Mistakes when choosing an air-heated fireplace

The generally accepted scheme for choosing heating equipment in this case is unacceptable. Most believe that the power of the firebox is selected for the area of the room at the rate of 1 kW per 10 m2. Time has shown that choosing a fireplace insert for a country house with air heating requires an integrated approach.

Too powerful gas stoves lead to overheating of the apartment. Residents have to open windows or reduce the amount of fuel used for heating. Frequent temperature fluctuations provoke colds and other unpleasant symptoms - weakness, dizziness and insomnia.

Fireplace area calculation table

How to calculate the required power of the fireplace insert with air heating? Experts advise contacting sales consultants with this question. It is necessary to contact a specialist correctly, that is, with the provision of information on the area of the room, the type of ventilation and the number of rooms. Only in this case the seller will select the required equipment power.

Some features of self-designing a fireplace

The project of the house must necessarily include sections on the construction of the fireplace and its individual elements.

Above the firebox of each fireplace there is its own chimney, the cross-sectional area of the chimney duct of which should be 1/10 of the firebox area. The distance from the junction of the chimney with the combustion channel must be at least 5 meters.

The chimney duct should be equipped with a special damper that will separate the firebox from the chimney, and a hole designed to remove soot that accumulates during operation. The design of the slide damper can be retractable or fixing (using piano hinges).

Average fireplaces can weigh about 500 kilograms or more. Therefore, it is necessary to provide a sufficiently strong and reliable base under the fireplace.

If a fireplace is to be installed in an already built house, then additional work may be needed to strengthen the supporting structures.

Air-heated fireplaces

Air heating of rooms and premises by a fireplace provides for heating the air passing between the body of the firebox and its outer surface.

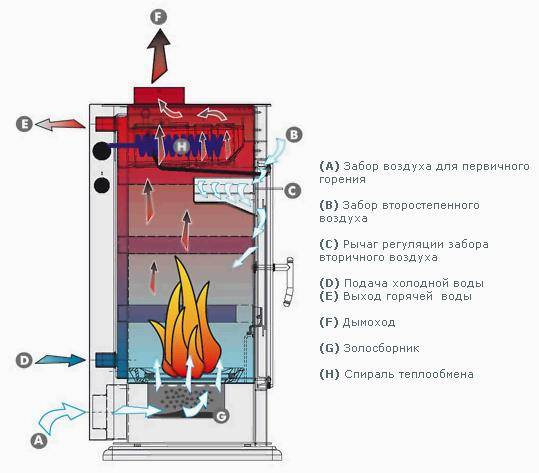

Diagram of a fireplace with air heating. Click to enlarge.

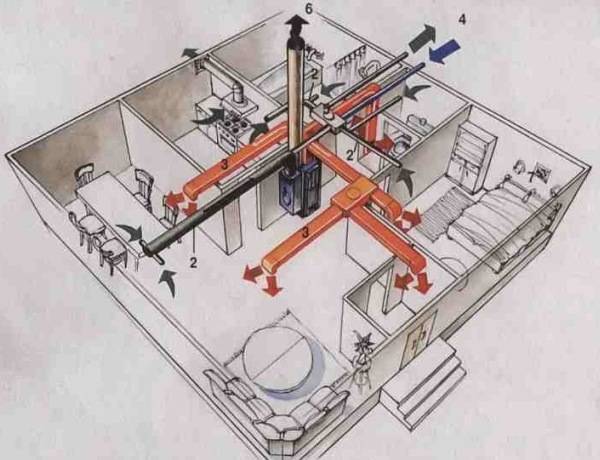

Distribution of heated air to the rooms of the house is carried out using pipeline channels installed in the walls or in the ceilings.

For the installation of air channels, aluminum or steel pipes are perfect.

In simpler schemes, the gravity method is used for air supply, based on different values of the density of cold and warm air.

Fireplace air heating of this type does not depend on electrical energy, but it can be used to heat only a few rooms.

Fireplace air heating of a house with a large number of rooms and a length of pipelines of more than 3 meters should be carried out according to a scheme with forced circulation.

The structure of such a scheme should include a pump that supplies air under the furnace body or above itself.

Forced air circulation can provide high-quality heating of a sufficiently large country house.

