Styling tips

Laying ceramic tiles does not require any special tools. An ordinary grinder is suitable for cutting elements of the desired size. It is worth using tiles with a thickness of no more than 8 mm.

Fireplace preparation and cladding are performed as follows:

- Remove old finishes, if any, along with plaster and paint. Clean and deepen the joints between the bricks, moisten the surface with water.

- Smooth the brick surface with heat-resistant mastic or clay mortar. Wait for the material to dry. If the surface is very uneven, level it with a grinding wheel. The better the surface is leveled, the easier it is to lay the tiles.

- Apply a primer. It helps to reduce dustiness and helps the previous layer dry evenly. Leave the primer to dry for two hours.

- The glue is mixed according to the instructions using a mixer or drill with the desired attachment. Glue for temperatures above 500 degrees in living quarters is not needed, the surface of the fireplace does not warm up to this level. A large number of solutions provided by current manufacturers will make it easy to choose the right material.

- The tiles are laid out from the bottom, applying the glue with a notched trowel. So that there is the same distance between the tiles, special corners are used. Every few rows we check the masonry with a level vertically and horizontally.

- After the completion of the masonry, jointing is performed. If desired, the seams can be convex or depressed, which is achieved by applying a solution with a special curly element.

- The tiles dry for two days at room temperature. After this period, the fireplace can be heated.

The choice of natural stone for facing the fireplace

Real stone cladding offers a wide variety of materials. Suitable for work are marble and travertine, sandstone and granite, tuff and limestone. When choosing the appropriate option, it should be remembered that smooth materials need less care, cleaning from dirt. Stones such as granite and marble are heavy, requiring a very solid fireplace foundation

It is equally important that the chosen decor blends well with the interior.

Properties of different stones:

- sandstone - layered, has a wide range of colors (from red-pink to dark gray), changes color when the illumination changes, is resistant to temperature extremes;

- shale - it can be red, yellow, green, brown, black, etc., is relatively expensive, requires periodic treatment with dirt-repellent mixtures;

- travertine is usually yellowish-gray in color, porous, not too dense, therefore, to improve its properties, it is coated with special compounds;

- granite - the most durable, reliable, durable, resistant to impacts, chemicals, temperature extremes. The color range is from white-gray to almost black, from pale yellow to maroon. The price is very high, but the appearance is strict, solid;

- marble - looks luxurious, is expensive. Colors - white, gray, black, variegated. The material easily tolerates temperature extremes, physical influences, but is not resistant to aggressive chemicals, household dyes, therefore it needs a special coating;

- onyx is a semi-precious stone, the presence of which in a room makes it unique. The material perfectly transmits light, it can be yellow, green, orange, brown, resistant to high and low temperatures, but chemicals are destructive for it, and the cost is about three times more than that of other stones.

Rules for working with marble, other natural stone

Working with real stone, be it marble, granite, sandstone or others, is laborious. Each tile will have to be carefully sized and chosen by tone.For work, you will need special grinding machines, stone cutting devices.

Laying procedure:

- the surface of the stove is cleaned of dirt, a reinforcing mesh is mounted;

- facing elements are adjusted so that all tiles are of the same size, shade, thickness;

- laying begins with the largest parts, fixed with tile glue;

- culling, if necessary, is used in inconspicuous places;

- in order not to confuse the locations of individual tiles, they are marked on the back;

- it is advisable to add compounds to the glue that increase its elasticity, the material should not fall on the front side of the tiles;

- work begins from the lower left corner, observing the order: from left to right, from bottom to top;

- for tiles with a thickness of over 10 mm, additional wire reinforcement is used;

- the seams are rubbed two days after laying, trying not to stain the material with grout.

How to ennoble stoves and fireplaces in a private house with your own hands? Finishing methods

The folded stove does not always look complete and in almost all cases requires additional intervention with the help of finishing materials

If the functionality of the device is enough for one owner, and he does not want to cover it with anything other than plaster, then for another, it is important that the guests of his house are amazed by the grace of artificial stone or correctly selected tiles.

Plaster

This type of finish is the coating of the stove with the same mortar that was used for the masonry.

