Coniferous (pine, spruce) firewood

Application: for stoves (with strict adherence to safety precautions, since firewood sparks strongly, and coals can fall out of the firebox; regular cleaning of the chimney is also required); for a bath.

In our latitudes, spruces and pines are the most common conifers. Therefore, it is these breeds that are most often implied when you are offered a coniferous firewood machine. They are inexpensive, but do not rush to rejoice. They are far from ideal for kindling.

"Pros" of conifers

- They flare up quickly and give a lot of heat. Pine is superior in heat transfer to spruce due to its higher resin content. However, this wood forms more soot.

- Crackle pleasantly when burning. The characteristic crackle from burning conifers cannot be confused with anything. It creates a special comfort in the house, especially on cold evenings.

- They have a pleasant aroma. Conifers are valued for their unique aroma, which has a positive effect on the upper respiratory tract. It is better to add coniferous "relaxants" towards the end of the kindling.

"Cons" of conifers

- Burn out quickly. We often have to report firewood to the firebox.

- Smoked heavily when burning. Due to the high resin content, they form a lot of soot and soot.

- Creates a fire hazardous situation. Spruce "shoots" sparks, and pine - smokes.

Spruce has a fairly high radius of "fire" with sparks, so when lighting the fireplace, remove all flammable materials from the "affected area". Safety precautions should also be observed when melting the stove, because coals may fall out of the firebox.

Advantages and disadvantages

End-cut products are significantly more expensive compared to conventional wood, plastic and ceramic boards. This is due to the high cost of the components, because only durable types of wood and high-quality, healthy glue are used for the manufacture. The second reason for the increased price is manual and painstaking work. Each bar is individually ground and then carefully adjusted to the rest. Then the specialist treats the board with special mineral oil twice, each layer dries for 4-5 hours. Complete manual production of such a board takes at least 4 days.

A kitchen product can weigh several kg, and also has considerable dimensions. You can order a board according to individual measurements, but it is more convenient to use large-sized utensils, especially if you plan to cut meat and fish.

If we talk about the advantages of an end cutting board, then there are a lot of them:

- Due to the structure, wooden products of this type retain their original appearance longer and have increased wear resistance. The fact is that when gluing the wood fibers are parallel to the movements of the cutting tool. That is, the knife does not cut, but moves them apart. After cutting, most of the fibers will close back together. For this reason, the cuts on such a thing are practically invisible even after operation for several years.

- The manufacturers of these products only use durable woods that do not split when dropped. Unlike ordinary boards, often glued from thin boards, small chips do not fly from the surface when cutting or shredding. You can be sure that they will not get into food.

- At the end of production, each board is coated with mineral oil; during operation, the owner is also advised to treat the board with a special substance. This coating is necessary not only for aesthetic appearance, but also for water repellency. But even oil will not protect the product from dampness and mold if the item is kept in water for a long time or left on a wet surface. After use, the end board should be washed and wiped dry with a cloth.

- The wood fibers on a face-type product are closed back after using kitchen cutting tools on them.This property increases the resistance of things to infection by bacteria, their entry is blocked. Frequent oiling increases the hygiene of the board several times, the wood fibers swell and the substance clogs the micro-cuts. In addition, oiled wood darkens and hides knife marks.

- When the blade touches the surface of the end board, it pulls the fibers apart rather than cutting them. The edge of the kitchen appliance retains its cutting properties longer, the need for sharpening occurs less often. Therefore, professional chefs prefer butt-boards, which saves them time.

- The functionality of this product has not been lost over the years. It can be used for cutting meat, fish, minced meat, shredding vegetables and fruits, cutting noodles. Its appearance is so elegant that food can be served directly on it, such as Japanese cuisine or whole baked game.

- Ease of use — manufacturers attach legs to their product. They can be of any material, but they must be coated with a non-slip coating. This will protect the board from sliding and the owner from injury. If moisture gets under the thing, thanks to the legs, the product will not get damp from below.

