Rating of purchased metal hearths

The corner fireplace stove made of brick is distinguished by a rather complex assembly and installation, the simplest are ready-made purchased metal hearths. In this table, you can familiarize yourself with the most inexpensive and popular models today:

|

Descriptions and characteristics |

|

|

Bayern corner

|

Installing such a hearth is quite possible with your own hands. The fireplace body is made of steel, the thickness of which is six millimeters. The interior of the installation is faced with fireclay bricks. The sides are made of ceramics, and the power of the heating unit is 6 kilowatts, which allows you to heat a house with a total area of up to 50 square meters. |

|

|

The model is based on a small fireproof panoramic glass. The design itself is equipped with a small hob for cooking on two burners. Power of nine kilowatts, allows heating a house, the footage of which is about 170 cubic meters. The sides of the model are also lined with refractory ceramic panels, which significantly increases the efficiency and heat transfer of the hearth. |

|

|

The instructions for this model indicate the possibility of simple use. Such a firebox has a power of 6 kilowatts, which allows you to evenly heat a space with a total area of up to 50 squares. Additionally, the fireplace is covered with heat-resistant paint, which significantly extends its service life and prevents rust and corrosion from forming. |

|

Teplodar

|

One of the most powerful combustion chambers is 12 kilowatts. Such a heating unit is suitable for buildings with a footage of up to 70-80 square meters. Refractory glass ceramics are used to decorate the door. The main part of the structure is made of stainless steel. |

In order to familiarize yourself with the models presented in the table in more detail, we recommend that you also watch the video in this article.

Advantages

The Swedish stove has a very "flexible" design - it can be adjusted to the conditions and desires of the owner, modified and improvised with functions. The stove not only heats the premises, it can be folded so that:

- cook food on it,

- dry herbs;

- bake in the oven;

- dry outerwear, as well as shoes;

- equip a warm lounger;

- additional shelves;

- admire the open flame.

But that's not all. Swedish oven:

- Has a high level of efficiency.

- With good efficiency, it is small in size.

- Heats up pretty quickly.

- The combustion process is regulated (by dampers).

- Can be made with "winter" and "summer" moves.

A Swedish stove will give off 20% more heat than a Dutch stove built with the same amount of materials. And it is more convenient to cook on it than on the Russian one - you do not need to bend over and use a grip.

You can put food cooked in the evening in the cooking niche above the stove and close it with a flap. Then in the morning you can save time to warm up your breakfast - it will be still warm.

Furnace device

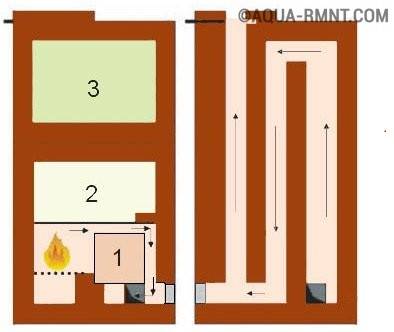

The final result consists of two parts: one is a chamber oven, in which the chamber blown with hot flue gases is at the same time an oven; the second is a duct convector from a Dutch oven stretched to the sides and placed behind the first part. As if nothing complicated, but it took a long time and painstakingly to select and calculate the parameters at which the efficiency of the unit, the heating rate and heat transfer would be maximum.

Scheme of a Swedish oven

Consider the technical features:

- The purpose of the chamber part, in addition to cooking, is to assimilate the very first heat generated during the combustion of light fractions of coal and firewood. This is the first difference from the "Dutch": in it, this heat was almost completely thrown into the chimney, since the brick, due to its low thermal conductivity, did not have time to assimilate it.

- The Dutch kiln did not have an afterburning zone for such fractions.The "Swede" was equipped with a kind of bell, in which the gases completely burn out, and for the best assimilation of thermal energy, a large metal oven was introduced into the brick body of the furnace (item 1). Due to the high thermal conductivity of steel, it heats up almost instantly, which made the effect of forced heating possible.

- If the cooking niche with the stove installed in it (item 2) is closed with a wooden shutter, then the dishes prepared for breakfast and left on the oven will be still warm by morning. They can be quickly reheated in the oven, which will heat up almost simultaneously with the start of the morning heating.

