Peculiarities

Hilti anchors have a huge range of possibilities. They are used to secure massive surfaces with significant mass. Models will be the best option for mounting various bases, including aerated concrete, drywall, brick and concrete structures.

Anchors of this brand can have different technical characteristics. Each separate type is used for different materials. Samples can have all kinds of sizes and thicknesses, so in the range of products, any user will be able to find a suitable variety for him.

Expansion anchor

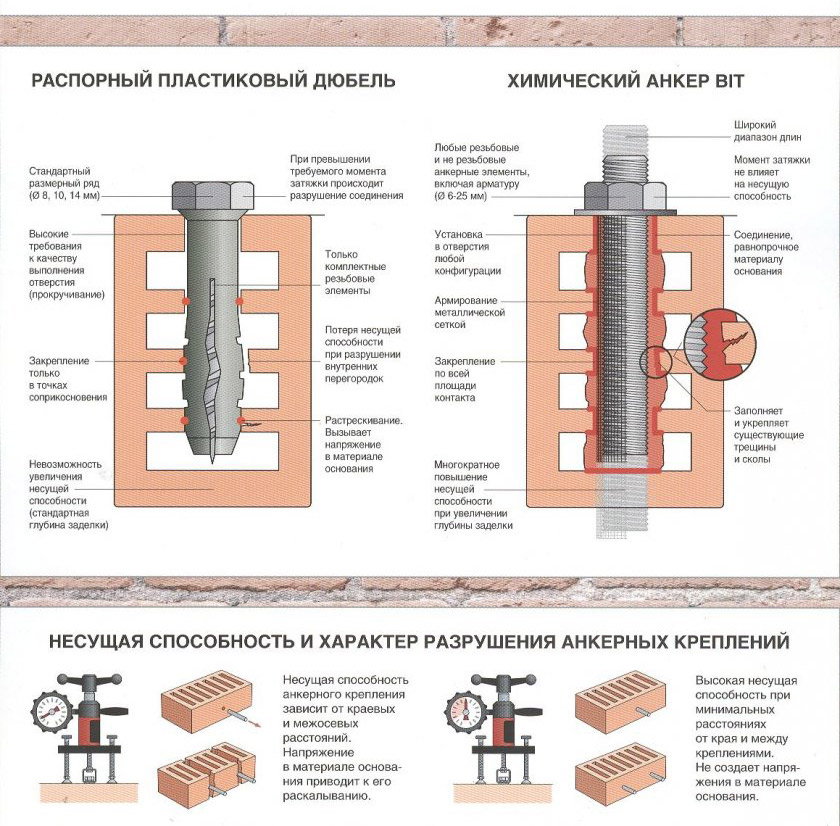

Developers are often forced to use HILTI expansion anchors. They are necessary when fasteners can be made with any hole shape, the material is not subject to reaming to fit the exact parameters of the project. Sometimes the base is not monolithic, it has a dense, granular structure, for example, a solid stone, a special type of monolithic slabs. For structures made of these materials, only spacer or chemical anchors can be used, but professionals will trust the first option more.

Spacer fasteners at the moment of tightening tend to expand along their entire length, in contrast to the stud anchor, which creates a wedge at the maximum attachment depth.

The expansion anchor does not differ in withstanding the maximum load, however, compared to other fasteners, it is easy to install and can be quickly removed from the structure if necessary.

Expansion anchors are used in various fields:

- Fastening of heavy structures, for the bases of which concrete or stone is used.

- Installation and strengthening of load-bearing walls and structures.

- Installation of lightweight structures for which shock protection is not provided. In this case, the expansion anchors are combined with self-tapping screws for sandwich panels.

- Use in combination with facade fasteners.

Experts recommend choosing concrete and stone slabs as the basis for fastening. Among their mandatory properties, in the first place is the maximum possible degree of adhesion, the use of components in the composition that contribute to high-quality adhesion, and the second is high strength characteristics. It is undesirable to allow significant cracks in the material, since they make the anchor fragile and reduce the maximum permissible load on it by about half.

Expansion anchors are resistant to negative mechanical and chemical influences. All elements of the fastener design are made of high quality materials. Bolts and spacers are made from shock-resistant alloys that are not destroyed by moisture, chemical factors and other influences.

Expansion anchors are allowed to be used in conjunction with the chemical compounds required to create combined fastenings in materials with cracks and gaps.

Anchor bolt: dimensions and other technical characteristics are discussed in this article.

Anchor bolt: dimensions and other technical characteristics are discussed in this article.

And here is an article that talks about a wedge anchor.

Advantages and disadvantages

Anchor bolts manufactured by Hilti offer a number of important and significant advantages.

- High quality. The products of this company allow you to create strong and durable connections. Moreover, they will not collapse under chemical, mechanical or atmospheric influences.

- Convenient transportation. Such anchors are small and lightweight.They are easy to transport, open containers with chemical compositions can be stored in this form for one year, for transportation they can simply be slightly covered with a lid.

- Convenient installation. Anyone can fix this fastener. Their installation does not require any special knowledge. In addition, along with such anchor bolts in one set, there must be a detailed instruction for use, which describes how to carry out the installation step by step.

- Reliability. With sharp temperature changes, chemical models will not expand or contract, they will retain their consistency, will not lose their properties, and will be able to provide a reliable connection.

But the products of this manufacturing company also have some drawbacks. So, many highlight the too high cost of these anchors. First of all, this applies to chemical capsules with glue. But at the same time, we can also say that the quality of the joints created with their help will fully correspond to the price of the product.

Also, as a disadvantage, one can single out too long hardening duration. This disadvantage applies to chemical samples. It sometimes takes too long for them to become completely solid, which leads to significant installation time.

Sizes of anchor bolts for concrete

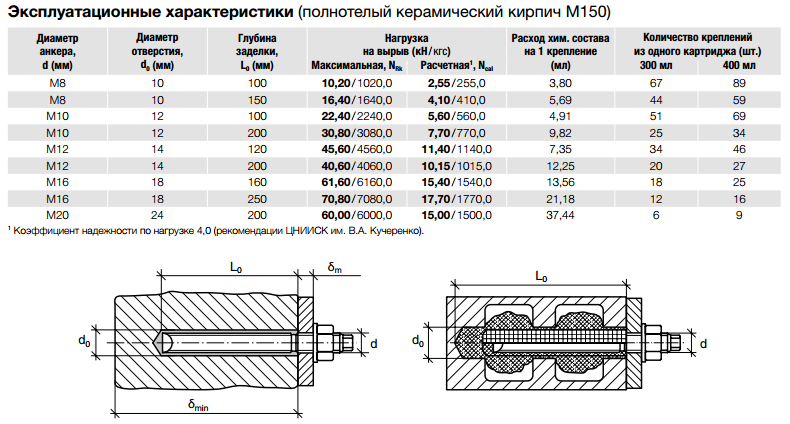

Usually, the main ones are indicated in the format, for example: M10 12x100. This designation is deciphered as follows: M10 is the diameter of the bolt thread, the number 12 denotes the installation diameter in millimeters (a hole of this diameter must be drilled in the concrete before installation), the number 100 is the length of the anchor in millimeters.

