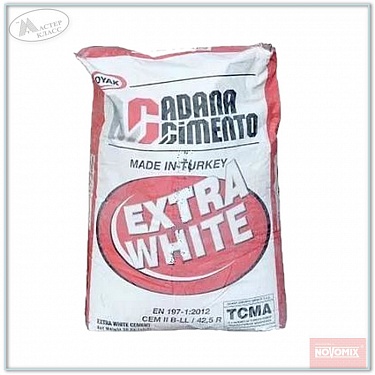

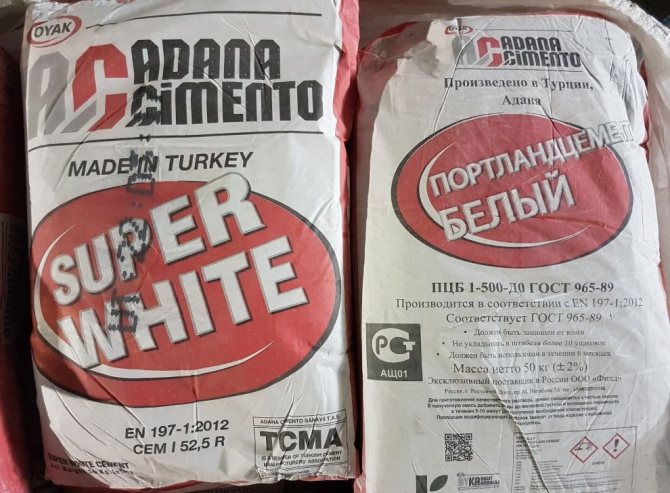

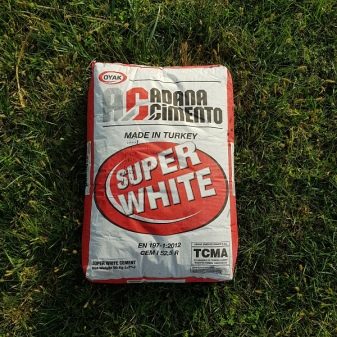

Cement WHITE M 600 D-0 Turkey super white Adana bag of 50 kg

Promotion details:

- - from the 28th to the 2nd day of each month

- - the promotion applies to all products

- - order amount from 50,000 rubles

- - delivery within Moscow within the Moscow Ring Road or delivery outside the Moscow Ring Road *

- * when delivered outside the Moscow Ring Road, only the mileage is paid.

* The order must consist of the goods from the above sections.

We offer Turkish-made white cement M 600. The material is manufactured using a special technology that minimizes the iron content. This feature gives the cement a super white color, comparable in whiteness (90%) only to titanium dioxide.

Specifications

Fully hardened cement mortar:

- Resistant to moisture and its sudden changes.

- It is characterized by high final strength. Cement M 600, in contrast to the analogue M 500, has increased resistance to corrosion and strength properties. As a result, its use in construction and repair ensures the durability of the erected objects, structures and individual elements.

- Resistant to temperature influences, seasonal thawing / freezing cycles.

During operation, structures or individual elements made of Adana cement do not lose their original white color, even under conditions of negative atmospheric exposure, dampness, and ultraviolet radiation.

Application area

Used white cement M 600 in construction and repair. It is used for the production of individual reinforced concrete products (beams, slabs, blocks, etc.), as a binding agent for finishing plasters, putties, leveling mixtures, grouting. In landscape design, structures of small architecture and sculptures are made from cement mortar. Adana can be used independently as an assembly (installation of windows, sockets, etc.), restoration and restoration or adhesive material.

Table for calculating the cost of delivery of orders:

For orders up to 100 kg, a budget delivery cost is offered (delivery time up to 2 days):

| Delivery area | in Moscow | Moscow region from MKAD (up to 15 km) ** |

| Cargo weight up to 10 kg | RUB 290 | 490 rbl. |

| Cargo weight up to 15 kg | RUB 350 | RUB 590 |

| Cargo weight up to 20 kg | 450 RUB | RUB 690 |

| Cargo weight up to 50 kg | RUB 550 | RUB 790 |

| Cargo weight up to 100 kg | 650 RUB | RUB 990 |

* Drywall, insulation, lumber, profile for gypsum board, foam block and brick are calculated from the table from 100kg.

