How to use this design

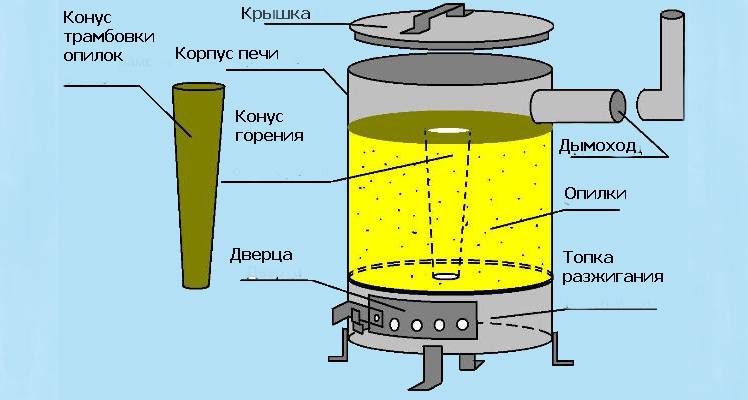

A cone is inserted into the very middle of the inner cylinder. The remaining free space is filled with sawdust. When falling asleep, they are well tamped. The decay time depends on the density of the rammer. The denser they are, the longer the process takes.

To exclude the fire of the upper part, sprinkle sand on top with a thin layer. After that, the cone is carefully pulled out. A tapered hole is obtained inside the oven. An air flow will pass through it, ensuring good smoldering of the sawdust.

The stove is closed with a lid. To set it on fire, a small fire is created in the box, which will create combustion.

During the operation of the furnace, when the sawdust smolders, there is no need to add them additionally. When they are completely decayed, the oven is loaded with a new batch.

That is why they talk about such a stove as a structure that creates a long burning. For example, after loading a 200-liter barrel once, the sawdust will smolder for about 10 hours.

The principle of operation and the device of the furnace

A long-burning boiler differs from other solid fuel heating devices in that there is no combustion inside, but smoldering, which generates enough heat to provide them with one or two rooms. To create a smoldering process, the fuel is rammed so that a minimum of air remains between its particles, since oxygen increases the intensity of the process with a huge heat release.

In this case, the fuel is quickly consumed, and it will need to be reloaded. Such boilers do not bring any savings, and excess heat will go through the chimney and not be used for its intended purpose. A long-burning boiler uses the energy released during smoldering and is equipped with a regulator that measures the air intake. Smoldering in briquettes or sawdust forms a "flue" gas, which releases a large amount of thermal energy during combustion in the ignition chamber.

There are two options for the design of the furnace:

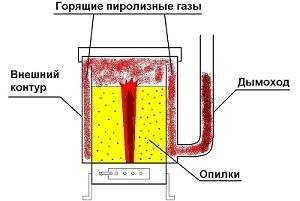

- In which the furnace gas as a result of fuel combustion rises up through the compressed sawdust, falling into the chimney.

- In which the furnace gas, when the sawdust is burning, enters the external circuit, where it cools down and is disposed of through the chimney.

- Standard long-burning boilers consist of the following basic elements:

- Fuel tank (furnace), in which there is a damper that regulates the flow of primary air.

- Afterburner chambers with holes drilled through which secondary air enters.

- Chimney.

Rules for operating a homemade oven

For all its effectiveness, a home-made device works simply:

A cone-shaped pipe is installed in a hole in a metal sheet - it is easier to remove it at the right time.

The container is filled with sawdust to the level of the chimney in small portions, carefully ramming each layer.

The pipe is carefully removed, leaving a hole in the center for the oxygen supply to the fuel and the exhaust gas outlet.

The stove is closed with a lid and the fuel is ignited from the side of the blower. To make lighting easier, you can pour some flammable liquid onto the metal partition before loading the sawdust.