The range of standard sizes of anchors used in everyday life is usually limited by these parameters: thread from M6 to M12 with a length of 55 to 160 mm. Of course, there are many other options, but they, rather, belong to the category of professional or highly specialized fasteners.

Types of anchors and their features

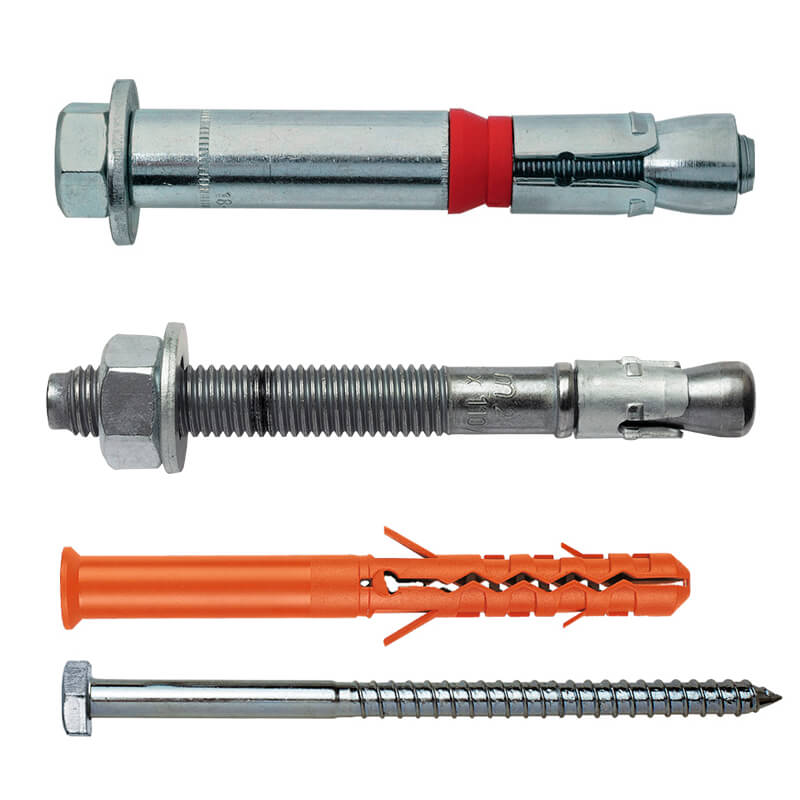

Currently, the Hilty company produces several types of anchors:

- chemical;

- spacer;

- hammered.

Chemical anchors

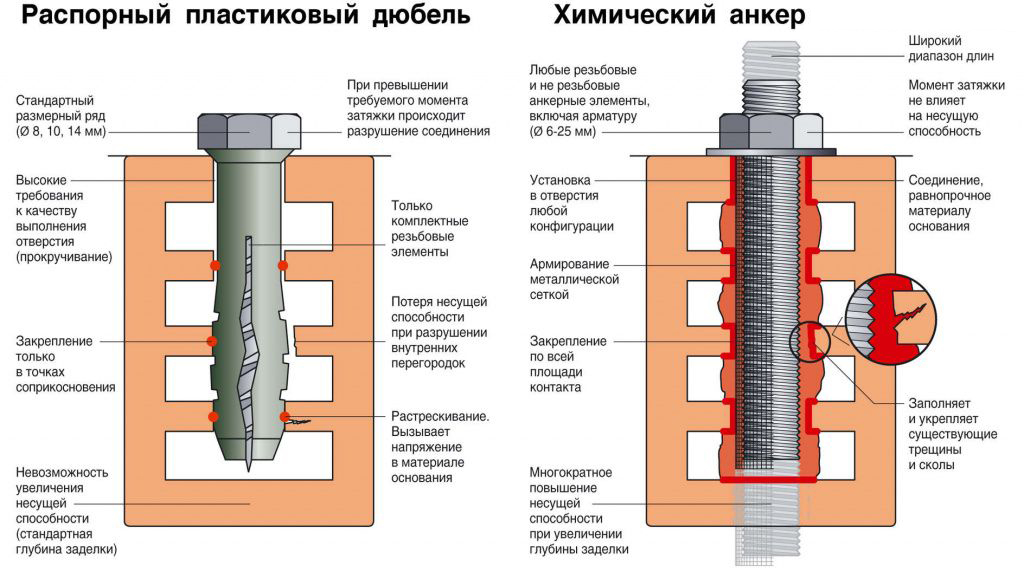

A chemical anchor is a special dowel that is equipped with an adhesive for fixing in materials such as:

- hollow brick;

- expanded clay concrete;

- shell rock;

- limestone and so on.

Due to its peculiarities, fastening to porous substrates is highly durable and as reliable as possible. However, replacing such a fastener, if necessary, will be quite difficult, since the base will have to be somewhat destroyed.

Currently, chemical anchors are available in two types:

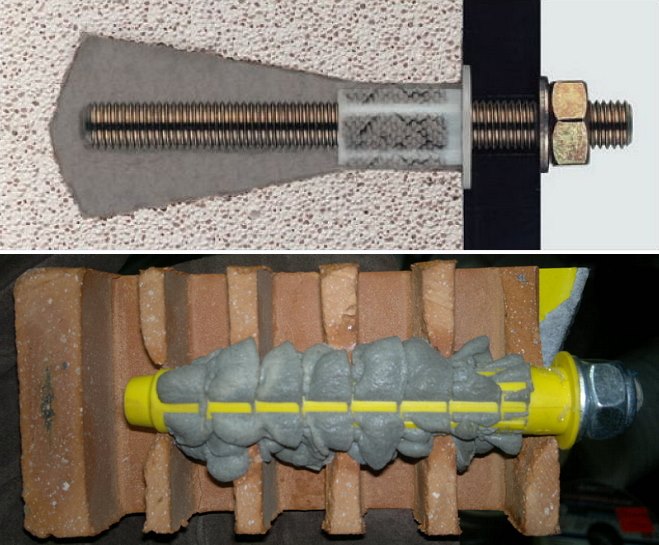

- Chemical capsules (labeled HVU). The devices are a container (most often made of polyethylene) of a certain size, inside which is a two-component adhesive composition.

