Reinforcement and grouting

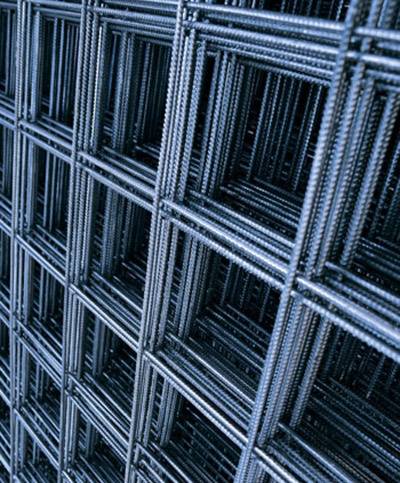

To strengthen the foundation, it must be reinforced. For these purposes, use reinforcement or mesh-netting. You can pre-weld metal rods together or lay them in a trench. The net must be secured on pegs so that it does not twist. The reinforcement is laid so that a grid with a side of a square of 10 cm is obtained. It is also advisable to prime it for better bonding with concrete.

Pouring a monolithic foundation under a barbecue with nothing does not differ from the same for a summer house or ordinary living quarters. It must be done at a time. Therefore, you need to make sure that there are enough materials. Otherwise, it will no longer be a monolithic foundation, and its parts may not bond well together. Then it can crack and burst in the cold season, if there is moisture at the junction of the layers. Such a foundation will be fragile.

To create a concrete mixture, cement of the M 400 grade and higher is usually used. To make the foundation have a flat surface, beacons are installed. This role can be played by metal rods installed at the same height along the perimeter of the formwork. Also, evenness is checked with a level or a fishing line stretched along the edges. After pouring the solution, its surface is smoothed with a spatula so that no irregularities remain.

To remove the formwork, you need to wait until the concrete mixture hardens. This usually takes several days. During this time, it is necessary to water the foundation with water to protect it from drying out. And you can move on to the next stage when after 21 days the concrete will gain 70% strength.

The right barbecue size for different ways of grilling meat

Meat cooking technology makes certain requirements for dimensions and design features. What dimensions are correct will depend on:

- processing temperature;

- used inventory.

We offer you to get acquainted with the general recommendations for choosing the geometric parameters of the structure on skewers and barbecue grills.

Frying method may vary

Frying method may vary

Dimensions of the model for barbecue on skewers

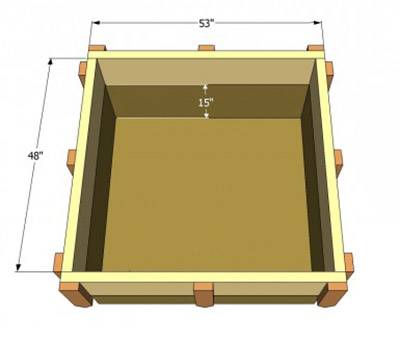

When working out the scheme and choosing the size of the barbecue for a shish kebab, the optimal length, width and depth are determined, taking into account the geometric parameters of the skewers that they plan to use. If the family is large, it is worth choosing a model about 1 m long in order to be able to roast meat on 10 skewers at the same time.

The standard width is 30–40 cm. This is enough to hold 6–8 pieces of meat. Increasing the parameters is ineffective. In most drawings of a barbecue grill, the optimal depth is 15 cm.

A separate place is provided for each skewer

A separate place is provided for each skewer

Barbecue models

When working out the parameters of the barbecue, you should, first of all, take into account the size of the grill for the barbecue. They are 18 × 28 cm.The grill should be located at a distance of 5–8 cm from the surface of the coals. In this case, it will be possible to ensure uniform roasting of the meat. Most often, the dimensions of the barbecue for barbecue made of iron are chosen 18 × 30 cm.This is enough to accommodate one lattice.

Lattice dimensions - the main parameter

Lattice dimensions - the main parameter

Where to place?

A stove with a barbecue for a summer residence, first of all, should be placed in such a place so that the prevailing wind direction does not blow away the smoke from the coals to the residential building. It is also undesirable for him to go to the adjacent sections, where he can make the neighbors dissatisfied, or to the roadway. A high chimney can solve this problem, the smoke will diffuse high above the garden area.

Outdoor kitchens with a barbecue oven should be located on a relatively flat place with a flat relief, without an abundance of floating soil. This will simplify construction, make the recreation area safe. With massive structures of a brazier, stove, oven and other elements, it is imperative to carry out concrete pouring in compliance with the level for the site.

