Gas boiler installation in combined kitchens

In modern construction, the arrangement of studio apartments or layouts is actively practiced, in which the living room and kitchen are combined into one large space. Of course, this solution has a lot of advantages - for example, a large part of the free space appears, perfect for the implementation of all kinds of design ideas.

The problem is that such layouts are regarded by gas services as residential, therefore the installation of any gas equipment in them is prohibited. In studios, this problem cannot be solved, but when combining a living room with a kitchen, options are possible.

The purpose of the boiler room

A boiler room in a private house is sometimes called "furnace" or "boiler room". A heat generator is installed in the room for heating and supplying residents with hot water. The units have one or two heating circuits. The first type of equipment is designed for heating, the second one combines both functions at once. useful article about gas heating of a private house prepared by our authors.

With equipment power up to 60 kW, it is not required to allocate a separate room for the boiler room. This is permitted by the regulation. The boiler can be placed in the kitchen if the ventilation, glazing and room dimensions are met.

More powerful heating units are installed in special rooms equipped according to SNiP requirements. It is advisable to entrust their design to professionals who take into account all regulations.

This is interesting: Do-it-yourself water drilling rig (video)

Wall-hung boiler installation

Wall-mounted units of low power may be placed outside a specially equipped boiler room, while they are prohibited from being mounted in residential premises and bathrooms.

It is convenient to mount a compact heating unit in the kitchen if it meets all the requirements

This room already has water supply, sewerage, electrical wiring, there is or will be a gas pipeline. In this case, you should pay attention to the following requirements for installing a wall-mounted gas boiler:

- the space under the boiler unit must remain free;

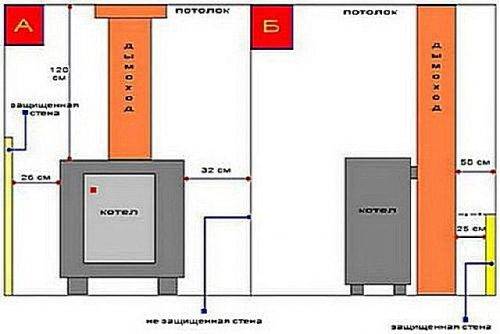

- a wooden or frame wall of the house must be protected with a screen made of non-combustible material;

- the distance from the rear wall of the boiler to the fireproof wall is from 2 cm, from the protective screen - from 3 cm;

- distance from side walls - 10 cm for non-flammable, 25 cm for unprotected hard-flammable and combustible.

Installation of a wall-mounted double-circuit gas appliance

Standard mounts are mounted on the wall, the boiler unit is hung on them. The chimney is connected to a pre-assembled chimney. Connect the power supply for the automation (the socket must be grounded). Connect the heating circuit pipes. Gas connection and commissioning are performed by specialists of the relevant service.

Installation of boilers in individual houses

The method of placing a heating boiler in a residential building depends on its design and can be floor-standing or wall-mounted. It should be noted that floor-standing models in most cases exceed hinged heat sources in terms of thermal power.

In addition, the freer circulation of the coolant in such devices allows their installation for operation in autonomous heating systems with natural circulation.

Installation of floor-standing boilers in a separate combustion room

If it is necessary to install a heat source with a capacity of more than 32 kW, gas boilers with a floor installation are chosen, since the thermal performance of serial mounted models does not exceed the named value. The developed standard furnace schemes for private houses provide for the presence of:

- expansion tank;

- domestic hot water heater;

- capacitive or high-speed separator;

- distribution comb;

- at least two circulation pumps.

In addition, it is required to install emergency relief lines and safety valves that are triggered when the pressure in the pipelines rises.

Boiler installation work begins with the preparation of brick or concrete foundations not only for it, but also for all tanks, which, after filling with water, will become quite heavy. After that, it is necessary to assemble the distribution manifolds and pumping units with shut-off valves, and fix them on the wall according to the design scheme.

Do I need a window in the boiler room of a private house according to the norms of the Republic of Belarus?

The need and size of the window in the boiler room of a private house are regulated by clause 21.12 of change No. 7 to the above sanitary norms and rules (SNiP) of the Republic of Belarus.

In a room with installed gas boilers for ventilation, it is imperative to provide an opening window that faces outside (onto the street) with a minimum area of 0.25 m2.

Important! For heating boilers with a coaxial chimney and a closed combustion chamber, the presence of a window in the combustion room is not necessary. Coaxial chimney for a gas boiler is made according to the principle of "pipe in pipe"

The double-circuit design allows you to forcibly remove the combustion products and suck in the required amount of atmospheric air into the closed combustion chamber of the heating device from the street

The coaxial chimney for a gas boiler is made according to the pipe-in-pipe principle. The double-circuit design allows you to forcibly remove the combustion products and suck in the required amount of atmospheric air into the closed combustion chamber of the heating device from the street.