When in contact with a metal dowel, the container is depressurized and, under the influence of air, mixes and hardens, thereby fixing the fastener.

The main advantages of this type are quick and easy installation. The negative qualities include the relatively high cost and dosage of the adhesive composition, which does not allow achieving strong fixation of the anchor when installed in large voids.

Capsule chemical anchor

Only one fastening element can be secured with the anchor capsule.

- Chemical injections (labeled HIT) are double-capacity ampoules, one of which contains an adhesive composition and the other contains a hardener.

In contrast to capsules, injection dowels can be produced with different volumes, which contributes to reliable fastening even in voids. Another advantage of this type is the lower cost, justified by the use of glue of a different composition. A significant disadvantage of the injection anchor is the need to purchase (rent) additional equipment for installation.

Injection type chemical anchor

With injection anchors, several fasteners can be fixed at the same time.

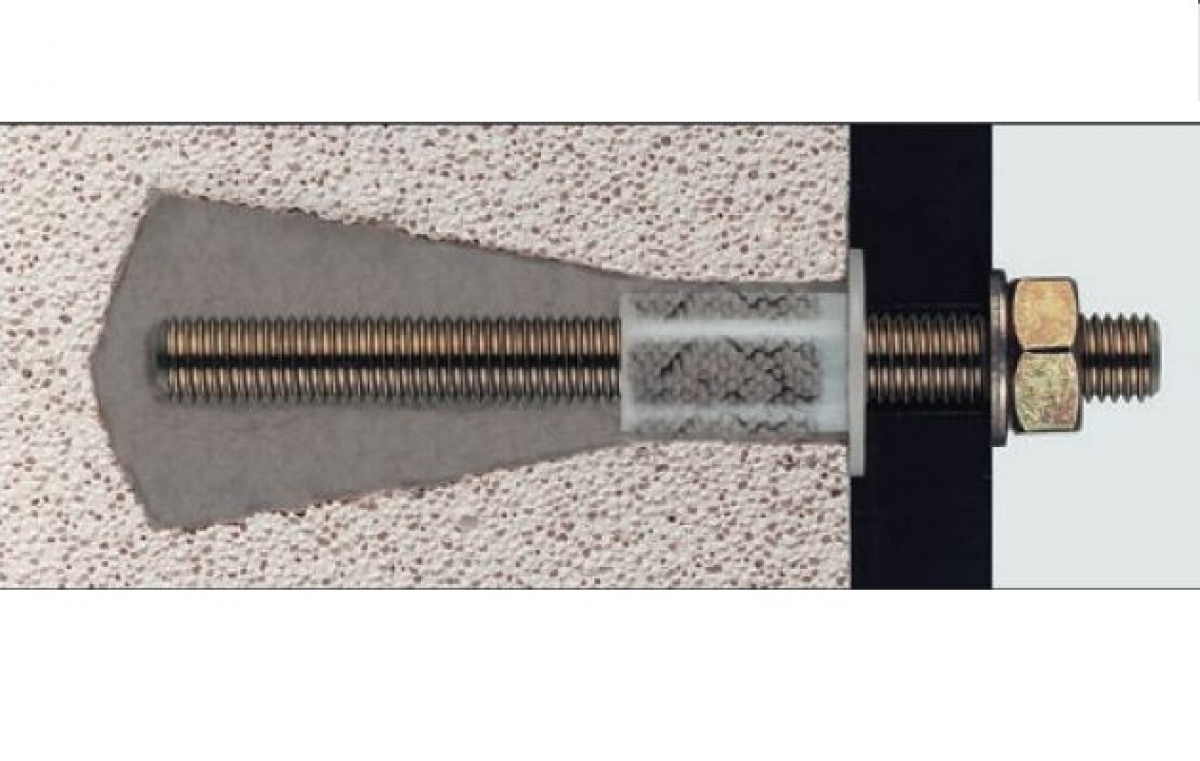

Expansion anchors

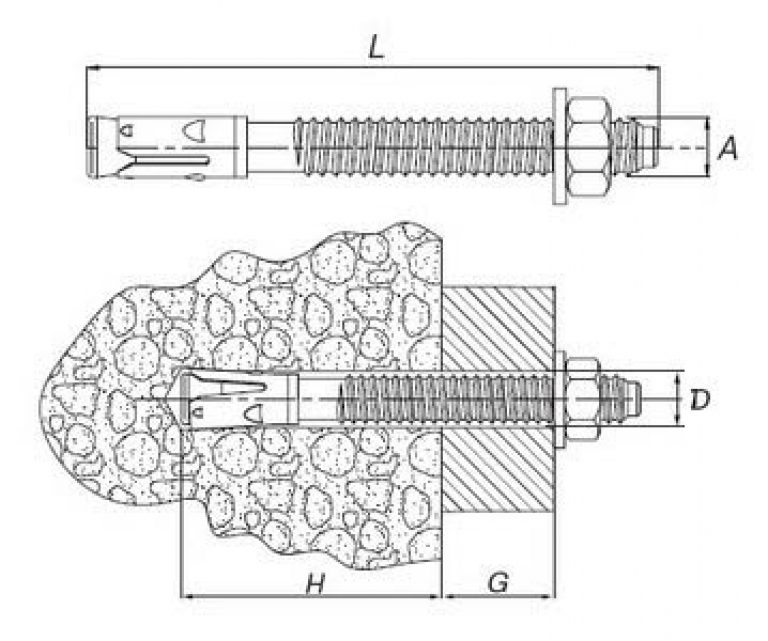

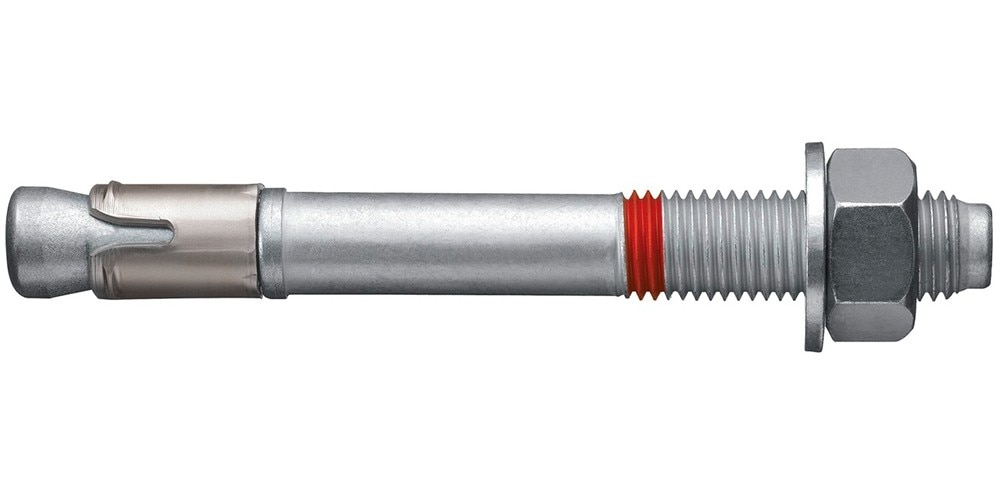

In contrast to the chemical anchor, the expansion anchor is a more standard fastening element. As the threaded rod is tightened, the expansion part of the anchor increases along its entire length, which makes it possible to create strong fasteners even for massive structures.

Standard anchor for anchoring heavy structures

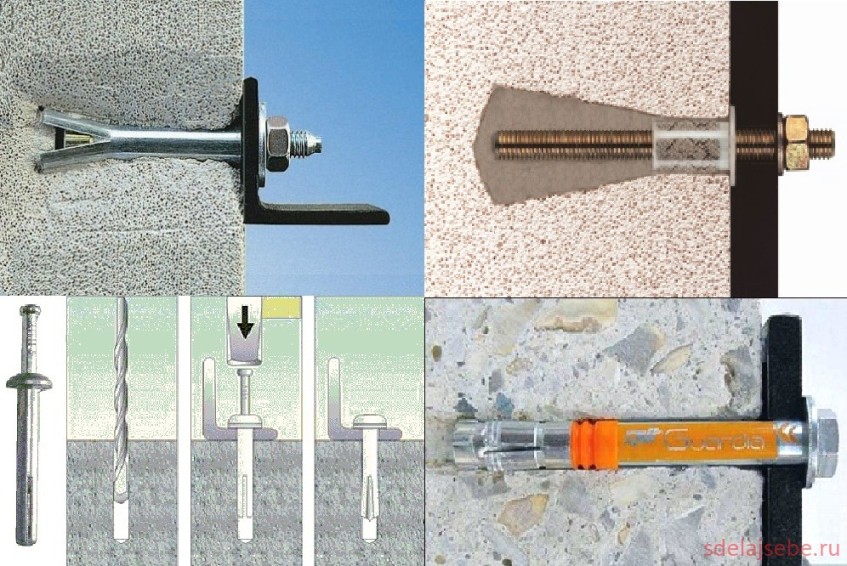

Depending on the type of base to which additional elements must be attached, the following types of anchors are distinguished:

- for cracked concrete - HST / HST3. this view can also be used for installation in areas with seismic activity;

- for solid bases - HSA or HSV (more budget option, also characterized by high strength);

- for fastening heavy structures - HSL 3 or 3G.

Unlike chemical fasteners, expansion anchors can be replaced without destroying part of the base.