When choosing and installing such a scheme, it should be remembered that the air exchange proceeds in a closed cycle.

It is more rational to build a fireplace with air heating in the process of building a house, since otherwise you will have to face tedious and very costly work - punching holes intended for laying air ducts.

Fireplaces with water cloak

The firebox of fireplaces with a water cloak has one significant structural difference - the body of the firebox consists of two layers, between which the heated water is circulated.

A fireplace in your room is not only an interior element, but also a source of heat.

The heated water is supplied to the radiators of the heating system through special pipelines.

The device of a special heat exchanger (coil) in the upper part of the fireplace will provide an opportunity not only to heat the premises, but also to heat water for domestic purposes, the circulation of which will be carried out by means of special pumps.

Fireplace frame with water cloak. Click to enlarge.

Manual regulation of fireplaces is possible by increasing or decreasing the air flow into the fireplace insert. Automatic regulation is carried out due to the operation of thermostats with which the pumps are equipped.

Thermostats provide automatic activation of the pumps after heating the water to the required temperature.

Heating circuit

House heating can be carried out using units of different categories. Intermittent combustion fireplaces with a single laying of firewood provide a room with heat for up to a quarter of a day.

Continuous burning devices with an equal amount of fuel increase this period to 8 hours. Even at the minimum power, the amount of heat produced will fluctuate from 3 to 6 kW. High heating levels are achieved with wide open air blowing. At the same time, depending on the design, from 2 to 4 kilograms of firewood will be burned per hour.

The power with which heating fireplaces will work can be calculated based on the size of the heated room. In a room with a ceiling height of 2.8 meters, 1 kW of heat is enough for heating 10 m2 of area. Accordingly, with a power of 10 kW, such an oven will be able to serve 100 m2 of area.

Air

When energy is transferred from one medium to another, the amount of transferred heat is significantly reduced. A properly designed air-heated fireplace can solve this problem due to the small number of thermal transitions. Its device involves burning fuel in a separate chamber, heating the metal part of the furnace and the air inside the room. In this case, the transfer of energy is carried out using flexible heat-insulated channels connected to other parts of the residential building.

Air flows can move naturally or be driven in the desired direction by a forced injection system. With a vertical orientation, a normal air flow is sufficient for high-quality heating. If the location of fireplaces with air heating is far from the premises to which heat must be delivered, it is recommended to install special fans.

Water

If there is an ordinary wood-burning unit in the house, you can connect a heating system to it and achieve a good result in terms of thermal efficiency. Inside a fireplace of this design, a water circuit is installed, connected to the general heating communications of the dwelling. Burning firewood in its firebox increases the temperature of the coolant in the pipes and, due to this, provides high-quality heating of the entire building. The two main connection schemes imply the operation of open and closed systems, respectively.

To install a fireplace in the house and connect an open heating to it, you will need to hang an expansion tank above it, which works on the principle of communicating vessels. With the closed method of connecting the furnace, a common tank is used in the structure, and a separate expansion tank is not built in.

Chimney arrangement

After the "body" of the fireplace is ready, you can start creating the chimney. Its passage must correspond to the calculated value.From above, the chimney should be reliably protected from precipitation. For these purposes, you should use a wide smoke hood made of galvanized sheet metal.

There is no better material for a chimney than red ceramic brick. Here is what one of the participants of our forum thinks about it.

The advantages of a brick chimney are considerable. It is much more difficult to achieve the formation of condensation in a brick pipe than in a sandwich - you have to try. The combustion of soot is not scary, the heating of the outer surface of the pipe in the attic is minimal or even completely invisible. The durability of a properly folded brick pipe is many decades.

A galvanized pipe made of heat-resistant steel can be used as a chimney. Such a chimney is made multi-layered (as a result, a kind of "sandwich" is obtained), on three sides it is closed with plasterboard.

During those periods when the fireplace is inactive, any chimney becomes the cause of drafts. In order to avoid such a harmful phenomenon, special valves (gates) are mounted in the chimney shaft. They open only when the firebox "comes to life", filling the room with pleasant warmth.

The cross-sectional area of the cylindrical chimney with the area of the fuel portal must have a ratio of 1:10.

