Classification of modern chimneys

In a wooden private house, you can install all types and models of modern chimneys, which are made from different raw materials. They may be:

- Brick.

- Steel.

- Ceramic.

Let us single out coaxial chimneys in a separate class, operating on a completely different principle.

Brick construction

It would seem that the choice depends on the preferences of the owner of the wooden house. But experts say that this is taken into account in the last place. The main selection criterion is the type of heating boiler, stove or fireplace.

When choosing, you need to take into account:

- Heating equipment power.

- Combustion products temperature.

- Smoke flow pressure.

- Possibility of condensation forming inside the pipe.

- The material from which the chimney is made. This is important in terms of the potential for soot to ignite.

- Fuel used in the boiler and the amount of corrosive substances generated.

- Construction type.

Brick chimney

This is a traditional design that has long proven its superiority over others. But here's the amazing thing - a brick chimney does an excellent job with high temperatures. And if the soot inside him suddenly ignites, then nothing will happen to him - he will withstand such a load without problems. Therefore, experts recommend using this type of device for solid fuel boilers that produce combustion products with a high temperature.

But it is not worth using it in heating boilers operating at low temperatures. This is due to the fact that condensation will begin to form in the brick chimney. It will quickly destroy an ordinary brick, so its service life in this case will not be very high.

Often, solid fuel boilers are changed to gas boilers if gasification has been carried out in a suburban village. This is a real success for the residents of the village, but for the chimney it is a big disadvantage. Do you really have to break a brick device? In no case! There is a way out of this situation. It is necessary to make a steel liner in the form of a chimney and insert it inside the brick pipe.

Steel and ceramic chimneys

Curious novelty

A chimney made of ceramics or steel is an excellent solution for flue gas removal for boilers with low power. Both materials perfectly cope with the duties assigned to them, have a presentable appearance and high strength characteristics. True, a ceramic pipe is several times more expensive.

It should be noted the steel version. He is very popular today. It is a design with low weight, low price and easy installation. So in all respects it is superior to the rest of the options today.

Device and principle of operation

Chimneys for fireplaces or stoves are channels through which a mixture of gases, which are products of fuel combustion, is removed from the furnace of a heater into the atmosphere. The design of these elements of the heating system is made in the form of a pipe or a brick shaft, the tightness of which determines whether the system works correctly. Chimneys for fireplaces and stoves are necessary, since without them it is impossible to operate heat-generating devices, the work of which is as follows:

The scheme of work and air circulation in the fireplace

The scheme of work and air circulation in the fireplace

- Fuel is placed in the firebox of heat-generating equipment (stove, fireplace, boiler). Basically, the devices operate on wood, gas, compressed or coal, fuel oil.

- The fuel is ignited using an open flame source, as a result of which the system generates a large amount of heat, which is used to maintain the optimal temperature in the room, and smoke.

- Smoke, which is a product of fuel combustion, consists of a mixture of carbon dioxide and carbon monoxide, ash, soot, and other corrosive chemicals.The temperature of the smoke entering the chimneys for fireplaces or stoves reaches 400-500 degrees, therefore, obeying the law of convection, it rises up, making room in the firebox for cooler air.

- The design of the smoke exhaust ducts is a vertical sealed shaft through which hot smoke rises only upward. Thanks to this process, fresh air, saturated with oxygen, is supplied to the furnace, which is necessary to maintain combustion.

In order to correctly make a smoke exhaust duct for a stove or fireplace, you need to carefully study the information on the heating device specified in the instructions, as well as calculate the volume of gas in the firebox. It is quite difficult to mount a chimney for a fireplace with your own hands, since this complex design requires special knowledge and experience that only experienced craftsmen can boast of.

Device

The device of a metal chimney is practically no different from the previous two types. The only difference is that there is no need for the organization of the chimney ducts, since the chimney is installed directly on the stove. Also, top-mounted chimneys do not need a foundation.