It not only loses to other materials in terms of external components, but also reduces the efficiency by 5-10%, reducing the thermal conductivity of the furnace.

The time for heating the walls is increased by 20-30%.

Therefore, before applying the plaster, you need to think about whether it is worth saving or additional investments are possible.

Reference. Plaster without the use of top material looks dull, but it will save a lot of money if the task is only the practical use of the stove, that is, heating the room.

Whitewash

Our ancestors also whitewashed the stove for each season, since expensive materials were not available to all people. It doesn't take much skill to whitewash a stove. This is the easiest way to finish: a lime or chalk mortar is applied to the stove.

It is important to remember that this type of coverage presupposes a careful attitude on the part of the tenants, since the white color is easily soiled

Dyeing

Modern manufacturers produce various heat-resistant paints. It is this type of material that is required when covering the surface of a folded stove, since its wall will often be thermally affected when ignited. If desired, the painted surface can be coated with a special varnish.

Photo 1. Painting the stove with white paint. When facing such products, it is necessary to choose heat-resistant materials.

Can I smear with clay

The use of clay mortar to strengthen the furnace is justified by the fact that it contains sand, which strengthens the surface of the walls and gives additional protection against chips and other cracks. This type of decoration does not differ in originality and is used mainly for practical purposes, which do not imply giving the house individuality and the embodiment of design ideas.

Decorative artificial stone: gypsum, acrylic. Photo

Many homeowners want to see their stove with a stone laid out on top of it. But not everyone can afford to buy expensive materials. For these purposes, an artificial stone is used for decoration, which in many properties is not only not inferior to natural, but also has additional positive characteristics:

- simple masonry that even a novice craftsman can handle;

- the laid-out oven will not be cumbersome, because the material is light in structure;

- saving money when choosing a finish;

- a wide range of shapes and colors;

- the opportunity to embody various creative fantasies when decorating the interior.

In addition, the material also differs in structural diversity:

Plaster dough. Outwardly it resembles natural sandstone, has good strength characteristics.

Photo 2. Decorating the fireplace and walls next to it with an artificial stone based on gypsum dough.

Acrylic stone. Even more durable than the previous version.

Photo 3. Fireplace with acrylic stone cladding, the color of which resembles natural marble.

- Artificial stone with the presence of natural stone chips.

- Porcelain stoneware. Consists of several types of clay, mineral salts, marble chips and pigments. High resistance to mechanical damage and high temperatures.

Photo 4. Fireplace with black porcelain stoneware cladding.

Heat-resistant composite. The material is made on the basis of concrete, quartz or minerals. Its strength can be compared to granite.

You will also be interested in:

Decorating the fireplace with natural brick is beautiful

If your fireplace is built by a professional stove-maker, does not have distortions and blemishes, chips and cracks, you do not need to resort to expensive finishing, but simply cover the brick with heat-resistant stone varnish. The lacquered surface perfectly repels dirt and soot, water and dust, as a result you get a beautiful old English style fireplace at no extra cost.

Can it be done beautifully from simple plaster?

If the masonry is not even enough, or you do not like the look of natural brick, you can resort to an inexpensive finishing method, which was very popular in the old days - to plaster the fireplace and cover it with a layer of heat-resistant paint. The advantages of this method:

- Low cost of materials;

- The method is simple to perform and does not require special skills and the use of a tool;

- It is easy to refresh or repaint the fireplace, giving it a new look;

- The cladding does not make the fireplace heavier, there is no need to strengthen the foundation.

Decorating a fireplace with plastering and painting includes several stages:

- Prepare the surface of the fireplace - remove dirt, dust from the surface, as well as old plaster, if any. This is done with a spatula or grinder. After cleaning, the surface is treated with a primer.

- After cleaning, the surface of the fireplace is moistened to reduce dusting and the seams of the masonry are embroidered by 0.5-1 cm - this is necessary for better adhesion of the plaster mortar to the brick.

- The fireplace is preheated and dried. When plastering, its surface must be warm, otherwise cracks will appear on the plaster the first time it is heated.

- On the surface of the masonry, the reinforcement mesh is fixed with the help of small studs. It will serve to strengthen the plaster layer.