For convenience, you can choose a place for the summer barbecue oven, adjacent to the wall of the house. So, you do not need to build additional structures. If the site already has a ready-made summer cottage, then it will not be a problem to build a small brazier inside. The main thing is to make sure that the hearth has a reliable concrete base that can withstand high temperatures, and that smoke escapes from the enclosed space using an exhaust hood or chimney.

Wall masonry

To prevent leakage of the walls of the future furnace, roofing material is laid over the screed. After that, depending on the shape of the openings, blanks are made. For rectangular shapes, you can use a simple corner. Now you can proceed directly to the laying.

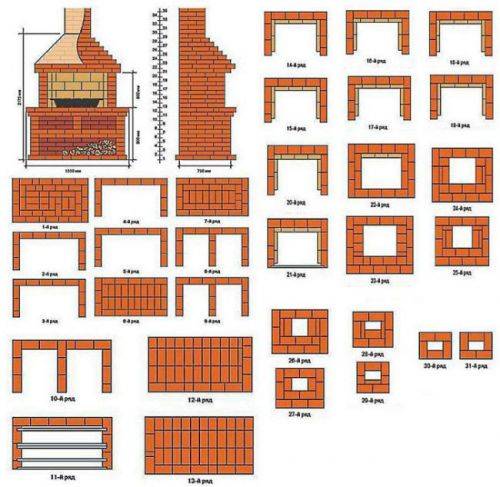

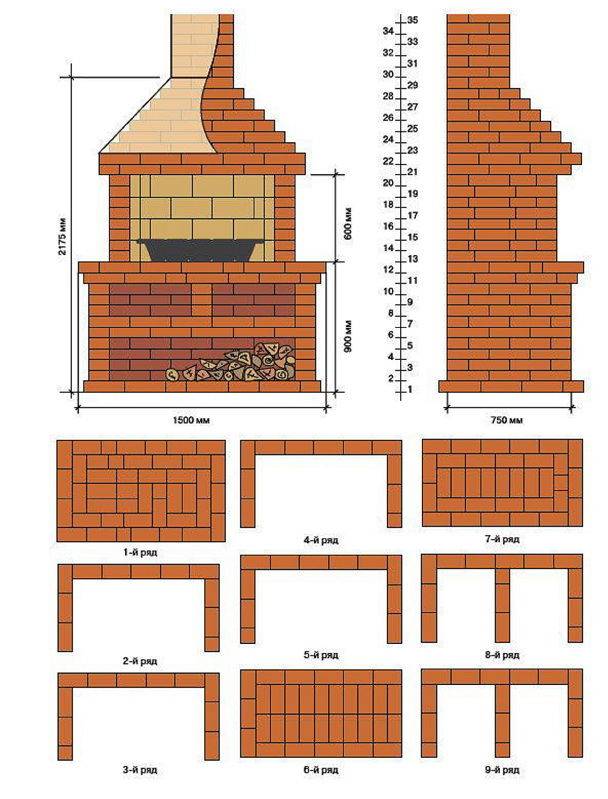

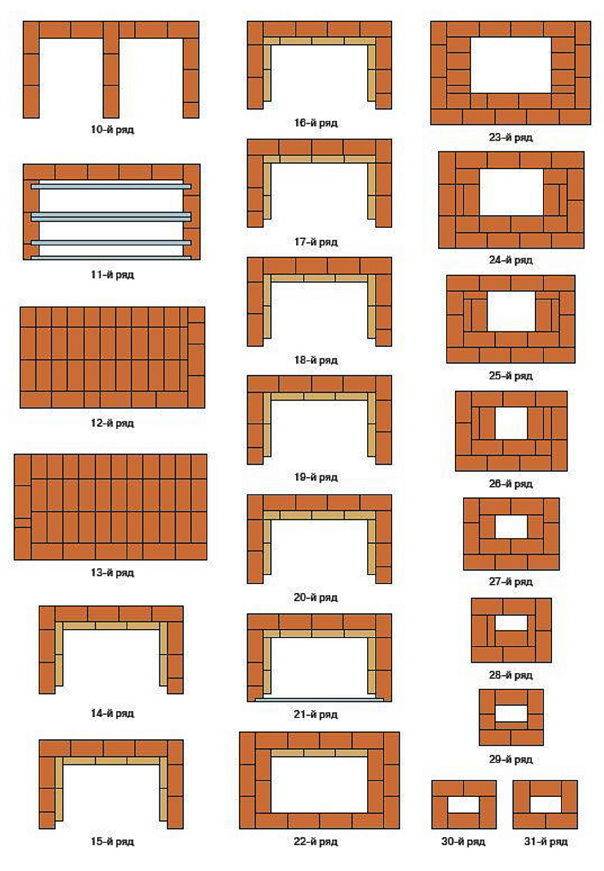

Row 1 is the most important. It is necessary that it be even. Indeed, the evenness of all walls will depend on this. You can follow this if you drive in the pegs along the edges and pull the fishing line or thread at level 1. Pull it tight, as the cord can sag over time. The masonry is carried out on a conventional cement-sand mortar. The walls are laid out in half a brick up to row 5, and the laying starts from the corners. It must be remembered that the distance between the bricks should be about 3 mm. To make it easier to put them, you can make an order. This is a metal or wooden slat with serifs.

The bricks are placed in a checkerboard pattern so that the joint of the lower row falls in the middle of the next brick. The evenness of each row is checked by the level, both horizontally and vertically. For these purposes, a plumb line is used. Every 3-4 rows it is necessary to lay a reinforcing mesh. It is required to remember that before laying, you need to moisten the brick in water for better adhesion to the mortar. After every 2-3 rows, it is necessary to embroider the seams.

6 row will depend on what kind of barbecue organization the owners have

It is worth paying attention to the description of the project. After all, some examples of barbecues have a removable sheet that serves as a pallet.

In others, it enters the masonry, and it is impossible to remove it. In both cases, the pallet must be at least 3 mm thick. If the sheet is removable, bricks are laid across in the 6th row. They act as a shelf. The next rows are laid again in the usual way.