Particular attention should be paid to the height of the outer part of the chimney:

-

if the gap from the ridge to the chimney is less than 1.5 m, then the chimney must be at least half a meter higher than the ridge;

-

if the distance from the chimney to the ridge is more than 1.5 m, then the upper cut of the chimney should not be lower than the level of the ridge.

Advantages, disadvantages

The positive qualities of the units include:

- the principle of operation of a simple fireplace model: the release of heat energy of the stove occurs during the process of fuel combustion;

- chimney ducts are designed to remove carbon monoxide. If you additionally provide for channels through which air will move convectionally, the temperature marks will become higher;

- there is no localization of heating zones near the fireplace;

- simplicity, ease of the heat carrier air circulation system;

- high level of security. Compared to a water circuit, even the smallest hole in the piping can cause a rupture. Hot water can cause burns, greatly harm a person;

- lack of heat carrier;

- lightness, simplicity of turning on, turning off the heating;

- in comparison with the water circuit, it is significantly cheaper;

- absence of temperature drops across localization zones.

Negative sides:

- the cost of organizing the system. Constant fuel filling;

- fuel cost.

Dignity

Let's consider the main advantages of fireplaces with convection heating, and then move on to the device. Heating systems with air circulation have a whole list of advantages over a classic fireplace, we will highlight only the most significant of them.

Household heat distribution diagram

- Heat transfer by means of radiation is completely stopped when the fireplace is stopped. When a fireplace with a convection heating principle goes out, the air continues to circulate for a while, heating all rooms. This fact contributes to fuel economy and efficiency increase.

- Due to the fact that air is used to heat the house, it is possible to increase the efficiency of the fireplace due to additional heat exchange not only in the area of the firebox, but also in the chimney.

- Air circulation implies the flow of new portions from the outside. This provides additional ventilation in the room.

- Compared to water heating, where the transfer of energy is carried out in two stages, the air heating circuit directly transports the heat carrier, which will fill the room.

- The presence of fans, which are involved in the circulation of the coolant, increases the length of the ducts with air ducts up to 10 meters.

It is necessary to think about the possibility of installing a fireplace when erecting walls.Firstly, the construction of the foundation for the fireplace is easier to carry out when there is no floor covering yet, and secondly, the routing of the air ducts requires partial destruction of the walls. During their construction, you can immediately supply the rooms with channels.

The device of a classic brick fireplace

Strictly speaking, open hearths are not very suitable for heating private cottages due to the low efficiency of burning firewood, the efficiency is only 20-30%. While the fire is burning in the firebox, heat is spread throughout the room by means of infrared radiation. After damping, the intensity of heating decreases and stops after 2-3 hours, when the brickwork has cooled down.

Despite the low heat dissipation rates, fireplaces remain attractive to homeowners as they create a unique home-like environment. The device of a classic English hearth is shown in the diagram and includes the following elements:

- underground part - foundation;

- base of 2-3 rows of bricks;

- bottom part with forward-protruding furnace platform;

- portal - brick framing of an open firebox;

- smoke collector - an upward-tapering channel in the form of an umbrella above the combustion chamber;

- the chimney tooth at the beginning of the smoke collector serves for better heat extraction from hot gases;

- chimney leading to the roof;

- traction force is regulated by a gate valve.

Diagram of the device of a classic open hearth

If the construction budget allows, then outside, the walls are tiled, as is done above in the photo. It is not necessary to decorate the walls of the structure - the correct brickwork looks quite neat.

Interesting: Marble portals for fireplaces - learning from all sides

Principle of operation

Factory models of heating boilers for such fireplaces have a heat exchanger around the body in the form of a spiral or a radiator made of thin pipes through which water or air circulate. When heated, they flow through the heating pipes to the radiators in other rooms.

A wood-fired fireplace with a water circuit has a low efficiency, not exceeding 60%. In addition, simple models require a constant supply of firewood to efficiently supply the house with heat. Pellet fireplaces are relieved of these problems. They use pellets as fuel, which have a higher specific heat of combustion than wood. The pellet is automatically loaded from the back of the firebox. The intensity of the feed and, therefore, the power of the fireplace can be controlled using the electric control panel.