- Also, the oven was equipped with a spacious niche-dryer (item 3), in which a couple of sets of very wet clothes can be completely dried overnight.

- For the sake of simplifying and reducing the cost of the design, the hailo, which is a rather complex element, was not used by Swedish engineers. A transfer window was simply arranged under the oven. This is the reason for the inability of the "Swede" to keep warm for a long time after heating with an open view.

- The role of the heat accumulator is played by a vertically elongated duct convector installed behind the chamber furnace. It is designed according to the Dutch principle: inside there is a labyrinth of channels through which flue gases pass before entering the chimney. Here the heat generated during the combustion and puffing of the main body of fuel is assimilated.

Initially, the channels were made vertical. At the same time, the heating of the lower part of the furnace worsened, but the fuel was burned in a more complete volume. In the version with a horizontal arrangement of channels, the bottom is heated much better, but the stove becomes overgrown with soot faster (a sign of incomplete combustion of fuel). In general, manipulations with the channel part, which does not have any cunning heating devices, do not affect the characteristics of the furnace in any way. You can safely vary its size and position relative to the chamber part, so that it becomes possible to heat 3 rooms.

Option for placing a Swedish oven

The vaults in the Swedish oven are not made in the form of arches, but with the help of steel rolled ceilings - a corner and a strip. Usually, stove-makers try to avoid the introduction of metal elements into the masonry - due to the significant difference in the values of the thermal expansion coefficients of brick and metal.

But in this case, the authors nevertheless decided to take such a step for two reasons:

- the arched vault significantly increases the height of the stove, which was unacceptable for low Swedish ceilings;

- it leads to a noticeable increase in the cost of the structure, since it is a rather complex unit.

As time has shown, the coexistence of brick and steel in a Swedish oven is quite possible, unless there is direct contact between them: both materials should always be separated with a 6 mm wide seam filled with mortar.

Manufacturing recommendations

The quality of the stove will be determined by the correct proportions of the firebox. If errors were made in the calculations, then not a single element will function correctly. The correct dimensions are:

- firebox: height - 28.1–33.3 cm, width - 30.5–35.6 cm, depth - 40.6–50.6 cm;

- ovens: 28.1-30.5 cm; 33.0–38.1 cm; 45.6-50.6 cm; oven wall thickness - at least 4 mm;

- cooking stove - 71x41 cm.

The distance from the walls of the oven to the grate should not be less than ¾ of a brick or even a whole brick. The walls of the oven are very important. If they are thin, the fuel will burn out, and the walls will cool quickly. And having made it too dense, over 6 mm, the material will heat up for a long time.

Independent creation of a Swedish stove

Independent creation of a Swedish stove

The hob must be made of a material that conducts heat well. It can be:

The type will depend on the project budget and the aesthetic preferences in the interior. The cookware will be warmed up by the hotplates during cooking. By isolating the oven from the firebox with asbestos or vermiculite, you can bring them closer together, which will allow the oven to warm up faster.

Note: Choice of door will be important. The fact is that the Swede implies high heat loads. And if the door is made of thin metal, it will deteriorate very quickly.

It is best that the elements of its fittings are embedded in the masonry, therefore it is important to choose a door immediately when purchasing all materials

As for metal, you can't live without it in a Swede. It is the metal structures at the base that reduce the cost of the entire furnace, but most importantly, make its appearance complete. After all, Swedish houses are not high, therefore, the ceilings in the rooms are small and a standard Russian stove simply would not fit there.

Cooking and heating stove Swedish, made by hand

Cooking and heating stove Swedish, made by hand

Naturally, in terms of heat-conducting qualities, it is best to do without metal, however, the long-term use of metal in Sweden is so common that the design calculation is impossible without the selection and calculation of metal elements.

Preparatory work

Before proceeding with the independent laying of the Swedish oven, it is necessary to equip a reliable foundation and prepare a working solution. When choosing a place for a heater, two basic rules are followed. First, the unit is installed in a wall between two rooms, preferably in a corner. Second, the chimney of the stove should be as close to the center of the building as possible. In this case, the pipe for the exit of combustion products will be in the most advantageous place - near the ridge, which will give good traction and ensure that the structure meets fire safety standards.

