Furnace device and its elements

The design of Buleryan stoves is designed for the use of solid fuel - firewood, less often coal or pressed wood waste is used. The device of such furnaces is extremely simple, which allows you to assemble them yourself using a minimum set of tools.

A stove - a stove-stove of the Buleryan type externally represents a steel barrel with pipes that can be located above and / or below the structure. It combines the pyrolysis type of combustion and the functions of a convection heater. The heat generated during the combustion of the fuel immediately goes into the pipes (air ducts), which increases the productivity of its work up to 80-85%.

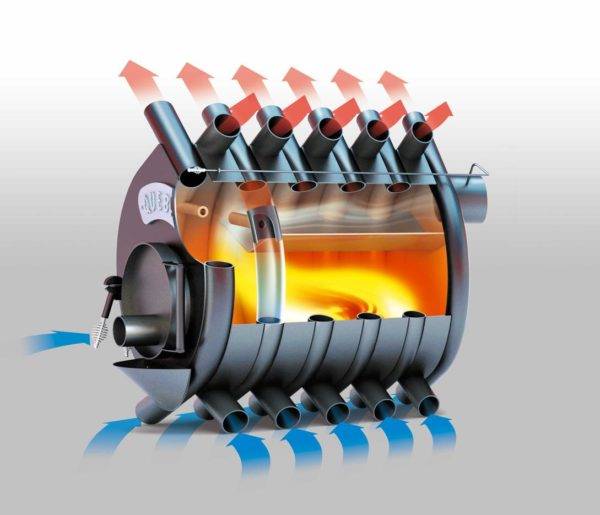

Buleryan furnace device in the photo (in section)

Buleryan furnace design:

- The largest part of the structure - the combustion compartment of the placed solid fuel cell (occupies 85% of the volume) - processes of primary ignition and generation of pyrolysis products take place.

- Compartment for afterburning fuel (25% of the internal volume of the unit) - the pyrolysis products enter, after which the residual fuel burns out with the formation of a flame, the process is accompanied by the release of high temperature.

- Injectors - tubes for supplying air to the afterburner (necessary for the combustion reaction of pyrolysis products).

- Pipes for the convection process - this element of the Buleryan pyrolysis oven is made from thick pipes made of metal. They receive the heat released during combustion, which enters the room through the hole in the pipes in the form of streams of warm air.

- Regulators - this part of the furnace consists of two mandatory elements required to regulate the operation of the unit - a damper and a throttle on the door. A function is implemented that allows you to regulate the air supply to the afterburner. The temperature of the discharged air is monitored.

- Chimney (with or without condensate collection tank) - function for removing combustion products.

- Ash pan (located at the bottom of the structure).

Design features and principle of operation

Buller-breneran differs from the usual "potbelly stove" in the following way:

- The furnace is surrounded by curved vertical pipes in which the air is heated. Thanks to this solution, the stove heats the room very efficiently, while its body remains relatively cold.

- The blower is made in the form of a pipe cut into the furnace door and is equipped with a damper (choke), through which the power of the furnace can be controlled.

- The upper quarter of the firebox is separated by a plate with holes. This space plays the role of a combustion chamber for wood (pyrolysis) gas, which is formed during the high-temperature decomposition of organic molecules.

Axonometric section and specification

Axonometric section and specification

Note that Buleryan and similar furnaces are not gas-generating (pyrolysis) in the full sense of the word. In a real pyrolysis heat generator, higher temperatures are created, and air is forced on. The creators of the buller sought to simplify its design, as a result of which the pyrolysis in it proceeds sluggishly and not in full. This mode is usually called partial gas generation.

The above-mentioned partition does not reach the front wall of the furnace for 20–25% of the length of the furnace. Due to this, the main flow of flue gases on the way to the afterburner is deflected towards the front of the furnace. Thus, Buleryan belongs to front-burning stoves, which surpass the classic ones in ease of control.

The flue duct begins with a horizontal section having a length of 0.8–1 m. This element, as it were, holds the draft, allowing most of the flue gases to burn out in the firebox.

The gate damper, installed at the beginning of the vertical section of the chimney, has a cut-out measuring 25% of the entire area, due to which it can under no circumstances be closed tightly.Thus, the risk of carbon monoxide poisoning of people is completely eliminated.