You will learn more about how to correctly design the entrances to a private boiler room.

Rules and regulations for installing a gas boiler in a private house

The choice of the installation site for the gas boiler depends on its power:

- with a power of up to 60 kW, installation is possible in the kitchen (subject to certain requirements);

- from 60 kW to 150 kW - in a separate room, regardless of the floor (provided that natural gas is used, they can be installed in the basement and basement as well);

- from 150 kW to 350 kW - in a separate room on the first or basement floor, in an annex and in a detached building.

This does not mean that a 20 kW boiler cannot be installed in a separate boiler room. You can, if you want to collect all life support systems in one place. But there are requirements for the volume of premises. The minimum size of a boiler room in a private house must be:

- for boilers with a capacity of up to 30 kW, the minimum volume of the room (not area, but volume) should be 7.5 m3;

- from 30 to 60 kW - 13.5 m3;

- from 60 to 200 kW - 15 m3.

Only in the case of installing a gas boiler in the kitchen, other standards apply - the minimum volume is 15 cubic meters, and the ceiling height is at least 2.5 m.

Option for installing a wall-mounted gas boiler - up to the wall at least 10 cm

For each option of premises for a gas boiler room, certain requirements are imposed. Some of them are common:

Any boiler room in a private house must have natural light. Moreover, the area of the windows is normalized - at least 0.03 m2 of glazing should fall on 1 m3 of volume.

Please note - these are the dimensions of the glass. In addition, the window should be hinged, open outward.

There should be a window or a transom in the window - for emergency ventilation in the event of a gas leak.

Ventilation and removal of combustion products through the chimney is mandatory

The exhaust of a low-power boiler (up to 30 kW) can be discharged through the wall.

Any type of boiler room must be supplied with water (feed the system if necessary) and sewerage (coolant drain).

Another general requirement that appeared in the latest version of SNiP. When installing gas equipment for hot water supply and heating with a capacity of more than 60 kW, a gas control system is required, which, in the event of a trigger, will automatically stop the gas supply.

In the presence of a boiler and a heating boiler, when determining the size of the boiler room, their power is summed up

Further, the requirements differ depending on the type of boiler room.

This is interesting: The design of hanging rafters: we learn in detail

Chimney device standards ↑

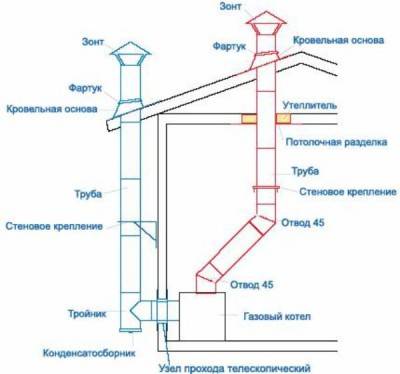

The material for the chimney is selected depending on the fuel to be combusted and the type of boiler.For a gas boiler, pipes must be cylindrical and made of metal, preferably stainless steel. Such chimneys are the safest, most durable and reliable.

The chimney is led out above the ridge of the house. A hatch for cleaning the chimney must be installed. In order to ensure the convenience of collecting soot during cleaning, collecting and draining condensate, an empty space is required under the chimney inlet.

Gas boiler chimney diagram

Gas boiler chimney diagram

When installing the chimney, there should be no more than three elbows and turns. The pipe connecting the boiler and chimney should be as short as possible, no more than 25 cm.

The vertical section at the outlet of the boiler must be equal to at least two diameters. Behind this vertical section, the pipe of the connecting section must necessarily rise upwards with a slope towards the boiler.

Smoke extraction in this case is carried out by natural draft through the chimney.

Compliance with all the requirements and rules for the installation of gas boilers will ensure their efficient operation, durability and fire safety.

Features of installing boilers in apartment buildings

To create an autonomous heating system, it is necessary to install a gas boiler in an apartment building, the requirements for it are almost the same. For autonomous systems of apartment buildings, turbocharged boilers with a closed combustion chamber are selected. References to SNiP, in which the installation of boilers in multi-storey buildings is prohibited, do not stand up to criticism.

To create an autonomous heating system, it is necessary to install a gas boiler in an apartment building, the requirements for it are almost the same. For autonomous systems of apartment buildings, turbocharged boilers with a closed combustion chamber are selected. References to SNiP, in which the installation of boilers in multi-storey buildings is prohibited, do not stand up to criticism.