In order to achieve the best results in the construction of this type of chimney, you can use the following tips:

- the chimney must be brought out so that it is as close as possible to the ridge of the roof;

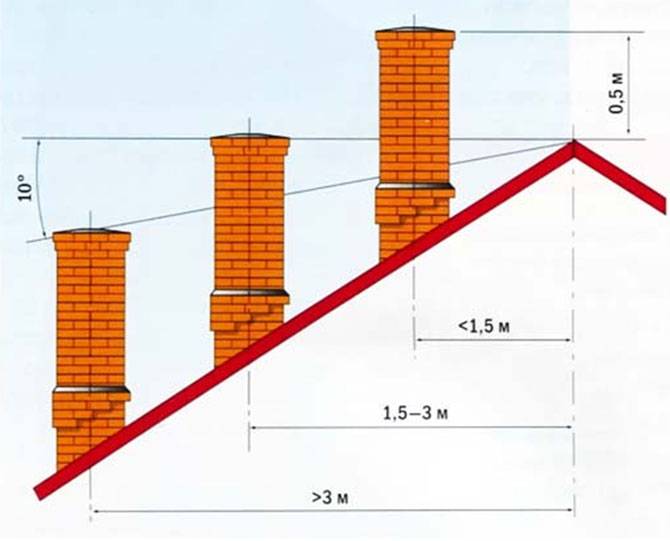

- the height of the chimney above the roof is selected based on the distance to the ridge. The optimum pipe height can be determined from the following diagram:

- if the distance from the ridge is less than 1.5 meters, the height of the chimney above the roof must be 50 cm;

-when the distance to the ridge is from 1.5 to 3 m, the chimney can be brought out to the height of the ridge;

- if the distance to the ridge is more than 3 m, the chimney may be below the level of the ridge. - In the case of close placement of trees or wooden buildings, the chimney pipe is wrapped with a ceramic chimney pipe. This is necessary to reduce the likelihood of a fire;

- the chimney must end with a visor that protects the pipe from precipitation;

- there must be a mesh at the end of the chimney, which is designed to prevent unburned fuel particles from escaping from the pipe.

LIKE, share with FRIENDS!

Subscribe -

How to make a chimney for a boiler?

We select the overall dimensions of the chimney

The gas boiler chosen for heating a private house must be available to you, only after that you will be able to choose the correct chimney for a gas boiler and calculate its dimensions (see Calculation of the chimney).

- It is advisable to use a circular cross-sectional shape. A rectangular section is also possible. The calculation of the useful area is made as follows: the inner perimeter is multiplied by the length of the chimney. The area of the entire useful section of the pipe must be larger than the internal area of the boiler. Read more about the calculations. What does useful section mean? For calculations, you need to use the inner diameter of the pipe used. If it is not specified by the manufacturer, then you need to subtract the wall thickness from the outer diameter of the pipe, thereby you get the inner diameter of the chimney for a gas boiler. It is this that you take in the further calculation. S = π * d internal * L, where L is the length (height) of the chimney.

-

The height of the chimney depends on its location relative to the ridge of the house.

The diagram shows all possible locations of the chimney relative to the ridge of the structure. Be careful when determining the height that the chimney should have for a gas boiler in a private house. Use the table below.

Chimney height, depending on the location relative to the ridge of the house

Table 1.

Chimney length variations

Having chosen the required diameter, length for the chimney pipe and calculating its useful area, it may turn out that this very area will be less than the internal area of the gas boiler.If you change the diameter of the pipe to the next one (all pipes are of standard diameters), then with the same length you will get an excess chimney area and, accordingly, an overrun of material.

What can be done in this situation? Increase the length by using a smaller pipe diameter. The table shows the minimum pipe heights. They can be increased, not decreased.

After calculating the overall dimensions of the chimney pipe and purchasing the necessary building materials, you can proceed with the installation.

Chimney construction rules in a private house

Each type of fuel has its own rules and norms for smoke removal and installation and repair of heating equipment. They are outlined in the official docs:

- SNiP 41-01-2003;

- NPB 252-98;

- VDPO.

It is necessary to strictly follow these standards in order to preserve the building from fire and the life of households from poisoning. During combustion, hot gases, ash and soot are formed, which must be removed through the pipe immediately. If the chimney in a private house is mounted incorrectly, then overheating of the walls or ceiling is possible.

The second danger is the ingress of carbon monoxide into the room. Carbon monoxide is odorless and colorless. It is heavier than air, so it concentrates closer to the floor. Causes death and poisoning if inhaled. Formed from lack of oxygen in the furnace (poor draft). The common name is "the silent killer".