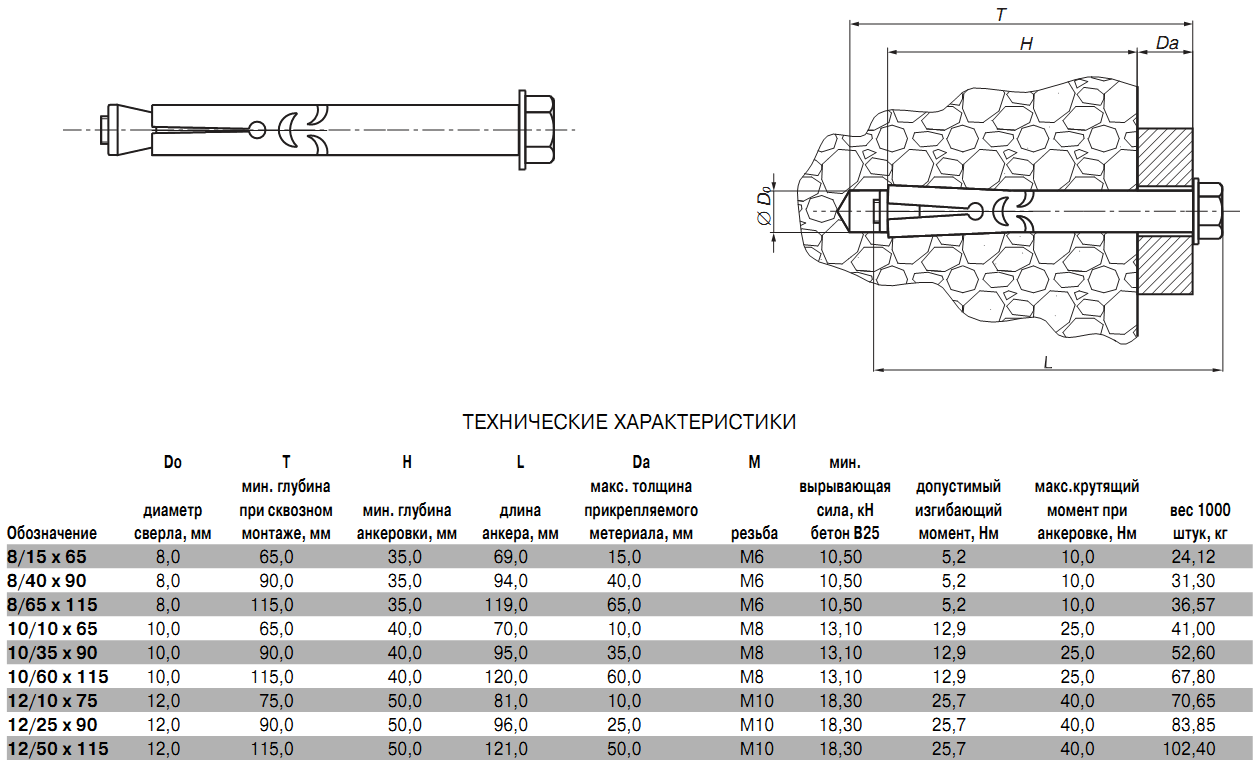

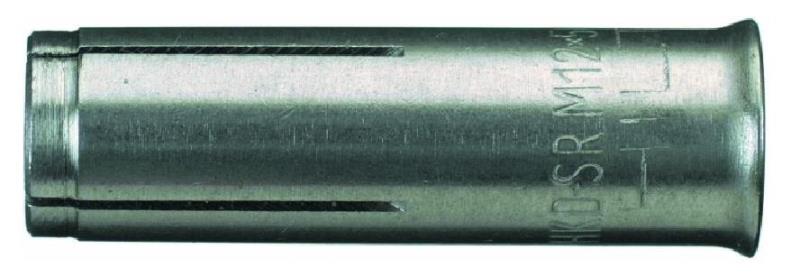

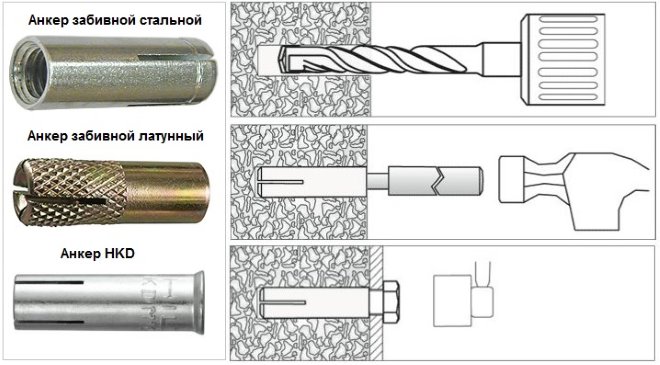

Drop-in anchors

The latter type - drop-in anchors are easy to install. Such fasteners are intended for fixing cladding (drywall, wall panels, etc.), insulating materials or light load (lightweight structures).

They can be manufactured:

made of metal. They are distinguished by greater strength, but at the same time, higher cost;

Drop-in anchor made of metal

made of plastic. Designed for fastening lightweight structures.

Drop-in anchors made of plastic

Features of the installation of anchors for concrete

The reliability of the fastening obtained with the anchor bolt is influenced by a number of factors:

- the quality of the material in which the anchor is installed;

- the type and size of the fastener, which must be selected in accordance with the loads taken by such a product;

- the correctness of the preparation of the place for the placement of fasteners and the observance of the technology of its installation;

- strength characteristics of the anchor itself.

Sequence of assembly operations (click to enlarge)

Installation of anchor-type bolts can be carried out in various designs, the material of manufacture of which must be distinguished by a sufficiently high strength. These include, in particular:

- concrete foundations;

- walls and partitions made of concrete and brick;

- floor slabs, which are usually made of concrete.

Installation diagrams for mechanical anchors

Items and structural elements that are attached with such bolts are usually:

- metal beams of various types;

- elements of suspended ceiling structures;

- lamps and chandeliers;

- wooden beams used for the installation of floor and ceiling coverings;

- elements of staircase structures;

- load-bearing structures of great weight and dimensions.

Calculation of the load depending on the parameters of the anchor

As mentioned above, fixing an anchor-type bolt inside a pre-prepared hole can be achieved in two main ways:

- by wedging the spacer inside the hole;

- due to a special adhesive that connects the bolt and the inner walls of the hole (chemical anchor).