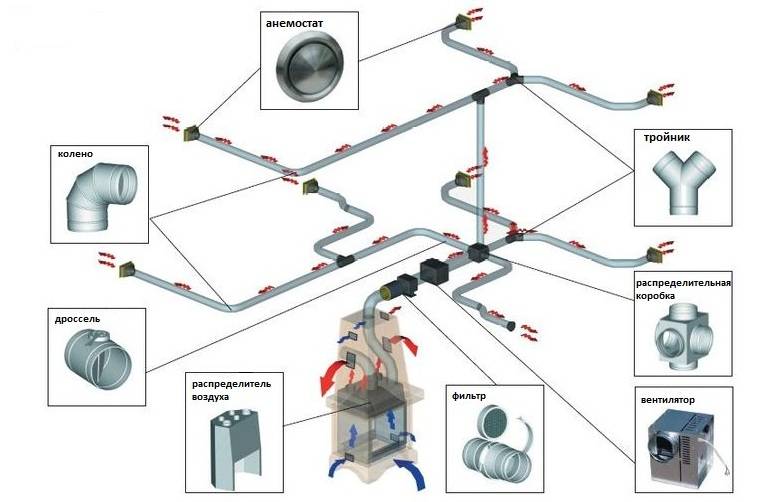

Fireplaces with an air duct can have an efficiency of up to 80%. Complex models can be designed with a heating function in the firebox and in the wall. This achieves maximum heating of the circulating air. Unlike water circuits, air systems require fans, which requires additional wiring and more energy consumption. But on the other hand, pipes for them are less demanding on strength, most often they are made of thin and cheap aluminum.

For safety, most fireplaces with air and water circuits are equipped with a fireproof glass protective door. Heat penetrates the room through this glass due to infrared radiation. This eliminates the possibility of sparks entering the room, and the owners can enjoy the sight of a bright flame. A soot protection is provided to keep the glass shutter clean.

Air ducts - device features

As well as for laying the firebox, brick or metal is used when arranging the ducts of the air duct system. You can also use special flexible pipes, which can be bought here, but they are recommended only for short sections, as they interfere with the movement of air.Failure to comply with this condition will require the installation of more powerful fans, which will increase the cost of your fireplace.

Do not forget about the thermal insulation of the channels. This will not only reduce heat loss, but also increase the safety of the entire structure. For high-quality air movement (minimizing air resistance):

- provides the most even surface of the inner part of the channels;

- the number of bends in the system is reduced;

- large straight channels are laid;

- a fireplace with an air duct is connected by separate channels.

Thus, a fireplace with combined heating allows you to quickly heat the premises of the house, has a simple device, is safe and has a low price. However, you will have to work a little in the field of cleaning the chimney and firebox, to attend to the arrangement of the place for storing firewood.

Features of the stove device

Refractory brick dimensions

It has been proven above that air circulation is much more efficient than traditional fireplace heating. High efficiency rates are maintained due to the special design of the stove. It is worth noting that gas fireplaces differ little in the design of stoves.

A cassette fireplace is the most demanding design for the correct arrangement of the stove. For its arrangement, builders use only refractory bricks or metal structures made of cast iron.

Cast iron stoves are considered the most heat-intensive and efficient heating devices.

Fans are located above the stove. Practice has shown that heating the house with a fireplace depends on their reliability. Therefore, experts recommend choosing only fire-resistant fans if you plan to install them yourself.

As for decorative elements, their presence is optional for a private house. Nevertheless, summer residents are actively buying fireboxes with decorative elements with glass doors, modern opening mechanisms, etc.

When choosing a stove for a fireplace in a country house, special attention should be paid to the power of the device, which can be determined in the technical passport. The power of the stove grows with its size

Experts came to the conclusion that it is better to buy stoves 10-15% more powerful than the equipment requires.

The scheme of heating the air in the fireplace

Separately, it is necessary to note the closed stove. The closable structure additionally increases the power of the entire structure due to smoldering, which is provided by a closed door. As a result, not only the power of the equipment increases, but also the economy of the consumed fuel increases due to the decrease in the air supply. Thus, a closed firebox is an efficient and economical equipment for space heating.

Which is better: a fireplace with a water circuit or with air ducts?