The smoldering process in a barrel with a volume of about 200 liters lasts at least 8 hours - during this time, the furnace lid must not be opened and sawdust added. A new load can be done only after the complete combustion of the previous batch of fuel.

Fuel is loaded from above

Suitable heating systems

- heating stoves;

- heating stoves with water heating register or air heater;

- water heating with radiators;

- water heat-insulated floor;

- air heating;

- air heat-insulated floor.

Heating stoves heat the space around them, therefore they are suitable only for small houses. At a distance of 10 meters from the stove, the temperature drops by 10-15 degrees, so in large houses the stove can only act as an additional heater.

Heating stoves with hot water register or air heater combine the advantages of stoves and boilers. They provide the same heat as a conventional heating stove and heat the coolant, which flows through pipes or air ducts to remote rooms.

The large mass of the stove turns it into a heat accumulator, thanks to which you do not have to re-heat the boiler every 2 hours or throw firewood into it every hour. The stove will maintain the temperature of the coolant for up to 6-10 hours, so you can heat it 2-3 times a day.

Water heating with radiators in each room can be used both with a water boiler and with a sawdust oven if a water register is embedded in it. Like any other water heating, it can work on natural or forced circulation of the heat carrier.

Water and air underfloor heating not only heats the room, but also improves its microclimate. In winter, it is very pleasant to walk barefoot on the floor, feeling its warmth with your feet. The main disadvantage of underfloor heating is the high cost of materials and work, because it is necessary not only to lay air ducts or a water pipe, but also to qualitatively insulate the space between the floor and the ground or foundation.

Air heating is just as expensive as underfloor heating, because it is necessary to lay air ducts throughout the house, as well as install automatic humidifiers due to the strong drying out of the air. A heater with a heater can be used as a heat source.

The difference between stoves and boilers is only in the presence of a water jacket on the boiler, that is, the space between the hot body and the outer casing is filled with water.

The difference between stoves and boilers is only in the presence of a water jacket on the boiler, that is, the space between the hot body and the outer casing is filled with water.

Here are the distinguishing features of each heater:

- oven - direct heating of air and surrounding space;

- air heater - heating air for delivery to other rooms without heating the surrounding space;

- heater-heater - heating the surrounding space and heating the air for delivery to other rooms;

- register oven - heating the surrounding space and water for delivery to other rooms;

- boiler - heating water for delivery to other rooms.

Therefore, heaters and boilers are installed in utility rooms and are often insulated outside. After all, it makes no sense to spend thermal energy on strong heating of the utility room, and the less heat is spent on this, the more other rooms will get.

What is the principle of the sawdust oven

The principle of operation of a long-burning sawdust stove consists in the main temperature processes:

- Heat accumulation as a result of wood fuel smoldering and gas utilization through it into the chimney.

- The release of heat from the glowing fuel and the removal of pyrolysis gases into the chimney through the external circuit after they have been completely cooled.

Slow combustion provides a high heat transfer from heating equipment, reducing the consumption of fuel material and the total number of loads.

One fuel load is designed for 8-10 hours of smoldering with the accumulation of a sufficient amount of thermal energy. In addition, such a furnace is equipped with a regulator for dosing the internal volume of air during combustion.

After loading the sawdust into the fuel compartment, all inlet openings are closed to reduce the inflow of air masses from the outside. The smoldering process is accompanied by the release of pyrolysis gas, which contributes to the accumulation of a large amount of heat.

Fuel types

There are plenty of varieties of sources for providing a house with heat, but they can be conditionally subdivided into gas, liquid and solid fuels. Gas-powered systems are mainly used by those summer residents who want to have the same level of comfort in a cottage as in an apartment.

However, solid and liquid fuels are environmentally safe and cannot harm the health of the owners of a country house.

Firewood and briquettes with sawdust

The oldest way to heat a private house is to use firewood. True, in recent decades, firewood has become a fairly expensive form of solid fuel. For self-cutting, you will need to obtain permission, and the sellers' firewood costs quite a lot of money. In addition, for their storage, you will definitely need to equip a special place that is reliably protected from moisture.

That is why briquettes with sawdust are so in demand today. Moreover, they solve the problem not only of summer residents who have a stove in their house - this is an excellent way to dispose of waste from enterprises that are engaged in wood processing.

Pellets

The analogue of firewood and sawdust is pellets - special granules made from shredded wood. However, such fuel has a number of insignificant, but disadvantages:

- the cost of pellets is quite high;

- when using such fuel, the stove must not be left unattended - the combustion of pellets must be constantly maintained;

- to increase the duration of combustion, finance will be required for additional equipment - a gas-generating furnace or a special boiler.

Coal

The efficiency of coal combustion is very high - 1 kg of such fuel can easily replace 2 kg of firewood. At the same time, their cost is practically the same.

When using coal, to provide heating for a private house, you will need to install a boiler or cast iron furnace.

Features of operation

To load fuel, remove the cover and the pressure ring together with the pipe. Fuel is poured to the bottom up to the chimney itself, which is maximally compacted. On top of it, small twigs are placed, and on them paper or a rag moistened with kerosene. A clamping circle is inserted from above and closed with a lid. After the fuel starts burning, the air damper is closed and the stove can be left for several hours until the next fuel load.

It is impossible to throw sawdust into boilers for long burning when the process is running. After its laying and until complete combustion, the furnace does not open. An increase or decrease in the force of combustion is possible, while the heat generation will also increase or decrease. The combustion process starts from the bottom in the center, and spreads to the sides. As it burns, the compressed fuel is lowered, providing the combustion process for a period of 8-10 hours.

The main requirement for fuel is the possibility of its good pressing inside the combustion chamber, in the center of which there is an air channel. The size of the stove is selected based on the estimated fuel combustion time. So, the combustion that has begun from the middle to the outside continues until the material is completely burned out at a speed of 3 cm / h. Having loaded sawdust into a container with a diameter of 30 cm, the process will continue up to 6 hours. The amount of heat generated during combustion depends on the diameter and depth of the furnace. In a tall and narrow design, heating will occur faster, and a product with a large diameter will make the process long and hot.

Stove from a pipe

The sawdust oven is easily assembled on the basis of a piece of thick-walled pipe. The recommended pipe diameter is 400 mm. Prepare a smoke exhaust pipe with a diameter of 100-150 mm. Additionally, you will need a sheet of metal with a thickness of 6 mm or more.

First step

Make a fuel tank. Cut a hole in the upper part of the prepared metal pipe with a diameter of about 100 mm.

Second step

Make a bottom for the future stove. Cut a circle out of the sheet of steel with a diameter similar to that of the body. Make the markup first. To do this, it is enough to place the pipe on a metal sheet and circle it with a marker.After that, you just have to cut out the intended workpiece using an ordinary grinder.

In the central part of the cut out circle, make a hole with a diameter of about 50-80 mm.

Third step

Make a pipe for supplying air to the stove. The length of this pipe should slightly exceed the height of the firebox. Select the diameter of the pipe according to the diameter of the previously prepared 50-80 mm hole.

In this pipe, you need to make about 50 holes with a diameter of about 1 cm.

Fifth step

Make a cover for the stove. To do this, cut out a polygonal or round piece of steel sheet. Create a hole in the center of the workpiece. The diameter of this hole must match the diameter of the previously prepared perforated pipe so that the cover fits on it as tightly as possible.

Also prepare an extra hole closer to the edge of the cover. You will install a damper on it to supply air to the unit and control the level of draft.

Sixth step

Install a smoke exhaust pipe. To install, first attach the pipe to the hole in the upper side of the body by welding, and then attach the flue pipe to the pipe using a clamp.

The pipe-to-branch connection must be additionally sealed with heat-insulating material. Tighten the connection from above with metal wire.

