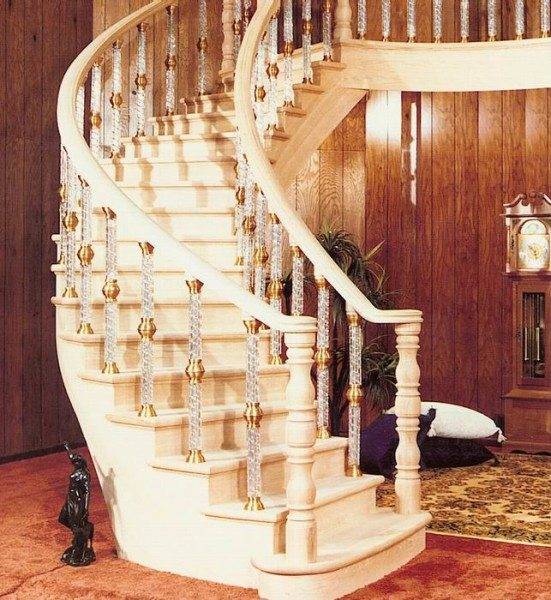

In simple terms, balusters are ordinary vertical posts, the purpose of which is to protect the space and make movement on the stairs safe. Handrails are attached to them and various materials and even their combinations are used for their production. Balusters for metal stairs on a wooden staircase will not surprise anyone, the combination of glass and metal is so commonplace that it is taken for granted.

And if everything is quite transparent with the design of the stairs, then problems may arise with the choice of balusters, but our instructions will tell you why.

The reasons are commonplace

As an element of fencing, these products appeared in ancient European civilizations during the construction of palaces, bridges, luxurious residences of the nobility. Terraces with balustrades adorned many buildings of that period, and since they have survived to our time, this indicates their thoughtfulness and necessity.

Difficulties with the choice of products will arise neither from the fact that there is some kind of shortage of these products on the market, but rather, on the contrary, oversaturation. There are several divisions of these supports, but from a practical point of view, we will be interested in the types of balusters for stairs with a division by materials, since the fastening method depends on the materials..

So:

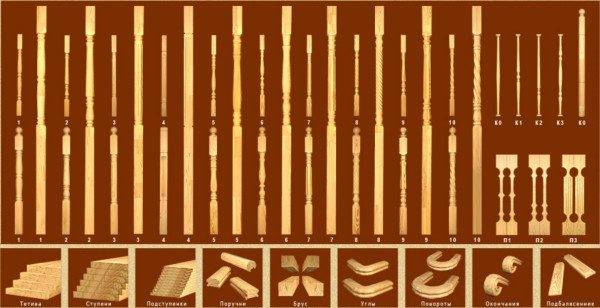

- Staircase balusters made of wood;

- Metal products, including the most popular ones - forged balusters for stairs and analogs from lighter alloys;

- Balusters of stairs made of stone;

- Combinations of materials, as well as independent solutions for the type of plastic.

From cause to effect - a tree

Moving away from the general characteristics, let's go through the products from the corresponding materials in more detail.

Let's start with wood, since it is this material that gives the maximum opportunity to make with your own hands exactly what you need and the reasons for this order of things we sound:

- Wood is perhaps the cheapest material and if you buy blanks for your intended dimensions, then the price you pay will be minimal;

- The wood is very well processed on machines, it can be easily machined with a chisel, which allows you to give products any conceived shape, in addition, it is possible to arrange the entire ensemble so that the balusters of one span or the entire staircase will meet a single semantic solution. There is also the possibility of using inserts of other materials, but in this situation the main thing is not to replay;

Our advice!

Wood can be combined with almost all the materials from which the stairs are made directly, we lower the tree and everything is clear, metal requires lightness and airiness, so the use of wood is possible, but it is better to arrange it in the appropriate style; the stone itself is massive and requires more massive supports for the railing, therefore the laws of the genre are the laws of the genre, when preparing balusters from wood, pay attention to the main material from which this staircase is made.

- It is difficult to imagine a material more environmentally friendly than wood.

Nevertheless, we move from praise to the practical part, namely the installation of products. Before covering the usual assembly algorithm, I would like to draw your attention to one practical and useful nuance.

Note!

Usually one baluster is enough for one step, as a rule, it is installed in the middle of the tread and fixed, but if you have small children in the family, then for the sake of safety, it is better to reduce the distance between the balusters on the stairs so that the baby on the stairs does not could completely crawl between the racks.

And then the simplest and most digestible solution is to install two supports on one step.