Installation diagram of the outer part of the chimney

Installation diagram of the outer part of the chimney

Having chosen a place for installing a Swedish heat generator, they outline the contour of the foundation. We remind you that it should protrude beyond the outer perimeter of the stove by at least 10–15 cm. If a plank floor interferes with the construction of the base, then a cutout is made in it, corresponding to the section of the heater. After that, a pit is dug, the depth of which corresponds to the point of freezing of the soil.

The bottom of the pit is tamped and covered with a layer of sand 100 to 200 mm thick. A sandy pillow is poured with water and covered with rubble to a height of 150–170 mm. The drainage layer is well compacted, after which formwork is installed along the edges of the pit. Usually she is knocked out of just about anything. We recommend taking even low-grade, but even edged boards. Remember that the formwork neatly knocked down and aligned to the level of the side will allow you to build a perfectly flat foundation with a minimum of time and effort.

The structure is lined from the inside with polyethylene or roofing felt, after which a reinforcing mesh is installed at a height of 5-10 cm from the bottom. Then thick concrete is kneaded, which includes 1 part of M-400 cement, 3 parts of sand and 6 parts of crushed stone. The solution is poured into the prepared fence, after which the surface of the slab is compacted and leveled. The initially level edged boards greatly simplify this work. All that needs to be done to obtain a perfectly flat foundation is to follow them with a rule that can cover both sides of the formwork structure.

The device of the foundation of the Swedish stove

The device of the foundation of the Swedish stove

The poured concrete is left for several days, and after it has completely set, the wooden shield is removed and the foundation is covered with roofing felt or other waterproofing material.

The preparation of the mortar begins with kneading and soaking the clay. After that, sand is added to it and the mixture is thoroughly mixed. The amount of one or another component is determined depending on the fat content of the clay - the higher this indicator, the more sand will be required. It is not necessary to immediately prepare a large amount of the solution, since during settling it will be divided into its constituent parts - you will have to do all the work again. As for the factory refractory compositions, then, among other things, they also have a shelf life when mixed, which is recommended to be strictly observed. Experienced stove-makers use up to 20 liters of masonry mixture for every hundred bricks.It is on this figure that it is recommended to be guided in the process of preparing for work.

Do-it-yourself Kuznetsov oven ordering drawings and description of the oven masonry

IV Kuznetsov has been designing, manufacturing and improving furnaces since 1962. During this time, more than 150 different designs were invented, each of which strove for an absolute indicator of efficiency - 95% efficiency. In this article we will tell you how to make a Kuznetsov oven with your own hands.

Photo 1 Kuznetsov's stove

The principal feature of the development is the system for separating gases into cold and hot streams. Due to the unique bell structure of the furnace, hot air is retained inside, and cold air is discharged through a separate channel into the chimney. Considering that a higher combustion temperature is maintained in the bell, and the heat is evenly distributed over the body, the efficiency reaches its peak. For comparison, the efficiency of conventional furnaces is 30-35%, solid fuel boilers - 80%, pyrolysis - 85%.

The low performance of most solid fuel units is due to the fact that warm air comes out together with the combustion products into the pipe. In addition to the fact that the remaining volume is not always sufficient for full heating, the rapidly escaping flue gases further reduce the thermal threshold. In some designs, they try to solve this problem by increasing (lengthening) the chimney, but then there is a risk of a decrease in draft and, as a result, a decrease in efficiency. The creation of such a unit that would provide full traction and increase heat transfer, and became the main goal of the designer Kuznetsov.

Video 1 Construction of a heating furnace according to the Kuznetsov system

Varieties of brick ovens

One of the main advantages of a brick oven is its high thermal inertness, which allows it to give off heat for a very long time even after a short-term heating of just a few hours.

The choice of a suitable type of stove, first of all, depends on the mode of residence and the area of the house. A brick stove is more relevant for a private house in which they live permanently.

According to their purpose, it is customary to divide them into:

- exclusively heating;

- heating and cooking stoves, which are well-known Russian stoves, the so-called Swedes, etc .;

- cooking;

- narrowly directed corner stoves for a bathhouse, greenhouse, garage, etc.

According to their shape, they are divided into rectangular, square, round, T-shaped and corner brick ovens.

