Brick masonry fireplace

Fireplace construction work begins with laying the foundation. A separate foundation is laid under the fireplace. We make the dimensions of the basement area 6 cm larger than the basement of the fireplace.

Foundation

- Dig a hole for the foundation 10 cm larger than the dimensions of the finished foundation and up to 60 cm deep.

- At the bottom of the pit, fill up the crushed stone with a layer of up to 15 cm.

- Install wooden formwork and treat the inside with bitumen.

- Lay stones, broken bricks and rubble.

- Fill with a mortar made of cement and sand in a ratio of 1: 3. The solution must be thoroughly mixed and uniform.

- Level the completely poured foundation and make the horizontal control.

- Cover the foundation with foil and let stand for a week.

Fireplace masonry

Three days before starting work on the laying of the fireplace, you need to soak the clay by adding water in small portions so that the solution is not too thick. The quality of the masonry depends on the quality of the prepared solution. The finished clay pulp is poured into washed dried sand and thoroughly mixed to a thick jelly. Small sticks up to 15 mm thick are rolled from the finished mixture. With excellent quality of the solution, the sticks will not disintegrate and stick to the hands.

Calibrate the bricks carefully. Lay waterproofing on the finished foundation, it can be roofing material covered in two layers.

Everything is ready for work and you can start the main stage of work.

For laying the first row, add up to 30% of the bulk of Portland cement to the solution. The compiled order is kept next to them in order to periodically check the accuracy of the work. After laying the row and making a check to maintain the geometry of the planned structure, you need to put a mark in the project. The laying of a fireplace structure is a painstaking work, and such control will greatly simplify the task set before itself.

A trowel or trowel is used for laying continuous rows. It is better to lay the firebox and smoke box by hand. The seam thickness should not be more than 5 mm. Spread the mortar in the middle of the brick in such an amount that it does not go beyond the edges of the brick.

The laying of the firebox, smoke box and ducts is carried out with great care. Excess solution must be removed

It is very important to remember that these elements of the fireplace inside do not lend themselves to plaster.

For a beautiful high-quality masonry of a curved vault, you need to install a circle - a temporary formwork. Having laid the first brick in the middle of the vault, continue laying in both directions.

Chimney installation

check its verticality. wipe with a cloth soaked in liquid clay

It will be much easier to carry out work related to the installation of a chimney if you use special pipes in the chimney. These can be chimneys made of ceramic pipes, modular stainless steel, thin-walled structures made of acid-resistant and heat-resistant steel.

Installation of metal elements

During the installation of the fireplace structure, metal fittings are placed in the seams, leaving gaps of up to 8 mm. It is undesirable to lay a lot of metal elements in brickwork, but you will not be able to do without them at all. A fireplace insert and a view must be required.

The frames of the firebox and valves are not attached with anything, they adhere perfectly to the prepared solution. The valve is installed at a height of 2 meters.

Decorative finishing

grouting.

If, nevertheless, you have a desire to start decorating the fireplace, use special smooth or patterned tiles for cladding that can perfectly adhere to the hot surface of the fireplace.

Today, you can purchase portals from manufacturers of fireplaces made from natural materials of various qualities. It can be travertine, marble, stone. Ready-made portals will be able to adequately decorate the fireplace you have folded and give it even greater uniqueness and beauty.

An excellent addition to the fireplace will be a special fireplace set made of non-ferrous or cast iron forged metal. The sets always include tongs, a hook, a broom and a scoop. A beautiful and practical screen can protect the carpet spread by the fireplace from accidentally falling coal.

Corner fireplace: device specifics ↑

A corner fireplace is one of the most beautiful ways to heat a home. This is due to the fact that placing the fireplace in the corner is in itself very attractive, and if, at the same time, the opening of the firebox is symmetrically oriented relative to the angular axis formed by the walls of the room, then you cannot think of a better option for creating an original look of the house.

The corner fireplace looks organic against both the inner and outer walls. The main thing is to take into account the location of the future pipe. If the fireplace will be located against the inner wall above the drop roof, you should know that the chimney must be built above the ridge of the main roof.

The dimensions of the fireplace are chosen based on the area and volume of the heated room. But if you determine this parameter yourself, then there are numbers that must be taken into account without fail. For example, the height and width of the fireplace insert for a small fireplace is 2: 3 (height to width). The depth of the firebox is 1: 2 or 2: 3. These dimensions must be observed, because a shallower depth will cause smoke, and a larger one will reduce heat transfer.

The size of the smoke hole is selected in accordance with the area of the furnace opening, this value should be about 10 times less than it. To increase the heat transfer capacity, the rear wall of the firebox is tilted forward, starting from 1/3 of its height. A smoke collector is located above the firebox.