- Many housewives find wood end cutting boards to be difficult to maintain. But, when purchasing end cutting boards made of oak, you just need to stock up on a bottle of mineral oil, you can also use linseed oil. It is recommended to apply it after each use of the board, first you need to rinse the wood and dry it.

Features of storing firewood

Any firewood requires proper storage.

First of all, it is important to correctly position and lay the woodpile, take into account the length of the firewood. The best option is not far from the entrance to the house, so that in winter it would be easier and faster to go for an armful of firewood

It is better to prepare firewood in the warm season. This will help them dry out faster and burn well. Try not to place the woodpile in low-lying, damp places. Even the most unpretentious and dry wood will become damp, start to rot and lose its properties.

If possible, the woodpile is recommended to be placed under a canopy or in a dry shed. This will prevent precipitation from entering the upper rows. For stability, you can lay the firewood on a small hill (for example, trellises) and secure it.

Recommendations

The first most important recommendation is this - do not use the following breeds:

- Conifers. These trees give off resin. What causes an unpleasant odor. And in the process of smoking, dishes can get this bitterness.

- Birch. There are certain proportions of tar in the composition of this wood. It significantly spoils the taste of food.

Other recommendations:

- Chip parameters. This factor affects the uniformity of the smoke enveloping in the smoking apparatus. It is not necessary to use chips of too small parameters. It burns out pretty quickly. And the products get a burning smell.

- The moisture content of the wood used is required: 60 - 70%. Wood that is too dry burns out very quickly and does not generate the required smoke. And the products are deprived of their fat - it is simply melted. As a result, the dishes are characterized by dryness and hardness.

- Do not use diseased wood. Often the tree is destroyed by fungus and mold. When burned, their vapors can penetrate into the food.

- Wood with bark should not be used for smoking. During combustion, harmful substances are formed from it. As a result, the dishes may turn out to be bitter.

Each tree species gives an original taste and aroma to smoked meats. Smokers are quick to navigate the types of wood chips used in smoking

Each tree species gives an original taste and aroma to smoked meats. Smokers are quick to navigate the types of wood chips used in smoking

How to store the cleaver correctly

Storing a cleaver is no different from storing an ordinary ax.

Branded models are paired with plastic or leather cases, which allows not only storage, but also safe transport of the instrument in the car and even public transport.

The metal part is coated with grease to prevent rust formation.

A tool with a large head can be safely coated with a thin layer of automotive oil.

For branded expensive models, a special ax lubricant is sold.

Do not store tools with a wooden ax in direct sunlight.

It is also not recommended to work in temperatures below -20.

It is best to store axes in rooms with moderate humidity.

Linden firewood

Application: for a bath (due to its healing aroma), for a fireplace, for cooking meat (especially pork and lamb).

Linden wood is a kind of curiosity. The wood is light with a pleasant light pinkish undertone and a homogeneous, non-fibrous texture. The material does not darken like aspen.

"Pluses" of linden

- Has a revitalizing scent. Linden steam has a beneficial effect on the respiratory system, helps in the prevention of flu and colds, improves skin tone. Charcoal meat gives a slightly sweet flavor.

- Gives an even heat without flare-ups. Gives off an even heat throughout the entire combustion process. This is ideal for heating steam rooms.

- Does not crack or spark. Gives a picturesque flame with tongues of lilac-greenish tide.

"Cons" of linden

- It flares up badly. To light a linden tree is troublesome. Even dry trunks are quite poorly seized by the flame. Therefore, you have to use thin splinters or chips, and then put small logs.

- Refers to low-heat rocks. The calorific value is only 2040 kcal / m3. This means that this firewood is definitely not for heating the house in cold weather.

- Burns out quickly. Due to its low density, the burning time of linden is average. It is not one of those rocks that you can put in a firebox and forget about the stove for half a day.

- Rotting. Stored for about 2 years. Requires a dry ventilated area.

Main characteristics

The cleaver is not in the full sense of the ax, but it is directly related to it.