This question cannot be answered unequivocally. The advantages and disadvantages of both systems come from the characteristics of the heated room, the desired temperature regime in the rooms.

Heating fireplaces with a water circuit have the following advantages:

- efficiency;

- low cost;

- the contour of the fireplace can be easily integrated into the existing heating system of the house;

- the possibility of preparing hot water;

- low cost of equipment;

- low price of energy carrier.

A heating fireplace with a water circuit has disadvantages:

- low efficiency;

- the need for constant loading of the energy carrier;

- manual mechanism for adjusting the intensity of work.

If we compare fireplaces with open and closed combustion chambers, then the efficiency of the first is 20%, and the second is 70%.

A fireplace with air heating with your own hands is the easiest to make, because the equipment is not distinguished by a complex device. The very layout of the air ducts is also easy to organize. The room temperature is reached within a few minutes.

Disadvantages of a fireplace heating system with air ducts:

- constant circulation of dust in the house due to the operation of fans (in the case of forced air circulation);

- increased noise level due to air movement along the air ducts;

- the temperature in the room drops as quickly as it rose after the extinction of the fireplace;

- low efficiency;

- the need for manual control of the combustion reaction;

- the need for constant loading of the energy carrier into the furnace.

Heating a house with a fireplace with a water circuit and air ducts can be an excellent alternative source of heat, but not the main one. Such heating elements run on an inexpensive energy source. But fireplaces can be afforded by those people who are not too lazy to constantly throw firewood into the firebox, control the intensity of their combustion and periodically clean the chimneys.

Combined heating

Combined heating is said when the fireplace gives off heat not only by radiation from the flame, but also from heating the air inside itself. If everything is clear with the heat from the flame, then what is meant by heating the air in the fireplace?

In this case, the increase in air temperature is carried out in special channels located between the furnace cavity and the facing material of its walls. Warm air enters the room through the channels in the walls or ceiling. In order to avoid mixing it with combustion products, the latter are discharged through the chimney.

Heated air can enter the air ducts in the walls:

- By natural convection. It is achieved due to the difference in the density of cold air and warm air.

- Forced convection. In this case, air is pumped into the ducts using fans.

With the help of control systems, it is possible to control the power of these fans and, as a result, the distribution of heat in the house.

The design of air ducts must be carried out in the process of working on a project at home. In this case, you can foresee a lot of nuances in the work of the future fireplace, including the type of fuel used.

The efficiency of the air duct system is based on some fundamentals that are known only to specialists, which are recommended to be consulted. So, the greatest efficiency from a fireplace can be achieved by the device of a simple channel system, its centralization.

Those who are worried about the cleanliness of the air in the house should be aware that it is best to use fresh air to operate the fireplace. Otherwise, the following unpleasant situation will develop: polluted air from the fireplace room will enter the heating system, and under the influence of high temperatures it will return back in an even worse condition.

The scheme of the fireplace with air heating

Project number 1 - compact mini-fireplace

This hearth is suitable for heating a room of 16-20 m² in the country or a small country house. Another option for using the structure is as a street barbecue built in a garden gazebo. A feature of the fireplace is the side convection ducts that heat the air in the room. The size of the building is 102 x 51 cm.

To lay out a mini-fireplace, you will need the following materials:

- solid ceramic bricks - 240 pcs. (chimney is not included);

- revision door 24 x 14 cm - 1 pc .;

- cast iron grates 18 x 14 cm;

- latch 25 x 14 cm;

- stainless steel sheet 1 mm thick, size 500 x 1000 mm;

- a sheet of black or galvanized metal, laid in front of the firebox, dimensions - 70 x 50 cm.

Sectional drawing of a mini-fireplace. Convection channel outlets are provided on the side walls

The mini-fireplace shown in the drawing is laid out in this order:

- The first tier is solid. On the second, 3 air channels are laid - 2 side and one in the middle, located under the grate.

- On the third row, the bottom part and the nest of the grate are formed (made 5 mm wider than the product). Then the grate itself is placed.

- From the 4th to the 10th tier, a fireplace insert is being built.On the V row, 2 metal rods Ø5 mm are laid for mounting a stainless steel sheet.