Basic rules for the chimney device:

- The oven must stand on a platform independent of the structure. This is necessary so that in the event of a subsidence of the house foundation, the heating equipment does not "lead" and does not destroy.

- Combustible materials of walls, ceilings or roof slabs must be at least 38 cm away from the sandwich pipe wall. The space is filled with a heat insulator. Additionally, wooden structures are insulated with an asbestos or galvanized screen.

- The fewer the turns, the better the traction.

- The 90 degree turn is replaced by 2 x 45 degrees.

- The height of the pipe depends on the proximity of the ridge of the roof during the withdrawal. Near the ridge, the pipe is taken out 50 cm up. If the distance to the ridge is from 1.5 to 3 m, the pipe is sufficient for the ridge. When the distance of the pipe outlet from the ridge is more than 3 m, the calculation of the pipe height is based on the ratio of the angle between the ridge horizon and the top of the pipe. It should be 10 degrees.

Installation of a chimney in a private house as close as possible to the ridge is structurally more complicated than the outlet through the wall. However, this option allows you to mount an ideal chimney, without bends and horizontal sections, with the shortest pipe.

Chimney made of ceramic pipes - a universal solution for a boiler in a private house

Chimneys from special ceramic chimney pipes can be used for all types of boilers. The material is resistant to high temperatures and to any aggressive chemical compounds that can form in the chimney during the combustion of various types of fuel. This type of chimney is the most durable.

Chimneys from special ceramic chimney pipes can be used for all types of boilers. The material is resistant to high temperatures and to any aggressive chemical compounds that can form in the chimney during the combustion of various types of fuel. This type of chimney is the most durable.

Ceramic flue pipes are distinguished according to the maximum permissible flue gas temperature.

use pipes with a permissible flue gas temperature of 600-650 degrees C, resistant to combustion of soot deposits in the pipe and designed to work in a dry state.

For gas and oil fired boilers use ceramic chimney systems with a permissible gas temperature of 400-450 degrees C, intended for operation in a wet state - equipped with condensate drains.

The ceramic pipe and thermal insulation around it absorb moisture and therefore must be ventilated outside.

The purpose and operating conditions of the chimney system are specified in the manufacturer's attached documentation.

The smooth surface of the pipe and the round shape of the flue channel ensure that the walls are resistant to dirt and are easy to clean.

What is required from a chimney?

Its main task is to remove exhaust gases and smoke. The comfort of living and the safety of being inside a wooden house will depend on this.

The chimney must:

- Have great traction.

- Maintain a sufficient flue gas temperature.

- Possess high anti-corrosion properties. After all, condensation inside the pipe is a common thing.

- Have good resistance to aggressive chemicals.

- Have an ideal inner shape - a cylinder. In this case, the walls of the chimney should be smooth, which will reduce the need for cleaning. After all, soot will not settle on smooth walls.

At the same time, there are certain building codes. If you follow them, the installation of a chimney in a wooden house will be carried out with high quality.

Several important things

What else do you need to pay attention to?

- The diameter of the chimney is of great importance. It should be the same or slightly larger than the exhaust pipe on the heating boiler.

- If steel in the form of metal sheets is chosen as the material for the chimney, then, firstly, it should only be a high-alloy material. And, secondly, the thickness of the sheet must be at least 0.5 mm.

- Chimneys must have special cavities for soot deposition. Their depth is within 25 cm. In addition, it is necessary that these cavities can be easily cleaned of accumulated debris.

- The basis for the effective operation of the device is its maximum straightness. If bends are needed, then their number should not be more than three. In this case, the radius of curvature of the outlet should not exceed the diameter of the chimney itself.

- The minimum length of the exhaust pipe is 5 m.

These requirements should be met very clearly, since it is on them that the thrust and discharge of gases depend.

Chimney requirements and arrangement options

The task of the chimney is to remove fuel combustion products. This means that the structure will warm up to a very high temperature, while in contact with the aggressive chemicals generated during combustion. Another problem is condensation of water vapor, which inevitably appears due to temperature differences. Therefore, for the device of a fireplace chimney, the most durable materials are used, depending on which the following types of chimneys are distinguished: brick, steel, ceramic and glass.