There are requirements for holes in the fixture that must not exceed the values shown in the table. Large gaps are allowed to be filled with mortar

Usage

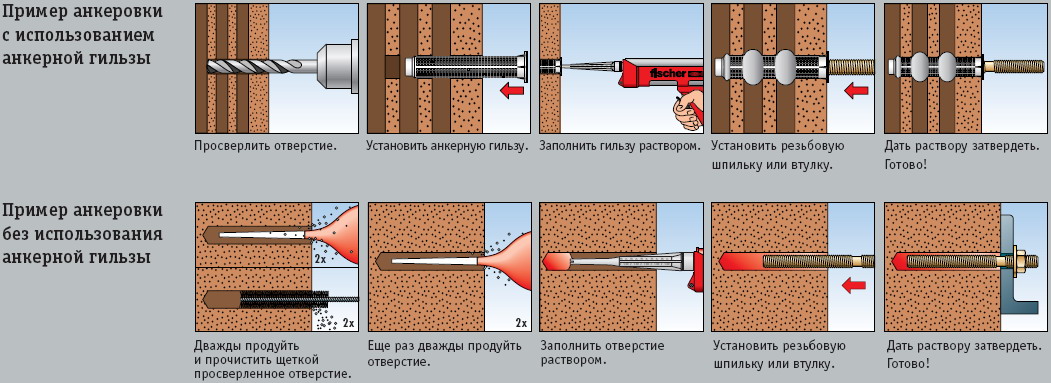

In order for the anchor fasteners to be able to provide the strongest and most reliable connection of the material, you should adhere to some important installation rules. Each individual model has its own mounting technology. If you plan to work with substrates that have porous structures, then the installation should start with filling the mesh sleeve in the pre-drilled recess. In this case, it is recommended to drill with a diamond tip. This will make the surface smooth and even after processing.

Then a little binder should be applied to the surface of the sleeve. In this case, the hole must be 2/3 filled. It is slightly pressed in together with turning the threaded rod (then the necessary element will be screwed to it). After the substance has solidified, the composition will provide a strong connection.

All the holes into which the clips will be inserted are thoroughly cleaned of various debris beforehand. The surface must be absolutely clean. After that, the recess must also be blown out with compressed air; for this, you can use a special pump.

If you are using a chemical capsule for joining, then it must be placed in a pre-made recess. One container is designed to hold only one piece.

The capsule is sharply pressed with a special pin, after which the hardener will begin to pour out of the container. It will enter into a chemical reaction with the adhesive itself. To make the consumption of the substance in the cartridge more economical, you can use the calculator of the required amount of injection mass. This allows for a slight reduction in installation costs.

Review of the Hilti HFX model in the video.

Selection Tips

When buying anchors, you should take into account some important selection criteria. So, it is necessary to take into account what material the selected models are intended for.

For connecting aerated concrete, concrete, brickwork it is better to give preference strong mechanical samples capable of withstanding significant loads. Such elements will make the fastening strong enough. For lighter and larger elements, different types of chemical liquid anchors can be used.