- In the 10th row, the rear brick protrudes a quarter into the firebox, the side stones move outward by 40 mm. The width of the firebox in this place is 49 cm.

- The ends of the side stones of the 11th tier are sawn at an angle of 28 ° to the vertical line. You will get the support platforms of the arched vault. 2 stones in the depth of the firebox are placed on the edge.

- The vault is constructed of 9 stones, cut in the form of a trapezoid, with base sizes of 65 and 52 mm, as indicated in the order. The radius of the circle is 51 cm.

- On the 12th tier, the formation of the vault is completed, the upper steel rods are placed and a stainless steel screen is installed.

- Tier 13-14 forms the outlet openings of the convection channels. The inspection door is installed here.

- 15th row - the overlap is being built, 16-18 - the beginning of the chimney.

The master will tell in detail the algorithm for laying a mini-fireplace in his video:

Project # 2 - simple heating fireplace

The dimensions of this structure are 112 x 65 cm, height - 2020 mm. The inner size of the portal is 52 x 49 cm. Accelerated heating of the room is provided due to the convective air channel. The building materials kit looks like this:

- clay corpulent brick - 345 pcs.;

- chimney valve - 250 x 130 mm;

- 2 steel equal angles 45 mm wide and 70 cm long;

- metal sheet 500 x 700 mm.

A feature of the masonry of the fireplace shown in the diagram is the setting of a large number of bricks at the base on the edge. Above, a narrow long channel is arranged, where the heated air of the room moves. Let's move on to the construction algorithm:

- The first tier is solid, consisting of bricks placed on the bottom. On the second tier, a heating duct with a section of 65 mm is formed, on the third tier the base of the firebox is laid.

- From the 4th to the 9th rows, the walls of the portal are being erected. The air duct moves to the inside of the rear wall of the fireplace. On the 9th tier, corners are placed - floor supports.

- Tier 10 - overlapping the firebox. On the 11th row, the front stones are extended by 130 mm, the 12th tier is a mantel. The convective channel is divided into 2 narrow shafts.

- Rows 13-25 make up the smoke box. The heating channel ends in the 14th tier.

- Row No. 26 closes the flue, which tapers to a chimney. The gate valve is installed on the 27th tier.

- The remaining rows 28-31 form the beginning of the chimney.

The technique of the trial kindling of the fireplace is demonstrated in the last video:

Masonry

Layout of rows for a corner fireplace

Cover the dried-up foundation with a double layer of roofing material. This will provide the necessary protection for the foundation.

Prepare masonry mortar. Traditionally, fireplaces are laid out using a pre-soaked clay mortar.

The first row of masonry is best done using a mortar with a small addition of cement (approximately 10-20% of the total mass of the mixture).

Calibrate the bricks in advance by selecting the most suitable sized products for the masonry of each row.

Immerse the bricks in water for a while before laying. This will allow the items to become saturated with moisture. Otherwise, the bricks will take water from the clay mortar, which will lead to a significant deterioration in the quality of the masonry.

Lay out the first row of bricks with an edge. Check the alignment of the row with a square and a level. Make sure the opposite sides and diagonals of the base are the same length.

The recommended seam thickness is up to 0.5 cm.

The laying is carried out in accordance with the order. The following will be a sequence of actions that are relevant for most existing types of fireplaces. For the rest, be guided by the drawings you have.

Fireplace laying, step by step instructions

Lay out three continuous rows of the base.

Fireplace laying, step by step instructions

Second step

Lay out 4-5 rows with an ash pan arrangement.

Fireplace laying, step by step instructions

Third step

Lay out 6-7 rows with the arrangement of the bottom and frame of the brick fireplace.

Fireplace laying, step-by-step instructions Fireplace laying, step-by-step instructions Fireplace laying, step-by-step instructions

Fifth step

Lay out rows 14-19 with the arrangement of the smoke box.

Fireplace laying, step by step instructions Fireplace laying, step by step instructions Fireplace laying, step by step instructions Fireplace laying, step by step instructions

Sixth step

Lay out 20-25 rows of fireplace with chimney arrangement.

Arrange the basement and continuous rows of masonry using a trowel or trowel. The chimney and fuel chamber are laid out manually, because

at these stages it is very important to control the quality of the solution used

Apply the masonry mortar to the middle of the bricks. The edges of the elements must remain free.