Option # 1 - brick chimney

The brick chimney is made of brickwork. This is the least costly option for removing combustion products, but, alas, not the most effective. Brickwork is a rather laborious process. A special steel liner should be inserted inside such a chimney, which will improve the removal of smoke.

Previously, a brick chimney was just brickwork. Today, such a chimney is rarely arranged. If you see someone have a brick version, then most likely it is a steel chimney lined with brick

Option # 2 - steel chimney

The steel chimney is a round pipe made of stainless or galvanized steel, equipped with insulation and an external circuit. It is quite simple to install and has a relatively low physical weight.

A steel chimney for a fireplace consists of an inner and outer contour, between which a layer of insulation is laid. Such a chimney is very easy to install.

Galvanized pipe costs slightly less than stainless steel construction, but experts warn that such savings can lead to a situation where the "stingy pays twice." The loads during smoke removal are so high that when choosing which chimney will be better for the fireplace, it is more expedient to stay on a more expensive, but corrosion-resistant "stainless steel".

Option # 3 - ceramic chimney

Installation of such a structure requires some professional training and accuracy. The sophisticated design of the chimney for the fireplace provides excellent thermal insulation, as well as a long service life - about 30 years.

The ceramic chimney consists of three layers: an inner ceramic liner, an outer layer of lightweight concrete blocks and an insulating gasket that is placed between these layers

Option # 4 - glass chimney

Glass is the most expensive and complex option, but this design looks very impressive in the interior. Resistance to corrosion, heat and moisture are the undoubted "pluses" of glass chimneys.

A glass chimney for a fireplace is expensive, but it looks great in the interior and has excellent performance characteristics. It is better to entrust the installation of such a structure to professionals.

Another important aspect is good traction. For this, the chimney channel, if possible, should be strictly vertical, and its walls should be as smooth and absolutely sealed as possible.

Wall chimneys

General concepts

Such a chimney is a kind of part of the wall, that is, like ventilation, it passes through the inner wall space (see How to bring the chimney through the wall). If you plan to install a chimney for the fireplace, then you should choose this particular option.

When planning, it is important to consider that the wall must be made of red brick. Rarely, but sometimes it occurs when the walls are made of wood, but the place left for the chimney is faced with red brick

Wall chimney device

The chimney should not be installed at the intersection of walls or in the corners of a building. The chimney walls should be thicker than half a brick.

External wall chimney

To connect a fireplace or stove to a wall chimney, it is necessary to equip the so-called cross-over sleeves. In fact, these are elements of the chimney structure that have a horizontal direction and are part of a common smoke channel.

Such channels must be laid out of bricks. When constructing them, care must be taken to ensure that the sleeves are not longer than 2 m in length.

- To make these sleeves with your own hands, you will need 2 steel pieces in the form of corners. These corners must be sealed into the fireplace at the stage of its construction. The steel corners should be approximately 6.5 cm lower than the exit channel. The second ends of the corners must be sealed into the chimney itself, and in the pipe from the outlet channel they must be located at the same distance, that is, 6.5 cm.

- The corners should have either a strictly horizontal arrangement or a slight slope towards the smoke outlet. Usually, a width of 1 brick, that is, 6.5 cm, is enough, but you can make it wider. On these strips, the bottom of the sleeve should be laid out further. In this case, bricks can also be laid in one brick, that is, it should be laid flat.

- The walls of the sleeve can be as thick as a quarter of a brick, that is, the brick should be placed on the edge. Laying should be carried out with vertical ligation of the seams.

- The chimney device begins with the arrangement of the base, which, as a rule, is located either on the top of the fireplace itself, or on the floor.

- The foundation on the floor is a concrete poured area. This area should have a level surface. After that, the first row of bricks is placed on the clay mortar.

- In this case, the corners are displayed, that is, the corners are leveled. After this, further brick laying is carried out. Do not forget to arrange a hole in the chimney with a door to clean the chimney.

- In a wooden private house, the place in front of the fireplace or stove is sheathed with galvanized sheet steel. The same should be done with the chimney sleeves.

Device and principle of operation

It is clear that such a discharge channel will not have global differences from furnaces. The chimney, the channel for the fireplace stove also allows exhaust gases to be discharged into the atmosphere. The gases flow through the pipe according to the classical scheme, due to the generated traction. The chimney device for the fireplace should be carried out by a qualified worker who has the skills to work with such systems and can navigate the technical features of buildings and buildings.