Another important technical design parameter is heat transfer. According to this criterion, they are divided into thin-walled, thick-walled and combined. Depending on the method of external finishing, the stove can be divided into: brick "for joining", a plastered structure, tied with stove tiles or tiles, in a metal casing (round stove structures). Not the last place when choosing a suitable stove is taken by the structure of chimney channels, which can be direct-flow or counter-flow, channelless or with bottom heating, with horizontal or vertical channels, etc.

Necessary materials

For the masonry of the cooking and heating Swedes you will need (+ 1-2 bricks each in case of rejection):

- Red brick (only for the oven itself) 553 pcs.

- Refractory bricks ША-8 = 32 pcs.

- Clay solution.

- 21 x 25 cm (furnace). It should be cast, with a mustache.

- 14 x 25 cm.

- 14 x 14 cm (for cleaning) = 3 pcs.

- 4.5 x 4.5 x 1m 20cm. = 1pc.

- 4.5 x 4.5 x 70cm. = 1 pc.

- 4.5 x 4.5 x 90.5 cm. = 5 pcs.

Oven for the Swede

- Steel strips 5 x 65 cm (5 mm thick) - 2 pcs.

- Latch 25 x 13 cm.

- Valve for steam extraction 13 x 13 cm.

- Grate 20 x 30 cm.

- Oven 45 x 25 x 29 cm.

- Stove (cast iron) 41 x 71 cm.

- Overlapping sheet for drying chambers 80 x 90.5 cm.

- Steel plate for small dryer 19 x 34 cm.

- Sheet in front of the firebox 50 x 70 cm.

DIY stove masonry

If you place the stove in the center of the house, it will warm up evenly.

If you place the stove in the center of the house, it will warm up evenly.

The construction of the Swedes begins with preparation. It is necessary to calculate its power, find the optimal location - between the rooms, as close as possible to the center of the room. It is better to build a stove simultaneously with the construction of the building itself. It weighs about 3 tons and a separate foundation is being laid for it.

It is allowed to install the stove in a finished building, but for this you will have to disassemble the floors, walls, and roofs. It is easier to buy a metal analogue of a Swede - Ryazanka or another mobile cooking and heating model.

- A hole is dug under the foundation, up to 0.8-1 m deep. The value is determined by the level of soil freezing. The foundation must lie below this depth.

- The scheme is usual: up to 15 cm of compacted sand, 20 cm of broken brick and stone, 10 cm of crushed stone or pebble and a layer of concrete of such a height that it rises 15 cm above the ground level. All layers must be compacted. The concrete is reinforced with a reinforcing mesh: it is placed in the upper layers, not reaching the open surface by 10 cm. The dimensions of the foundation are 10–15 cm larger than the dimensions of the furnace.

- After the concrete has dried, the foundation is waterproofed with roofing material.

- It is recommended to insulate the bottom of the stove. The Swede is designed in such a way that it creates a powerful, downward flow of heat. In order not to lose it, several layers of basalt cardboard are placed under the base of the furnace. A more expensive way is to lay out the lowest row of fireclay bricks.

- A do-it-yourself Swedish oven is laid out according to a certain pattern. You can find a ready-made description for a wide variety of sizes.

- Rows 1 and 2 are always solid. The brick is earthen, laid with an offset and with a strapping. This base provides structural strength.

- In the 3rd and 4th rows, an ash pan and holes for cleaning are formed. All of them are closed with doors. Their installation is the same: on a twisted steel wire, which is fixed directly into the brickwork. From the 5th row, according to the drawing, they begin to form a firebox. It is laid out with fireclay bricks, since clay does not withstand such a temperature. The oven is mounted in parallel. It is fixed in the same way as the doors - they walled up the steel wire between the stones.

- In rows 6-9, they continue to build a firebox. At 6, a chimney is also laid. Fireclay bricks inside the firebox and clay bricks outside are laid so that an air gap remains between them. This prevents deformation of the walls. Fasten the furnace door.

- In the 9th row, the bricks in the chimney are laid at an angle. The desired shape is given to them with a grinder. This ensures the discharge of gases into the chimney. At 10, the installation of the firebox is completed, installing a horizontal partition, and at 11, the hob is fixed.

- From 12 to 18 rows, according to the drawing, chimney channels are built. Their surface should be as smooth as possible. The walls are carefully leveled and smoothed out. In the 17th and 18th rows, metal corners and supports are placed to overlap the cooking chamber. An almost continuous row of bricks is laid out here.