** Delivery over 15 km, the calculation is based on the “tariff” + 50 rubles per 1 km.

For orders of 100 kg or more:

| Delivery area | Moscow inside the TTK *** | Moscow inside the Moscow Ring Road | Moscow region from MKAD |

| Cargo weight up to 400 kg * | 800 RUB | 800 RUB | 800 RUB + RUB 25 per km |

| Cargo weight up to 1 ton ** | RUB 1,450 | RUB 1,450 | RUB 1,450 + RUB 25 per km |

| Cargo weight up to 2 tons ** | RUB 1,950 | RUB 1,750 | RUB 1,750 + RUB 25 per km |

| Cargo weight up to 3 tons ** | RUB 2,950 | RUB 2,850 | RUB 2,850 + RUB 25 per km |

| Cargo weight up to 4.5 tons ** | RUB 4,150 | RUB 3,950 | RUB 3,950 + 60 rub. per km |

| Cargo weight up to 6 tons ** | RUB 5,850 | RUB 5,550 | RUB 5 550 + 60 rub. per km |

| Cargo weight up to 10 tons ** | RUB 10,000 | RUB 8,000 | RUB 8,000 + 60 rub. per km |

* provided that the ordered goods are placed in a car.

** provided that the ordered goods by volume are placed in a truck of the specified tonnage.

Delivery of not sawn 6 meter lumber (board, timber) with a volume of up to 2 m3 costs from 3,000 rubles.

When paying for delivery by bank transfer, 5% will be added to the delivery cost.

Additional requirements for the car, for example, a low height to enter the parking lot or an open body for vertical unloading, are paid additionally: + 20% to the cost of the standard tariff.

Unloading and lifting costs

Table for calculating the cost of unloading orders:

| Unloading | Up to 400 kg | From 400 kg to 3 tons |

| Unloading and lifting to the apartment | RUB 500 | 800 RUB (for 1 ton) |

| Unloading without lifting to the floor | RUB 500 | RUB 500 (for 1 ton) |

* The prices in the table are given taking into account the working freight elevator, regardless of the floor.

** In the absence of a freight elevator, the cost of lifting is multiplied by the number of floors to the apartment where the goods need to be unloaded.

*** The minimum order value for unloading and lifting is 500 rubles.

White cement Adana CEM I 52.5R Turkey M600

Packing: 50 kg bag.

The peculiarity of the super white Portland cement CEM I 52.5 R (M600) is a high degree of whiteness, about 90%, which is approximately equal to the whiteness of titanium dioxide, and is absolutely inert to pigments (does not “eat up” the color).

Properties of white Turkish cement Adana cimento: - whiteness - not less than 85% - insoluble sediment - 0.12% - loss on ignition - 2.61% - start of setting - 100 minutes - end of setting - 125 minutes - compressive strength: 2 days - 38 MPa, 28 days - 59 MPa.

White cement is made from low-iron clinker (the gray color of ordinary cement is mainly due to the presence of iron compounds in the initial raw materials. Raw materials for the production of white Portland cement are kaolin and chalk (or limestone), characterized by a limited content of coloring oxides - iron and manganese oxides.

Comparison with regular gray cement:

It gains strength much faster at the initial stage of drying and hardening, which is due to its chemical and mineralogical composition. In 16 hours after laying the solution, it hardens by 60%. The gray composition reaches this indicator only on the 28th day! Secondly, products made from such a solution are characterized by a higher degree of strength and resistance to weathering. They retain their original color for a long time, do not turn yellow even in rain and direct sunlight, and do not crack. All these properties make it possible to avoid additional costs for repairs and painting. Thirdly, due to whiteness, cement has a high light reflectance, which makes the finished product made of it more attractive. Moreover, the addition of dyes to the white formulation allows for a brighter and richer color.

Advantages of Super white cement Adana CEM I 52.5R: - increased weather resistance, - whiteness about 90%, - inertness to pigments (does not “eat up” the color).