The operating mode of the unit is regulated by means of a slide gate:

- when firing up (flame mode), it opens completely;

- when switching to the mode of long burning (smoldering) - it closes.

The heat in the firebox calms down a little, while the gases in the chimney cool down and its work resumes. The draft is restored, the heat in the firebox increases again, the formation of flue gases becomes more intense, they flash again in the economizer and the firebox dies out again. In the long burning mode, this cycle repeats constantly.

The structure of the "Buleryan" furnace and the principles of operation

The stove has an original design, in which everything is subordinated to the main task: rapid heating of air in the room, and then maintaining the temperature.

The furnace body consists of parabolic pipes, between which metal strips are welded. Most of the pipes are inside the firebox, protruding only 1/3 of their diameter. Such a system is a highly efficient heat exchanger, in which air acts as a heat carrier. As soon as the furnace is fired up, air is sucked into the lower ends of the pipes, which takes most of the thermal energy from the heated metal. This stream is very intense. With active combustion, 4-6 cubic meters of air pass through six pipes in a minute, and its outlet temperature exceeds 120 ° C (up to 150 ° C).

Active combustion is not the main mode of operation of this furnace. Most of the time, the fuel smolders. Then the air in the pipes no longer burns "only" 60-70оС, but the temperature of the body is in the region of 50оС (of course, not immediately after the "swing").

Cold air is sucked into the lower pipes, and heated from above comes out

The firebox is internally divided into three parts: from below ¼ part is separated by a grate, from above ¼ is also diverted under the afterburner. The grate is either a standard cast iron grate, or a steel grate made of steel at least 4 mm thick. The upper partition does not reach the door by about a quarter of its length. And this is not a solid sheet, but with holes. Through these openings, air from the furnace enters the fenced off afterburner zone to maintain the combustion of gases. The area of the holes is about 7% of the total area of the partition.

There is a gas outlet in the upper part of the rear wall. A damper / gate is installed here, which has a smaller diameter (a gap of about 10-15% of the diameter of the chimney). Additionally, a sector of 90 ° is cut in the damper. This device allows you to adjust the draft, but the existing clearances will not allow carbon monoxide gases to go into the room in any position of the gate. This will not happen even with the door open. Then, however, the room will dry out completely, but safety is above all.

"Buleryan" prefabricated with an economizer

This is how it works. Partially cooled gases pass into the section of the insulated pipe. A certain amount of thermal energy has already accumulated here. The gases heat up again and flare up. Due to the increase in temperature, they expand, and since they have nowhere to go in the pipe, they clog the chimney. A gas lock is formed (this phenomenon is known to stove-makers and the owners of their unsuccessful creations). The gases burn out and cool down, the cork dissolves. For some time, the oven operates as usual until the required amount of heat accumulates in the economizer. This process is spontaneous. The frequency and duration depend on the characteristics of the wood and the position of the dampers.

To regulate the intensity of fuel combustion, there is a throttle in the stove door that blocks the air flow. The door itself is usually round and large in order to fit large logs - this is the best option for the smoldering mode. But this is not the most important thing

It is important to ensure a tight fit of the door: combustion products should not leak through it. This is also the complexity of making pyrolysis ovens with your own hands.

With the design and the principle of operation, it seems, figured out. Now you can start assembling spare parts and components.

Calculation of homemade Buleryan for the house

The calculation of the firebox of a solid fuel heat generator is quite complicated, but its simplified version is quite suitable for the amateur level. It is performed in two stages.

Stage one: determination of the power of the furnace at full (flame) combustion

In this mode, the fuel loading will burn out in about 1 hour (3600 seconds), and the furnace efficiency will be about 50%. To calculate, you need to know the calorific value of the fuel. Here are the data for some types of wood:

- birch: 16200 kJ / kg;

- ash: 18200 kJ / kg;

- oak: 20,000 kJ / kg.

Let's make a calculation for the fuel with the lowest performance - birch. A log weighing 1 kg per hour of operation, taking into account efficiency = 50%, will burn with the following power:

W = (16,500,000 / 3600) x 0.5 = 2300 W.

Therefore, for a power of 15 kW we need:

M = 15 / 2.3 = 6.52 kg of birch logs.

