Types of floor standing boilers with two circuits

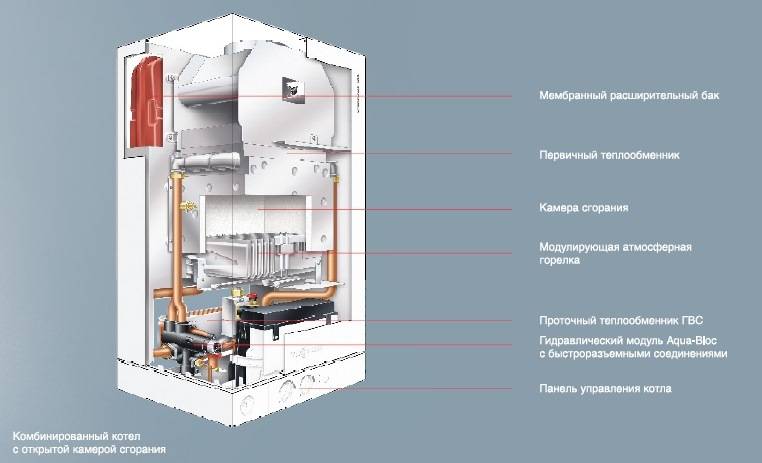

Depending on the characteristics of the room where the heating unit will be installed, the user needs to choose the correct type of combustion chamber. It is a key piece of equipment and influences many operational factors.

With a closed combustion chamber

It is not always possible to install a chimney in the room, for example, due to the architectural features of the structure. In such situations, a turbocharged version equipped with a closed chamber is chosen.

The flue gases formed in the process of fuel combustion are removed forcibly, for which a special fan in the boiler structure is responsible. The intensity of rotation of its blades can be adjusted by selecting the optimal pressure in the system.

The advantages of such a unit:

- Suitable for any premises.

- In the absence of an open source of fire, the likelihood of carbon monoxide entering the house decreases.

- No chimney needed. This reduces the cost of installation work, thereby offsetting the high cost of equipment.

- During operation, the air from the room is not used, thereby reducing heat losses. The fire is supported by air coming from the street.

Certain disadvantages of such boilers are still present. You need to know about them in order to have an idea of the strengths and weaknesses.

Cons of a boiler with a closed combustion chamber:

- The fan may start to malfunction over time, so it needs timely maintenance.

- The turbine produces, albeit small, noise.

- Increased power consumption.

A turbocharged boiler is the best type if the structure does not provide for the installation of a chimney.

With an open combustion chamber

They are also called "chimney". Combustion products are removed naturally through the chimney system. For work, air from the room is used, supplied to an open combustion chamber.

This type of equipment has the following advantages:

- relatively affordable cost;

- simplicity of design, which facilitates maintenance;

- combustion products can be removed at a considerable distance from the house.

These are durable and easy-to-use devices that are widely demanded by most users. Still, you need to take into account certain disadvantages of such equipment.

Disadvantages:

- We need a chimney. This entails additional expenses, because a "competent" installation requires permission, installation of a sensor that measures the level of carbon dioxide, and so on. In addition, the chimney must be properly insulated, since modern models heat up the gases somewhat at the outlet, which can cause condensation to form on the pipe walls.

- Air from the room is used for combustion. Supply ventilation must be provided.

The operating conditions of chimney models force them to be installed in a special room - a boiler room.

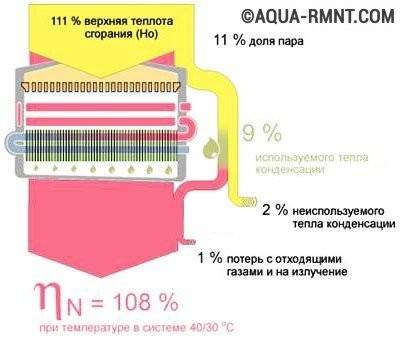

Condensing

In such equipment, more modern electronics and modernized gas valves are installed, which allows you to configure gas automation in a wide range of power. A special fan is responsible for the supply of combustion air, and the automation itself calculates how much oxygen is needed.

This distinguishes condensing boilers favorably from traditional heating equipment in terms of efficiency. Modern models are equipped with systems that adapt to many characteristics, which makes the equipment economical.

An additional advantage of condensing units is that they use the latent heat of combustion of the gas. In simple terms, part of the heat in traditional installations is lost during combustion.

Condensing ones allow you to set the supply temperature to +60 ° C, as a result of which part of the heat is returned due to the effect of condensation. But this circumstance obliges the user to provide for the drainage of condensate from the boiler into the sewer drain.Modern models are already qualitatively heat and noise insulated.