White cement has a very wide range of applications:

- Architectural and decorative concrete works, production of finished plaster and mortars; - Production of adhesives and materials for filling seams; - Production of furniture elements for parks and gardens (borders, flower beds, balcony decorations, columns, etc.), art products (small sculptures, restoration work, etc.); - Production of floor materials (paving slabs, etc.); - Production of prefabricated elements (finished balconies, steps, concrete blocks, decorative facing stones, facade cladding, etc.).

Production technology

The constituent components are ground and mixed in cone crushers equipped with a protective lining of porcelain, basalt or silicon slabs. Such processing provides a high fineness of grinding, which is different from traditional cement.

The resulting powder is fired at high temperatures, followed by rapid cooling. The process significantly increases the strength characteristics of the clinker and enhances its whiteness.

For firing, various types of fuel are used, which do not leave soot or ash particles after combustion. Cooling occurs in an oxygen-free environment when the temperature drops from 1200 to 200 ° C. There is also known a method of water cooling from 1500 to 500 ° C, followed by drying in a drum up to 300 ° C.

Markings

The name of the building material contains only minimal information about it. The main indicators are encrypted in the marking, the index of which is determined by two characteristics of the cement:

- the ability to withstand the maximum permissible load after final hardening - denoted by the letter "M";

- the amount of impurities in percentage terms in relation to the total volume of clinker - letter "D".

For example, from the M500 D20 marking it follows that cement that can withstand a load of up to 500 kg / cm3 without compromising the quality of the grout contains 20% mineral additives. If the package has an index D0, then this means the complete absence of impurities.

The fineness of the binder mixture is determined by sieving through a sieve with a mesh size of 0.08 × 0.08 mm. The remainder of standard cement should not exceed 12% of the total weight. Ultrafine grinding ensures a homogeneous working solution and smooth surfaces of finished products.

Comparison of white and gray cement

Advice

For high-quality performance of work using white material, experienced builders are advised to take into account some of the features:

- To obtain a high-quality solution, it is necessary to use only marble chips and sand with a low percentage of iron, as well as clean water without heavy salts and impurities.

- After 20 hours, 70% hardening occurs, which will significantly reduce the time spent on repairs.

- Versatility, color fastness and aesthetic whiteness allow the material to be harmoniously combined with other decorative elements of the interior.

- Strength and resistance to the appearance of chips and cracks will reduce additional costs for repair and restoration of the structure.

- The tools used for finishing work must be kept perfectly clean, all surfaces must be cleaned of corrosion and dirt.

- Deepening the reinforcement into a reinforced concrete structure to a depth of at least 3 cm will avoid corrosion of metal surfaces and the appearance of stains on the white coating.

It is obligatory to apply gray cement on the iron structure with a thickness of at least 30 mm.

You can use in the production process plasticizers, retarders and additional additives that do not affect the color of the solution.

Titanium white can be used to increase the percentage of whiteness.

It is necessary to dilute the solution with extreme caution, observing all safety rules and using personal protective equipment for the eyes, face and respiratory organs.

Cement can be stored for 12 months in undamaged original packaging.

Cement is the backbone of any construction process. The reliability, strength and durability of the structure depend on the quality of the selected material. The modern building material market offers a huge range of goods. Before making the final choice, it is necessary to carefully study all manufacturers and their proposals in order to avoid purchasing a low-quality product with low technical properties and characteristics.

For information on how to prepare a white cement mortar, see the next video.

Manufacturers

On the construction market, you can find white cement from various manufacturers - Iranian, Egyptian, Danish and, of course, Turkish. The cheapest product is from Iran, but cheap does not mean high quality. It is worth getting acquainted in more detail with well-known manufacturers who are famous in many countries of the world.

Aalborg white

Danish cement plant Aalborg White is popular for using clean raw materials and advanced production technologies

The brand's products can be found in 80 countries around the world, because it attracts attention with its excellent whiteness and increased durability. Today, the company's factories are located in Malaysia, China, Denmark and Egypt.

But apart from the advantages, the products have one significant drawback - the high cost.