- For plastering and finishing, special heat-resistant mixtures are used - you can buy them in hardware stores. The mixture is poured into water in the recommended proportion and thoroughly mixed with a construction mixer until smooth.

- The plaster is applied using two spatulas: narrow and wide. Scoop the mortar with a narrow spatula and spread it evenly across the width of the large spatula, and then apply the distributed mixture to the surface of the fireplace. The inner corners and embossed projections are trimmed with a narrow spatula.

- As a solution, you can also use the old-fashioned method - a mixture of clay and sand. Oily clay is mixed with sand in approximately a 1: 1 ratio, diluted with water so that the mixture does not spread, but does not form cracks when leveled with a spatula. Apply the solution in the same way, rubbing it with a wooden float and finally leveling it with a piece of burlap or other coarse weave fabric.

- Drying of the solution is carried out for several days. For clay plaster, it is quite possible that it will take about a week, during which the fireplace must be slightly heated, especially in the cold season.

- A layer of paint or a special decorative stove putty is applied on top of the plaster. Fireplaces need heat-resistant silicone paint, and you can give it the desired shade using a water-soluble color.

- Coloring the fireplace can be done without plaster, right on the brick - in some cases, such fireplaces fit perfectly into the design of the house.

This method has a drawback - the finish is not durable, and in case of accidental impacts, it is prone to shedding, especially at the corners. This flaw can be corrected by revealing the corners with stone or tiles, and how to do this - read below.

Facing with decorative stone

Which facing stone to choose?

When choosing a future facing for a fireplace, the first thing you should pay attention to is the appearance, color, texture. They should be combined with the style in which the whole room is decorated (see

Decorative fireplaces in the interior). But the durability of the stone is of no less importance.

The longest service life is distinguished by natural decoration of fireplaces with decorative stone, that is, decoration with marble, granite, limestone, sandstone, tuff, etc.

The strongest and most expensive rock is granite, moreover, it is easy to process and polish. Slightly cheaper will be facing with marble - no less beautiful and interesting natural material.

Decorating the fireplace with artificial limestone

If you cannot afford such an expensive finish, it can be successfully replaced with an artificial stone, which outwardly is almost indistinguishable from natural, but costs much less.

How to decorate a fireplace with decorative stone?

You should start with surface preparation:

Stone marking before laying

1. Thoroughly clean the brickwork of the fireplace from dirt and dust.

2. Use a sharp, sturdy metal object to deepen the joints between the bricks.

3. Cover the entire surface to be finished with masonry mesh.

4. Fit all parts of the veneer dry. To do this, draw a projection of the fireplace walls on the floor with chalk and lay out all the cladding elements, adjusting them in shape, color and thickness.

If you use tiles of irregular shape, then be sure to mark it before laying by writing its number on top, and on the edges - the numbers of neighboring elements. The small pieces left after trimming and trimming can also be used to fill the voids at the bottom and in the corners of the fireplace.

The laying process starts from the bottom corner. Having faced the corner, they proceed to laying out the upper horizontal row and continue from top to bottom.

After finishing the work, it is necessary to withstand two days for the glue to dry, after which you can proceed to grouting. But first you need to check on the trimming of the decorative tile, whether the selected grout will not leave marks on it.

Thus, fireplaces are decorated with both artificial and natural stone. If you have chosen ceramic tiles for cladding, the technology of work will be slightly different.

Ceramic tile

Ceramic tiles have the same fire resistance as brick.

Moreover, she simply has an incomparably greater variety of external forms.

Now, instead of tiles, almost all manufacturers have mastered the technology of semi-dry pressing, which allows you to create any patterns and textures on the tile surface.

This material received the trade name "Keramogranite", although there is no granite in its composition. Decorating the stove in the steam room with tiles has its own advantages, and the main one is the design variety of solutions. Unlike bricks, tiles can be of any color.

The side of the old tile had a size of 10-15 cm. In modern porcelain stoneware tiles, the side length can reach 40 cm. The longer the side length, the more accurate the coating is.It has fewer seams, but the complexity of the installation is significantly increased. Porcelain stoneware tiles must be installed by specialists.