A lattice will be placed at a height of 2 rows from the sheet. It can be fixed on metal brackets that are attached to the brick with dowels, or small metal rods can be laid in the seam. In the lower rows you can cook meat dishes, and in the upper rows you can use vegetables to heat food. If the project includes several gratings at different heights, you should lay out the required number of rows of bricks, plus a few on top to protect from the wind. After that, openings or an arch are laid out in accordance with your project.

If you plan to line the walls with decorative bricks, this can be done only when the mortar has set. It must be remembered that the constructed structure must stand for several days before operation. This is done to prevent the seams from cracking.

Selection of the area for the barbecue

This is the initial stage of work. If your site is small, and almost every square meter counts, it is difficult to choose a site for a barbecue. And its drawing is created based on the parameters of the zone where its construction will follow.

The instruction, according to it, the factors taken into account are as follows:

- The brazier should not interfere with ordinary summer cottage affairs.

- It is placed so that the prevailing wind draws the smoke away from the house.

- There should be a main pipe not far from the place of the barbecue.

- It is not reasonable to connect the whole water supply network to the object.

- Above the barbecue, at least a modest canopy is desirable.

- The location of tall bushes and fertile trees is not permissible near the barbecue.

- On the site with a barbecue, it is recommended to arrange a place for storing firewood, put chairs, benches, a table.

- The ground surface for construction must have perfect evenness.

- The barbecue area is placed at a short distance from the kitchen. This makes it easier to equip the place with water and lighting.

- When erecting a barbecue, immediately determine where the meat will be cooked, served and washed.

The brazier is a source of uninsulated flame. It must be far enough away from residential buildings and vegetation.

The brazier is a source of uninsulated flame. It must be far enough away from residential buildings and vegetation.

Required tools for work:

- Bayonet shovel.

- Sledgehammer.

- Shovel shovel type.

- Roulette.

- Rule.

- Level

- Fork set.

- Hammers: carpentry and rubber.

- Saw.

- Trowel.

- Chisel.

- Bucket.

- Jigsaw.

- Wheelbarrow.

- Pick.

Sizes and types of brick barbecues on the example of three projects

The most popular barbecue oven options are as follows:

- simple oven;

- barbecue oven with hob;

- oven complex with a stove and a working area.

The simplest barbecue oven is created without the use of special construction skills, using ordinary masonry. Such a furnace will have 13 rows in height, 702 mm high, depending on the thickness of the joint. The length and width of the structure is 1810 * 900 mm.