Taking into account that the density of birch is 650 kg / m3, we calculate the volume of a bookmark with a mass of 6.52 kg:

V = 6.52 / 650 = 0.01 m3 = 10 liters.

Based on the fact that the filling factor of the furnace for solid fuel stoves is 0.63, we calculate the volume of the furnace:

VT = 10 / 0.63 = 15.9 liters.

Stage two: determination of the furnace power in smoldering mode

Usually this value is only 10% of the nominal power, that is, that with which the unit operates in the flame combustion mode. For our example, the smoldering power is only 1.5 kW. Thus, in order to ensure the heat output in the smoldering mode at least at the level of 4.5 kW, the volume of the furnace must be increased 3 times - up to about 48 liters. Then it will be possible to fit about 19.5 kg of birch logs into it.

Design features and principle of operation

When developing the brandaran, Canadian experts used the long-known design of a long-burning convection boiler, called a hot-air furnace. Due to the increase in the furnace door, it became possible to load not only chopped logs, but also parts of rhizomes, as well as large blocks of wood. The new form of the blower - in the form of a pipe cut into the loading hatch - made it possible to abandon the two-door scheme. To adjust the amount of air required for fuel combustion, a throttle was installed inside the blower - a round rotary damper. The throttle control lever brought out to the outside allows, if necessary, to reduce or increase the air flow, thereby controlling the power of the buleryan.

Buleryan design

The furnace of the heating unit is a metal cylinder, from both sides of which tubular metal heat exchangers bent in the form of knees are cut through at equal intervals. Due to the fact that two-thirds of the diameter of the pipes are recessed into the body of the stove and are in the combustion zone, the air receives up to 70% of the heat that is released when burning wood. The remaining kilocalories heat the body of the stove and are subsequently also spent on heating the room. Due to this distribution, the buleryan body usually heats up to only 60–65 ° С, while the air that comes out of the convection channels has a temperature of more than 100 ° С. It must be said that it is precisely the high heating rate that ensures the active suction of cold air masses in the lower part of the tubular heat exchangers and their ejection from the upper openings of the air heater.

The combustion chamber inside the device is divided into three chambers. In the lower part of the furnace, at a height of up to ¼ of the body diameter, a metal under or a removable grate is installed. You can do without these elements, but with them it will be easier to light the furnace and remove the ash. Under the arch of the furnace, at the same distance from the body as under, a perforated metal sheet is welded in, which does not reach the loading hatch for a quarter of the buleryan's length.The upper chamber is designed for the afterburning of volatile compounds that are released during the operation of the unit in the gas generator mode.

Rapid air heating is provided by convection heat exchangers that make up the furnace frame

The combustion products are discharged through an opening located in the afterburner, from the rear wall of the unit. At the beginning of the smoke channel, a damper with a cut-out 90-degree sector is mounted. In addition, there is a gap of at least 10-15% of the chimney diameter around the gate (a metal plate that regulates the chimney draft). This design makes it possible to set the correct draft and, at the same time, does not allow carbon monoxide to enter the room, even if the smoke channel is completely blocked during intensive gas formation.

Increased requirements are imposed on the buller chimney

A horizontal section of the chimney departs from the outlet opening, designed to reduce the temperature of the combustion products, and then an elbow is installed, which directs the pipe vertically. Here, at the "real" units produced by Bulerjan, a device for pyrolysis combustion of gases, called an economizer, is installed. The chimney must be high enough to obtain high-quality draft and insulated so as not to allow the combustion products to cool down too much. If this requirement is not met, as well as when using fuels with a high moisture content, the temperature in the afterburner will be reduced, as a result of which the content of tar and other unsafe carbon compounds in the flue gases increases.

Varieties with photos and geography of using buleryan

In order to understand the difference between Buleryan, Breneran, Buller, Butakov's stove and other types of convection ovens, let's take a closer look at all the nuances. First of all, we would like to note that Buleryan is a brand of the German company Bulerjan, which produces super-bourgeoisie. Often, furnaces of this type are called the shorter word buller. "Breneran" - the same units, but produced by domestic factories under license. The furnace developed in Russia by Professor Butakov is very similar in principle to the original design, but it has some differences:

- convection heat exchangers recessed into the housing;

- cubic body shape instead of cylindrical;

- the use of an ash pan and grate;

- flat platform at the top of the body for warming food.