A lot of experience is needed here. If the tiles are small, then the cladding can be carried out independently. There are no particular difficulties here. Laying is carried out using a conventional mortar on a sheet of heat insulator. It is better to use a special mortar based on a dry construction mixture for the appropriate purpose.

Natural stone is as fire resistant as brick. It is equally suitable for finishing the stove, but its appearance is much more decorative.

Furnace finishing is carried out not with raw stone, but with finished products from it. These are tiles or special stone elements for decorating fireplaces.

Classic types are used from stone: marble, granite, but in the bath they may turn out to be inappropriate in design and are expensive. In this case, they are replaced by cheaper sandstone and shale stone. Slate stone is often chipped into flat pieces, so its price is very low.

Decorating the stove in the bath with decorative stone begins with the selection of material. Untreated stone is cheaper, but its surface in the bath can quickly become dirty.

Part of the portal, which is laid out on the floor, is especially susceptible to pollution.

Despite the fact that the raw stone looks beautiful, it is recommended to use a polished and polished version for a steam room.

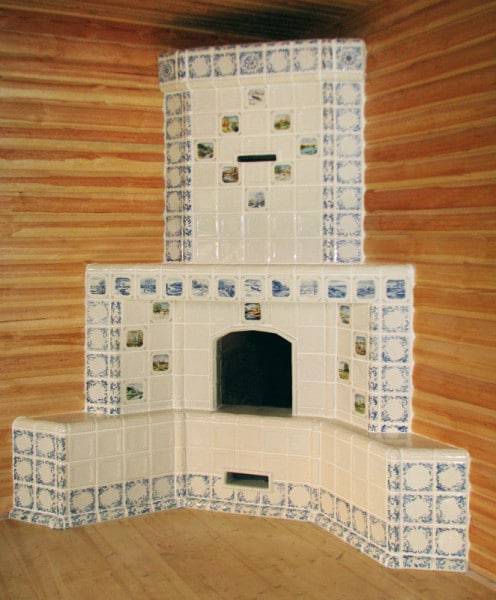

Tiles are a classic solution for decorating stoves. They have cheap production technology and very reliable assembly. The tiled exterior looks like high-quality, thick tiles.

This appearance will be ensured only if you use tiles without a pattern on the front surface. They do not produce a special decorative effect, since they do not differ much from the usual tiles. The gain is only in the strength of the fastening, so other tiles with a three-dimensional pattern on the front side are more popular.

The tiles are laid according to the same pattern as the tiles, but they require a significant thickness of the finishing layer. If a portal for a sauna stove is made of them, then a part of the wall and floor is covered with tiles. On the floor, they may not be used if the furnace foundation is raised above the floor by one or two brick rows.

If the tiles have holes for the wire, then it must be used.

The diameter of the rods is selected according to the instructions. The larger the diameter, the higher the strength, but at the same time the complexity of the installation increases.

On average, tiles are the same thickness as one brick.

They can just as well be used to create the same protective layer.

Material calculation

Before planning a trip to the shops, you will need to first take all measurements from the planes that will be faced.

Do not neglect the processing of adjacent surfaces, which will also be exposed to high temperatures. The floor, adjacent walls and the ceiling will also need to be protected with fireproof shields.

Tile glue is counted separately, manufacturers attach instructions directly to the package, so now you only need to know the area that will be covered with it.

Do not think that you will be able to avoid cutting the tiles, this is impossible, so you will need to purchase or borrow a tile cutter.

Before decorating the stove, it is imperative to strengthen the planes, usually this is done using a ready-made metal mesh or by tensioning the wire.

Properties of decorative stone

The advantages of decorative stone include:

- Durability and reliability. Due to its strength characteristics, artificial stone is very resistant to mechanical and physical damage.

- Ease of maintenance.The surface of the coating is easy to clean and clean.

- Moisture resistance. A protective layer on the surface of the decorative stone protects the coating from moisture absorption. Therefore, you can safely wash it with a damp cloth and mild detergent.

- High temperature resistant and flame retardant. Artificial stone will withstand even prolonged exposure to open fire, since it does not burn at all.

- Wear resistance. Despite constant wet care, the stone finishing of the stove retains its decorative properties for a long time without losing its appearance.