- From 19 to 28, an upper drying niche is built and holes are laid for cleaning chimneys with views, and at 27 - a regulating valve.

- At level 29, the smoke channels are blocked, leaving only one main hole for the chimney. The drying chamber is also closed.

- In the 30th row, an expansion is made, and in the 31st they return to their original dimensions. Then they build up a brick pipe in a straight line. Overlapping floors are recommended to be insulated to avoid overheating. In the attic, you can connect a brick chimney with a metal one.

What is needed for the construction of a heating device

The furnace, which is offered for manufacture, has a width of 1020 mm, a height of 2170 mm and a depth of 880 mm. The choice of these parameters is due to the size of standard bricks - when laying the unit, you will not have to look for a half or three-quarter piece once again, which significantly reduces the construction time. The principle of the multiplicity of the dimensions of the furnace to the size of the red brick is also recommended when changing its proportions to suit your own needs.

In the process of masonry, you will need both simple red and refractory fireclay bricks.

In the process of masonry, you will need both simple red and refractory fireclay bricks.

By the way, in the Scandinavian countries, whole sets are produced for the construction of stoves of any size. This "constructor" includes everything you need, including a mixture for preparing a solution. We can save a little, because the thrifty and economical owner will always find something from the list of necessary materials below. So, here is a list of what you need:

- 500-700 pcs. high-quality red brick of the M-150 and higher brand, which must necessarily go through a good firing and not have foreign inclusions more than required by GOST;

- refractory fireclay brick of the SHA-8 brand (its dimensions correspond to red brick, which will facilitate laying);

- furnace and blower doors - 1 pc .;

- cleaning doors - 4 pcs .;

- pre-furnace sheet with a thickness of 0.5 to 2 mm;

- oven;

- grates;

- cast iron two-burner stove;

- metal corner with a shelf of at least 40 mm;

- exhaust valve;

- sheet steel;

- cement;

- sand;

- construction mesh for reinforcement;

- rammer;

- formwork boards;

- a rule with a length of at least 1 m;

- refractory masonry mixture (in extreme cases, it can be replaced with a mixture of clay and sand);

- asbestos or basalt sealant.

Furnace casting has a decisive influence on the appearance of the furnace, so why not take advantage of the original developments of the foundry designers when choosing it?

Furnace casting has a decisive influence on the appearance of the furnace, so why not take advantage of the original developments of the foundry designers when choosing it?

The tools that will be needed for the preparation of the solution and the actual construction of the Swedish oven:

- construction hammer pickaxe;

- trowel;

- wooden or rubber mallet;

- jointing;

- construction level;

- square;

- cord and plumb line;

- roulette;

- shovel shovel;

- containers for solution.

You cannot do without a comfortable trowel during the construction process

You cannot do without a comfortable trowel during the construction process

The classic Swedish stove, unlike the Dutch stove, is not tiled or tiled. Nevertheless, nothing prevents you from decorating the stove at your own discretion if the brickwork does not fit into the interior design.

Swedish heating and cooking furnace project

Before starting work, a few tips from a stove-maker on laying ovens from Sweden with his own hands:

Before starting work, print the order on the printer and, in order not to get confused, by laying out the next row, circle or cross it out on the plan.

When laying out the foundation, it is very important to check its horizontal level by its level. However, all further rows need to be checked periodically with the level.

Each brick is immersed in water for 15 seconds before being laid.

But you can't soak bricks!

Starting a new row, lay out all its bricks in place without mortar, specify the dimensions, adjust, and only then lay out the row.

The grinder cuts bricks of the desired shape very evenly, but this results in a lot of dust, so it is better to prepare all the halves and quarters in advance in the open air.

Scheme of ordering a Swedish heating and cooking stove with an oven

Ordering

Consider the order of a Swedish brick oven with a do-it-yourself oven.

- 1 row. Solid (28 red bricks).

- 2 row. Duplicate (if in the previous row all the bricks were intact, then there are many halves and ¾).

- 3 row. Marked with bricks: on the left is the ash chamber, on the right is the space under the oven (a quarter of refractory bricks are laid here) and in the background there are vertical channels. Doors are installed: ash pan (25 x 14 cm), three for cleaning (14 x 14). Several bricks are installed on the edge. Red bricks - 19 pcs.

