As we climb or descend stairs, we instinctively feel for the handrail, which helps us feel safe. That is why it is very important that the height of the stair railings is optimal, and the railing itself has the correct design. Many craftsmen, when designing stairs, do not think about it - and completely in vain.

Below we will tell you what to look for when planning stair railings, and how you can make different types of handrails.

Requirements for stair elements

Fencing construction

When starting to design a staircase, you need to take into account not only the issues of convenience and design, but also the current regulatory documents.

If we talk about railings, then their design is regulated by:

- SNiP IV – 14–84, sections "Ladders of residential buildings" and "Ladder structures".

- GOST 23120–78, "Ladders, flight platforms and steel railings."

As a rule, specialists operate with other standards, but we can limit ourselves to only a basic list. Naturally, this applies only to those cases when we build or reconstruct a private house for ourselves. If the work is carried out to order, then the dimensions of all elements of the stairwells will have to be coordinated not only with the customer, but also with the licensing authorities.

So what do the docs tell us about step railings?

- First of all, you need to take into account that any staircase with a height of more than three steps must have side rails.

Note! This requirement does not apply to external capital structures, which are stepped rises within the same household. However, in this case, at least parapets should be installed on the sides to prevent falling.

- The need to install handrails also depends on the dimensions of the staircase. If the width of the span does not exceed 1250 mm, then you can limit yourself to the installation of one handrail, but only if on the other side the span is limited by a wall or a main partition.

- For flights from 1250 to 2500 mm, the installation of handrails on the sides is required. If we make a wider staircase, then experts recommend installing another handrail in the center.

- In the same way, railings are mounted on both sides of curved stairs. The screw structures are fenced off on one side (simply because the other edge of the steps is attached to the axial post).

Railings and railings can be of very different designs:

- The most reliable are solid ones, which are monolithic or prefabricated panels mounted on the sides of the staircase. Such fences are used in the design of staircases in public buildings.

- In private construction, a monolithic barrier can be found almost exclusively when erecting an external stepped rise, and then its height will be small.

- Lattice are the most common designs. They are handrails mounted on vertical support pillars. The space between the posts is filled with either vertical balusters or inclined rods. These elements support the handrail and at the same time serve as fall protection.

- Combined - combine features of the two previous types. For combined railings, handrails are attached to vertical posts, and panels made of plastic, glass, metal, wood, etc. are installed between them.

Handrail dimensions

The height of the stair railing is one of the key parameters.At the same time, the size according to the GOST should be observed not only because you can be fined for a violation. The thing is that going down stairs with too low a fence is banally inconvenient, and the risk of falling increases significantly.

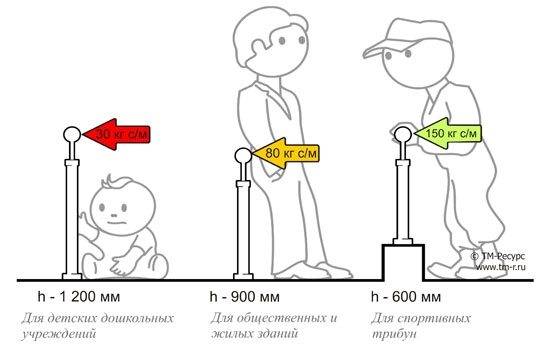

So, what are the requirements put forward by the current standards for the fence:

- The minimum height of the railing of a wooden staircase in a residential building is 900 mm.

- The minimum size of the fencing of the marching platform (as well as the platform for entering the stairs to the attic or attic) is 900 mm.

- The smallest permissible height of the handrail for an external staircase is 1200 mm.

- Railings at the stairs installed in educational institutions (i.e., where children are systematically moving along the steps) - 1180 mm or more.

In addition, wall handrails designed to facilitate movement on steps are also mounted according to the following rules:

- The installation height must match the installation height of the handrail on the free side... Simply put, the railing should be fixed at the same level.

- The distance from the handrail to the wall must be at least 40 mm... The standard design is 75 mm from the center of the brown strip.

Advice! If there are children in the house, then an additional handrail should be installed on the railing just below the main one. What height will be optimal here depends primarily on the age of the child.