- Resistant to sudden temperature changes. Such a material retains its properties, despite the differences from very low to high values, and vice versa.

- And the biggest advantage is the ease of laying decorative stone with minimal time and materials.

It is interesting: Lining the stove in the bath with bricks (video)

Cladding types

After a properly prepared surface, you can make a quality finish. There are many products available in retail for this.

Decorative brick

Brick for decorating a fireplace is used quite often, it should be used for several reasons:

The use of decorative stone in the decoration of the fireplace

- Resistant to temperature extremes and perfectly tolerates high humidity.

- Environmentally friendly material that does not harm human health.

- It tolerates high temperatures perfectly.

- The many shapes of the material allow you to make a practical pattern and give any style, there are different colors.

- The price of the material is quite affordable. You can make a finish for any natural stone and at the same time pay little money.

- This work can be done with your own hands, without resorting to outside help, than to reduce the cost of the product.

- Inexpensive to maintain. One has only to wipe it with any non-abrasive cleaning agent - and the original appearance will remain for a long time.

Wood trim

This is a nice finish. True, it should be used only for decorative electric fireplaces.

Many advantages can be seen here:

The use of wood in the decoration of the fireplace

- Your product will look pretty rich. Moreover, now there are many substitutes that give the appearance of expensive breeds.

- When crafting, you can give it almost any shape and style. And it won't be that expensive. Moreover, the work can be done by hand.

- There is also a minus in this material. It will only last for quite a long time if you pay enough attention to maintenance, and it is not so cheap and takes time. Moreover, it is not worth doing such a finish in places where there is no constant heating. The material tends to absorb moisture. After drying, cracks may occur and the appearance will be lost.

- The light weight of the structure allows it to be done without an additional foundation. Execution on the floor is also possible.

Tiling

Ceramic tiles are also used in our time (see Ceramic tiles for fireplaces and stoves - make a choice). It has its advantages and disadvantages.In order to make the right choice, you should dwell on this type of finish in more detail:

The use of tiles in the decoration of the fireplace

- This material does not change its properties for a long time.

- The tile is resistant to temperature extremes and can be placed in rooms with intermittent heating. It perfectly tolerates temperature changes of the order of 75 cycles - this is a rather high indicator.

- It is able to withstand high temperatures and allows it to be used not only on decorative fireplaces, but also on traditional ones.

- High heat capacity. It warms up well and cools slowly.

- It has a variety of colors, which allows you to choose exactly what you need.

Tiling

Decorating with tiles will help turn your brick fireplace into a real work of art. Of course, this is a rather expensive design option, but also one of the most durable.

Tiles are usually called tiles based on clay of a special shape, decorated with an ornamental or figured image. The tile has a glazed surface, which facilitates the maintenance of the coating. In addition, clay tiles retain heat well, which will reduce fuel consumption.

The process of finishing with tiles differs little from the process of finishing with ordinary tiles. However, there are certain nuances. In particular, a clay-based solution is used for laying tiles.

The size of the tiles is chosen according to your taste. Using small tiles will help achieve a mosaic effect, however, laying this tile option requires a lot of experience. In any case, the design of the patterns and the layout of the tiles must be developed in advance.

Plasterboard finishing

This material is used quite often in the decoration of electric fireplaces.

The use of drywall in fireplace decoration

So:

- Such a finish is perfect for facing a false fireplace (see DIY false fireplaces - what and how to make). However, it cannot be applied to an existing structure. The material does not tolerate temperature extremes and is not suitable for heating.

- For use in an apartment, this material is quite practical. It is environmentally friendly and does not harm human health.

- It is possible to make finishing of almost any shape and carry out further cladding with any material.

- A person can do all the work with his own hands, without resorting to outside help. If using other materials requires a little practice, then drywall can be installed without much experience.

How to veneer a fireplace with stone

Technologically, decorating a fireplace with stone is not much different from laying tiles. The difference is in working with the material itself, but there are almost no technical features. The only thing is that when using natural limestone, be sure to wrap the fireplace with a net. Without it, it will fall off.

Decorating the fireplace with stone is one of the options

Features of working with artificial gypsum stone

This type of decorative stone is inexpensive and lightweight; fireplaces can be trimmed, especially without overloading the floors. There are only some nuances, without which you will not achieve a good result.