These are the standard sizes of this type of brick barbecue.

A barbecue oven with a stove will allow you to cook food in the summer. To build such a structure, you will need some skills in stove construction and knowledge of the principle of Dutch masonry (when it is not necessary to tie the seams in the rows). Dimensions of the barbecue oven with the cooker of the complex (in mm): depth - 1778, width - 434, height - 1900.

Furnace complexes are built by professional stove-makers, but you can try to build simple barbecue projects with a stove and a working area yourself. Dimensions of such a complex (in mm): depth - 1210, width - 2240, height - 1900.

Estimates of materials for the above options

Now that we have decided what sizes and types of brick barbecues are the most common, let's start calculating the cost of a structure of one type or another. The larger the oven, the more materials it needs and the more expensive it is. The final estimate is also affected by the amount of additional materials, their manufacturer and cost.

Consider estimates of typical barbecue options.

If you decide to build a mini do-it-yourself brick barbecue, then you will need:

Solid ceramic brick M200;

Using the drawing, we will calculate the required number of bricks (in rows): 16 + 16 + 16 + 16 + 16 + 45 + 10 + 10 + 10 + 29 + 10 + 10 + 10 = 214 pcs.

- Varnish KO-85 (reduces water absorption, which allows you to extend the life of a simple barbecue oven) - 1 pc .;

- Board 25 x 250 x 6000 mm - 1 pc .;

- Reinforcing mesh 150 x 150x5 - 2 liters;

- Cement - 150 kg;

- Grill grid 390 x 560 x 8 mm - 1 piece;

- Wooden flooring - 2.25 sq. m.

For a barbecue oven with a hob, you will need the following materials:

Solid ceramic brick M200;

Calculation of the number of required bricks according to the drawing: 49 + 49 + 32.5 + 33 + 34 + 34 + 39 + 30 + 42 + 40.5 + 44 + 27 + 27 + 27 + 27.5 + 26 + 36 + 27 + 37 + 26 + 28 + 25 + 26.5 + 39 + 36.5 + 28 + 31 = 901.5 pcs.

- Cement - 150 kg;

- Board 25 x 250 x 6000 mm (for the construction of formwork) - 1 pc .;

- Metal waste to strengthen the foundation;

- Cast iron plate 410 * 410 mm;

- Blowing door - 1 pc .;

- Steel sheet 5 mm - 2 pcs.;

- Corner for lintels - 4 pcs.;

- Bar 230 mm - 1 pc .;

- Grate - 1 pc .;

- Furnace door - 1 pc.

For the simplest version of the furnace complex with a stove and a working area, you will need:

- Project for the construction of the complex - 1 piece;

- Red bricks - 885 pcs.;

- Fireclay bricks - 14 pcs.;

- Cement - 300 kg;

- Formwork board - 1 pc .;

- Table top - 1 pc .;

- Washing - 1 pc.;

- Steel sheets - 5 pcs.

- Blowing door - 1 pc .;

- Furnace door - 1 pc .;

- Metal doors for the cutting table - 1 pc .;

- Metal waste to strengthen the foundation;

- Corner for lintels - 4 pcs.;

- Roofing material - 2 m.

To implement such a project, you will need fewer bricks than for the previous one. But there are more complex and dimensional complexes, for the construction of which you may need 2 or even 3 times more bricks.

Use the above data as an example for your own calculations. Take your project and substitute your barbecue dimensions in the given diagrams: the drawings on which you will work must contain this data.

Closed barbecue

If the property owner has chosen a closed-type barbecue project, if he wants the summer house to be under the same roof as the brazier, it is necessary to consider a chimney system. A barbecue device of this kind is more complicated, but the design looks much more solid. The difficulty of this type of brazier is that it is necessary to be able to correctly create traction. If this is done incorrectly, the smoke will remain in the stove, spreading through the gazebo, instead of leaving through the chimney. If a person is not sure that he can make such a barbecue, it is better to turn to professionals in this field. After all, it will be possible to check the thrust only after construction, and in case of an error, change something in masonry will be almost impossible.

The step-by-step instructions can show the main stages of work. But it is worth remembering that there are many nuances that are taken into account when building a furnace. Therefore, the guidance of an experienced craftsman may be needed.

Laying process in stages

Classic masonry scheme. The initial line is laid without composition. This measure will make the walls diligent and even. On the base, marks are indicated for the positions of all subsequent masonry lines.