The hand tool has a hatchet on which a wedge-shaped working part (head) is mounted without sharp sharpening.

The cleaver is designed for a single blow, after which the block will split into pieces.

It is not the sharpening of the blade that is important here, but the force of the blow.

Outwardly, the cleaver looks more like a sledgehammer than a classic ax.

One side of the head is flat (butt), and the opposite is wedge-shaped, made in the form of a two-sided cut at an angle of 40-50 degrees.

The weight of the cleaver reaches 5 kg, which allows him to cope even with large logs.

The meaning of this design lies not in cutting through the wood fibers, but in their delamination.

The thickness and length of the ax depends primarily on the size of the cleaver's head.

At the same time, the size of the handle directly affects the efficiency of the work, since a long hatchet paired with a heavy head concentrates a decent impact force on a small area.

Blade

As already mentioned, the cleaver blade is not sharp.

Depending on the shape, there are wedge-shaped (wedge-shaped) and eared options.

The second type, as the summer residents themselves note, is much inferior to the wedge-shaped cleaver in terms of convenience of work.

It is noted that the head, due to the presence of the "ears" set apart, often gets stuck in the logs, after which it is difficult to remove it.

The manufacturers themselves respond to this claim by the fact that such a design is designed to work with dry wood.

In reality, the owners of a private house use a tool to split raw, recently cut logs, which is incorrect.

The piercing edge is straight and rounded.

The first variant of the cleaver is suitable for working with large dry logs.

The rounded blade has a larger size, which makes it possible to cope with tarry and damp wood.

The cleaver's head is made by the following methods:

• Stamping

Medium carbon steel is used.

In most cases, forged cleavers weigh more than 2.5kg, and their center of gravity is concentrated in the head. This allows you to use such a tool for working with large logs.

• Casting

The blade is made of hardened steel and is usually smaller than the one mentioned above.

They are both straight and rounded.

Cast cleavers are more like an ax.

Handle

The wooden ax is a classic.

It has always been used, it will remain relevant for more than one decade.

Unlike metal, wood has the useful property of absorbing shock and vibration.

In addition, wooden handles are relatively cheap and easy to manufacture.

All this affects the cost of the instrument for the better.

However, among the minuses, it is worth noting the fact that the handle, with the wrong technique of working with the cleaver, splits.

An alternative to wood is fiberglass - a composite material with good strength indicators.

Some models are produced with a rubberized handle, thereby increasing the convenience of work.

At the same time, it is lightweight, which allows you to shift the center of gravity of the instrument towards the head.

The fiberglass handle is a suitable solution for heavy cleavers.

Hardness

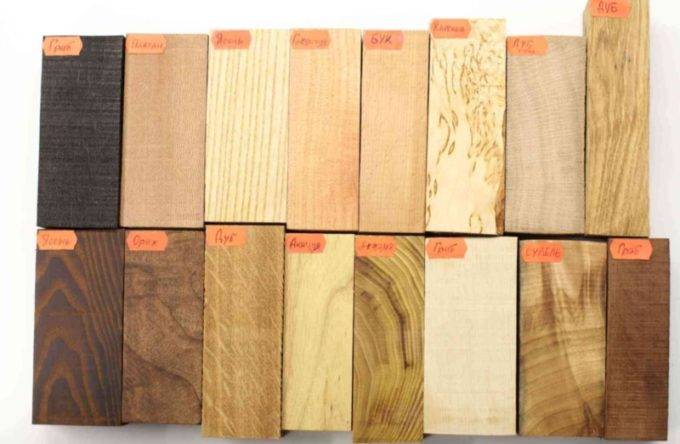

Hardness is the ability of wood to resist the penetration of harder bodies into it. The degree of hardness is influenced by the moisture content of the wood.