The technology for the production of gypsum stone is such that on each element there are some irregularities, nodules, protrusions. We grind them with a knife, since plaster is cut without problems. We grind each element of the cladding so that a frame with an angle of 45 ° (or so) is formed at the back, along the perimeter.

Moreover, often the corner elements of a plaster decorative stone are several millimeters higher than an ordinary one from the same collection. To make the cladding look monolithic, you also have to remove this difference - grind it down. When all the cladding elements are fitted, they can be glued in place. Heat-resistant glue is used for facing fireplaces, although with the correct design it almost does not heat up.

Working with natural stone

Most often, fireplaces are faced with natural stone, sawn into plates. It is also called flagstone or stone tiles. The shape of all the fragments is different, you have to adjust to make everything look beautiful. In this case, it is definitely better to first lay out the whole picture on some plane, pick up and process the elements. Only after the mosaic is folded can it be glued. The whole technology of installation on the walls of the fireplace is described above and is practically no different. The whole process can be seen in the video.

Tiles suitable for decoration

Not every type of tile is suitable for decorating a fireplace. Depending on the manufacturing technology and structure, the material is classified into several types. Each of them differs not only in cost, but also in characteristics, installation features and service life.Tiles are selected based on the characteristics of the room, which is decorated with a fireplace.

For example, a heavy-duty material is bought for a bath, which will not be afraid of high temperatures and high humidity. An imitation with similar characteristics is selected for the kitchen. Living rooms, bedrooms, offices are less demanding on tiles. Their microclimate is stable.

Terracotta

Clay acts as the main component of the tile. The material is perfectly attached to any surface using ordinary liquid nails. Terracotta has high vapor and air permeability. This helps the decor to absorb excess moisture in the room and participate in the formation of a favorable microclimate. Not only fireplace portals are faced with terracotta, but also the facades of houses. The material is frost-resistant, so it is ideal for decorating rooms with unstable temperatures (for example, baths). The special surface texture allows terracotta to give off heat for a long time, therefore fireplaces decorated with such tiles cool down more slowly. In terms of strength, the material does not lag behind oven bricks.

Majolica

Majolica is glazed terracotta. An additional glossy layer allows cleaning the surface with abrasive compounds, contact with which will not damage the tile. According to its characteristics, majolica does not lag behind terracotta. It is also easily fixed on the surface, gives off heat for a long time, and can be used in any type of room. During production, the top layer of majolica is decorated with patterns. A rich assortment of drawings allows you to choose the material for the interior design.

Heat-resistant clinker tiles

The clinker is made from several types of clay and chamotte powder. Natural dyes are added to the composition. The material is environmentally friendly. Since its structure is low-porous, it slowly gives off heat. Frost resistance allows you to decorate fireplaces in houses and temporarily used baths. Clinker thickness varies from 0.9 to 1.2 cm. The tiles are strong, durable and insensitive to mechanical damage. On the surface, the clinker is fixed with liquid nails. Unfortunately, the material does not have terracotta adhesion, therefore, a reinforcing mesh is additionally used for finishing.

Porcelain stoneware

We owe Italians for the appearance of porcelain stoneware. The production technology of the new facing material was first tested at the end of the last century. The monolith is non-porous, which significantly increases its service life. Porcelain stoneware is made from marble chips, metal oxides, quartz sand with the addition of pigments by pressing under high pressure. The artificial material has performed well during tests at low and high temperatures. This quality of porcelain stoneware allows it to be used when decorating fireplaces in steam rooms, in the kitchen and for decorating the facades of houses. The material can be used to decorate a room with almost any style, as it is available in a wide range of color and texture options. The surface of porcelain stoneware does not fade under the sun's rays.

Tiles

Tiles are piece decoration pieces made of special types of clay. Their surface is treated with glaze, which gives it a glossy shine. Due to the high cost, the tiles did not manage to break out into the market leaders. The technology of their manufacture involves firing at high temperatures, which makes the material heat-resistant and durable. Tiles are characterized by high heat transfer, which is useful for those rooms where the fireplace is not just an interior element, but also an alternative source of heat.