Prices for a double-circuit floor-standing gas boiler

double-circuit floor-standing gas boiler

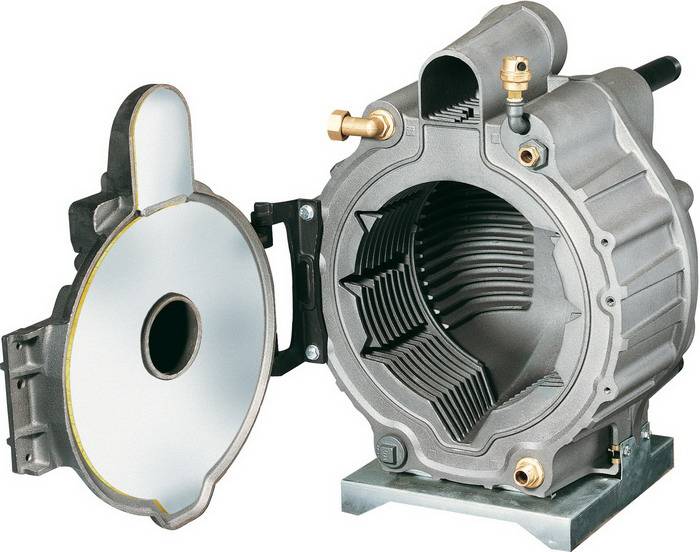

Materials for the manufacture of a heat exchanger

Currently, this structural element is manufactured from three materials: copper, steel and cast iron. Each of them has its own operational characteristics.

Steel

The most common option is installed in models of domestic manufacturers. This is due to the availability of the material and the ease of processing. The material has good ductility, and equipment with a steel heat exchanger has a relatively low cost. The property of plasticity plays an important role, since the surface of the element is exposed to thermal influences during operation, which can lead to cracks.

Steel heat exchangers have one significant drawback - susceptibility to corrosion. In addition, they are quite heavy and bulky, so the boiler will need more energy to heat them up.

Copper

It is compact, corrosion resistant, lightweight and small in volume. Despite its small size, due to the peculiarity of the material, it transfers more heat than steel and cast iron versions.

In the first versions of the equipment, the copper heat exchanger quickly collapsed, since there was a large thermal effect per unit mass of the copper device. In modern units, this feature of the material is taken into account, therefore, the burner power gradually decreases, depending on the degree of heating of the coolant. In terms of durability, a copper heat exchanger can be compared to a cast iron one.

Cast iron

Heat exchangers made from this material are durable and corrosion resistant. In turn, they have serious operational requirements. For example, due to the accumulation of deposits, the heat exchanger may begin to heat up unevenly, which will significantly reduce its service life.

At the moment, this type of heat exchanger is not so common, which is explained by their high cost, heavy weight, bulkiness and high inertia.

Main classification

A wide variety of boilers can be found on the heating technology market. A user who is not versed in this topic simply will not understand what is the difference between them. In fact, gas boilers are classified according to many parameters.

Household heat generators are divided into several types according to:

- Installation method. Wall-mounted and floor-standing models are now available.

- The method of preparing water. There are single and double-circuit. The boiler can be built-in or flow-through.

- Burner type. Distinguish between one-, two-stage, atmospheric, supercharged and smooth modulation.

- The type of traction. It can be natural or forced.

- Heat exchanger material. This element is made of steel, cast iron or copper.

- Dependencies on the power grid. They can be connected to the mains or work autonomously.

- The type of coolant. Some work only on water, but there are models that allow the use of both water and antifreeze.

Each point plays an important role and should be carefully considered, which will allow you to choose the optimal model.

Differences between "double-circuit" and "single-circuit"

A double-circuit gas boiler allows you to avoid unnecessary costs associated with the purchase and installation of equipment for hot water supply. Two heat exchangers independently of two heat the heat carrier in the heating system and water for sanitary needs. This is especially true for buildings under construction, or for those who, due to circumstances, decided to completely replace the heating and hot water supply systems - it's time to optimize.

A double-circuit boiler allows you to reduce construction costs.Installation and maintenance of a boiler with a DHW circuit will be cheaper than for two separate systems

Floor-standing gas boilers, like wall-mounted ones, can be paired with an instantaneous water heater or an external or built-in boiler. The latter can be sixty to one hundred liters in volume, and some models are equipped with 150-liter containers. Wall-mounted boilers cannot boast of such characteristics. A large water heater is relevant for houses with a large number of consumption points.

Most models of wall-mounted gas boilers are available with a capacity of up to 60 kW. Much less common are specimens that can provide heating for buildings with an area of 800-900 square meters. But floor-standing gas boilers are produced with a capacity of four to several hundred kilowatts. Agree, there is much more room for choice. Therefore, for large buildings, in which there is the possibility of equipping a separate boiler room, it is better to buy a floor-standing gas heating boiler.