According to this parameter, all tree species at 12% moisture can be divided into three groups:

- soft - end hardness of 40 MPa or less (pine, spruce, cedar, fir, juniper, poplar, linden, aspen, alder, chestnut);

- hard - end hardness 40.1–80 MPa (larch, Siberian birch, beech, oak, elm, sycamore, mountain ash, maple, hazel, walnut, persimmon, apple, ash);

- very hard - end hardness more than 80 MPa (white acacia, iron birch, hornbeam, dogwood, boxwood, pistachio, yew).

Hardwoods are more durable than softwoods. This is essential when processing with cutting tools: milling, sawing. And also when installing floors, stairs, railings, since during operation the wood is subject to abrasion. In the production of parquet and parquet boards from solid wood, rocks with a hardness of at least average are used.

Valuable wood species

Valuable breeds have a wider purpose than ordinary ones. They have an interesting, beautiful texture, have a wide range of colors, original patterns, high density. The color scheme of wood is used by construction designers to create decorative interior items. Valuable breeds are much more expensive than building breeds due to the listed artistic qualities.

A rare and valuable species of wood is boxwood, which has a pleasant, yellow-gray wood color. It has great strength that can be compared to bone strength. Boxwood is used to make wooden parts of musical instruments, engraving boards, carvings, buttons. The engraving on boxwood turns out to be elegant and even, which has a positive effect on its quality.

In the distant 18th century, timber was imported to Russia from distant subtropical countries. The height of fashion was furniture made from mahogany mahogany, and the work was done by master cabinetmakers. This kind of furniture was used to furnish the chambers of the royal palaces, and later the dwellings of the wealthy nobility. The mahogany tree has a white sapwood and a contrasting red-brown core, which creates a very interesting combination and fertile ground for the manifestation of the artistic imagination of the masters.

Black ebony, which has a white sapwood and a glossy black core, was no less popular. Such colors of the wood created a unique artistic contrast, which was very attractive for master artists who made souvenirs and all kinds of decorative items. It was also used for the production of piano keys, woodwind instruments, inlay. The density of wood is 1000 kg per 1 cubic meter.

Domestic breeds are also valuable breeds. These are walnut, ash, oak, alder, cherry and others. The list can be continued with rare tree species growing in remote areas.These are sequoia, eucalyptus, yew, rosewood and others.

All these breeds are used for the manufacture of interior items, works of art, designer jewelry, which allows us to fill our life with positive energy, positive emotions and a sense of peace.

Timber and meat

Above were indicated suitable breeds for smoking fish, meat, etc. Some questions may arise here. For example:

- Are the breeds suitable for smoking pork and for boar or elk? Which one exactly?

- Can all birds be smoked using these breeds?

|

Meat and other products |

Apple tree |

Pear |

Cherry |

Apricot |

Plum |

Alder |

Beech |

Oak |

|

A fish |

+ |

+ |

+ |

H |

+ |

+ |

+ |

H |

|

Hen |

H |

+ |

+ |

+ |

+ |

H |

H |

+ |

|

Goose. Duck |

+ |

H |

+ |

+ |

+ |

+ |

H |

+ |

|

Pig. Boar. |

+ |

+ |

H |

+ |

+ |

H |

+ |

+ |

|

Cow |

H |

+ |

H |

+ |

+ |

H |

+ |

+ |

|

Ram |

H |

+ |

H |

+ |

+ |

H |

+ |

+ |

|

Elk. Deer |

H |

+ |

H |

+ |

+ |

+ |

+ |

+ |

|

Hare |

H |

H |

H |

H |

+ |

+ |

H |

H |

Hunters more often ask such questions than ordinary summer residents. The answers to them can be found in the table.

If the wood is suitable for smoking this or that meat, + is put in its column. If not suitable, N.

Some secret nuances of smoking

If you want to give the dish a steppe flavor, then add hay to the wood used, and put a little thyme on top of it. Smoked brisket and bacon are especially tasty.

You can add elegance to smoked poultry meat using prune and laurel leaves. The bay leaf must be noble (a variety of this plant).

You can enrich the taste of smoked pork thanks to pepper (both red and black are suitable) and lovage sprigs.