For fireplaces, a boiler, it is important to completely remove the exhaust gas, and for this you need to correctly calculate the structure, form it, and it is also important to choose a really suitable material for these purposes

Correct design calculation will avoid heavy pollution of the chimney, the formation of soot, and the like.

Also, pay special attention to the fact that firewood is often used as fuel for fireplaces. And, as you know, it is from firewood that the greatest amount of soot and soot appears.

In just a few months, with ineffective work, reckless attitude towards cleaning, the channel can be clogged to such an extent that it will not be possible to heat normally. Back draft will be formed, there will be a weak removal of gases that will enter the room, what this leads to, there is no need to explain.

Chimneys from a variety of materials can differ not only in cost, which is primarily what a person pays attention to, but also in their technical and functional abilities. They may differ in design, so carefully analyze this issue, consult with specialists.

When choosing, you need to focus on individual characteristics, for example, what is supposed to be heated, what will be the outlet temperature, and the like.

Pay particular attention to the temperature in chimney chimneys, because draft is formed on its basis when interacting with cold air. The diameter of the pipe is also important.

Even with all human desire, it is physically impossible to build a channel that does not require cleaning.

Even the most sophisticated channels, over time, may encounter difficulty in removing gases. Carry out preventive, seasonal cleaning work, best of all during the period when the fireplace is idle

In addition, pay great attention to cracked walls, cracks, potholes, and the like. They are capable of violating the integrity of the channel, which is unsafe not only for the formation of traction, but also for human life.

Installation example of a steel chimney

Before making a steel chimney for a fireplace, some preparatory work needs to be done. First you need to install a fireplace insert. If special legs are not provided, you should make such a support yourself from metal, fireclay bricks, stone, etc. The distance from the firebox to the wall should be 150 mm, taking into account that the thickness of the thermal insulation layer will be 50 mm.

After the position of the firebox is determined, you should arm yourself with a plumb line and determine the axis of the outlet of the firebox smoke collector. The axis of the chimney must be completely aligned with it. The projection of the firebox on the adjoining wall and also on the floor should now be noted. If the firebox is placed on a metal support, the support should be covered with a layer of fireproof paint. Pieces of brick should be placed under the legs of the support so that its position corresponds to the level of the floor covering. A good idea for this kind of support is the adjustable legs.

It is possible to begin work on the installation of the chimney only after the firebox is placed in the place intended for it, and its position is carefully verified vertically and horizontally, and then fixed with a metal corner.

After the connection of the elements of the steel chimney for the fireplace is completed using sealant and rivets, the connection is wrapped with aluminum tape

Now you can start installing the chimney. First, seal all internal seams of the chimney with sealant. Then they begin to assemble its elements from the bottom up. A double layer of sealant is applied in a circle to the joints of the individual elements of the chimney. First, the inner contour is connected, and then the outer one. In this case, the upper element of the inner contour must go inside the lower element, and not vice versa. This will prevent condensation from entering the insulation. The outer contour is fixed with rivets, then the joints and rivets are glued with aluminum tape. In this case, it is necessary to ensure that the joints of the chimney elements do not fall under the thickness of the ceiling.

The correct fastening of the chimney deserves special attention. To fix the pipe, the outer contour is compressed with a special clamp, which is fixed with rivets. Then the clamp is fixed to the floor using a special angle and fixing bolts. In this case, the main weight of the chimney chimney should not fall on the base of the fireplace insert, but on the clamps and corners fixed to the ceilings.

After the connection of the elements of the steel chimney for the fireplace is completed using sealant and rivets, the connection is wrapped with aluminum tape

When attaching a steel chimney, take into account the possibility of thermal expansion of the metal when heated. To compensate for this process, a special flexible element should be installed at the bottom of the first section of the chimney chimney. If such a part is absent, it is necessary to provide for a play of about 1-1.5 cm when fixing the clamps at the corners to ensure the structure can move during thermal expansion. If the chimney contour is rigidly fixed, then during operation the lower section of the structure will be squeezed down, which can lead to damage to the equipment.

As they say, it is better to see once than hear a hundred times. Therefore, we provide a video with useful tips from an experienced stove-maker: