Firewood laying and ignition

In order to lay firewood in the combustion chamber, it is necessary to lift the press from the outside by the pipe sticking out of the stove. Bookmark and light fuel from above. You can open the firebox door halfway. In this case, the open end of the 80 mm pipe must be closed, for example, with a small piece of steel sheet. The chimney damper opens completely.

In this position, on solid fuel, the stove should work for about twenty minutes so that it warms up well. When all the firewood burns out, it is necessary to remove the remaining fuel and ash from the firebox and make a new bookmark. This firewood is set on fire from above, for this you can use paper, cardboard, dry branches and other materials. As soon as the main fuel ignites, a press is lowered onto it, the furnace door closes, an 80 mm pipe opens, and the chimney gate is half closed.

The wood smolders, releasing pyrolysis gas, which, together with a small amount of smoke, passes into the gap between the edges of the press and the walls of the stove. In the second chamber, the gas is mixed with heated air, which flows through the holes made in the 80 mm pipe. Through it, the bulk of the air enters the upper furnace, the minimum - into the smoldering firewood zone. The air is heated by the fact that it passes through a pipe, which is located in the very heart of the flame obtained from the combustion of pyrolysis gases.

This is one of the simplest designs that you can quickly do with your own hands. For a small house heating system, this is the most acceptable option. Practice has shown that one bookmark is enough for 12 hours.

Functioning principle

The Slobozhanka stove has the following operating principle. The fuel burns out gradually, starting from the top layer and ending with the lowest, that is, from top to bottom, and not from bottom to top, as in classic stoves.

The air heats up and transfers thermal energy to the walls of the case, rises upward, warming up the chimney.

The degree of oxygen supply intensity, and hence the temperature, the intensity of combustion (smoldering) are regulated by dampers, there may be several of them, it all depends on the design features of a particular model.

The combustion chamber has a "jacket" through which cold air is sucked in from below, it heats up during its passage and, when it leaves the stove, heats up the room, providing continuous circulation of air masses. The volume of heated air in most cases is regulated using a reflector cover, which also allows you to adjust the temperature in the room.

From theory to practice

So, let's move from theory to practice. Let's take a model with a central air supply to the combustion chamber.

We need to make an air supply and distribution channel. It is made from a thick-walled pipe. Just take a piece of pipe along a length that does not exceed the height of the combustion chamber. At the bottom, you need to weld the bolt. Then cut a penny out of sheet steel in a diameter equal to the diameter of the pipe, drill a hole and fasten it to the bolt with a nut. It turns out that the pipe in the lower part is closed by a penny shifting along the axis, and the intensity of oxygen supply to the furnace depends on how closed the section is, and therefore the nature of fuel combustion and the temperature in the room. Using an angle grinder, cut grooves in the pipe for supplying air to the firebox with a width of at least 10.00 mm. You also need to weld the circle. To do this, cut out a "pancake" from steel - a circle with a diameter smaller than the diameter of the combustion chamber, cut a hole in the center corresponding to the diameter of the pipe. It remains only to put the circle on the pipe, 20-30 centimeters and weld. Now let's move on to the body. You can use a gas cylinder, barrel, or weld a sheet steel cylinder.In a cylinder or barrel, it is necessary to cut off the upper part, and weld the bottom in the cylinder; In the upper side part of the body, a hole is cut for a chimney, with a diameter of at least 100 mm for the removal of combustion products and a pipe of the corresponding diameter is welded; A hole is cut in the bottom in the center for installing the oxygen supply pipe we have made. The hole diameter is equal to the outer diameter of the pipe, which is installed as an air duct; We turn to the manufacture of the heat dissipation disk. Use sheet steel 10 mm thick. Cut a circle in diameter slightly less than the diameter of the body, you can weld a handle from steel wire or reinforcement for convenience; Next, we need to make a convection jacket (oven casing). To do this, take sheet steel and weld a cylinder with a diameter that exceeds the diameter of the main body of the stove by a few centimeters. It is difficult to imagine a Slobozhanka oven without a convection jacket; We connect the main body and the convection jacket. For this, cylinders of the solid or tubular type with heads can be used. Make the holes with a drill. Then fasten the heads to the rivets with a riveter; We make a cover for the main body

You can take the cut off top of the cylinder or the barrel lid and weld the handles from reinforcement or large diameter steel wire; An important condition. The stove must be at least 25 centimeters above floor level. This is necessary to ensure air circulation in the convection jacket.

Therefore, do not forget to weld the legs, for example, from a corner of the appropriate length to the body.

This is necessary to ensure air circulation in the convection jacket. Therefore, do not forget to weld the legs, for example, from a corner of the appropriate length to the body.

As you can see, the Slobozhanka oven is not easy to assemble on its own, but very simple. The only thing but, as noted above, heating devices of this type can differ significantly in design features, so adhere to the selected drawing and general recommendations specified in our article.

Bubafonya

If the above-mentioned stoves that support long-term burning are necessary in most cases to be purchased at specialized retail outlets, then the heating devices considered below can be made independently with the necessary materials, tools and skills, which reduces the cost of equipment. In some cases, craftsmen can collect both Buleryan and Butakov at home, on their knees, but this applies to extreme sports.

Therefore, greenhouses are heated in most cases by homemade stoves that support long-term burning.

One of the types of such heating equipment is Bubafonya. At its core, it is a convection oven with a barrel or gas cylinder body, into which various types of solid fuel are put through the door. An ash pan is provided at the bottom. And smoldering is ensured by the fact that a metal pancake exerts a constant pressure on the burning wood or other type of fuel from above with its own weight. Thanks to this, greenhouses on one tab can be heated for a rather long time.

Slobozhanka

Greenhouses can be heated with this type of convection ovens like Slobozhanka, which are also called "super potbelly stoves".

This stove consists of:

- combustion chambers;

- air supply and distribution channel;

- convection jacket;

- additional elements (everything directly depends on the design features of a particular model).

The Slobozhanka stove can be purchased in specialized stores or assembled by hand, there is nothing complicated about it.

The main difference between this type of long-term combustion convection ovens is the upper system of ignition and fuel combustion, and the supply of oxygen from the bottom of the furnace.

In this case, combustion can be:

- upper side;

- top center.

Let's distinguish three main types of Slobozhanka stoves:

- with L-shaped pipe for lateral oxygen supply to the combustion chamber;

- with air supply along the central part using a guide pitoid;

- with air supply from the lower side part.

This ensures the most efficient heat exchange regardless of the method of air supply to the combustion chamber.

Note also that installing Slobozhanka stoves in greenhouses is also beneficial for the reason that various materials can be used as fuel, from classic firewood to cones and needles.

As you can see, there are many long-burning furnaces that differ in design features, functionality, cost and a number of other parameters. And we have listed only the main, but not all types of convection, gas-fired heating devices that can be used in greenhouses. The choice is yours, we only note that the continuous burning of fuel, which is provided by this type of furnace, allows you to maintain a certain temperature regime in greenhouses for a long period of time.

Materials for the manufacture of a long burning stove

Long-burning furnaces can be made by hand from sheet metal or various metal structures. Examples and drawings of such stoves are given below.

Barrel stove

A self-made heater, designed for heating utility rooms, is made of a two-hundred-liter metal barrel. The stove operates on sawdust, shavings and other woodworking waste. Inside the large barrel, a small barrel for loading fuel is installed on a stand. Under it is an ash pan - a drawer made of sheet metal.

The stove itself is placed on a stand, the role of which is played by a car disc. A chimney is made of pipe scraps with a diameter of 100-150 mm. The barrel is equipped with a sheet metal lid with a handle and an air inlet.

A log sharpened on a cone is installed inside the small barrel, it is indicated in the drawing. Sawdust is poured around it. After tamping, the log is taken out and the sawdust is set on fire. In the process of smoldering, gas is released into the space of a large barrel, where it is burned out.

Furnace with a metal pipe water circuit

A home-made stove of long burning from a metal pipe, which can work on wood or sawdust, is equipped with a water circuit. Loading is carried out from below; to intensify combustion, an air distributor is installed inside the furnace, pressing the smoldering firewood.

A home-made stove of long burning from a metal pipe, which can work on wood or sawdust, is equipped with a water circuit. Loading is carried out from below; to intensify combustion, an air distributor is installed inside the furnace, pressing the smoldering firewood.

A telescopic hollow pipe is installed in the center of the disc, through which air flows directly into the combustion chamber, where, thanks to the ribs welded onto the disc, it evenly distributes it over the entire surface of the firewood. It descends on its own as the fuel burns out. You can lift it before loading using a rope.

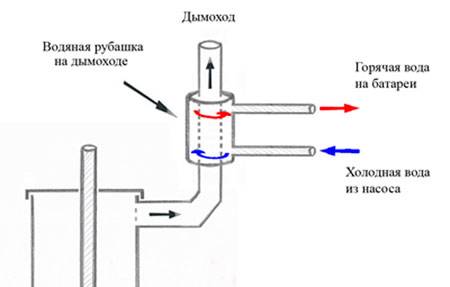

The loading door is located in the center of the oven. Below is a cleaning door and ash pan. In the upper part there is a chimney. The stove is equipped with a water circuit with nozzles for water inlet and outlet. With such a stove with a water circuit, you can quite effectively heat small houses and other rooms, and you can make it from scrap materials with your own hands.

Waste gas cylinder furnace

A stove from a gas cylinder can be made without extra costs and finding a suitable material.The dimensions of a 50 liter cylinder are excellent for making such a stove, and the wall thickness and tightness make it safe to use.

The design of the furnace as a whole does not differ from the previous model, this can be seen in the drawing. A cut-off propane tank is used as a body. A lid with a hole for the air distributor pipe is made of sheet metal with their own hands. Fuel is loaded from the top, filling the volume of the cylinder almost to the chimney. Such a stove works on sawdust and other waste, as well as on small wood. The fuel is thoroughly rammed, ignited with wood chips or an ignition agent, and an air distributor is installed, and then covered with a lid.

The efficiency of such a stove is quite high, and thanks to its sealed casing, it can be used to heat rooms where people are staying for a long time. If desired, it can be equipped with a water circuit by passing the chimney through the boiler.

The efficiency of such a stove is quite high, and thanks to its sealed casing, it can be used to heat rooms where people are staying for a long time. If desired, it can be equipped with a water circuit by passing the chimney through the boiler.

Butakov's stove

Convection ovens developed by Professor Butakov are widely available on the market and can be used for heating greenhouses, although this option is also rarely used.

This heating equipment is produced by various manufacturers, including companies:

- Zubkevich - a developer of this type of furnace;

- Termofor is one of the largest manufacturers for which Zubkevich developed the model;

- Teplodar is a clone, albeit a very successful one;

- Convection.

Furnaces from different manufacturers have both advantages and disadvantages. When buying, be guided by the recommendations of experts and reviews.

The principle of operation and functional purpose of this type of heating equipment is fully consistent with the Buleryan furnaces.

The stove body is a parallelepiped containing convective air ducts and a two-chamber firebox.

Also provided:

- ash pan;

- damper;

- chimney.

Comparative characteristics of long-burning furnaces with traditional heat generators

The principle of operation of most heating units is based on fast and intensive combustion of fuel. The fuel is ignited from below, the fire spreads, oxygen access to the combustion zone is open. The disadvantages of this heating method are sharp temperature jumps, incomplete combustion of the fuel resource with the formation of a large amount of soot and soot, the need for frequent fuel addition and traction control.

The principle of operation of long-burning furnaces is completely different. The fire moves from top to bottom, which makes it possible to completely load the combustion space. The fuel is used gradually, its combustion occurs in the direction from top to bottom. Air is supplied directly to the fire. Such combustion is a slower process with less heat generation.

This allows you to maintain an even, comfortable temperature, which is very important for greenhouses.

In this category of furnaces, the most economical are pyrolysis (gas-generating) models, in which gases formed as a result of slow combustion - smoldering - of fuel are burned. The efficiency of such a unit is significantly increased, and fuel costs are reduced.

The temperature of the gases discharged into the chimney is quite low, which leads to the formation of condensation. Therefore, insulated chimneys are installed for pyrolysis ovens.

Such furnaces operate in two modes - intensive and long burning. At the beginning of the heating process, the temperature is brought to the required value, and then the draft is closed and the unit is rebuilt into an economical mode.

Advantages of long-burning gas-fired heating devices:

- In the presence of relatively inexpensive solid fuel, long-burning furnaces are an economical and efficient (up to 85% efficiency) method of heating greenhouses. The cost of many models is also quite affordable.

- Fuel is loaded 1-3 times a day, the comfortable temperature after reaching the required value is maintained by the thrust force in the firebox.

- With the help of such furnaces, it is possible to organize air and water heating systems, and heat water.

There are several types of long-burning heat generators used for heating greenhouses. They can be both homemade and factory-made.

Furnace device

So what is the oven design?

This is a vertical furnace with one combustion chamber, which is loaded with fuel from above. Rather, not just from above, but from above and from the side. This allows you to conveniently load fuel, including during the operation of the furnace, without waiting for the first tab to burn out. At the bottom of the furnace there is a hatch for ash removal, which facilitates the maintenance of the heating device. On industrial models, special dampers are installed to regulate the air supply, as well as the gas outlet. A casing is fixed on top of the combustion chamber, passing through which cold air is heated and removed back to heat the entire room. A special chimney removes volatile combustion products outside the room.