The brickwork of a barbecue is carried out in a chess algorithm: the next line is always shifted by half a brick

The brickwork of a barbecue is carried out in a chess algorithm: the next line is always shifted by half a brick

Before laying, make sure that the base has acquired the required strength. This usually takes a minimum of a week.

Question with the composition for masonry

For the intended operations, you can use two types of composition.

- Standard. It will not come into direct contact with the flame. Based on the brand of cement, you need to calculate the amount of sand. So, for the M25 brand, the proportions are as follows: 5: 1 (sand-cement). For the M50, the ratio is 4: 1. For M75 - 3: 1.

- Clay of chamotte type. It is sent to the masonry of the combustion compartment. It is fire resistant and can withstand powerful temperatures.

The brick laying method is determined by the order of your preferred drawing. And even the slightest deviation from this order is not permissible. To comply with the parameters:

- Neatly laying out the bricks of the first line.

- The line starts from the corner. Then the side walls are created.

- The voids between the bricks do not exceed 1 cm.

- The correctness of the corners and the evenness of the masonry are controlled.

- The composition for the initial line is necessarily thick.

- The bricks in the next lines overlap the seams of the previous line.

- When laying out subsequent lines, the verticality of the masonry corners is checked.

- Every third seam is reinforced. Steel bars or mesh are used.

In this case, the work follows the following order:

It is very important not to deviate from it. To check the evenness of the masonry, a level and a vertical plumb line are used.

Grid question

A base for a brazier is arranged between two walls (opposite). Angles or rods are mounted here. They are metal. The creation of a combustion compartment is already underway on them. For this base, you can use a metal pallet

An important condition - ash must be easily removed from the combustion chamber

In its zone, side gaps remain in the masonry. This will allow air to enter the firebox. Without it, the fuel will not ignite

In its zone, side gaps remain in the masonry. This will allow air to enter the firebox. Without it, the fuel will not ignite

The suitable height for this section is 10 masonry lines. This is approximately 70 cm. The bottom here is laid out from a sheet of metal. The top of the compartment is finished with a concrete ceiling. One brick line is made in it.

Chimney question

Here, the easiest way is to put a conical metal box. It should taper upwards.

Making a brick chimney is a tricky business in itself. Even the slightest miscalculations in determining its height are not allowed here.

The combustion chamber and chimney are erected only from fire-resistant bricks

The combustion chamber and chimney are erected only from fire-resistant bricks

The back wall of the chimney is often used to mount the chimney. In this case, three bricks are placed on the back side of this wall, on the sides - brick by brick. 6 masonry lines are created for the required height. The front side of the chimney is covered with a concrete slab. One and a half meters of masonry is laid out in a pipe format. A visor is placed at the top to protect the chimney from precipitation. For its manufacture, galvanized metal is used.

It is important to install valves in order to be able to additionally adjust the temperature in the combustion chamber.

Brazier construction process

It is necessary to consider building a barbecue step by step. Regardless of the project and design, the basic stages of construction are the same:

- Creation of the foundation.

- Wall masonry.

- If desired, the barbecue is trimmed with decorative bricks or tiles.

- Manufacturing and placement of equipment.

- Arrangement of the cooking area.

Now you need to figure out how to build a barbecue in stages.

At stage 1, a base for the oven is created. The strip foundation is poured if the barbecue project provides for a not too massive structure. If the owner plans to make the facing with decorative bricks, build a table or cupboard next to it, he will need a slab foundation.

When constructing a strip foundation, they dig a trench around the perimeter of the barbecue. And if they fill the entire site, then they dig a hole under the entire area of the furnace. The depth in both cases will depend on the weight of the structure. Usually, a brick barbecue does not exceed 1 ton. Based on this calculation, the sand and gravel substrate should be located at a depth of about 30 cm. To make the trench even, use a thread stretched between the dug stakes.

The width of the trench and pit depends on the thickness of the walls of the future furnace and formwork boards. The foundation is laid based on the following: wall thickness plus 6-7 cm on each side. After the trench has been made, gravel and sand should be poured. First, sand is poured with a layer of 7-10 cm and carefully compacted. This can be done by flooding it with water. Then comes a layer of gravel 5-7 cm, which is also tamped.

