall and the block house. It is made of a bar with a section of 100 * 40 mm.

- Thermal insulation. Insulation rolls, such as mineral wool, are best suited. The optimal layer thickness is 10 cm.

- The windscreen is attached to the sheathing timber. It protects the facade from the wind, and the insulation from the moisture contained in the air.

- Counter-lattice - wooden slats, to which the boards of the block house are attached. They have a section of 20 * 40 mm. Creates an empty space between the windshield film and the outer sheathing, which protects the inner surface of the boards from moisture.

- The outer layer is the block house itself.

The structure is light enough, does not create a load on the foundation. It is possible to equip such a facade not only during the construction of a new house, but also during the repair of old buildings.

Preparation and accessories

Before the start of installation work, the block house should be prepared. For this, a short period of time is allocated for the acclimatization of the material. This usually takes several days. At this time, insulation, waterproofing is laid outside the walls, and the material is calculated in a cube.

Also, the installation of panels provides for the assembly of vertical battens from slats or bars. The distance between the elements of the frame should be 70 cm. To provide the necessary waterproofing, a thin frame is additionally attached to the self-tapping screws over the insulated lathing.

To install the boards, you need to purchase certain components.

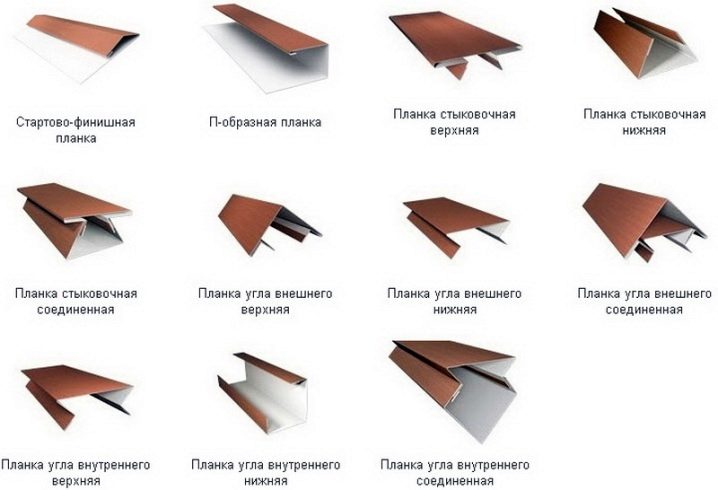

- Universal planks.

- Hanging profiles. They are usually fastened over window openings to protect the finish from moisture. If the facade consists of several levels, then the profiles are used between the transitions.

- Starting bar. It is necessary for mounting the bottom row of boards.

- Finishing profile. It is placed along the edges of the wall to secure the last panels.

- Connecting strips and corners.

- Special fastening elements (kleimer and self-tapping screws).

Installation tools should consist of a standard set including tape measure, level, screwdriver, hammer and drill.