The Slobozhanka oven drawing can be easily found on the Internet in the public domain. Inventors do not hide the characteristics of their development. On the contrary, in their opinion, Slobozhanka will enjoy special trust and demand among rural residents after they learn more about it.

Bulleryan and Slobozhanka

The first type of greenhouse furnace is used extremely rarely. This is a convection type design that can maintain the required temperature for a long time. Common firewood and wood products are used as fuel. However, there are also disadvantages to installing such a stove, it is not very convenient, you need to constantly add fuel. In addition, a temperature controller is not provided here.

The appearance resembles a horizontal barrel, on top of which there are exhaust pipes. For the smallest model, there is the possibility of passing air in an amount of up to 5 cubic meters. m. in one minute. In this case, the body does not get hot.

"Slobozhanka" resembles a classic potbelly stove, but the principles of action are different. Heat exchange is carried out in this way:

Scheme of operation of the Slobozhanka furnace.

- thermal radiation;

- heat transfer;

- convection.

We can say that the Slobozhanka device contains three different units:

- gas generator;

- directly the oven itself;

- heater.

The body itself is externally a barrel-shaped oval. It has a two-tier firebox through which there are seven vertical pipes (for some systems there may be more). The pipes go to the center of the firebox in a curved state.

The design provides for:

- the presence of a draft regulator;

- smoke damper;

- door for loading firewood.

There is no pallet in order to rake out the combustion products; it must be placed separately. A greenhouse equipped with such a furnace can heat up quite quickly, but there is one big drawback - the fuel must be supplied regularly.

General information

We all know how quickly firewood burns in a "stove", often not giving as much heat as we would like. But in brick, this process continues not only longer, but also with greater efficiency.

In most cases, it depends on the draft and the chimney, for which it is increased in the first, and in the second, it is regulated with a special gate. Then the heat "does not fly out into the pipe", but accumulates on the pipe or the furnace itself.

If it is not enough, it will become smoky and dull, blue lights will run over it. In this case, the firewood, of course, will burn longer, however, it will not be possible to achieve the required temperature in the firebox.

The name - "long burning stove", appeared due to the fact that heating devices changed their technical characteristics.

- have a powerful heating element that allows water or air heating of the greenhouse;

- do not depend on the gas supply system, firewood or wood products can be used as fuel for a long time;

- Efficiency is about 85%;

- ease of maintenance;

- profitability.

The design of long-burning cast-iron stoves differs from conventional ones, where the main "accumulator" of heat is red brick. The metal heats up faster, but it also gives off heat. Therefore, in order to increase the heat transfer time, a conceptual decision was made - to reduce the combustion rate, for which the oxygen supply was reduced.

On the photo is the Vologda oven

Although the fuel in this case cannot give the same combustion temperature as in the traditional mode, it is enough to heat metal walls to 60 - 70˚C, which corresponds to the heating of the surface of a conventional red brick furnace after the end of the active furnace.

However, heat begins to be given off from the device after 30 minutes, and not after 1-1.5 hours. This parameter is the main trump card of manufacturers, which is based on the fact that you do not need to constantly monitor the stove, it is enough to throw firewood into it two or three times.

Features of the slobozhanka furnace

The slobozhanka oven belongs to the convection type. A stove like this produces warm air and thus gives warmth to the room. The air is heated by combustion that passes through the outer casing of the chamber. Cool air on distance 10-15 cm from the floor is naturally absorbed into the skin, thereby moving upward. Warm air enters the room and gives off heat.

The Slobozhanka stove has two principles of operation:

1.central;

1.central;

2. lateral.

A certain amount of solid fuel is deposited in the chamber, which serves for its combustion. Then a small amount of wood chips and paper are placed on top. When you bring matches or a lighter, the fire ignites the paper, and after the fire, you must immediately close the lid (damper). After that, the Slobozhanka must do the work on her own without any outside interference. In this oven, the draft works flawlessly. At the very beginning, air is supplied to the very bottom of the combustion chamber, and only after that into the chamber where the fuel is stored. Due to the fact that Slobozhanka's design is simple, the manufacturer acquired a long-burning furnace. This stove can provide warmth in a room for up to 12 hours with a single fuel filling.

