Something, but the staircase needs no introduction. It is well known to the residents of high-rise buildings, especially the residents of the top floors in the entrances with inoperative elevators "love" it. But seriously, without stairs it is like without water and not up or down.

More recently, individual elements of a staircase (namely, railings and handrails) were made from a strictly limited amount of materials: metal and wood. Now the choice has become much wider.

New materials - new perspectives

Currently, metal and wood are no longer materials monopolists in construction and in the construction of small architectural forms, which are stairs. Plastic, or rather PVC, as well as fiberglass are actively competing with them, and although there is no equivalent replacement yet, in some elements the competition is palpable.

So, where is it currently possible to replace rather heavy and bulky metal with PVC elements, and also where can plastic be used in combination with other materials:

- Vertical safety guards for the safety of stairs, commonly referred to as railings. The need for them is clear and transparent - protection against a possible fall and support when lifting for people with disabilities;

- Handrails - The upper end of the handrail, designed for ease of lifting. A plastic handrail for stair railings is quite convenient and has many more advantages than wood, but more on that later;

- Steps. Plastic steps for stairs are still quite a rare development and its main direction is stairs in swimming pools like plastic Roman stairs. Although PVC-based materials are already being used in public areas such as hospitals. The coating itself is produced in the form of PVC linoleum with an anti-slip effect, which not only has a relief pattern, but also contains quartz chips in the PVC base;

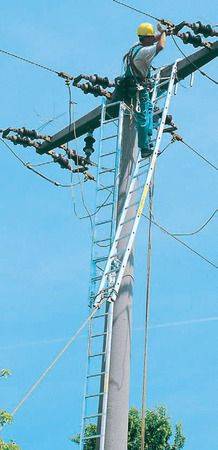

- Ladders. Plastic ladders are not only light and strong, but also have dielectric features, although for greater objectivity it must be said that they are still fiberglass stairs, but more about this in its section.

Our help!

PVC material (polyvinyl chloride) is a plastic that has a fairly wide range of applications and an already impressive track record.

Pipes, heaters, various gratings and decorative coatings - this is an incomplete list of applications for this material, now it’s the turn of stairs.

Why PVC

And indeed, why the choice fell on plastic, when various lightweight alloys have proven themselves very well.

The fact is that PVC has a number of advantages:

- The plastic is chemically resistant to withstand the effects of various acids and alkalis, as well as detergents and cleaning agents produced on their basis;

- Plastic railings for stairs are in contact with metal parts (plugs, stair fasteners). Even if corrosion phenomena are detected in the PVC metal, this defect does not threaten the railings;

- Plastic products are already ready to use. The algorithm for their installation will be discussed by us a little below, but I would like to say that to install, for example, handrails, an industrial hair dryer is enough;

- PVC is resistant to mechanical stress, in addition to moderate shocks, it does not care;

- The mounts are strong enough and well thought out, the sliding effect is excluded;

- Products do not change their color under the influence of sunlight and do not require periodic color renewal;

- Plastic is an excellent dielectric, which is important in public places, as well as when working on objects;

- Has a wide range of colors that will perfectly fit into almost any interior;

- Polyvinyl chloride refers to environmentally friendly substances and is allowed for use in children's institutions, hospitals and other facilities where increased requirements are imposed on this issue;

- The price of plastic products is budgetary and democratic.

Working with PVC

This is a really simple process that will allow you to quickly give the products the necessary shape and strengthen them in a stationary place with your own hands.

Here's a simple and powerful guide:

- As we have already mentioned, the railings, although they have a different shape (round, rectangular or curly), are quite easy to bend and necessary transformations with the help of an ordinary industrial hair dryer;

- Working with a hairdryer requires a special protective screen, in addition, a temperature attack on the handrail must be carried out from a distance of at least 7 cm;

- If you do not have the skills to work with an industrial hair dryer, then it is better to leave this area of work to the master. The fact is that not only the place of the bend is subject to heating, but also the nearby areas. With insufficient heating of the PVC material, the handrail simply will not bend, but cracks and defects will appear. With significant heating of the product, singed areas are not excluded, and this is already a marriage option;

- In the process of working with a handrail, sometimes a matte coating appears, this is not a marriage, but a completely permissible deviation. There is no need to use special polishes, the hands of visitors will polish the surfaces of products much better than any chemistry.

Fiberglass - a springboard to the future

The material itself is quite an interesting development. It consists directly of glass fibers and binder polymers, which are used as various resins. The advantages of this particular polymer "alloy" will be discussed below.

Products made from it, for example, a fiberglass staircase, have a very specific and independent direction - this is work at energy facilities and everything related to electricity.

The fact is that fiberglass itself is an excellent dielectric, but now about the advantages:

- A plastic ladder is practically an airy product, which is two times lighter than an aluminum analogue and five products from other metals and alloys;

- Products are not subject to deterioration in the form of corrosion like metal, drying out and rotting like wood;

- High transparency of the material (this effect is achieved due to the transparent resins that are part of the fiberglass);

- Although the quality of the dielectric has already been mentioned, but, nevertheless, this is perhaps the main advantage.

All these qualities will certainly be in demand when working with electrical equipment, especially those located at ground level and requiring special protection.

Like any staircase in a modern design, fiberglass is available in three categories:

- Ladder;

- Stepladder ladder;

- Retractable ladder.

As you can see, all products correspond to the line of products that are presented on the market mainly in aluminum design. The only option that has not yet been launched into mass production is a 4-section fiberglass transformer, but if such a need arises, it can be expected in the near future.

In the meantime, a few useful and practical tips for choosing such a product:

- Although low-quality fakes have not yet been noticed, nevertheless, attention should be paid to the condition of the steps, they must have a raised surface in order to avoid slipping;

- A tool tray is often added to the ladder kit, a trifle, but nice, and most importantly, convenient when working.Also, pay attention to the work area, which should be comfortable enough;

- Developers and manufacturers have taken care of workers with different constitutions. When choosing a ladder, select it in such a way that it is convenient for you to work.

Some helpful tips when choosing plastic products

As you may have noticed, plastic is taking an ever-widening niche in construction, displacing materials whose credibility seemed impeccable and whose presence was not discussed. But it just so happened.

When choosing plastic products, you should still pay attention to the following parameters:

- Compliance of products with passport "registration" (country of origin, color, grade, and so on);

- Appearance and condition of products. In the presence of cracks, noticeable darkening, delamination and other defects, it is better not to take such material, it is already defective and when given the necessary curvature, its behavior is unpredictable;

- Plastic is plastic, it is a conglomerate in which dyes are already present. However, different batches under the same nomenclature may differ in shades from each other, so it is better to purchase material in one go.

Finally

The staircase is gradually losing its metal and wooden attributes. It all started with decorative elements, then fencing and handrails, covering the steps, and what will replace plastic tomorrow? The video in this article is also ready to demonstrate your vision of the topic.