You yourself can experiment with different ingredients in order to create exquisite dishes. And you can have your own culinary secrets.

Heating with wood

They have been used by our ancestors for a long time.

Pros:

firewood quickly flares up and gives off heat, which makes the process of heating the room fast enough;

low cost, especially when the preparation of firewood for the winter is carried out independently;

not subject to mechanical damage;

well-dried firewood has a very high heat transfer;

when burning wood, beautiful tongues of flame appear, which is very important when the fireplace is operating;

in the process of burning firewood of different tree species, essential oils are released, which have a beneficial effect on the human nervous system and respiratory tract.

It is important to know: the best combustion product is two years old firewood, which was stored in the right conditions.

Minuses:

firewood, as well as fuel briquettes, require special storage conditions. They should be protected from the slightest ingress of moisture and ensure good ventilation of the room.

What determines the hardness of wood

Density is different for each wood species, but there are a number of common factors.

Even one tree can have varying degrees of strength if it grows in high or low humidity conditions.

Even one tree can have varying degrees of strength if it grows in high or low humidity conditions.

Factors affecting the degree of hardness of wood:

- the age of the breed, the older the wood, the higher the strength characteristics it has. A young tree is moist, and an old one dries up and becomes stronger;

- climate and geography of growth. Trees are stronger in colder climates because they grow extremely slowly;

- the way the tree was sawn. There are certain techniques for enhancing the strength when cutting;

- the area where the trunk is cut. The density of the bark is always higher than that of the core of the tree.

What is more profitable

So, a cubic meter of fuel briquettes costs about 6 thousand rubles, while the price for the same volume of wood is about 3,000 rubles. The price of firewood is approximate and directly depends on the number of wood species in each specific region.

Take a note: in the total mass of firewood, 20-30% is firewood that has been well dried for several years, up to 50% of raw firewood, 20-30% is stale firewood. While in fuel briquettes the mass of water is no more than 9%.

The difference in price between wood and briquettes can vary between 2-4 thousand rubles. Thus, the cost of briquettes is about 2-3 times more expensive than firewood.

In the course of numerous experiments and comparisons, the following facts were established:

- Fuel briquettes burn for 2 hours, while wood for 1 hour.

- The heat transfer of firewood is much higher than fuel briquettes, which is especially noticeable when approaching the stove (fireplace).

- Ash after briquettes is ¼ less than after firewood.

See the following video for a visual experiment on which is better: fuel briquettes or firewood:

Oak firewood

Application: for a fireplace, barbecue, less often for a bath and home heating (due to the high cost).

Only Russians can afford the luxury of stoking the stove with oak wood. All over the world, wood of this species is considered elite and is used mainly for the manufacture of furniture. A car of oak logs in the Moscow region will be expensive, but many believe that this is a reasonable expense. Especially when it comes to kindling a fireplace or open stoves for cooking.

Finding a specimen suitable for kindling is not easy. Young oak trees give little heat, and old ones form a lot of ash, emit a minimum of heat and make the air in the room heavy and stale. The ideal variant is “middle-aged” trees.

"Pros" of oak

- It has a maximum heating value. Oak wood is very durable, it burns for a long time and gives a strong heat. The coals smolder slowly. The amount of heat generated is 15% more than from birch and 35% more than from spruce. This reduces the consumption of logs.

- Stores well and for a long time. Oak is resistant to negative environmental influences. Does not deteriorate for a long time when stored outdoors.

- It has a pleasant and healthy aroma. The mild and slightly tart aroma of oak when burning has a positive effect on the nervous system, strengthens health and relaxes.

- Does not emit harmful substances when burning or decaying. There are no resins in the wood, and the firewood itself burns by 89%, emitting only carbon dioxide. Practically does not pollute the chimney.

The ability of oak wood to produce intense heat is both an advantage and a disadvantage. They release so much heat energy that not every stove can handle this load.