Seventh step

Prepare supports for installing the stove. They can be made from a metal profile. To do this, cut 3-4 pieces of the same length from the metal profile and weld them to the furnace body.

Sawdust oven

Ashtray of the furnace on sawdust

Consider the fact that all structural elements made of metal will heat up during the fire. Therefore, it is strictly forbidden to install the stove near flammable objects.

Experts recommend equipping such ovens with protective screens. The best option is a brick screen. It is enough to simply lay out brick walls about a meter high around the stove.

Do not leave the oven unattended for a long time.

Potbelly stoves with a water circuit

The upright sawdust-burning stove can be adapted to heat water. Here, its low efficiency will play into our hands, since the flue gases leaving through the pipe have a fairly high temperature. To take advantage of this circumstance, a small economizer is installed on the vertical section of the chimney, which takes away the heat of the exhaust gases. It is a water jacket for the chimney with inlet pipes. The device can be purchased ready-made or made from a pipe section whose diameter is 50-70 mm larger than the gas duct.

Such a potbelly stove with a water circuit, made by hand, is connected to a water tank or to 2 small heating radiators. In this case, you should not use forced circulation in the system, the movement of water should be convective. However, it is necessary to monitor its temperature and pressure by installing such control and safety devices as a pressure gauge, thermometer and safety valve.

Knowledge and skills are the key to safety and success

The installation of a highly efficient register can further increase the efficiency and will allow even a small house to be heated with this system.

In conclusion, a few words about safety. When assembling the boiler with your own hands, do all the work efficiently and accurately. This especially applies to welding and working with a sander.

If you do not have sufficient experience in working with these types of tools, it is better to invite a friend or hire a specialist who can perform these types of work.

Remember that any stove and boiler are fire hazardous units, if improperly operated, the consequences can be catastrophic.

Good luck and warmth to your home!

Basic rules for thermal insulation

But that is not all. The efficiency of the boiler can be significantly improved by insulating it.

We have talked about the thermal conductivity of materials many times on our pages. In the article Do-it-yourself iron stove for a bath - knowledge is power, there is a video that tells about such an effect as thermal radiation.

Briefly, we note that during the operation of any furnace, thermal radiation is generated, which freely passes through the metal. If our boiler worked without a register, it would be great, it would easily heat the room in which it is installed.

- But after all, our boiler is mainly aimed at heating the coolant passing through the register installed on the chimney.

- This means that we absolutely do not need heat losses going through its walls, they must be directed into the chimney.

We build a boiler on sawdust

How to make such a boiler yourself?

A plug is welded to a pipe with a diameter of 400 mm on one side. This will be the bottom of the boiler. The height of the boiler depends on your needs. Expect in such a way that during normal operation one bag of sawdust is enough for 8-10 hours.

- A lid is cut out of 10 mm thick metal.

- In the picture above, you can see that it is made in the form of a polygon, this is not important, it is just that it is much easier to cut out thick metal if you use a guillotine.

- Exactly in the middle of the lid, it is necessary to cut a hole of such a diameter so that a pipe with a diameter of 76 mm can be freely inserted into it. The gap should not be too large.

Self-production in stages

Owners of a country house or, for example, a garage can make a sawdust oven with their own hands, but before installation work, you should equip the foundation - this will ensure the fire safety of the unit. After installing the equipment, it must be lined with refractory bricks or a water circuit must be installed. For installation work, the following materials will be required:

- a barrel with walls at least 10 mm thick (the desired barrel volume is about 200 liters);

- two metal pipes;

- refractory bricks and cement.

From the tools you will need a channel, a welding machine, a grinder (plus cutting wheels), a hammer, a hacksaw for metal.

Fuel tank preparation

The upper part of the barrel, from which the fuel tank is made, is cut off with a grinder. You can, of course, use a hacksaw for metal, but the trimming process will be delayed. Cut off the top of the barrel only after the correct marking, otherwise the workpiece will be damaged.

