For safe movement between floors, wooden handrails are created for stairs, but only doing it yourself has a positive effect on the budget. Thanks to the railing, the external appearance of the structure is determined and a finished look is obtained. The above factors speak in many respects about the importance of these elements, therefore certain conditions must be observed during the construction.

Basic Provisions

Railings are an important part of the staircase, being fences to protect platforms and flights. If the span implies the presence of more than three steps, then these elements are installed without fail. There are a lot of device options, but for each of them, you must adhere to some rules.

Requirements

- The lines of the railing must in any case coincide with the direction of the bowstring or stringers, then the width will remain the same.

- Future fences are made so that there is no imbalance with the overall design of the room.

- The side struts must be able to withstand a horizontal load of approximately 100 kilograms per linear meter.

- Balusters are mounted at a distance that will prevent a person from falling out.

- If longitudinal elements are used in the process of work, then a gap of no more than 4 cm is left between the lower part and the end.

- The presence of sharp corners at the edges of the railing is not allowed; it is best to make the ends rounded.

- Throughout the march, the wooden handrail for the stairs should not be interrupted.

- When mounted directly against the side wall, a small gap of 50-70 mm is left.

Note! When the steps on each side are surrounded by vertical planes, there is no need for a railing. However, they can be made for more convenient movement.

Components

Flight and landing fences include only two components: support posts and crossbars. Structures can be both vertical and inclined.

There are many variations depending on section, location and other factors.

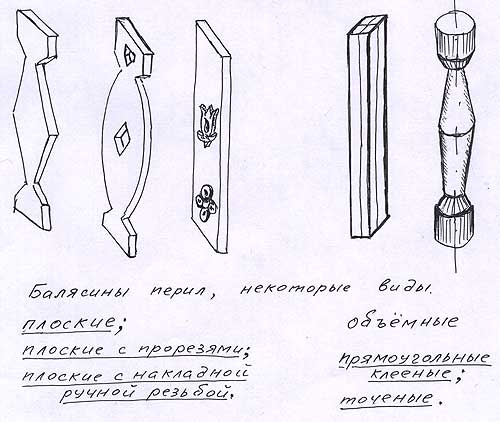

- Balusters are low posts designed to support the railing... These elements can be three-dimensional or flat. Modern products are manufactured using special equipment, so it is better to purchase finished products. It is quite difficult to cut aesthetic columns at home.

- The handrails are made in the form of a transverse bar, which serves for easy movement between floors... Such structural elements also support the balusters. That is, they provide the reliability of the staircase.

Attention! With an opening width of more than 125 centimeters, railings can be made from both sides at once, since the distance makes it possible for people to move simultaneously in different directions.

Implementation of works

Wooden handrails for the stairs are installed when the steps are completed. The height, as a rule, is selected depending on the height of the owners of the dwelling, but it should not be more than 85-90 cm, otherwise the versatility will be lost. Manufacturing technology is not so complicated, as evidenced by the instructions below.

Approximate order of actions

- A simple device is being made for making axial holes in the posts and balusters. To carry out the centering, the beam is fixed to the chipboard, while drilling is performed.

- The bar will act as a guide for the baluster. The hole is made strictly along the axis of the uprights.With the help of a milling machine, grooves are turned in the transverse strips.

- A rail is prepared corresponding to the dimensions of the lower groove. In the future, it will need to be attached to the balusters (see also the article Balusters for stairs - a trifle that creates a mood). A decorative strip is installed on top.

- Studs with a diameter of 8 mm and a length of 100 mm are screwed into the vertical elements. For convenience, you can use nuts that are removed immediately after fixing the parts.

- The same operation is performed with the side posts, but thicker pins are used. A hole is made in the lower rise, after which the supporting post is screwed into the step.

- The upper post is installed, then a regular fishing line is pulled between the two elements. On each rise, using a square, the lines of the axes of the balusters are marked.

- The centers of the uprights are determined. For this, a small recess is made using a thin drill. Studs are installed directly into the elements and twisted into the steps.

- The flatness of the balusters is checked with a square, and after that the entire march is mounted. A line of the future cut is applied to the rail, which is a reference point for all racks.

- A wooden handrail is superimposed on the bar. Its ends are cut at a specific angle. After making sure that the edges fit snugly, fixation is carried out with self-tapping screws.

- When cutting component parts with a miter saw, it is recommended to wrap the ends with tape to prevent chipping.

Important! When installing a railing for stairs made of wood, certain difficulties can arise. This is especially true for rotary joints, which are filed in various planes.

Renovation work

Loose railings can be repaired using glue, wedges or fasteners. As for cracked racks, it is advisable to completely replace them.

A common cause of vertical beams swaying is too large grooves or damaged studs, so the load-bearing components are simply replaced.

- The stand is sawn, and its lower part is turned with a gas wrench, which breaks the adhesive connection. By removing the elements directly from the grooves, a thorough cleaning is performed.

- Determines the distance from the bottom base to the top hole in the wooden handrail where the end of the post was inserted. From below, installation can be done on a bowstring or a step.

- With a pencil, the markings are applied to the new beam and adjusted to the specific size. The accuracy of the cut plays an important role, so the process must be approached responsibly.

- The measurement of the grooves on all parts is carried out, and the tenon joints are carefully adjusted. That is, the ridge must match the dimensions of the grooves.

- Fasteners are glue-mounted. The upper edge of the rack is wound directly under the handrail, and the lower side of the baluster is inserted into the lower base.

Note! If the connection with the use of an adhesive composition cannot be destroyed, then the stand is removed with any sawing tool, and it is cut flush with the lower part.

Additional recommendations

- When installing the railings with your own hands, it is advisable to make sure that the studs fit tightly, otherwise the fence will quickly loosen.

- It is advisable to recessed the self-tapping screws deep inside, then it will be possible to eliminate all roughness and irregularities.

- To achieve the desired aesthetic effect, decorative elements are used that can decorate the rungs.

- You should purchase wooden blanks with a small margin, since most often a tenth of the material is spent on scrap and waste.

To better understand the lesson on installing wooden handrails, you need to watch the video in this article, which will help you perceive the information visually. Although the price of wooden elements is not so high, in the event of damage to several parts, quite tangible financial losses can be incurred. Therefore, it is advisable to study the installation process in great detail.