Coniferous firewood - pine, spruce, larch

Softwood contains a large amount of resin, which contributes to a fast and intense combustion with a lot of smoke and soot. Regular use of coniferous wood contributes to the formation of thick layers of soot on the walls of the chimney.

Coniferous firewood logs

That is why coniferous wood is practically not in demand for heating houses; it is used for kindling stoves in baths. The melted hearth with pine needles fills the steam room with a classic spruce aroma, which soothes the nerves and has a beneficial effect on the respiratory system. The forest coniferous aroma appears due to the essential oils present in the needles. When burned, spruce and pine firewood emits a characteristic crackling sound that many people like.

Note that burning coniferous firewood is difficult to extinguish, and the embers flying out of them make this wood the most fire hazardous. Therefore, it is best to heat a closed stove or fireplace with pine or spruce wood.

After analyzing all existing types of wood, you can easily find the best firewood for heating stoves in your home and baths. Use different types of trees, find the best solution for a specific situation. Enjoy the pleasant aroma, warmth and coziness that burning wood firewood gives you.

Coniferous wood is prized for its unique resinous aroma.

Spruce firewood is not as hot as pine wood - keep this in mind when harvesting.Larch firewood is used quite rarely - this type of wood is not so widespread in our country. But if you come across such logs, remember: when they burn, they form a lot of carbon monoxide, so in no case do not rush to close the damper and take care of good ventilation. By the way, soot and soot from resinous coniferous firewood will settle on the walls of the stove and chimney no less than from birch ones.

Areas of application of different types of wood

According to their purpose, all wooden building materials are subdivided into finishing and general construction materials. The latter are intended for the construction of enclosing and overlapping structures, as well as for other loaded elements of the building. Finishing materials are used to decorate surfaces.

It is clearly seen from the above information on wood species that they differ in their technical and operational characteristics. Therefore, almost always, when building a house, several types of wood are used, each of which is best suited for a specific area of construction.

- Pine is great for building enclosing structures.

- Spruce lumber is often used to make floor beams, elements of the rafter system, flooring, and ceiling sheathing.

The unique properties of larch even allow for the strengthening of the banks of reservoirs and the installation of walkways and berths

- Larch is used for laying the lower rims of the house, as it is highly moisture resistant. In addition, larch trunks are used for pile foundations, even for structures built on water, for example, bridges or piers, as well as for strengthening the banks of reservoirs.

- Oak is most often used for the manufacture of windows, doors and openings. In addition, oak can be used for interior wall decoration, as well as for flooring.

- Maple, linden and alder are used for joinery and carvings because of their soft structure. For example, this wood is used for the manufacture of platbands or carved cornice trim.

- Birch or alder are used for interior decoration. The textured pattern and color shades of alder wood allows it to be used to imitate more valuable wood species.

CORRECT BOILER FURNACE

There are several simple rules that must be followed in order to achieve maximum efficiency and proper operation of the heater:

- Whatever fuel is used, the firewood should be at least half of the bookmark.

- The gas-fired boiler must not be heated with insufficiently dry wood. The maximum humidity level is 20-30%. If they are damp, this will lead to a decrease in the combustion temperature, as well as a drop in the level of efficiency by 2-3 times.

- The efficiency that the boiler is able to achieve decreases if the filling is incomplete. It is not recommended to lay the heater in less than half way, as as a result the wood does not burn out completely and there is an increased formation of soot and soot. As a result, the chimney and heater will have to be cleaned much more often.

- The correct length of logs is 25-35 centimeters. Firewood can be bought in bulk or by weight.

Cleaver rules

Having even the most expensive branded cleaver at hand, you will not be able to work effectively without experience.

However, at first, the following tips will help to some extent cope with this problem:

• The widest log with an even cutting area serves as a support for the logs. Installed in a stable vertical position.

• To make it easier to work, you need to wait until the freshly sawn wood chips are dry. Otherwise, the wood will be sticky, and this will lead to jamming of the tool. In winter, it is better to let the raw material freeze. So it will become loose.