In fact, the use of a grate in a gas generating unit is unnecessary, since intensive firewood burning is assumed only in the first minutes after ignition. In addition, its purpose is not clear, given that it is below the level of the blower. There are also doubts about the effectiveness of the platform for installing a pot or kettle. When entering the operating mode, the temperature of Buleryan rarely even reaches 75 ° C, so it will take a lot of time to warm up the food.

The Butakov stove is a modernized buleryan

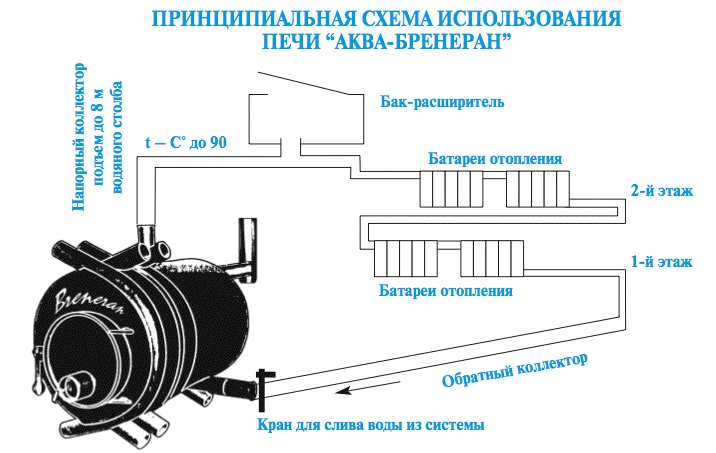

Despite the fact that the heater was originally designed as a stove with an air heat exchanger, some craftsmen loop convection channels by connecting them to a water heating system. The resulting aquabuller, of course, has a right to exist, but the feasibility of such a solution is questionable. Firstly, the heat capacity of air is 800 times less than that of water, therefore, a furnace designed for convection will operate with a reduced efficiency under conditions of liquid heat exchange. Secondly, even if Brahneran is taken as a long-burning unit, then this is also irrational, since there are more suitable specialized designs of solid fuel boilers using pyrolysis. Despite this, aquabullers have found their place in the line of units, which are modernized buleryan.

The water jacket turns the convection oven into a hot water boiler, which is called an aquabuller.

Despite the fact that initially the heating stove was developed for domestic use, now Buleryan is widely used in all spheres of economic activity:

- for heating summer cottages and country houses, including wooden ones;

- in production workshops;

- for heating utility rooms;

- in garages and workshops;

- in baths and saunas;

- to maintain the required temperature in greenhouses;

- as heating units for country cafes and restaurants;

- for heating administrative buildings in rural areas, etc.

When installing buleryan, the power and dimensions of the heating unit must be taken into account, since it depends on this whether the device can evenly heat the entire room

It is equally important to choose the right place for installing the Canadian stove, equip the chimney in accordance with all the rules and ensure its regular maintenance.

Installation diagram of the convection unit

Design features

It is really very simple to assemble a Buleryan stove with your own hands. But only for those who know how to handle tools and iron, and also have an idea of \ u200b \ u200bthe device of solid fuel stoves. There are no particular structural difficulties here, but you need to remember that working with iron requires special care - it is not as malleable as wood. But as an end result, you should get an excellent heating unit that will delight you with quick warm-up and long burning.

The Buleryan stove assembled by its own hands is a traditional solid-fuel unit that runs on wood according to a gas generator scheme. That is, firewood burns here with the release of pyrolysis products, which are sent to the afterburner and burned there with secondary air. The combustion products are sent to the chimney, leaving the atmosphere and partially falling out in the form of condensate - we will tell you how to get rid of it with just one movement of your hand.

Potbelly stove Buleryan consists of the following parts:

- The main combustion chamber is spacious and capacious, the firewood here lies directly on the convection pipes;

- Afterburner - located above the combustion chamber, it is a perforated or solid sheet of iron that separates the upper quarter of the entire internal volume;

- Tubular convector - a set of curved pipes, most of the area of which is in direct contact with wood, coal and combustion gases;

- A loading door with a small blank flap - through it, firewood is loaded into the Buleryan oven, made by hand. It also allows you to adjust the oxygen supply to the combustion chamber;

- A chimney with a gate damper and a condensate collection chamber - ensures the removal of combustion products and collects condensed combustion products with their subsequent removal.