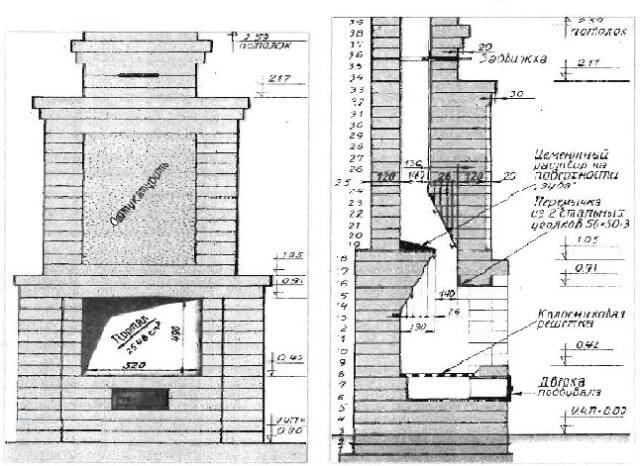

Intending to make a fireplace stove, order will be the main assistant for high-quality work. Ordering is a detailed diagram showing the position of each brick. Whatever you ask in the search for "ordering: fireplaces" or "ordering: stoves, fireplaces" almighty Google will provide you with the same information - ordering will accurately calculate the number of bricks, avoiding overpayments for materials.

Ordering a corner fireplace

Ordering a corner fireplace

Instructions for laying a brick fireplace

You should strictly adhere to the order of the fireplace with your own hands made of bricks, especially if you want to build it in the English style. The first thing to do is to insulate the wall adjacent to the fireplace with sheet metal or sturdy foil. All wooden elements are impregnated with fire retardants for interior work. In addition, a fireproof coating is laid on the floor, which is not afraid of sparks and embers.

Before starting construction, it is worth going through and sorting the bricks, setting aside the specimens with chips and cracks. Such defective bricks can be used for laying the base. Each stage of the masonry can be done first without mortar in order to grind and trim the bricks.

A simple ceramic brick must first be soaked, but fireclay - you can only wipe it off with a damp cloth. Then the solution will dry out more evenly.

For laying the base of the fireplace, a solid brick with an area of 1140 × 1270 mm is used, having laid out of it two rows with a dressing.Pre-check the horizontality of the foundation, and, if necessary, level the level with a masonry mortar, adjusting the thickness of the seam. At the same time, the solution is used cement-sand with proportions of 1: 2 or 1: 3. The next two rows are laid according to the scheme, but fireclay bricks and a heat-resistant mortar are already used for the bottom of the firebox. It is made from clay with sand, mixed so that the solution does not slip off the trowel, but does not stick to it either.

Next, the walls of the furnace are driven out. According to the ordering scheme, the inner walls of fireclay bricks are laid out on a clay mortar, and the outer walls are made of ceramic bricks on a cement-sand mixture or clay mortar with the addition of 20% cement. Diagonal cuts are made on the bricks in the rear corners of the firebox to improve heat transfer.

In the 12th row, as the masonry of the firebox is completed, a steel strip and corners are laid according to the scheme. In the back of the chamber, a brick is laid in a butt method, making cuts on it to obtain a vault.

During masonry from 13 to 16, the arch of the fireplace and the gas tooth are taken out, preventing the penetration of carbon monoxide into the room. In the 15th row, the chimney opening narrows so that an increased draft is formed. And then, in the 16th row, the chimney is made wider and a damper is built into it to clean the soot. The inner walls of the chimney are made of refractory bricks, and the outer walls are made of red ceramic.

Then you need to gradually, in strict accordance with the scheme, build a chimney with a pipe. All seams from the inside are carefully rubbed by hand and passed on top with a damp cloth to eliminate any roughness. Otherwise, soot will accumulate in such places.

At the very end, the chimney is laid, narrowing its lumen to 1 brick. In the 25th row, it is covered with a flap.

When the laying of the fireplace is completed, it is left to dry at room temperature for 2-5 days, and then slightly heated. In this way, the clay solution in the furnace is evenly heated and baked. Thanks to this, the masonry will become stronger and more durable. Only after that you can proceed to external finishing work.

How to make a fireplace with your own hands

Before starting work on laying a fireplace, it is imperative to decide on a design project, calculate all the required parameters, and record the results in the form of diagrams and drawings.

Useful article: Country house: layout and interior design. Photo

In order for all work to be successful and quickly enough, you need to determine: - the type and design of the future fireplace; - the place in the house where the fireplace will be located; - basic drawings and diagrams, according to which the work will be carried out; - basic building materials and tools.