• For rational fuel consumption, it is better to chop the lumps into pieces with a diameter of about 10 cm.

• Splitting large blocks in half the first time may not work. To save time, it is best to break off the pieces around the edge and then chop up the “core”.

• If there is a crack on the log, it is advisable to hit it with a cleaver. When working with knotty material, it is necessary to hit the tool either along one of the knots, or between them.

• An old cleaver with a wooden handle must first be soaked in water. The hatchet at the junction with the head will swell and securely fix, preventing the metal part from falling off during operation.

• The tool handle always has an extension at its end. This is done so that the hands do not slip when struck. The tool should be taken at the very extension in order to achieve maximum impact force due to the lever.

An instrument stuck in a deck can be removed in several ways:

• Loose.

• Hit the butt with a sledgehammer, which will split the wood.

• Swing the cleaver along with the chock, turn the tool in the air and hit the butt on the log-stand.

Due to the enormous force of the blow, working with a cleaver carries the risk of serious injury.

Following the simplest rules, you can significantly reduce or eliminate the risk:

• The block must be placed on the edge of the deck from the far side. In the event of a miss, the instrument will stick into the stand.

• Hold the cleaver by the edge of the handle, keeping your legs wide apart. Again, in the event of a miss, the blade will go into the ground and not into the leg.

• To avoid damping a blow with a deck - stand, it must be installed on a solid surface (asphalt, concrete).

• The work area must be free of foreign matter. It is better to remove already chopped logs from under your feet immediately.

• In the immediate vicinity of the workplace, the presence of people is unacceptable, since wood chips flying in all directions are traumatic.

The warmest firewood

The cheapest and hottest firewood is birch and alder. They give off a little less heat, while they have disinfectant properties and remove soot from the chimney

It is important to observe good traction so that tar does not form on the walls, since with poor air flow, the wood begins to smoke strongly

Conifers are used much less often, as they heavily clog the chimney. They are best suited for kindling baths, rather than permanent use. They are also distinguished by their fire hazard due to “shooting” coals.

The maximum heat transfer can be achieved by combining two types of hard rock. For example, birch and alder. These warmest woods allow you not to clog the chimney and effectively heat the room.

Wood properties

In most breeds, the core, in comparison with sapwood, has a greater mechanical strength, a darker color.

The sapwood has a high moisture content compared to the heartwood, and is less resistant to decay and insect damage.

Many conifers (pine, spruce, larch, cedar, etc.) have resin passages, which are thin channels in the wood filled with resin. They are absent in fir, juniper, yew. The resin increases the resistance of the wood to decay.

In accordance with GOST 20022.2-80, the classification of wood is established by resistance to decay and impregnation with protective agents, the speed of re-preservation and vulnerability of protected objects, as well as the classification of wood protective agents.

According to their resistance to decay, wood species (Table 1) are subdivided into 4 classes: resistant, medium-resistant, low-resistant and unstable, and the classification is carried out both by sapwood and by the core.

Table 1. Resistance of wood to decay

Class

Wood species

Sapwood

Core

Persistent

Scots pine, ash

Siberian cedar pine, Scots pine, larch, oak, ash

Medium resistant

Spruce, Siberian cedar pine, larch, fir

Spruce, fir, beech

Low resistant

Birch, beech, elm, hornbeam, oak, maple

Elm, maple

Unstable

Linden, alder, aspen

Birch, linden, aspen, alder

By impregnation with protective agents, wood species (Table 2) are subdivided into the following groups: easily impregnated, moderately impregnated, difficult to impregnate.

Table 2. Impregnation of wood with protective agents

Class

Wood species

Wood species

Sapwood

Core

Easily soaked

Scots pine, birch, beech

_

Moderately soaked

Siberian cedar pine, European larch, hornbeam, oak, maple, linden, alder, aspen

Siberian cedar pine, common pine, aspen, alder

Difficult to soak

Spruce, Siberian larch, fir

Spruce, European larch, Siberian larch, fir, birch, oak, elm, beech, ash