Also in the design of the furnace there are tubes (injectors) for supplying secondary air - it is needed in the afterburner for the combustion of pyrolysis.

It is the simplicity of the Buleryan convection oven (it is also called the Breneran oven) that gave it its well-deserved popularity.

Improvement and modernization of the heater

The finished structure is successfully used for heating a small room. The finished heating stove does not look very attractive, therefore it is often used for outbuildings.

Distribution of heat to the rooms of the house

For heating the whole house, corrugated pipes are used, which are connected to heat exchangers. The opening is ennobled with a decorative lattice. It is recommended to carry out the layout at the stage of planning and execution of drawings.

In all rooms, special channels must be made in the walls that will supply warm air.You can install a heating stove in the basement, and run air ducts through the floor in all rooms. Buller's design is subject to improvement. Collectors are installed in all chambers. They will ensure timely and fast air distribution.

Basement piping

Basement piping Air heating in the house

Air heating in the house

Improving the appearance of the unit with brick or masonry

You can make the lining of the stove using bricks. This method has a huge number of advantages:

- improving the appearance of the oven;

- ensuring safety during operation;

- increase in heat capacity indicators.

You can make buleryan, which is stylized as a Russian stove or fireplace. Home owners have the opportunity to bring different design ideas and solutions to life. It can be semicircular or square. Brickwork is done as close to the body as possible.

Stylization Buleryan under the Russian stove

Stylization Buleryan under the Russian stove Normal installation without decoration

Normal installation without decoration

Alteration of a potbelly stove for liquid fuel

The structure can be converted to use liquid fuel, car oil. This design cannot be used in residential premises. A liquid fuel stove is ideal for a garage, utility room.

To transfer Buleryan, you need to do the following:

- the oil container is installed at a slight elevation;

- the fuel supply hose is pulled to the structure;

- a hole is cut in the furnace door, which is intended for the tube and connection of the control valve.

To use engine waste oil, it is necessary to provide traction, fuel adjustment. You can install a homemade burner.

Installation for the use of liquid fuel

Installation for the use of liquid fuel

Installing the water circuit

To loop all the heat exchangers, you can make a furnace from sheet steel. The result is a structure of the correct cylinder shape. At the top, another cylinder is connected. It is used as a water jacket.

The lower part of the oven warms up slightly. That is why the oven moves downward. To maximize the use of heat, an additional circuit is routed to the outlet of the flue channel.

Water jacketed oven

Water jacketed oven

Video: installation and first start-up of the heating device

One of the advantages of the Buleryan brand stove - the simplicity of the design - turned out to be very useful for home craftsmen. As you can see from our article, it is not difficult to make a copy of this unit on your own, which has quite acceptable characteristics. Inexpensive device is great for rooms with inconsistent stay of people. As for residential buildings, it is better for their owners to fork out for a pyrolysis boiler or brick oven. Buller, on the other hand, can be used for forced heating while the main unit is melting.

Furnace device in classic design

In order to make a homemade unit, you should carefully understand its design and understand the principle of operation. An all-metal product consists of a minimum number of elements. The basis of the stove is a cylindrical firebox with curved metal tubes tightly fitting to its walls. On the front side there is a door for loading fuel and a device that allows you to adjust the power and set different combustion modes. In the firebox itself there is a secondary combustion chamber and an outlet pipe to which the chimney is connected.

To increase the efficiency of such a furnace, it is imperative to provide high-quality thermal insulation of the smoke channel. For this, ordinary mineral wool is perfect (a layer ≥ 3 mm is sufficient). Do not forget that a blower should be provided to supply air to the combustion site.It will be useful to install a small ash pan. The performance of the double back wall also contributes to the efficiency of the device. Some models have a double-layer furnace body.

The work "Buleryan" is based on the physical principle of convection heat transfer, that is, the movement of heat that occurs in a certain way. The tubes on the outside of the furnace body are welded into it and warm up during the operation of the device. The heat is transferred to the air in them, which is then discharged into the room. At the same time, a vacuum is created in the lower part of the tube, due to which a cold air flow from the lower layers of the room enters it. This process goes on continuously as long as wood is burning in the stove.