Fireplace drawing with dimensions

Fireplace drawing with dimensions

Important requirements for the future fireplace: - It should not give off smoke and let smoke into the house. - The fireplace must be beautiful and provide aesthetic pleasure to the owners of the house. - It should give warmth and create a comfortable atmosphere in the room.

How to determine the location for the future fireplace

There are no specific rules for choosing a place for a fireplace. Traditionally, it is installed in the central room where relatives gather or greet guests. The fireplace can be built into the wall, located in the corner or act as a free-standing element of the interior. It all depends on the availability of free space and the tastes of the owner of the house.

Where to place the fireplace

Where to place the fireplace

However, there are a number of points that still need to be considered when installing a fireplace. It is never placed near a window, as this will lead to the fact that all the heat will go outside. Also, when choosing a place for a fireplace, take into account the presence of free space near it. It should not be located very close to furniture and other interior items, because even the smallest spark from an open fire can cause a very large fire.

7 secrets of proper operation

Fireplace starts by opening the chimney damper and checking the draft. At the slightest suspicion of reverse draft, clean the grates, air inlets and chimney.

If the fireplace has not been used for a long time, then the kindling begins with the removal of cold air from the chimney. To push out the air lock and create a positive pulling force in the chimney, it is enough to light a pile of straw or dry paper under the gas channel. You can start the fireplace only after making sure that there is a draft.

When choosing firewood, preference is given to aspen, birch, oak, beech, hornbeam. Aspen firewood not only forms a minimum amount of carbon deposits, but also helps to clean the channels from soot. Stove-makers recommend that every tenth firebox be carried out with aspen.

For kindling, it is convenient to use coniferous wood chips, pine or spruce cones, as well as shavings.

The firebox should not be loaded more than 1/3 of its volume.

This will create an optimal balance between the performance and economy of the wood-fired heat generator.

Particular attention should be paid to the flow of fresh air into the room. If the house has modern windows and doors, then it is necessary to provide a ventilation system.

With daily furnaces, soot is removed immediately after the end of the heating season

If the fire is lit only on weekends and holidays, then the service is carried out no more than once every three to four years.

Fireplace portal

There are two basic types of portal overlaps - straight and arched. The straight structure has the simplest form, but at the same time its installation is rightfully considered the most difficult. The main problem of arranging a direct overlap is the requirement for the accuracy of calculating the angle of the brick cut and the complexity of its laying.

The underfloor unit located at the bottom is usually made in the form of a rectangle or trapezoid. A mouth is formed directly above the furnace, into which all the smoke emitted during fuel combustion goes. A damper installed in the front of the chimney is used to regulate the smoke exhaust. At the front edge of the mouth there is an overlap, and behind it is a chimney tooth.

Arched portals, depending on their shape, are divided into three categories:

- Semicircular. In such structures, the radius of the arch is exactly half the width of the combustion chamber. Semicircular portals are considered the most reliable and simplest.

- Onion. The bending angle of bow arches is slightly less than that of semicircular arches, therefore this option is best suited for furnaces with a large width. In addition, the arched arch of the portal may well be used in situations where there is a need to limit the height of the combustion chamber.

- Straight.

The material used for masonry do-it-yourself fireplace

To build a fireplace you will need: red brick, rubble stone, clay, sand, cement and crushed stone. To build a fireplace that can be used for a really long time, you need to carefully choose a brick - by the piece. Brick for fireplaces should be perfect: no flaws, have a uniform structure of orange-red color, regular shape with smooth surfaces and right angles. Each brick must be checked by hitting it with a hammer - it should make a clear sound. If the brick has not been sufficiently heat treated, it will be lighter in color and its fracture is heterogeneous in structure. After being hit with a hammer, such a brick will emit a dull sound, which indicates poor-quality firing.

Burnt brick has a blue-black or dark gray color; traces of melting are visible on its surface. Hitting such a brick with a hammer will produce a high pitched sound. If there are white spots on the surface of the brick, they indicate a broken drying technology (it is overdried). The required number of bricks is about 200-300 pieces (depending on the size of the fireplace and excluding the chimney). Fireplaces and stoves are laid out using a binder solution consisting of clay, cement and sand. There is an opinion that wood-burning fireplaces last the longest if they use Cambrian clay (blue) when creating them. But red and even ordinary clay is quite suitable. If you are using refractory bricks, you will need refractory clay for the masonry.You will need from 0.2 to 0.5 m3 of clay (depending on its fat content). When creating a fireplace with your own hands, you need to take care of the cement. Packaged Portland cement grade 200 or 300 is quite suitable. Requirement: 70-100 kg (including foundation work).