Aalborg White M700 white cement has the following technical characteristics:

- the degree of whiteness is 85-90%;

- belongs to the first grade;

- sold in 25 kg paper bags;

- the price for one bag is 300 rubles;

- the setting of the solution begins after 85 minutes, and ends after 2 hours;

- strength 36–44 MPa is achieved on the second day, and 68–78 MPa - on day 28;

- expansion - up to 2 mm.

Cimsa

This company is a very famous manufacturer of building materials not only in Turkey but also in other countries. In addition to decorative white cement, she produces decorative plasters, various putties and groutings.

Turkey is the birthplace of white cement, and the company's products fully confirm this through the creation of a durable and sought-after product. High quality at an affordable price is the main advantage of Cimsa products.

Cimsa M600 white cement has the following technical characteristics:

- the degree of whiteness is from 92 to 97%;

- compressive strength after 3 days - 37.0 MPa, after 7 days - 49.1 MPa and after 28 days - 60.7 MPa;

- shrinkage is only 0.01%;

- the beginning of setting occurs after 100 minutes, and the end - 130 minutes;

- the density is 3060 kg / m³.

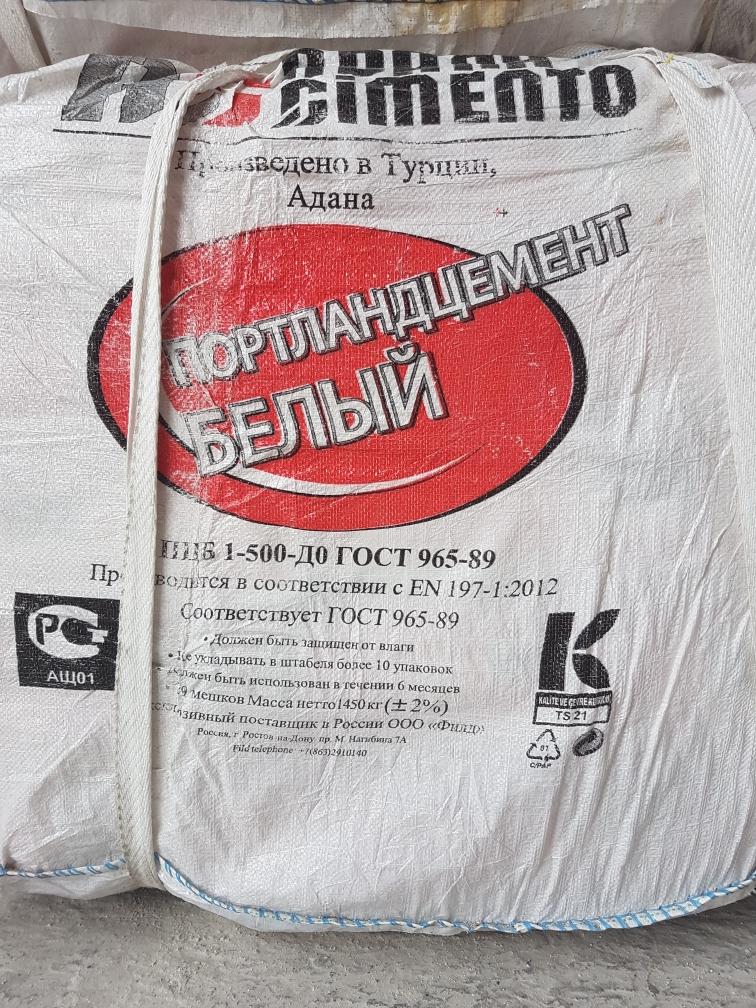

Adana

Another popular Turkish manufacturer is Adana. It ranks second in the market after Cimsa and is a renowned exporter of construction products, including white cement.

A prime example is the super white cement CEM I 52.5R. It is characterized by increased weather resistance, inertness to pigments and can be used for various purposes due to its strength and reliability.

The technical characteristics of white cement CEM I 52.5R are as follows:

- strength class - M600;

- light reflection coefficient - 90.13%;

- setting of the solution begins after 140 minutes, and ends - 190 minutes;

- compressive strength after 2 days - 38.3 MPa, after 28 days - 61 MPa.