The operating principle of the Buleryan unit is clearly presented in the video:

Such equipment, without exaggeration, can be attributed to the most efficient heating devices among all that run on solid fuels. Today, there is only one type of device that surpasses such furnaces in terms of efficiency. We are talking about high-tech boilers in which the fuel burns almost completely.

It is recommended to use firewood, peat briquettes, waste from the wood and paper industry for the operation of the furnace. It is undesirable to use coal of any brand, since there is a high probability of damage to individual elements of equipment. It is strictly forbidden to use gas and liquid fuels.

Some Buleryan devices are called a very successful hybrid of a potbelly stove and a long-burning wood-burning stove.

Buleryan stove for a bath

Gradual modernization has led to the fact that such designs began to be produced for the sauna. They are equipped with several modes - supply of dry hot air or supply of wet steam. Many are interested in who the manufacturer of such products is: it is the Russian company Breneran. Such installations are heated only with wood or paper. It is realistic to make a chimney for the buleryan stove ourselves, because this method will help to match the structure of the bath as closely as possible.

Alteration of the Buleryan furnace for mining

Buleryan Waste oil stove

The video, where the Buleryan stove operates according to the basic rule on wood, confirms that it is not designed for exploitation. Experienced craftsmen will always find a way out of the situation: they will improve the product with their own hands so that it is operated on used oil. There are 2 ways:

- Installation of a dropper for mining. The method does not require large financial costs and consists in assembling an oil container. A hole is made in the firebox for the pipe, as well as a tap that will regulate the fuel supply. Such a solution will have low heat dissipation and performance.

- A nozzle is placed on the door of the combustion chamber - this is a burner that will convert the device to oil. Previously, such solutions were made by hand, but today the burner can be purchased ready-made.

After the alteration of the buleryan to fit his needs, the person is fully responsible for its operation.

How to make a Buleryan oven with your own hands

Do-it-yourself Buleryan type stoves

There are a wide variety of models in heating appliance stores. For example, the Buleryan Aqua Siberia 400 option is an air-heating stove that can be heated with a birch tree. Low fuel consumption saves money, and the device itself is ideal for summer cottages. But some owners of private houses decide to make the device themselves. Instructions on how to make a Buleryan oven out of a pipe are described below:

- Materials. For the construction of a convector oven, pipe sections with a diameter of 350, 120, 60 mm will be required. Also useful are 4 mm sheet metal, hinges for fastening, an asbestos cord for sealing and a lever for the door. It is necessary to work with a grinder, a welding machine and a pipe bender.

- At the initial stage, the pipes are bent. Bend the pieces of the required length with a diameter of 60 mm in a circle so that they fit into the frame. For a heater, 6-8 such segments are required.

- Next, weld the grate device.

- In the next step, cut out the metal to cut the back wall, as well as the door.

- Weld the locking lever to the door, then place it on the hinges.

Important! To save even more fuel consumption, it is recommended to make a third combustion chamber - an economizer, which will help preserve heat for a long time.

If the heating device is made for a private house, make the cladding: this can be done with brick or artificial stone. Now the house will heat the buleryan stove: photos in the interior of various options can be seen in this material.

How to arrange heating?

How to organize heating using a Buleryan type stove

Heating with buleryan is considered an economical solution, because the fuel completely burns out, which increases the efficiency. With the maximum filling of the furnace, the stove will be able to heat up for more than 12 hours. Before installing this structure in the house, you need to decide which room is the most spacious and, if necessary, make a fan for cooling. The device is installed on the ground floor.

Advice! Modern options are more suitable for an industrial style, but by finishing to taste, you can combine the product with any design.

A cast iron or steel stove must be protected by a galvanized sheet for fire safety. Buleryan heats not only private buildings, but is suitable for a greenhouse - there it must be installed in the center.

Buleryan wood stoves are popular designs that help in heating a house, garage, greenhouses and other structures. Availability, ease of cleaning, easy maintenance, the possibility of self-production - all these advantages make Buleryan a popular reliable device among users.

Did you make a Buleryan type stove with your own hands?

Not really