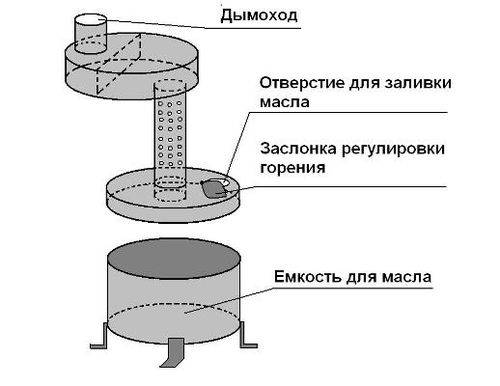

The internal structure of the long-burning furnace "bubafonya"

Consider a bubafoni device. An old, household gas cylinder - the base of the stove. Wood burns inside the bubafoni. Pyrolysis, as the basis of the process, decomposes wood with the help of high temperature into gases, which, when burned, give rise to thermal energy. Wood burns in stages:

- Stage No1 - the fire heats the wood, burning out light combustible substances. Having overcome the bar of two hundred degrees, firewood decomposes into simple substances and gas begins to burn.

- Stage No2. This stage of combustion is the most efficient, as the gases are heated to a temperature of 700 degrees Celsius.

- Stage 3. We get what this device can give - the required heat.

Pyrolysis boiler device. The inner chamber is divided into two parts. This makes it possible to burn solid fuel in one chamber, and burn pyrolysis gas in the second. In the chamber below, which is filled with wood, the wood is initially burned. In the upper part, there is a filling with wood burning products, which ignite. The heavy press pushes the fuel down and the wood is burned efficiently.There is a hole at the top of the firebox, to which the chimney is connected, and the smoke leaves the stove through this system. Air enters the combustion chamber through an air duct located on one press structure. The air supply is regulated by the air duct damper.

Long burning ovens in detail

The slobozhanka stove is a concept that denotes a whole group of long-burning units. They all differ in three ways.

- The capacity of the firebox.

- The presence of a secondary ignition element in the design.

- Method of supplying air to the furnace.

This variability does not negate the essence of such models: they all use a combustion system and are able to extract energy only from solid organic fuel. Methods for entering oxygen into the furnace:

- welding the pipe in the form of the letter "G" to the bottom of the combustion compartment;

- connection of the channel directly in the center of the bottom of the tank (distribution also goes up);

- contact of the pipe on the lower side section, which ensures excellent heating of the tank walls.

The combustion process itself can be realized in two ways. The choice between them depends on the design parameters of the air distribution channel, the configuration of the delivery unit and on the type of air supply system to the zone of raw material splitting. There are 2 types of combustion (operating principle).

| Combustion | Principle of operation |

| Top side | Fuel burns from above towards the bottom of the chamber and is tilted at a certain angle to the chimney |

| Central | Also goes from top to bottom, but the flame is distributed to the periphery of the furnace |

Regardless of which option you take as a basis, you will definitely need the corresponding drawings. If everything is done correctly, your handmade stove will definitely provide the required heat transfer, and, consequently, work efficiency.

Unlike classic heating units, long-burning stoves convert raw materials into energy, starting from the top, not from the bottom layers. This ensures the most optimal conditions for absolute fuel combustion. The heated air transfers heat to the body and rises upward, which causes an increase in the chimney temperature.

The efficiency of the furnace is up to 90%. By changing the rate of oxygen supply, heating can be controlled. This is done using three dampers. The chamber is equipped with a so-called "jacket" through which cold air passes from below. By heating up and leaving the device, it fills the room, thereby ensuring constant air circulation.

The device and principle of operation of the slobozhanka furnace

Characteristics of the Slobozhanka furnace

Let's list the main characteristics of the furnace:

- 1. Included in the form of long burning stoves.

- 2. The heat supply is gentle.

- 3. The principle of operation takes place on any solid vegetable fuel.

- 4. With one large load of fuel, the stove can work for 12 hours.

- 5. The maximum volume of the combustion chamber is 200 liters.

- 6. High fire safety, as the fire is completely closed.

- 7. Good for holding greenhouses, as plants can already grow up to 50 cm from the oven.

Thus, if you have the necessary material and tools, you can easily make a Slobozhanka oven with your own hands.

The Slobozhanka stove has the following characteristics:

- Long-term combustion, and therefore the supply of heat, is provided for six to twelve hours, everything directly depends on the type of solid fuel used. For example, well-tamped sawdust smolders up to twelve hours, and needles or cones about six hours;

- The efficiency is about 90%, which ensures the production of heat energy up to 16.00 kW / h;

- The furnace operates on various solid types of energy carriers of plant origin, and some models operate on waste oil;

- Heating time at full load is about 12 hours;

- Different volumes of the combustion chamber. In the event that you use a metal barrel for the case, then 200 liters. That is, you can choose the volume of the combustion chamber that best suits the heating conditions for rooms with different functional purposes and area;

- High degree of fire safety due to the absence of an open flame and soft combustion, fuel smoldering. This allows the use of heating devices of this type in greenhouses (plants can grow half a meter from the stove).