And now about the assembly:

- Based on the recommendation just voiced, we will determine the number of balusters on the step;

- We choose products in such a way that at the beginning and at the end of the march there are more durable balusters than in the middle. This is an element of strengthening and safety, while it must be remembered that the overall design of the structure should not be disturbed;

- The balusters can be fastened in several ways, you can use special pins, you can use wooden spikes. In both the first and second cases, holes are drilled in the steps and in the supports themselves: for spikes in diameter, for studs in the support 1 mm less;

- In the first case, the fixation will take place with glue, in the second, the hairpin will simply be screwed into the wooden body of the support;

- For a rough installation, between the first and last posts, pull the thread so that all the supports fit under a single level of the support;

- After sawing off excess fragments of balusters, the supports are installed permanently, and the props are fixed on them with self-tapping screws;

- Then the railings are attached on top and if they are made of wood, then the whole structure is varnished with stain in several layers.

Advice!

It is possible to strengthen the railing directly to the supports, for this it is necessary to prepare the cells for self-tapping screws and simply install them as a fastening element.

In this case, you will have to prepare a cell for each support, then fill it with a special compound, polish and varnish, with the support rails it is easier, they are clamps, and the stair railings already serve more as a decorative element.

From material to material: stone

The stone is reliable and durable, products from it are created for centuries.

But it also has several negative sides:

- firstly, it is expensive;

- secondly, it is cumbersome.

Therefore, very often such stairs can be seen in old mansions or common areas, office buildings. In modern conditions, the reproduction of such stairs is also possible, in which case the stairs and balusters will be made of the same material, for example, marble.

Stone stairs with forged balusters decorated with complex ornaments will look interesting. But we got carried away a little, let's approach the installation.

In this case, the following techniques are used:

- In the production of stone stairs, there are already pins in the steps, therefore, to strengthen the stone supports, you need to outline the hole in which the pin will be located;

- The hole is drilled, as a rule, in the center of the workpiece with a diameter several mm larger than the diameter of the pin;

- An adhesive mixture based on cement mortar is placed in the prepared hole and the support is installed in place. In this case, the excess solution is removed.

Recommendation!

In the same way, you can put a stone railings, while the pins can be both in the railings and in the balusters.

Metal products are simply welded by welding.

From stone to metal

Wrought iron stair railings are quite a common occurrence, let's make a reservation right away that pleasure is not cheap, especially if the product itself is subject to a single solution and is equipped with additional decorative elements. We will not focus too much on the positive qualities of metal and all kinds of combinations with the use of other environmentally friendly materials, but let's get straight to the point.

So the assembly:

- If you purchase factory products, then self-installation is easy and quick, that all metal balusters have a thickening on the support, which are equipped with holes for fasteners. You need to make markings on the tread of the location of the support;

- Then, using a drill and a drill, prepare holes for bolts of the required diameter;

- Finally, install vertical supports;

- Attach the plank to the upper part and then the stationary railing. In some cases, it is possible to use special fasteners, in which case the props are not needed.

The original solution is the hollow tubes, which are made of a lightweight chromium-plated alloy. The products themselves are much lighter than forged counterparts, moreover, they are easily assembled on their own and have special movable fasteners that do not require a finishing fit, as they say, just add a railing.

In addition, the products do not fade in the sun, they can have several colors and do not corrode.

The installation method is even simpler than the previous ones, so:

- The marking and preparation of holes for fastening occurs independently and, by analogy with the one already described;

- Fixing the balusters to the steps also occurs in the same way with the described rules;

- And then everything is simple, laid out the lodgements at the required angle and inserted a railing, a curtain.

A few words about new materials and combinations

The widespread use of plastic, or rather PVC products, did not disregard balusters. In this case, a complete set is produced, with the color spectrum and the number of solutions increasing from year to year.

Many interesting solutions are provided by a combination of materials, for example, glass + metal, metal + plastic. Design techniques are changing, innovations are quickly becoming classics, or are being shelved until better times, but this is a topic for a separate essay.

Interesting to know!

Another practical bonus at the end of the material.

You can choose any materials and combinations, but you cannot escape the laws of ergonomics.

The height of the balusters on the stairs, this is the dessert we left for you.

In this case, do not look for numbers in reference books and the Internet, but use a simple advice: the height of the balusters + handrails should be at such a level that you, standing at full height, hold on to the handrail without bending in the body and without bending your arm at the elbow joint, which called freely.

Finally

We talked about the materials, the types of fasteners too, the video in this article prepared its own report on the topic, we are watching.