When choosing such retainers, their cost also plays an important role. The most expensive are chemical capsules. Injections cost much less, but at the same time for their use you will need a special pistol with a dispenser, which will have to be purchased separately. Mechanical varieties are the most affordable options. In addition, they do not require additional mounting parts (apart from some stud models).

When purchasing anchor bolts, it is better to look at the material from which they are made. The best option would be steel (carbon or alloy). Parts made of this metal have a high level of strength, resistance to chemical and mechanical stress.

Check the coating of each anchor. Traditionally, they are coated with a special zinc compound. If the fastener is released without a protective material, then it can quickly lose all its important properties, become covered with a layer of corrosion, which will lead to further destruction of the connection made. Before buying, make a decoding of the marking of the anchors.

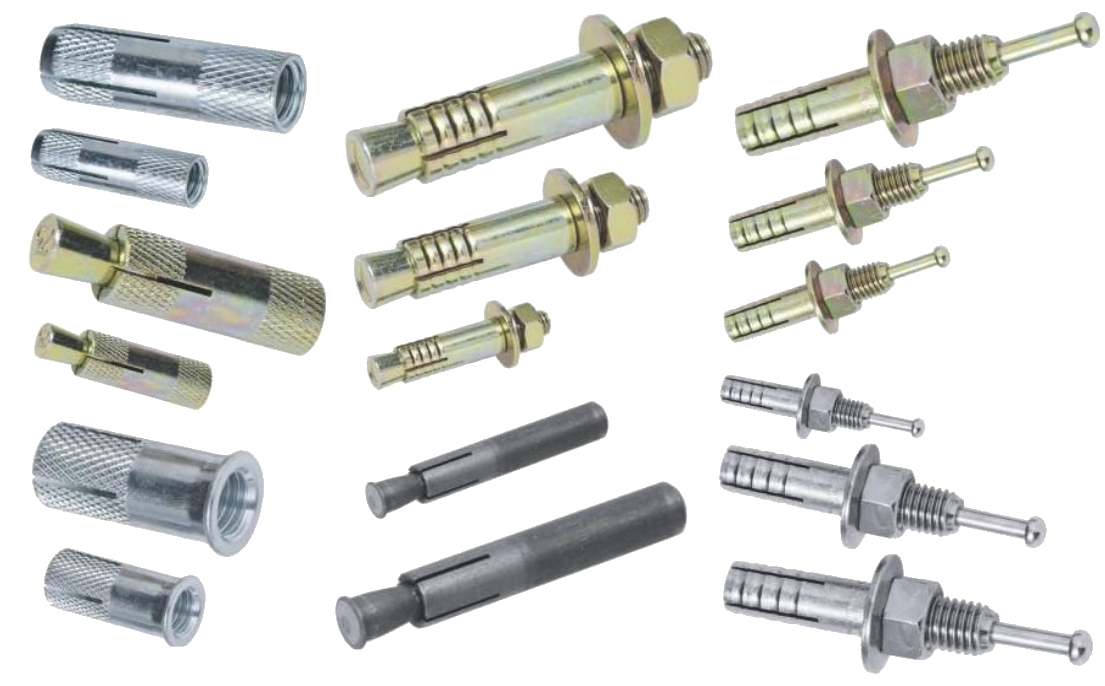

Mechanical anchor bolts for concrete

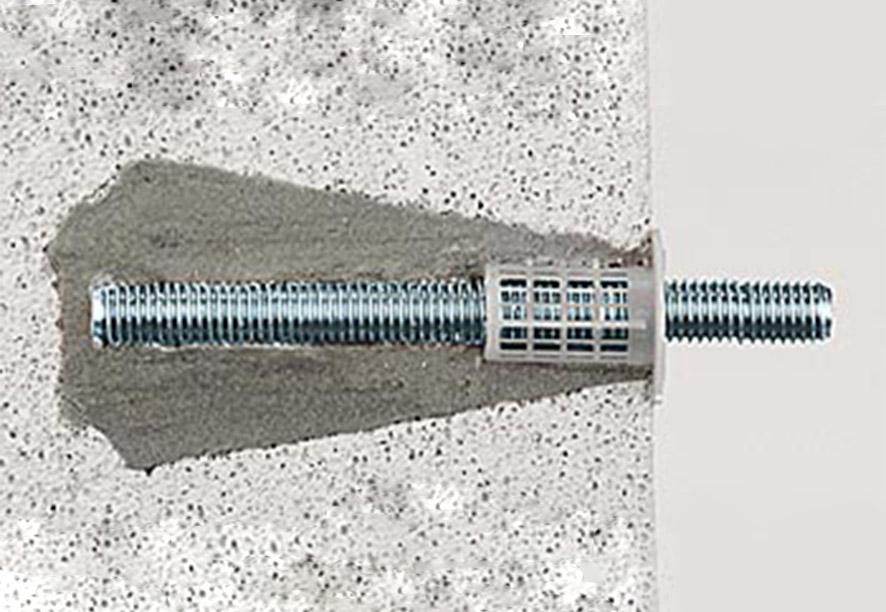

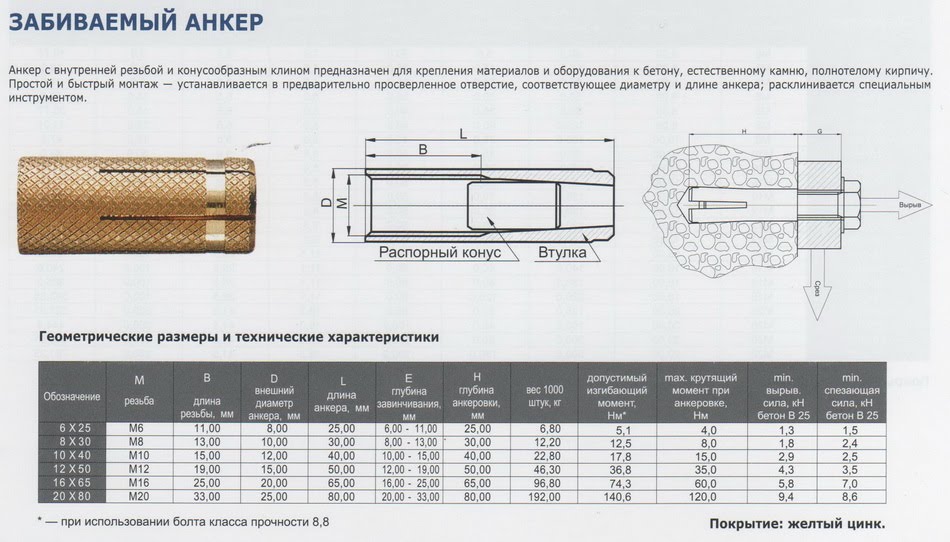

Hammered

One of these products is a drop-in anchor, which has a thread inside the spacer sleeve. This anchor, designed for concrete and other dense and hard materials, is expanded in the hole due to a special device, after which the fastener itself is screwed into it.