Real Portland cement for fireplace masonry Sand for masonry mortar: fraction 0.2-1.5 mm, maximally cleaned of dirt and debris. Requirement: 0.7 m3 (including foundation work). Crushed stone of a fraction from 2 to 6 cm will be required - it will be needed for the construction of the fireplace foundation. Requirement: 0.2 m3. In addition to the basic materials, you will need: a smoke damper (it is also a stove valve), a grate, reinforcement rods (about 15-20 pieces, with a diameter of 8 to 10 mm, a length of 700 mm).

Finishing

It all depends on your desire, imagination and wallet. Classic fireplaces are decorated with columns.

Finishing material - marble. Pompous additions are welcome.

Tiles and glazed tiles are often used in Dutch fireplaces. But, if their style matches the general interior, you can beat any fireplace.

Decorating the fireplace with your own hands with wood creates a feeling of home comfort. Natural stone, on the other hand, makes the fireplace powerful, heavy, as from the scenery for the Viking sagas.

You can emphasize the seams and leave visible brickwork, in whole or in part. Brick is well suited for folk, rustic rooms.

Decorative plaster is the basis for many design ideas.

The marble can be wrapped in cellophane while it is being installed so as not to damage the surface.

Fireplace decoration with marble

Various elements of decor for fireplaces are specially sold:

- lattices;

- cast iron sculptures;

- forged elements;

- sets: broom, scoop, tongs and hook;

- stands and baskets for firewood.

All work is over. Now you need to be patient for a few days and let the fireplace dry properly. A test draft test is done by setting fire to crumpled newspapers. If the combustion is even and the smoke has gone in the right direction, then it can be heated with wood. Enjoy the cozy warmth.

Types of fireplaces and how to place them

Fireplaces are classified according to three parameters - shape, type of portal and size of the firebox. With a portal width of less than 51 cm, the fireplace is considered small, from 51 to 63 - medium, and all other devices are considered large.

Before making a fireplace with your own hands, you need to think about its placement, which can be done as follows:

- Central location. Quite an interesting, but not very popular option. Of course, a fireplace installed right in the center of the room with your own hands looks interesting and rather unusual, but the design will hinder free movement and take away a significant part of the free space. However, the desire to use the heat from the fireplace as efficiently as possible and create an interesting interior may well outweigh the obvious disadvantages.

- Placement near the wall. The most popular fireplace layout. Of the advantages of such a scheme, one can single out good heat transfer, saving free space and the ability to visually separate the recreation area from the rest of the room. The only drawback is that when installing a wall-mounted fireplace, you will have to pay maximum attention to the thermal insulation of the walls.

- Corner placement. Quite a convenient option for small rooms - a corner fireplace requires very little space. Despite the seeming modesty, the fireplace located in the corner will be a very good addition to the interior of the room. In addition, the ordering of such a fireplace is very simple, and the angular placement allows you to hide minor mistakes made during installation. Competent execution of finishing work will only contribute to the creation of a pleasant interior.

When deciding how to properly build a fireplace in a house in terms of its placement, the following recommendations should be considered:

- It is highly undesirable to install a fireplace directly opposite the front door - cold air entering through it will interfere with the normal circulation of heated air;

- If a draft constantly passes next to the fireplace, then it is better to look for another place to install the structure.

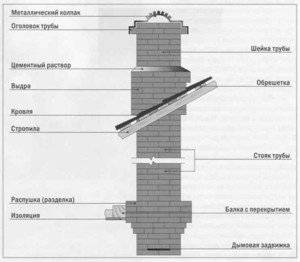

Chimney in a private house

The most traditional material used for chimney installation is brick. However, steel can also be used for these purposes - this item has practically no effect on the efficiency of the fireplace. There are solid ceramic chimneys on the market, but it is very difficult to work with them, therefore, it will not be possible to fold the fireplace with your own hands in case of such a choice.

When designing fireplaces with your own hands with a detailed description of their parameters, it is necessary to think over fire safety measures, which are to a large extent related to the design and location of the chimney:

- When installing a chimney, you need to take care of protecting the floors from high temperatures. Usually, asbestos material is used for protection, which is also suitable for insulating walls in the immediate vicinity of the fireplace.

- Insulating material (asbestos or sheet metal) must be installed under the base of the fireplace. To reliably protect the floor from flying sparks or firewood falling out of the firebox, the material must extend beyond the fireplace at least half a meter.

- The base itself must be strong and strong enough. If the fireplace is laid out of bricks, then its weight may well exceed 1 ton, so a separate foundation will be required for the structure. This is due not only to the total weight of the fireplace, but also to the shrinkage of the building, in which the fireplace should not move so that the tightness of the chimney is not broken.