- 4 row. The vertical channels have been merged so far. The ash chamber is expanding. Half of the refractory brick is placed in the space under the oven. 14.5 red bricks in a row.

- 5 row. Doors of all channels and chambers overlap. The ash chamber is laid out with refractory bricks (this will be the bottom of the firebox).An opening for the grate is left (a corner is cut along the perimeter of the hole, into which the grate is placed). 16 red + 8 fireclay bricks.

- 6 row. A firebox door is installed, vertical channels are separated. Between the firebox and the oven there is a quarter wall of refractory bricks. The oven is being installed. 13 red + 3.5 fireproof.

- 7 row. Duplicate.

- 8 row. The entrance to the channel behind the oven is fireproof. 13 red + 5 fireproof.

- 9 row. Two bricks are laid above the firebox door, one of which is cut obliquely from below, and the other from above. 13.5 red + 5 fireproof.

- 10 row. Similar to the previous row, the oven door overlaps. The wall between the firebox and the oven is not laid out. A corner is selected in the bricks to install the slab. A corner (1m 20cm long) is installed on the front of the stove. 15 red, 4.5 fireproof.

- 11 row. A cooking chamber is formed. 16.5 red.

- 12-15 row. Duplicate.

- 16 row. Preparing to overlap the cooking chamber. Place 70 cm in the front. corner, and above the camera - three corners of 90.5 cm. 14.5 red.

- 17 row. The cooking chamber is tightly closed, only the exhaust hole in the half-brick is left. 25.5 red.

- Row 18. Duplicate. Another corner is being installed. 25 red.

- 19 row. Increasing: exhaust duct, drying chambers, vertical ducts. 16 red.

- 20, 21 rows. Duplicate.

- Row 22. The smaller drying chamber is covered with a 19 x 34 cm steel plate. 16 red.

- 23 row. A place for the valve is cut above the ventilation hole. Latch 13 x 13 cm. 17 red.

- 24 row. Two vertical channels are combined behind the oven. 15.5 red.

- 25 row. The steam exhaust duct is combined with a vertical duct behind it. 15.5 red.

- 26 row. All cameras and channels are being expanded. In the front part, 90.5 cm is installed. corner. Above the drying chamber, two strips of 65 cm are laid. An angle is cut out in a large steel sheet (80 x 90.5) according to the size of the angular vertical channel. The sheet is laid, covering the entire surface of the stove, including two channels behind the oven. On all sides, a half-brick distance is left not closed.

- 27 row. Solid, covering the entire area, except for the vertical channel. The brick now "hangs" over the previous rows by 2.5 cm from all sides. 32 red.

- Row 28. Another continuous row, the bricks "overhang" even more from all sides (by another 2.5 cm). 37 red.

- Row 29. Continuous row, original oven size. 26.5 red. The furnace body is complete.

- 30 row. The base of the pipe is formed. A corner is cut in the bricks to fit the smoke damper. A gate valve is installed. 5 red.

- 31 row and beyond. Extension of the pipe.

Heating cooking stove Swedish: features, advantages

The Swede is often compared to a Russian stove, but the two devices differ in size and fuel consumption. It is compact, which cannot be said about the Russian stove, which is why many residents of private houses make a choice in its favor. The model was developed in Sweden according to the subtleties of the local climate. The functions include:

- heating the room;

- cooking food.

Depending on the model, it can be equipped with a fireplace, baking compartment. The main advantage is the ability to independently equip such a product in your home. Having chosen the desired option, you can lay out a brick stove with your own hands. To do this, you need to draw a detailed ordering diagram and select all the necessary materials.

How does a Swedish stove differ from a Dutch woman and a Finnish woman

At the moment, there are many types of brick ovens, but three similar designs are especially distinguished: Swedish, Dutch and Finnish. An inexperienced user should find out which is better of these three options and what are the differences between them:

Dutch woman. It has a rectangular shape and vertical smoke flows. Used for heating and cooking. The peculiarity lies in the simplicity of the calculation and unpretentiousness. If you overheat the model, then there is a danger of carbon monoxide. Due to the design: the stove can be installed on 2 floors.