Varieties and procedure for installing a drop-in anchor

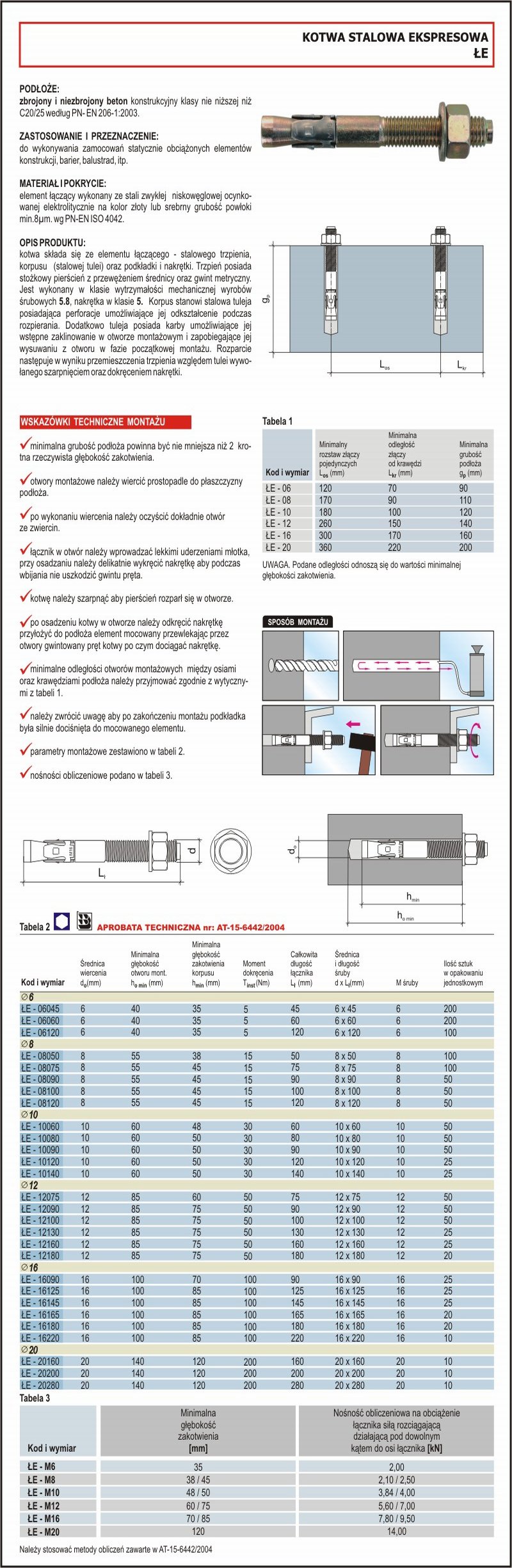

Spacers

Expansion anchors for concrete and other building materials are also widely available on the market today. In the design of such anchor fasteners, capable of withstanding very significant loads, there is a special wedge, which is responsible for expanding the spacer sleeve. Using such anchors, it is possible to ensure reliable fixation on a concrete surface of even heavy objects - metal gates, overall equipment, etc. largely depends on the strength characteristics of the structure in which it is mounted.

Stop anchor HILTI HSL-3

One of the representatives of this family of fasteners is. Bolts of this type are used for mounting windows and doors.The spacer sleeve of frame anchors has two wedging zones: at the head of the bolt and in the body of the bearing base.

Double-expansion concrete anchors, as their name suggests, have two spacers at the same time. Due to this, anchors of this type provide a more reliable grip, which allows them to be used for mounting objects with a significant mass.

Metal frame anchors designed for push-through installation in brick, stone and concrete