SNiP was developed in the last century. Subject to the relevant technical requirements for the premises for the installation of modern gas equipment, boilers for autonomous heating can be installed. After all, modern insulated boiler combustion chambers provide safety and comfort in the home.

SNiP was developed in the last century. Subject to the relevant technical requirements for the premises for the installation of modern gas equipment, boilers for autonomous heating can be installed. After all, modern insulated boiler combustion chambers provide safety and comfort in the home.

If permission has been received to create an autonomous heating system in an apartment building, then the most rational solution would be to install a double-circuit gas boiler in an apartment to provide hot water. The apartment was connected to central heating, which means that when installing separate heating, you will need to disconnect from it and mount a closed autonomous system. This means that it will be necessary to install heating radiators, connect them with pipelines that lead to the installed boiler.

If permission has been received to create an autonomous heating system in an apartment building, then the most rational solution would be to install a double-circuit gas boiler in an apartment to provide hot water. The apartment was connected to central heating, which means that when installing separate heating, you will need to disconnect from it and mount a closed autonomous system. This means that it will be necessary to install heating radiators, connect them with pipelines that lead to the installed boiler.

Before connecting the circuit to the boiler, it is necessary, and without fail, to pressurize the system with air or liquid pressure. For a new system, the pressure should be 2 times the operating pressure. In principle, the connection of the gas boiler to the heating system does not matter, the scheme is carried out after testing, but only licensed gas service workers can connect to the gas main and start the boiler.

Before connecting the circuit to the boiler, it is necessary, and without fail, to pressurize the system with air or liquid pressure. For a new system, the pressure should be 2 times the operating pressure. In principle, the connection of the gas boiler to the heating system does not matter, the scheme is carried out after testing, but only licensed gas service workers can connect to the gas main and start the boiler.

The first time, after starting the autonomous heating, you need to monitor and make sure that the boiler and its automation is working correctly. When the set temperature of the coolant is reached, the boiler should automatically turn off. If this did not happen, then it makes no sense to ask why the gas boiler does not turn off. A serious malfunction has occurred. Either the control unit is out of order, or the sensor is faulty. In this case, you need to call specialists who have the right to repair gas boilers.

The first time, after starting the autonomous heating, you need to monitor and make sure that the boiler and its automation is working correctly. When the set temperature of the coolant is reached, the boiler should automatically turn off. If this did not happen, then it makes no sense to ask why the gas boiler does not turn off. A serious malfunction has occurred. Either the control unit is out of order, or the sensor is faulty. In this case, you need to call specialists who have the right to repair gas boilers.

Preparing to install a floor-standing boiler

Before connecting a floor-standing gas boiler, you need to prepare tools and materials. You will also need to study the installation instructions for the unit and the operating manual.

From materials and tools you need to have at hand:

- cement and sand;

- shovel;

- container for solution preparation;

- drill;

- hammer;

- bolts and nails;

- wooden edging;

- pipes for the gas duct.

The installation of a gas appliance can be started only after the site has been prepared for its location.The floor-standing heating unit must be installed on a concrete base. The screed can be replaced with a flat sheet of metal. It is placed under the legs of the boiler so that it protrudes at the edges of the unit by at least 30 centimeters. The floor unit must be absolutely level.

In apartments located in multi-storey buildings or in individual buildings, boilers with a closed combustion chamber are installed, a coaxial chimney is led to them outside through the wall of the room. The opening for the flue, depending on the boiler model, is located either on its rear wall or on the top panel. As a rule, it is located at the back and thus the chimney can be easily led out through the wall.

Requirements for individual rooms

Boiler rooms, equipped in separate rooms, must comply with a number of requirements, which are very similar to the previous ones:

- The ceiling must be over 2.5 m high;

- The area and volume of the room are selected depending on individual preferences, but the minimum allowable volume is 15 m3;

- Each wall of the boiler room must have a fire resistance limit of 0.75 h and no flame spread (brick, concrete and building blocks correspond to this requirement);

- The same requirements are imposed on ventilation as when installing a boiler in a kitchen - a threefold outflow and the same amount of air intake, increased by the amount of oxygen consumed in the combustion process;

- The room must have at least one window with a glazing area of 0.03 m2 per 1 m3 of the room volume.

When installing gas boilers with a capacity of over 150 kW, it should be possible to leave the boiler room directly onto the street. Placing a gas boiler in an individual residential building assumes that the equipment cannot be adjacent to living rooms. In any case, the boiler room must be equipped exclusively with fire doors.