Other elements

Railings and handrails are not the only elements whose dimensions are regulated by standards for the design and construction of stairs:

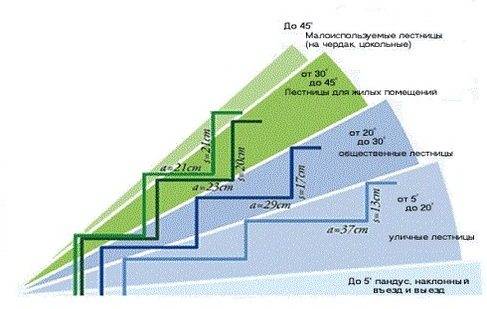

- The optimal slope is 1: 1.25... In various situations, it is allowed to erect internal staircase structures located at an angle from 20 to 450.

- Steps within the same span must be of the same size... The maximum offset is +/- 5 mm vertically and horizontally.

Note! This requirement does not apply to the first step, which can be partially recessed into the floor covering.

- The maximum allowable number of steps in one flight is 18.

The dimensions of the steps are also quite strictly regulated:

- Height - from 125 to 210 mm.

- Width - 210 - 355 mm.

- If the staircase has a curved shape, then in the narrowest part the step should be at least 150 mm wide, and in the center - at least 200 mm.

The platforms between the flights should be designed for staircases that are not already adjacent to them. The staircase to which the door opening outward exits must ensure the unhindered movement of the door leaf.

Manufacturing technique for different types of fences

Wooden

And yet it is not enough just to know the typical dimensions of each element of the staircase. If you want to make a structure with your own hands, you should study the method of installing different types of stair railings.

We'll start with the easiest to make - with a wooden railing:

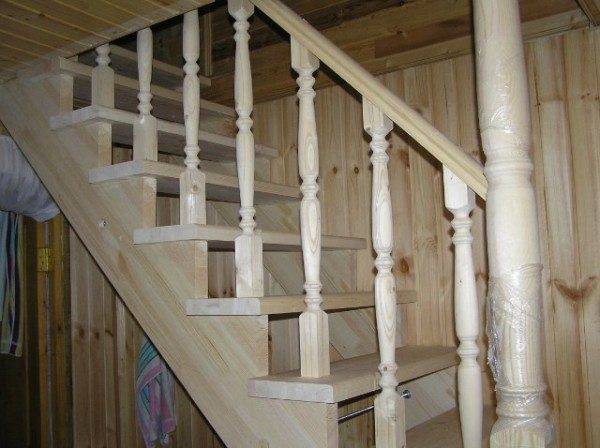

- Wooden railings are assembled from three main elements: support pillars (pedestals), balusters and handrails.

- For the manufacture of parts, both coniferous and deciduous wood are used. Of course, cedar, oak or larch are best suited, but the more affordable alder, birch or pine can also be used, and not without success.

- Independent production of blanks for a wooden fence is possible only with a woodworking machine. And in this case, the process will take a lot of time, therefore it is worth considering the option of buying ready-made parts.

Note! The common expression "sharpen the fringes" just describes the process of making balusters on a lathe, hinting at the tediousness and duration of work.

- Blanks purchased or cut out on their own should be treated with an antiseptic and opened with varnish. In some cases, varnishing can be carried out after the completion of installation.

The actual installation of wooden railings is carried out after the installation of all other elements of the staircase is completed:

- In the lower and upper parts of the span, we attach the support pedestals to the base. Anchor bolts are the easiest to use for fastening.

- Pull the lace between the support pedestals at a height of at least 900 mm from the upper plane of each step.

- We install balusters on the steps so that the gap between them is no more than 200 mm. We will do more - and with a high probability, sooner or later, we will need to free the stuck head of the child. Better not to risk it!

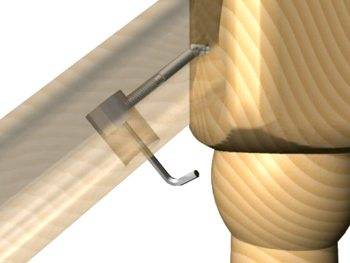

- To install the balusters, we use self-tapping screws, which we screw into the base from the wrong side of the step. Fastening "on a thorn" is more laborious, but provides a stronger connection.

- On the stretched lace, mark the cutting line on the balusters. We cut off the excess of vertical posts, the field of which we fix the handrail on them.

Either we embed the ends of the handrail into the support pedestals, or leave them free. In the second case, the projection of the railing beyond the edge of the steps should not exceed 300 mm.

Metallic

Metal railings are distinguished by great durability and reliability. At the same time, the rather high complexity of manufacturing and a significant price often become an obstacle, especially with a limited budget.

And yet, a simple metal fence can be made independently.

We will use a profile pipe as a material:

- Metal railings made of a profile pipe are most often installed on outdoor stairs.

- The staircase itself is made either also from metal, or from concrete, brick or stone. In the case of brick and stone structures, it is important to provide for the installation of metal embedded plates in the places where the handrail is installed.

- We begin installation with the installation of racks: we weld the cut-to-size profile pipes with a cross section of 50x50 mm to the embedded ones. If the mortgages are not on the side, but on the upper parts of the step, then a special bracket can be used for installation.

- We connect the upper parts of the racks with a sub-brown bar. It is a pipe or strip of metal of sufficient thickness.

- Weld pipes 20x20 mm between the supports as filling. They can be placed horizontally, vertically or at a certain angle - it depends solely on your desire.

- An alternative to shaped pipes can be forged rods of round or square cross-section, but the cost of the fence in this case will be much higher.

After completing the welding work, we thoroughly clean and paint the entire structure. We install a wooden or plastic handrail on the sub-brown bar.

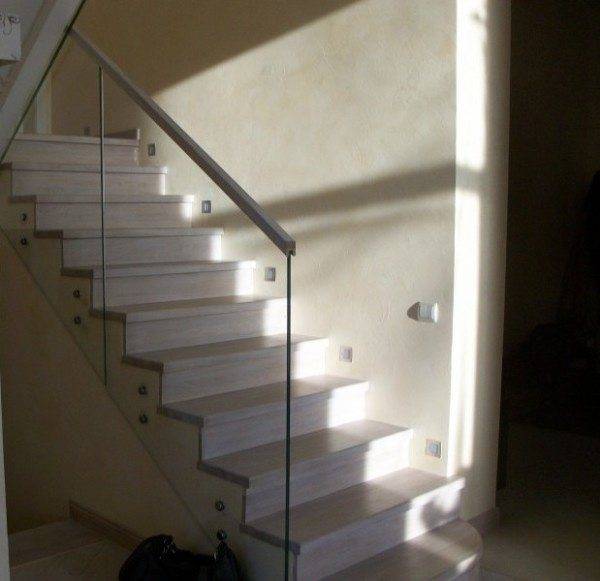

Prefabricated with glass filling

Glass is used quite actively in modern interiors. This is why glass-panel railings are no surprise to anyone today.

For the manufacture of such a fence, it is worth ordering panels made of heat-strengthened glass or triplex. It is simply not worth using thick glass in any case - even with the installation of protective end plates, the fence will be very fragile.

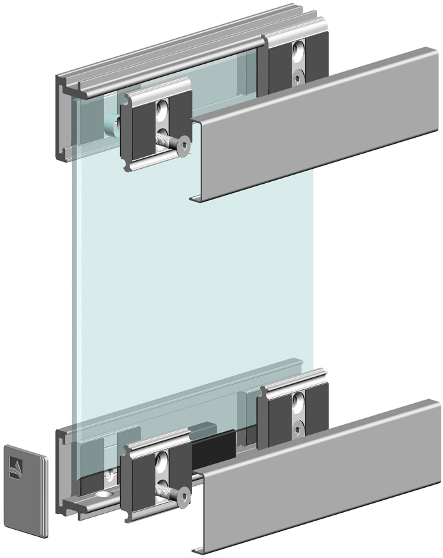

The following instructions will help us to correctly assemble the glass railing:

- First, on the platforms and on the steps themselves, we install support posts with a height of 1200-1300 cm. The step between the posts should not be more than 900 mm.

- The supports are fixed using anchor bolts. Typically, each support is secured with at least three anchors.

- We fix clamping fasteners with polymer inserts on the supports.

- Insert pre-cut triplex sheets into the fasteners.

- We mount the handrail on top of the glass filling using special brackets. Chromed or nickel-plated steel tube is most often used as a handrail. We close the ends of the handrail with plugs.

Despite the graceful appearance and complete transparency, the triplex has an enviable strength, therefore the fence turns out to be much stronger than an ordinary wooden one!

Output

When designing and erecting intra-house structures, it is worth paying attention to every little thing, and checking every nuance with the regulatory documents. This also applies to such parameters as the height of the handrail on the stairs, the dimensions of the steps and the design of the staircase - after all, in addition to comfort, your safety and the safety of your loved ones depend on the fulfillment of the requirements of GOSTs and SNiPs.

In the video presented in this article, you will find additional information on this topic.