Finca.It has one difference from the Swedish one - it is made with a bread chamber. The designs may vary, but the distinctive feature remains the same.

Swede. For the arrangement, certain skills and abilities will be required

If the work is done by a beginner, it is important to take into account all the nuances. Arrangement of the unit for a summer residence requires compliance with the order of the scheme and all norms.

Important! The Swede differs from other heating and cooking structures in that it is placed with a shield in the back.

Swedish stove is a compact and convenient construction option designed for home heating and cooking

Choosing between the three options presented, you should pay attention to the dimensions and purpose

Types of Swedish ovens

Depending on the structure, there are several types of Swedes:

- Without hob oven. The most common design, often masonry is performed with three firebox modes: the order is designed for masonry for three seasons. Depending on the desired temperature, it will heat up more or less. If you wish, you can make a mini oven with one burner for small spaces.

- With a water circuit. A heat exchanger is built into the firebox or chimney, which heats the water passing through the register and lets it through pipes to the radiators.

- With fireplace and hob. Such a device is called the Ryazankin oven. The Swedish fireplace stove looks beautiful, it is installed on the foundation. Dimensions - 102x102x217 cm, which indicates the possibility of using in a private building. You can build a stove on one side with a fireplace on the other, then the user can simultaneously admire the fireplace flame and use the firebox for its intended purpose.

- Without stove. A special type of construction, when the Swede plays the role of a heating device without the possibility of cooking.

Important! Those who want to independently build a structure are interested in the question of what products are in shape. They can be made round, rectangular or angular.

The type is selected according to the location.

Also, craftsmen can build a version with a drying chamber, where it will be possible to pre-dry the wood for kindling. A separate place is occupied by a Swede with a couch - such a simple design implies additional space for rest.

Depending on the structural features of the device, it can have several caps. For example, the Batsulin two-bell oven has an oven and a stove, an option with five wells, the size and layout of which will help to lay out the material correctly, is equipped with 5 sectors for the movement of smoke. The 2-bell version of brick is considered universal.

Preparatory work

In order to assemble a brick corner fireplace, it is necessary to complete a detailed drawing and choose the optimal place for installation, and then calculate all building materials, fittings and fasteners. For the assembly and construction of the corner structure, we need:

- Red brick of the M-100 brand (about 750 pieces, the material for the chimney assembly is calculated separately);

- Fireclay bricks 50 pieces;

- A steel strip measuring 600 x 300 x 3 millimeters;

- Steel corner measuring 100 by 100 millimeters, L = 750 millimeters;

- Two steel sheets measuring 300 by 300 by 3 and 530 by 400 and 3 millimeters;

- Sand and clay (0.5 and 0.8 cubic meters, excluding the chimney);

- Blower and firebox (140x250 and 210x250 millimeters);

- Two cleaning doors with dimensions of 140 x 130 mm;

- One burner and oven (410x410 and 300x280x510);

- Stove and fireplace damper (130 by 250 and 250 by 250 millimeters).

Erection of the foundation

Since a corner brick fireplace has a sufficiently large mass, for its installation, it is necessary to assemble a separate foundation. At this stage, we recommend using the following step-by-step guide and tips:

- The most reliable foundation is a monolithic reinforced one. The length of the foundation should be 8-13 centimeters longer than the fireplace on both sides;

- At the first stage, the marking is carried out, after which a pit of the appropriate size is dug;

- For a small house, the depth of the pit can be about 50 centimeters (tape);

- The first layer is filled with sand, its layer is 8-12 centimeters, after which water is poured on top, and the layer is well compacted;

- Next, the formwork is performed. For this, boards are used, the thickness of which is 20-25 millimeters. Alternatively, plywood can be used. The formwork can be either completely sealed or removable;

- Next, a lattice measuring fifteen by fifteen centimeters is laid with reinforcement from rods. The rods are tied with wire, in those places where they intersect;

- If the height of the foundation is more than 18 centimeters, the reinforcement is laid twice - in the upper and lower parts;

- Next, a cement-based solution is prepared. In a ratio of 1: 2: 2 (cement to crushed stone and river sand). Water is added so that the consistency is of medium density;

- The concrete mixture is poured into the formwork at a time (completely), in a large layer;

- The foundation itself should be below floor level by an average of 9-18 centimeters.