Choosing a gas boiler

Before putting a boiler in an apartment, you need to make the best choice. Wall and floor boilers can be installed in a multi-storey building. Wall-mounted models are considered more aesthetic and convenient in terms of placement. Their dimensions are comparable to the dimensions of kitchen wall cabinets and therefore they fit well into the interior of the room.

It will be more difficult with the installation of floor units, since they cannot always be pushed close to the wall. This nuance depends on the location of the smoke exhaust pipe. If it is on top, then the device, if desired, is moved to the wall.

Boilers also come in single and double-circuit. The first of them work only for heat supply, and the second - for heating and water heating. When other equipment is used for DHW, then a single-circuit model will suffice.

If the water is heated by a gas boiler, then you will have to choose one of two methods: an indirect heating boiler or a flow coil. Both options have disadvantages. When a coil is used, which means that instantaneous heating is carried out, not all units are able to maintain the set temperature.

For this reason, special operating modes must be set in boilers, they are called differently in different devices. For example, in Navien models (read about Navien boiler malfunctions), Beretta is “hot water priority”, and in Ferrolli it is “comfort”.

The disadvantage of boiler heating is that gaseous fuel is consumed to maintain a stable water temperature in the tank. In addition, the reserve of heated water is limited. After its consumption, you have to wait until the new portion heats up.

The choice of the above methods is an individual matter, but you need to remember that with the flow-through version you will have to focus on the productivity of heating water per minute, and with a boiler room - on the volume of the tank.

Gas units differ in the type of burner used, which are:

- single-position;

- two-position;

- modulated.

The cheapest are single-position ones, but at the same time they are the most uneconomical, since they always operate at full capacity. Slightly more economical are two-position ones, which are capable of operating at both 100% power and 50%.The best burners are considered modulating because they have many operating modes, which saves fuel. Their performance is automatically controlled.

The burner is located in a combustion chamber, which can be either open or closed. Oxygen for open chambers comes from the room, and combustion products are removed through an atmospheric chimney.

Closed chambers are equipped with a coaxial chimney structure, and oxygen for combustion enters them from the street. In this case, the combustion products are discharged along the central contour of the chimney, and air enters through the outside.

Equipment installation rules

Strictly follow all the rules and norms of SNiP "Gas Distribution Systems", without deviating from them.

Any attempt to improvise or change classical technology can be noticed by the reviewers.

And if this entails an accident or damage to other residents of the house, the owner faces administrative and, in some cases, criminal punishment.

- If the boiler is wall-mounted, the floor underneath should be perfectly flat, since the pump that pumps water can cause vibration and displacement of the boiler. If the vibration is severe, the gas pipes or water supply system may become disconnected from the boiler, leading to gas leakage or flooding.

- If it is possible to make a stand for the boiler, this will secure the structure and increase the strength of adhesion to the floor.

- If you install a boiler near a stove, boiler or other heating elements, then the total power of the thermal field between them will be higher than the sensors show, since they measure this only inside the system itself. This rule is not specified in SNiP, but is often the cause of premature wear of the mechanism or failure.

Features of the choice and installation of doors

If the boiler is installed in an annex or one of the premises of the house (including the basement), then the door to the boiler room from the house must be fireproof. That is, the structure must withstand at least 15 minutes of exposure to open fire - this will allow people to evacuate in the event of a fire. Fireproof doors must be made of metal and open towards the living area.

External doors in the boiler room of a private house (detached or in an annex) must be unreinforced (weakly reinforced). This will allow the blast wave to carry the door outside - the energy of the explosion will be directed to the street, and not to the inner walls of the house. In addition, gas will escape through the torn off doors.

The door for the boiler room also serves as one of the ventilation elements - a canvas with a grate at the bottom provides air flow into the room. The use of such a design may be a mandatory requirement for a boiler house installation project.

Calculation of boiler power

When the type of heating unit is selected, you should decide on its power. If desired, you can order a heat engineering calculation that allows you to determine the heat loss in the premises. Based on this figure, they begin to select the boiler power.

It is possible not to make calculations, but to use the norms obtained by experience, according to which 1 kW of boiler power is required for 10 "squares" of the area. This result should be supplemented with a performance margin for various losses.

For example, to supply heat to an apartment with an area of 60 "squares", a 6 kW device is needed. If water heating is planned, add 50% and get 9 kW of power, and in case of abnormally cold weather another 20-30%. The final result is 12 kW.

But this is a calculation for central Russia. If the settlement is located to the north, the unit's productivity should be further increased. The specific value depends on the degree of insulation of the house. For a panel or brick high-rise building, this will be 50% or more.

The process of obtaining a permit related to whether it is possible to put a gas boiler in an apartment is rather complicated, costly and time-consuming. But all the efforts are worth it, since it is much better to live at a comfortable indoor temperature. At the same time, you will have to pay for individual heating less than for centralized heating.