Cement white

ADANA CEM 1 52/5 N / R (Turkey) (M-600, white cement) can be used as a base for making light-colored concrete

Adana White Cement Concrete is often used for cladding conventional concrete surfaces, with particular attention to ensuring a secure bond between both concretes. To obtain the proper color, concrete is usually prepared from fatty concrete mixtures with a water-cement ratio of no more than 0.4

For the production of Adana cement, chemically pure kaolin, chalk, limestone or marble are used, with a low content of coloring metal oxides (iron, manganese, aluminum, etc.)

Aalborg White CEM 1 52/5 R (Denmark, white cement) has the highest degree of whiteness (M-700) and strength grade, and the manufacturer himself is one of the main manufacturers in the world for this product. To solve the most important tasks, consumers usually opt for this cement. Its main disadvantage is its higher cost compared to similar products.

Aalborg White CEM 1 52/5 R (Egypt, white cement) - today has a relatively low price and production technology of the recognized world leader - the Danish company Aalborg White. It appeared relatively recently on the building materials market. Disadvantages include imperfect logistics and supply disruptions.

Cimsa CEM 1 52/5 N / R (Turkey, white cement) - good price-quality ratio. These products have proven themselves well in the market. Many consumers work with this mixture.

JSC "Shchurovsky cement" (Russia, white cement) - is produced by the wet method, in contrast to the dry method, which is preferred by the manufacturers of Turkey and Egypt. In the Moscow region, it is the most demanded and, in comparison with its competitors, has a minimum time period from the moment of its production to its delivery to the final consumer. Its disadvantages include the fact that its color has a greenish tint.

Cement "TsSM" CEM I 42.5 N (Russia, white cement) is a material with a balanced formula and high final strength. Consists of mineral raw materials, completely safe for the environment. Belongs to the M-500 series - the most versatile and practical brand of building mixtures. CSM cement can be used in dry mixes for brickwork, plastering, concreting. Ready-made structures made using this material are distinguished by high mechanical endurance and durability.

Portland cement M-500 CEM 42.5N (Mordovcement M-500 D0, white cement) 50 kg is used in the production of critical concrete and reinforced concrete structures in industrial construction, where high requirements are imposed on water resistance, frost resistance and durability. Fast-setting cement for general construction purposes PC-500 D0 has an increased strength of the final structure, amounting to 500 kg per 1 cm2. More details ...

Portland cement M-400 CEM 32.5 N (Mordovcement M-400 D20, white cement) is a mixture for general construction purposes, an irreplaceable building material in transport and hydraulic engineering, in the production of reinforced concrete products and structures. Construction of structures for underwater structures located in saline waters, construction of underground and surface facilities. M-400, in contact with a sulfate medium, does not lend itself to corrosion, an irreplaceable assistant in the preparation of building mixtures. More details ...

AQUAMARIN LLC offers a wide range of white cements from various manufacturers. And also Portland cement M-500 and M-400 in bags and in bulk.

Specifications

White cement is produced in accordance with the standards and requirements established by GOST 965-89.

Cement is produced in several grades, depending on the level of strength:

- M 400 - average level of solidification, high percentage of shrinkage;

- M 500 - medium level of hardening, low percentage of shrinkage;

- M 600 - high level of solidification, minimal shrinkage.

The decorative whiteness of the material divides the mixture into three grades:

- 1st grade - up to 85%;

- 2nd grade - not less than 75%;

- 3rd grade - no more than 68%.

Manufacturers distinguish three ways to obtain clinker:

- Dry - without the use of water, all components are crushed and mixed with air, after firing, the necessary clinker is obtained. Advantages - savings on heat energy costs.

- Wet - using liquid. Advantages - accurate selection of the composition of the sludge with a high heterogeneity of the components (sludge is a liquid mass with a water content of 45%), the disadvantage is a high consumption of thermal energy.

- The combined type is based on wet production technologies with intermediate clinker dewatering up to 10%.

To knead the solution at home, it is necessary to mix industrially refined quartz sand or river washed and seeded sand, crushed marble and white cement. The required proportions are 1 part cement, 3 parts sand, 2 parts filler. Mix the components in a clean container without dirt and corrosion. The fraction of aggregates is minimal, the color of other materials should not be gray, but only white.

Persistent pigments added to the composition of the solution will help to make the part-cement colored:

- manganese dioxide - black;

- escolaite - pistachio;

- red lead iron;

- ocher - yellow;

- chromium oxide - green;

- cobalt is blue.

Characteristics of white cement

As already mentioned, Shchurovsky white cement, due to objective reasons (minimum delivery time), significantly exceeds foreign analogues in terms of the degree of "freshness", but also for objective reasons (features of local raw materials) is somewhat inferior to them in terms of light reflection coefficient (whiteness).

Light reflectance table of white cements from different manufacturers

| Characteristic | Brand, country of origin | ||||

| Shchurovsky plant, Russian Federation | Cimsa, Republic of Turkey | Adana, Turkish Republic | Aalborg White, Kingdom of Denmark | Aalborg White, Republic of Egypt | |

| White cement grade | M500 | M600 | M600 | M700 | M600 |

| Reflection coefficient, % | 83,5 | 85,5 | 90,3 | 88 | 87,3 |

Other advantages of white cement: a relatively high rate of curing at the initial setting stage (60% as of 16 hours after the start of hardening), absence of efflorescence, resistance to cracking, high strength, high weather resistance and durability of the initial appearance.

There is only one drawback of white cement - a relatively high cost compared to "gray" cements. So if a 50 kg bag of ordinary Portland cement can be purchased for an average of 250-290 rubles, then a 50 kg bag of Shchurovsky white cement will cost an average of 800 rubles in retail sale.

Average technical indicators of white cement of the Shchurovsky plant

| Regulated characteristic | Empirical (actual) value | Value according to regulatory documents |

| Residue on sieves with a mesh size of 45x45 microns,% | 0,1 | Not regulated |

| Specific surface (according to Blaine), cm2 / g | 5039 | 2500 (not less) |

| The beginning of the setting period, minutes | 120 | 45 (not faster) |

| End of setting, minutes | 170 | 600 (no later than) |

| Compressive strength (after 28 days), kgf / cm2 | 57 | 50 (not less) |

| Bending strength (after 28 days), kgf / cm2 | 7,5 | Not regulated |

| Uniformity of volume change | Withstands | Not regulated |

| False grasping | Absent | Not regulated |

| Workability | Excellent | Not regulated |

Recommended area of application: finishing of streets and facades of buildings, design of premises, production of colored panels, production of MAF products, production of facing bricks and facing stone, production of terrazzo slabs, production of dry building mixtures (plaster, glue, grout and putty).

Format of delivery and shipment by the manufacturer:

- White cement, CEM I 52.5 N (normally hardening without additives, strength class 52.5), manufactured, tested and packaged in accordance with the requirements of GOST 31108-2003;

- Sale and delivery: in bulk, in paper bags weighing 50 kg, in soft containers weighing 1000 kg;

- Shipment: by road and rail.

Applications of white cement

Currently, white cement in one form or another is present in almost all buildings under construction. But sometimes this building material is the only possible solution that successfully combines certain aesthetic and physical characteristics.

Currently, white cement in one form or another is present in almost all buildings under construction. But sometimes this building material is the only possible solution that successfully combines certain aesthetic and physical characteristics.

White cement is used:

when creating various building elements. At the same time, the facade decoration made of this material looks especially impressive. Snow-white architectural fragments and buildings amaze not only with their external beauty, but are also distinguished by greater durability than similar objects built on the basis of a gray analogue;

- in the production of terrazite plaster used for cladding facades of buildings, decorative bricks or paving slabs. To achieve maximum similarity with natural stone, white Portland cement is mixed with a dye of the desired shade, granite or marble crushed stone of the appropriate fraction and expanded clay gravel;

- as a basis for the manufacture of grouts, adhesives, self-leveling floors, cement-lime mortars, plaster mixtures;

- to create steps, flower beds, columns, decorative fragments, sculptures, borders and small architectural forms;

- when marking the road and airfield (it is practically indispensable in this case due to its high wear resistance and excellent reflective properties);

- as a material for road surfaces.

Advantages of white cement

White cement has such advantages as:

- Resistant to weather conditions. The high technical properties of the material prevent discoloration of the concrete. Accordingly, white cement can be used both outdoors and indoors. In this case, the whiteness of the finished object is able to persist for a long period of time.

- The ability to implement innovative creative ideas. Architects, sculptors, manufacturers of concrete products and cement products, thanks to the characteristics of white cement, have an excellent basis for the implementation of their custom projects.This material allows you to work with color, fillers, shapes, improvise with different concreting technologies, change, if necessary, the method of processing and finishing the hardened surface.

- Accelerated hardening and maximum strength. After 16 hours, the solution hardens by 60%, which significantly reduces and reduces the cost of the construction process.

- High dispersion. Prevents destruction of the material under the influence of moisture or aggressive solutions.

- Environmental friendliness This type of cement is made exclusively from natural mineralogical components.

- Chipping / cracking resistant. This advantage of the material minimizes the cost of restoration or repair work.

- Aesthetics. The bright white color of cement has a pronounced decorative effect, and its versatility allows it to be combined with various finishing materials.

- Multifunctionality. Used when casting bricks and floor slabs. It can be used as a decorative or building material. It is one of the components of grout, colored concrete, putty, dry adhesive mixtures, etc.

Find out about what a sewer aerator is from our review. Is a non-return valve required in the sewer? Read this article

Peculiarities

White cement is a material that is in demand due to its light shade, which is obtained through the use of a special production technology and the components used. It is made on the basis of low-iron clinker, and also contains mineral additives, gypsum, limestone, chloric salts, thanks to which the material acquires such an attractive color. Moreover, the content of manganese and chromium is practically zero.

All components can be fired, followed by rapid cooling. This process guarantees the strength and reliability of the white cement.

The technology for the production of white cement is carried out in special mills, crushers, which crush clinker and other raw materials (porcelain, basalt, flint slabs). The fineness of grinding of white cement is higher than that of the gray analogue, because it is 4,500 cm² / g, while for gray cement this figure is 3,500 cm² / g. The firing of the material is carried out thanks to the use of gaseous, liquid or other fuels that are not characterized by ash or soot emissions.

After firing, the cement is cooled in an acid-free environment, while there is a sharp change in temperature regimes from + 1200 ° C to + 200 ° C. Cooling can be done with water, then the firing temperature reaches + 1500 ° C, and water - + 500 ° C. To dry wet clinker, a drying drum is used, which has a temperature of + 300 ° C.

So, there are two main methods of making white cement:

- Dry. This method is quite common, since many large companies prefer it due to the low moisture content of the raw materials. Grinding, mixing and drying of all components is carried out in special shaft furnaces. The clinker can be fired at a temperature of + 800 ° C.

- Wet. The hard components are grinded in a special mill, and the soft ones are placed in a chatter box, while water is used. After grinding, the sludge is dried and amenable to further crushing, as in the dry method.

Since this material is characterized by the fineness of grinding, mesh No. 008 is used for sieving it, while no more than 12% of the raw material is deposited in the sediment.

White cement has the following advantages:

- Strength, reliability and fast hardening. After 16 hours, the solution hardens by more than 50%. This ability saves money.

- The material is protected from destruction under the influence of chemical solutions and moisture due to its dispersion.

- Environmental friendliness is achieved through the use of natural mineralogical components.

- The stability and strength of finished structures is due to the resistance to the formation of chips and cracks. This feature significantly reduces the cost of restoration or repair work.

- Attractive appearance.

- Color stability as the cement does not fade when exposed to sunlight.

- The versatility of the material lies in the ability to combine with various decorative materials for decoration.

- Functionality - white cement is used as a decorative and building material, it is part of putty, grout, colored concrete and various dry adhesive mixtures, and is also widely used in the creation of bricks and floor slabs.

If we talk about the disadvantages of white cement, then it is worth noting its high cost compared to the gray analogue. Some users do not perceive white cement as it should, but call it something in between clay and cement. Some buyers point out that many white cement compositions contain a large amount of additives that do not match the composition on the package.

Today, white cement is used in almost all areas of construction work. In some cases, you can't do without it at all. It is perfect for finishing the facades of buildings, since it gives them not only reliability and durability, but also expressiveness, attractiveness and beauty.