During work, you need to ensure that the grinder disc does not overheat, and also cut it off exactly along the marked line. You do not need to throw out the rest - it is suitable as a cover for the stove.

Installing the pressure plate and supply pipe

When preparing the pressure circle, it should be taken into account that its diameter should be slightly smaller than the diameter of the fuel tank (barrel with the top cut out). A hole is cut out in the central part of the circle, the diameter of which must correspond to the diameter of the supply pipe. The channel must be cut into 4 parts with a hacksaw and welded directly to the clamping circle - this will make the structure more durable.

Then, the supply pipe and the circle are combined with a welding machine. The pipe must be equipped with a damper for better regulation of the air entering the furnace - an easy-to-manufacture damper is a metal circle equipped with a steel handle.

Installation piping and cover

To remove smoke from the unit, a discharge pipe must be connected to the firebox. To do this, cut a special hole in the upper part of the fuel tank and attach the pipe itself by welding. It is connected to the main heating system using a clamp. It is optimal to use the previously cut top part of the barrel with welded handles as a lid. The furnace must be reliably protected from overheating, for which a reflector is welded to the outside of the tank. It is made of metal.

Such a design will give a long burning, and this will solve the problem of providing housing with heat. Moreover, in the independent manufacture of such a furnace, fairly inexpensive materials are used.

Manufacturing process

Single-walled. The device can be made from a barrel, a thick pipe, or bent from a sheet of metal. A horizontal partition with a central hole is placed in the lower part of the barrel. Under it is a chamber for an ash pan. The chimney cuts into the side. It should not be too high so that the first heat does not quickly leave the device, but not too low, otherwise it will be blocked by sawdust and the smoke will reluctantly follow the designated path.

The advantages of such models are the simplicity of the design - it is easy to make it yourself, you don't need a lot of material.

Heat transfer in such a structure comes only from the top. The efficiency is especially low if the furnace has one pipe outlet at the top.

Drawing of a sawdust stove

Two walls. By placing inside a larger container, a smaller one, you can get additional space between their walls, where smoke will pass before going into the chimney. The second circuit significantly increases the efficiency of the device. The inner container is placed here on a kind of support and is additionally fixed on the sides with spacers.

Instructions:

- A sheet metal bottom is installed on the outer tube.

- A lid is brewed for the upper part.

- Two identical holes are made on the side of the case - above and below.

- A door for the ash drawer is cut out from below.

- A long ash box is made according to the size of the hole.

- A round second bottom is made according to the diameter of the outer pipe. A hole is cut in its center for air passage. A low metal ring can be welded onto the hole. Its walls will prevent excessive shedding of sawdust into the blower. The bottom is welded to the inner tube.

- The inner container is inserted into the outer one and sealed hermetically.

- Nozzles with gates are welded.

- The oven is equipped with legs and is installed in place.

- The chimney is mounted, the stove is connected to it.

Sawdust furnaces and boilers

There are 2 types of furnaces, which differ in the way of air supply:

- from above, through a descending air duct;

- from below, through a pre-made channel in sawdust.

The most famous furnaces and boilers of the first type are devices under the Stropuva brand. They are produced both in the form of furnaces and boilers.

As we already said in the article (Fuel from sawdust), the difference between stoves and boilers is that the former heat the air directly, and the latter heat the coolant. Then the coolant, which can be both water and air, enters the rooms through pipes and heats them.

With drop-down duct

Stropuva's long-burning furnaces and boilers are arranged as follows:

- the body is made of a pipe with a diameter of 50–70 cm;

- two doors are cut in this body - a loading door from the top and a cleaning door from the bottom;

- a telescopic pipe passes through the cover (in home-made devices it is replaced by an ordinary pipe of large length) - an air duct;

- a steel circle with a thickness of 10 and a width slightly less than the inner diameter of the body is welded to the bottom of the air duct;

- a chain or steel cable is attached to the upper side of the disc to raise the air duct;

- corners or channels are welded to the underside of the disc, creating an optimal gap between the disc and the fuel;

- the smoke outlet is made slightly above the cleaning door.