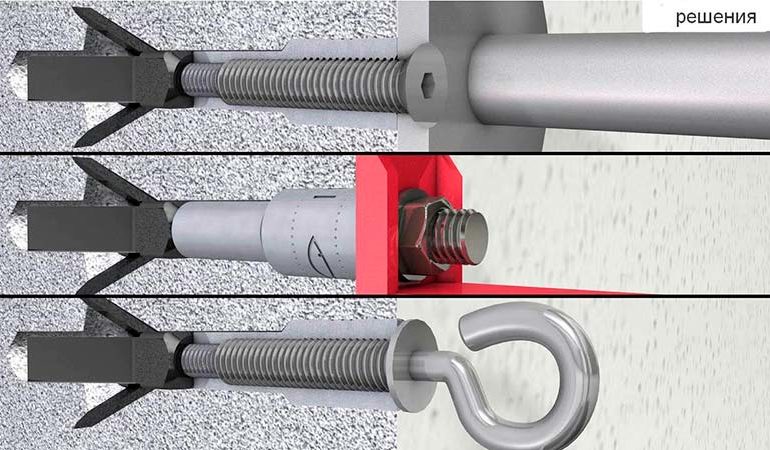

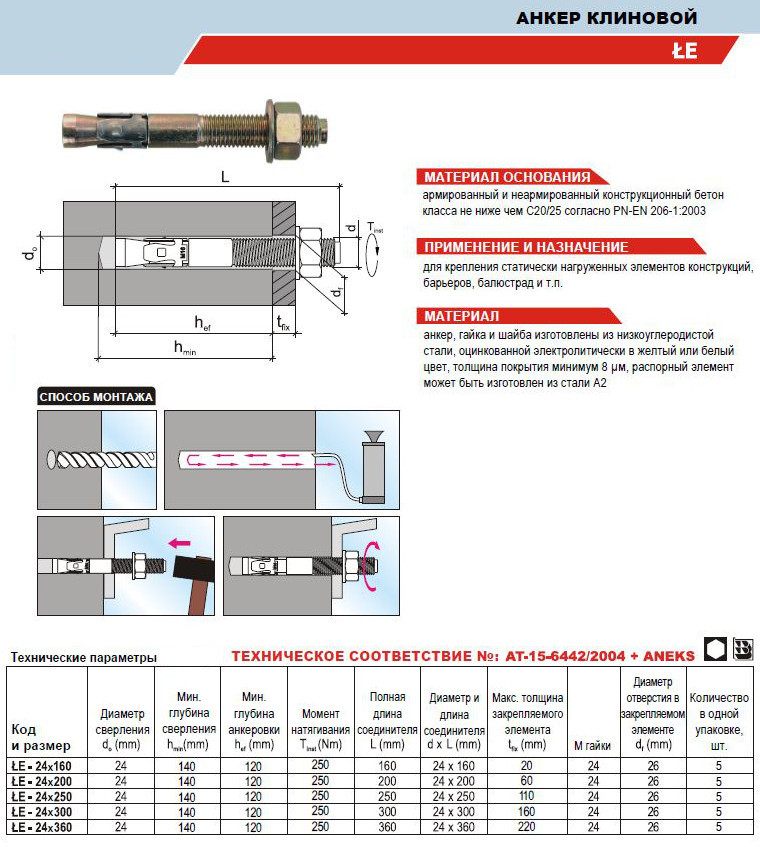

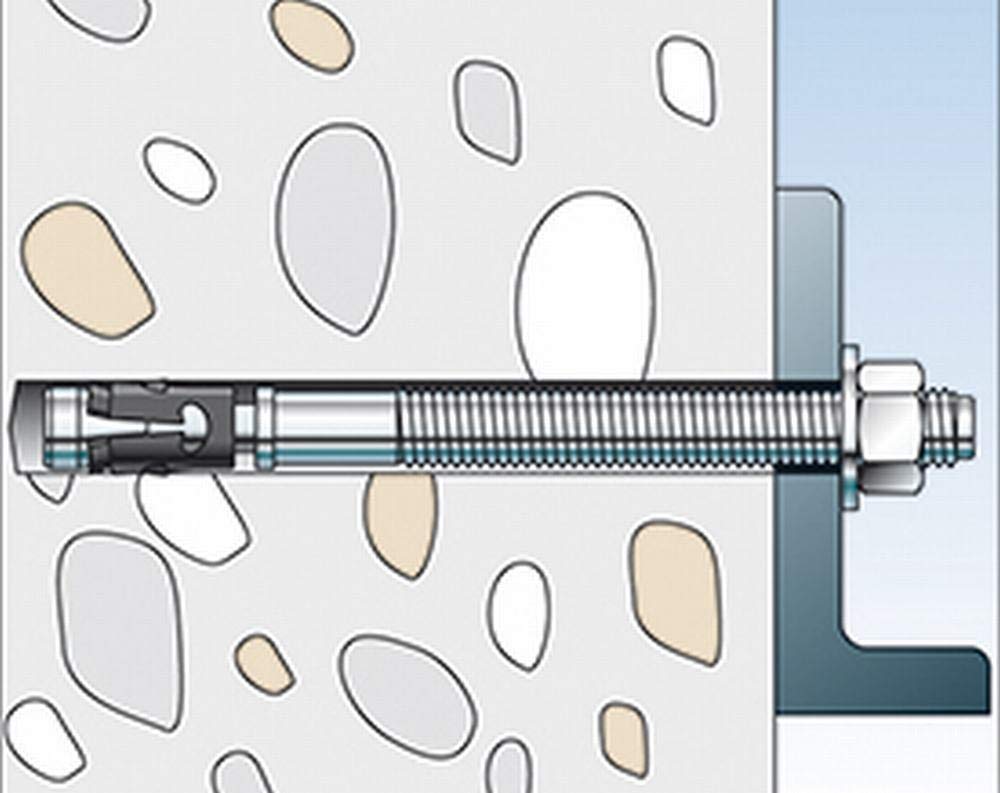

Wedge

The wedge type concrete anchor mentioned above can be of two designs. In the first case, a hammer and a special center punch are used to wedge the inner sleeve of such an anchor. After wedging the sleeve, such an accessory is removed from the inside of the anchor and a mounting bolt or stud is screwed into it.

When the wedge anchor is screwed in, the stud is pulled out and wedges the spacer skirt with its tapered shank

Installation in other types of concrete is somewhat easier. Their main element is a threaded rod, one end of which is tapered. When tightening the nut resting on the surface of the structure into which such a fastener is installed, its tapered part expands the spacer sleeve, ensuring its reliable fixation in the previously prepared hole. Some models of this type of anchor fastener have teeth on the outer surface of the spacer sleeve, which provide better adhesion of this element to the inner walls of the hole.

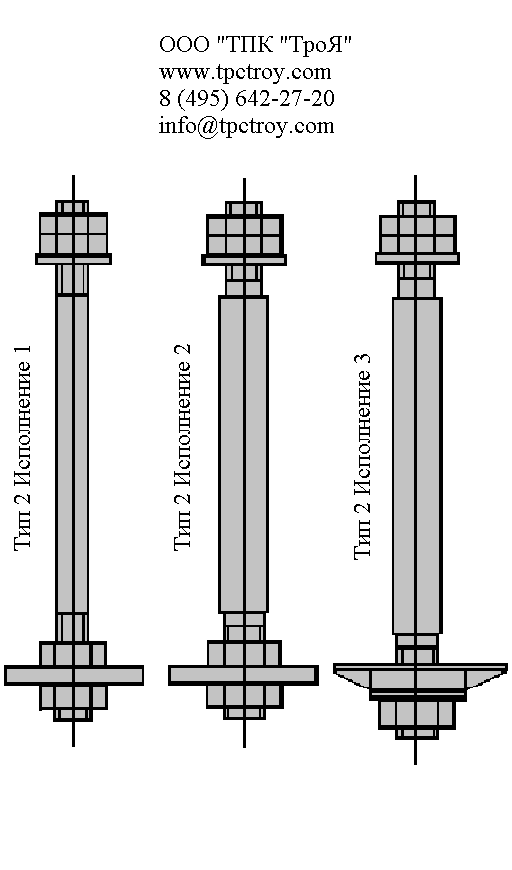

Rod anchor for adjustable floor

The rod anchor, which is also of the wedge type, different from the usual increased dimensions (bolt length). By means of such an anchor, the installation of multilayer systems with a significant thickness is carried out.

The choice of the type of anchor is made, focusing not only on its dimensions, which are stipulated by GOST, but also on the type of fastening that must be performed with its help

It is also important to calculate the load that will fall on the concrete anchor. When performing this calculation, it should be borne in mind that the load on the fastening element should not exceed 25% of that indicated by GOST