Basic requirements for the room for the installation of heating gas equipment

Requirements for the room for the installation of heating gas equipment

Requirements for the room for the installation of heating gas equipment

The first thing you should pay attention to is that it is not recommended to install such equipment in a private house. Ideally, if a separate building is erected for these purposes

But this is not possible in all cases, so you can limit yourself to a non-residential room. An excellent way out of the situation is to equip a heating room in the basement. But this is only possible if you have a private house, which consists of only one floor.

Basic rules for choosing a room for a boiler room:

- Ceilings must be more than 2.1 m high;

- The doorway is more than 0.7 m;

- To install 1 piece of equipment, the area of the room must be at least 4 m2;

- The surface of the walls of the room is flat and covered with plaster (finishing should be carried out with fireproof materials);

- Smooth non-flammable floor covering;

- The window opening should be proportional to the size of the room: 30 cm2 of the window surface per 1000 cm3 of the volume of the room.

The boiler room must have access to a chimney of sufficient diameter, an earthing loop and a water supply.

Boiler installation diagram

Boiler installation diagram

In a private house, the rules do not prohibit the installation of certain types of boilers - you can safely choose the right one. Also, there are no restrictions on the location of the premises for the arrangement of the boiler room. You can safely plan, even from the moment of designing a house, the installation of large heating equipment on gas in an extension intended for these purposes, from which it is possible to heat not only residential premises, but also a garage, utility room, etc.

Installation of a gas boiler in an apartment: coordination of installation

Technical conditions

To obtain a technical specification for connecting housing to gas supply, they go to the city gas service.

You will need to write a statement indicating how much gas consumption is expected (you will need to find out in advance: calculate the power of the device by the area of the room, select a model, and on the Internet you can see what gas consumption this model has).

Obtaining technical specifications is the main permitting document. It will take about 1 - 2 weeks to complete.

Installation project

The second stage is project development. It is made, of course, not by the owner of the home, but by specialist engineers.

They will work out a scheme for installing equipment, laying gas pipes, and for a house, also passing these pipes through the site.

Floor standing gas boiler in a private house

Expect to pay a lot at every paper step.

Gorgaz approval

After revision, the project is sent to Gorgaz (Oblgaz, or other relevant service). In addition to the project, you will need to attach the documents that will be handed to you when buying a boiler:

- Technical passport of the device already purchased.

- Instructions from the boiler (many sizes and conditions will be taken from there!)

- Certificate of conformity.

- Sanitary certificate.

- Conclusion of the expert examination on the boiler.

If the project has passed the verification, installation work begins. If not, you will be provided with a list of recommended edits and reasons for refusal. You will need to do everything and resubmit the documents.

It is difficult to say how long this stage of registration will last. They can do it in a week, or maybe three months.

Installation of hood and ventilation

Safety precautions require that supply ventilation be provided to the room where the boiler is installed.

Everything is quite easy when it comes to a device with a closed combustion chamber (and there are most of them now). By installing a coaxial chimney pipe, the owner gets two in one: both the inflow of fresh air directly into the boiler, and the removal of exhaust gases.

If the hood is mounted on the roof, it is usually done in the same unit as the flue, but the latter should be one meter higher.

Gas workers will periodically check the pipeline for cleanliness and draft. Cleaning hatches and condensate traps should be provided.

How to hide communications

The design of a kitchen with a gas boiler implies not only masking the column itself, but also the tube, hose and chimney. During repair work, in no case should they be bricked into the walls. All parts of the gas boiler should be easily accessible and close at hand. It is enough to decorate communications in the right tones. They hide in special boxes and profiles with doors, which can be easily opened if desired. If the kitchen interior is made in high-tech style, then all communications can be left open and in plain sight. It is enough just to tint some in the desired colors.

Pipes and gas meter inside the kitchen module

The pipes in this kitchen fit well into the loft interior, and the column is simply covered with a decorative panel.

Characteristics and some elements of the installation of a parapet boiler

A parapet boiler is a variant of a boiler with a closed chamber, in which the coaxial pipe is part of the structure and is located on the back wall. Thus, the boiler is hung on the wall, and its small pipes are led out into the hole prepared for them.

This system greatly simplifies installation work. There is no need to buy separately parts of the gas duct and ventilation, they should be led through the roof.

Peculiarities:

- They, like ordinary ones, can only heat, or also heat water;

- There are convection holes on the body, thanks to which the unit can be used as a heater for one room and not connected to radiators;

- They can be from 15 to 45 kW.