When laying out each row, adhere to the selected order. For more convenience, you can number the products.

Pay special attention to the quality of the masonry of the fuel compartment and flue ducts - these elements must be laid out as evenly and as tightly as possible. Fireplace laying, step by step instructions Fireplace laying, step by step instructions Fireplace laying, step by step instructions Fireplace laying, step by step instructions

Fireplace laying, step by step instructions Fireplace laying, step by step instructions Fireplace laying, step by step instructions Fireplace laying, step by step instructions

To form a beautiful curved vault, gradually overlap the masonry elements.

It is important that the size of the overlap does not exceed 50-60 mm in each row.

Arrangement of curved lintels is performed using temporary formwork - circled. To fix such a formwork, use the supports under the equipped fireplace arch.

Start with a brick in the center and work symmetrically in both directions.

Periodically check the verticality of the flue pipe. Even the slightest deviations from the vertical can lead to the appearance of smoke in the room.

Fireplace laying, step by step instructions

For laying the chimney, use a mortar with the addition of cement, similar to the mixture used to lay out the fireplace base.

The chimney must be covered with a layer of fireproof insulation to increase fire safety. Insulation is installed in the places where pipes pass through the structures of the house (floors, roofs, etc.). The most commonly used insulation materials are asbestos.

Fireplace chimney

Types of fireplaces by material of manufacture

For the device of aquacamins, brick, natural stone, ceramics, cast iron, steel sheet, basalt fiber insulation, heat-resistant glass are used.

Brick

The fireplace stove can be custom designed for almost any configuration. Tiling will emphasize the individuality of the interior. As a rule, high quality working bricks (refractory) are used in such fireplaces.

Requires careful adherence to technology, high-quality installation. Installed on a separate foundation. The high starting cost is justified by the increased comfort.

Metallic

The most profitable because of the optimal price / quality ratio. Low weight, affordable price, easy installation, various designs contribute to their widespread distribution.

Combined

They combine the comfort of an infrared fireplace heating, the heat capacity of a massive stove, and the functionality of a water heating system. Have the highest possible efficiency. They give away the accumulated heat for a long time after the fire has extinguished.

A combustion chamber with a heat exchanger is built in during the construction of a brick or stone facade of the fireplace. Since access for repairs will then be difficult, the cast-iron option is optimal. A separate foundation is required, therefore a durable ceramic chimney is recommended.

Determination of basic dimensions

The ratio of the size of the fireplace and the room

Perform the necessary preliminary calculations. Determine the volume of the room set aside for the construction of the fireplace. The opening of the firebox should be 1/50 of the volume of the room you calculated.

The height of the portal should be 2 times the depth of the firebox.

The dimensions and ratios shown are very important. If the depth of the firebox is greater than the permissible value, the fireplace will significantly lose heat transfer. Smoke will occur if the firebox is smaller.

Select the dimensions of the smoke holes taking into account the dimensions of the combustion area. The cross-sectional area of the chimney should be 10-15 times smaller than the area of the firebox.

The optimal diameter of round chimneys is 100-150 mm. The length of the chimney can be up to 500 cm or more.

Fireplace base

Fireplace foundation

The foundation structure will include metal corners. They will additionally increase the strength of the site and protect it from destruction during seasonal changes in the soil.

Dig a pit for arranging the foundation in accordance with the design dimensions.

Fill the bottom of the pit with a sand and gravel mixture. Tighten the pillow and place the metal corners on it. Double the corner so that during the laying process the most reliable and durable base was created. It is recommended to weld the corners so that they do not move in the future.

In this case, the corners must be mounted in such a way that the elements of the masonry installed in the future are located parallel to the interior partition mated with the fireplace (if this option is chosen for arranging the structure).

Lay bricks in the corners, fill the entire structure with cement mortar and carefully level it with a plaster float.

In terms of density, the solution should approximately correspond to the density of sour cream. With such a consistency, the solution will be able to penetrate into all the cracks in the masonry without leaving the seams.

Make sure the base is level. Use the same cement mortar to remove uneven surfaces. Leave the structure to dry for a couple of days.