Such boilers and furnaces work on sawdust as follows:

- lifting the air duct with a cable or chain, load the oven or boiler with sawdust, tamping them as much as possible;

- after loading sawdust, kindling is placed on top - paper and various chips;

- after waiting for the kindling to light up, lower the air duct and close the loading door;

- the air supply is set to maximum, due to which the upper layer of sawdust flares up and the furnace / boiler goes into operation;

- fire and smoke rise through the space between the disc and the body and heat both the duct and the body;

- the stove begins to radiate heat, and the boiler heats up the water jacket;

- as the sawdust burns out, their level becomes lower and lower and the air duct descends behind it, such a system ensures a constant flow of air into the combustion zone and the optimal mode of fuel combustion.

With bottom air supply

Boilers and stoves without a descending air duct are arranged and operate in a slightly different way. They have an air duct that goes to the bottom of the firebox.

Boilers and stoves without a descending air duct are arranged and operate in a slightly different way. They have an air duct that goes to the bottom of the firebox.

Such heating devices are loaded through a hinged cover. The chimney is connected just below the hinged cover.

The hinged cover is sealed with an asbestos cord or tape.

During loading, a long wooden cone-shaped plug is inserted into the air duct (the upper diameter is 1.5–3 times larger than the lower one).

The sawdust is tamped tightly and after the loading is completed, the plug is pulled out - through the resulting channel, air enters the upper burning layer of sawdust.

After the sawdust has flared up, the air supply is reduced and the furnace or boiler goes into a long burning (smoldering) mode.

Boiler device on a permanent basis

"Underground" installation of a boiler with thermal insulation

If there are no problems with sawdust in your region, and this heating method is the most profitable, you can install this boiler more efficiently and conveniently.

The figure shows the boiler installation diagram:

- A pit of the appropriate size was dug for its construction.

- There is a foundation at the bottom of the pit.

- The walls of the pit must be strengthened from spilling.

- The boiler is installed in a pit.

- Thermal insulation is arranged around the boiler, inside the pit.

- The boiler lid is insulated separately so that it can be removed.

- The coolant pipelines are connected.

- The register is also insulated.

- The chimney is connected.

- The boiler is ready for use.

Positive characteristics of sawdust ovens

Heating units have a number of positive characteristics:

- The duration of the combustion process with one laying of sawdust is from 8 to 18 hours.

- Autonomous work without the need for human control.

- Ergonomic body and light weight.

- High heat dissipation in a short period of time.

- Does not require the arrangement of an additional foundation.

- Possibility of laying various types of fuel material - sawdust, firewood, wood chips and pellets.

- Durability, safety and reliability of operation.

- Complete combustion of fuel and a minimum amount of ash.

- Reduced smoke emission.

- Easy to assemble at home from scrap materials.

- Affordable manufacturing cost.

- The ability to use for organizing hot water supply and cooking.

There are practically no significant drawbacks to such homemade stoves. The only negative point is that they are completely ineffective for heating large areas.

How the combustion process takes place in a sawdust oven

If we compare this device with the standard design, then in no case should fuel be thrown into this stove during combustion. It will be correct if pressed sawdust is put in the oven and until they burn completely, you should not open the oven.

If we compare this device with the standard design, then in no case should fuel be thrown into this stove during combustion. It will be correct if pressed sawdust is put in the oven and until they burn completely, you should not open the oven.

For prolonged burning of fuel, in order to preserve heat in the room, you can reduce the combustion force. With a slow combustion, the beginning of which will be in the center at the bottom, it will gradually spread upward and along the sides, which will make it possible for the sawdust to fall during the combustion process. Some ovens are quite capable of providing combustion for 8-10 hours.