Before pouring the foundation, it is necessary to make the formwork and make the reinforcement. The formwork is made from wooden planks or plywood. It is fixed around the perimeter of the trench and fastened with nails or self-tapping screws. The boards should be tightly connected to each other so as not to let the solution through. And so that they do not fall or bend over, fix them with metal rods or wooden pegs. In order to easily remove the formwork after the cement mortar has dried, it is lubricated with a special grease.

If the geometry of the wall lines is simple, trimming of lumber can be used in the manufacture of formwork. But if it is complicated, it is better to take plywood.

Blueprints

Before starting the main construction, its plan (scheme) should be developed in order to avoid flaws and inaccuracies during work. There is no universal scheme, since your barbecue oven is an individual activity and it is you who must resolve the issue with its scheme, appearance, etc.

Calculate all the proportions correctly and do not forget to include a place for firewood and coal in the construction plan. The grill should be at a height of 65-70 cm. The oven should be 10 cm below the grill.

When the blueprints for the brick barbecue are ready, we proceed to the preparatory work, that is, to create the foundation.

Features of the construction of the foundation

Each type of furnace has features in the construction of the foundation, which should be taken into account in order to extend the durability of the furnace.

For a simple oven, the foundation is poured 50 cm more than the dimensions of the oven in all directions.Paving slabs, paving stones and so on can be selected as a coating.

If the foundation is made of slabs, it must be reinforced with a bar and knitted with wire or plastic clamps. The solidification time of the foundation is 1 week at an average temperature above 20 ° C and 2 weeks at a temperature of 17 ° C and below.

Since a barbecue oven with a stove is larger than the previous structure, it needs to be provided with uniform shrinkage using a strip reinforced foundation with a connection between the brazier and the stove. At least 10 cm of the foundation must protrude above the surface.

Attention! If you attach the stove to a previously built slab, the stove will pull the slab along with it when it shrinks. Therefore, in such cases, you need to make a separate foundation.

When the concrete hardens, the sod inside the foundation is removed and the openings are filled with a solution of sand, gravel and clay. A week later, the tape is covered with a two-layer roofing material to prevent moisture ingress and start laying.

During the construction of the furnace complex, a concrete foundation is made, and if it is not possible, foam blocks are laid. Depending on the size, the weight of the kiln complex can reach several tons. To fill a reliable foundation for such a structure, you need to dig a trench with a depth of at least 50 cm and make reinforcement.

A layer of sand and gravel is poured onto the bottom of the pit, tamped down. After that, a wooden formwork is installed along the walls and the pit is poured with cement mortar. For reinforcement, use a metal mesh or steel rods. The solidification time of the foundation for the furnace complex is at least 4 weeks.

Outdoor brick ovens and barbecues - photos, advantages and disadvantages

Before proceeding directly to the process of erecting this structure on your personal plot, consider the advantages and disadvantages of a brick barbecue stove.

Among the main advantages that brick grill oven in the country, you can name the following:

- versatility. The brazier oven is well suited for cooking not only meat kebabs, but will allow skillfully cooking fish, vegetables, poultry;

- big sizes. One of the indisputable advantages is the large area of the brazier. Its back wall distributes the heat evenly over the entire area, which contributes to even cooking;

- the ability to vary the cooking mode. In this case, the products used are not skewered, but can be evenly distributed on the wire shelf. Moreover, depending on what is being cooked in the oven, you can vary its height in search of the best cooking option;

- the possibility of using various types of fuel. In this brick brazier stove, both firewood and coal can be used;

- the design in the grill provides for an extractor hood;

- in more advanced models, a temperature level indicator can be installed, which allows for more convenience when preparing dishes;

- when using a grill oven, preliminary marinating of meat is not required.

Outdoor ovens and barbecues made of bricks - photo on the site

Outdoor ovens and barbecues made of bricks - photo on the site

Despite a number of advantages, one significant drawback can be noted:

construction is a rather expensive undertaking.

Fire safety

Do not forget that the barbecue is an extremely fire hazardous structure.

Failure to comply with safety precautions during careless operation of the brazier can lead to sad consequences

Explosive objects must not be left nearby. Construction should not be carried out near wooden objects, trees

Install sheds or other shelters with care so as to exclude the possibility of fire

Important! Under no circumstances should flammable materials be placed on or near a working oven. Knowing and using the most important safety fundamentals will eliminate the possibility of unexpected results

Knowing and using the most important safety fundamentals will eliminate the possibility of unexpected results.