Floor standing heating boiler, as a rule, requires installation in a separate boiler room. In this room, it is advisable to install a sensor that, in the event of a gas leak, will immediately turn off the fuel supply line.

Double-circuit floor-standing gas boilers with an instantaneous water heater provide hot water consumption up to 33 liters per minute. This figure can be increased by additionally installing a storage boiler. The most powerful floor-standing boilers are equipped with independent circuits that provide heating of the coolant for the underfloor heating and water for the pool.

Additional selection criteria

It is easy to get confused in the long list of technical characteristics of gas boilers. The main ones affecting the operation of the heating system were given above. Let's decipher the remaining characteristics of double-circuit floor gas boilers:

- Efficiency - coefficient of efficiency. Most boilers have between 80 and 92%. However, condensing boilers have a coefficient of 102 to 109%;

- hot water supply performance - the volume of water that is heated by the boiler to the set temperature in 1 minute. Typically, this figure ranges from 2.5 to 17 l / min. Powerful heating devices can produce more than thirty liters;

- the maximum temperature of hot water is usually 55 ° C;

- maximum water pressure - for most boilers is 6 bar;

- the maximum temperature in the heating circuit is 80-90 ° C;

- pressure in the heating circuit - most manufacturers produce boilers with a pressure range from 1 to 10 bar in the heating system;

- expansion tank volume - we are talking about built-in tanks, the volume of which is 17 liters or more;

- natural gas consumption - a modest 7 kW boiler consumes 0.78 cubic meters / hour. But the unit, designed for heating 1950 square meters, burns 24 cubic meters of gas per hour. It all depends on the power of the boiler;

- consumed electricity - the numbers opposite this parameter indicate that this boiler belongs to the category of electrically dependent. For the most part, this is what they are. Electrically independent equipment does not allow the room temperature to be adjusted so quickly and requires the additional installation of an expansion tank.

In the technical specifications, additional options are often found: display, autodiagnostics, frost protection, overheating protection and pump protection against seizure - their availability depends on the price segment of the equipment.

Condensing gas boilers have a much higher efficiency compared to traditional ones. They allow you to save 10 to 30% of fuel

Installation principle of a floor-standing boiler

When installing gas heating equipment, be sure to make sure that all the necessary clearances (specified in the instructions) are present, and for devices with an open combustion chamber, ventilation is available.

Installation of double-circuit floor-standing boilers is carried out by analogy with conventional single-circuit modifications. Most often, a separate room is allocated for them - a boiler room. But nothing prevents you from installing the equipment in any other place where there are windows and fresh air (for example, in the basement).Appliances with closed combustion chambers can work anywhere, even in the kitchen - they take air from outside the premises.

Next, the heating circuit and the gas supply pipe are connected, pipes for the supply of cold water and the intake of prepared hot water are also brought here. If necessary, a gas analyzer is installed in the room with the equipment, which provides control over possible leaks of gas fuel. The final check and connection should be entrusted to the gas service specialists.

Installation of floor models

Gas equipment requires a professional approach when performing installation work. Powerful boilers are also installed in boiler rooms or, at least, in separate rooms. During installation, you need to adhere to some requirements:

- The area of the premises cannot be less than 15 square meters.

- The height of the ceilings must be more than 2.5 meters.

- There must be a window with an opening sash in the room.

- A doorway width of less than 80 cm is unacceptable.

- All units and devices of the system must be provided with free access for periodic maintenance and repair work.

Liquid fuel boiler models

At the planning stage, the need for ventilation and flue ducts is taken into account. The boiler is installed in several stages:

- Arrangement of the foundation.

- Connecting the outlet of the heating equipment to the chimney.

- Connection of the main pipelines to the corresponding connections of the boiler.

- Installation of a coarse filter and connection of the boiler to the supply water supply.

- Hot water pipeline installation.

- Connecting the gas boiler to the energy supply lines.

All work is carried out in accordance with the requirements of regulatory documents and safety regulations. An amateurish approach when connecting gas communications is excluded. Only specialists who have been certified by government agencies are allowed to work. They also undertake to periodically monitor the operation of the gas installation and make its current repairs.

Modern models of floor standing boilers are completely safe and are widely used as household heat generators. They are equipped with automatic devices that prevent emergencies associated with overheating of the coolant and gas leakage. Most models have additional control devices that react to the slightest malfunction and inform the owners about it.

Read on:

Floor standing gas boilers - an economical way of heating

Floor heating batteries - materials used, advantages and disadvantages

The use of a gas floor boiler for a private house

What autonomous heating gives - myths and reality

What is an autonomous gas heater

Double-circuit floor-standing gas boilers

Gas units with two circuits operate on the principle of alternating hot water supply to radiators, then to taps. Water enters the device, which passes through a heat exchanger.

Heating occurs due to gas combustion and heat release. Having passed through the heat exchanger, the liquid is directed to one of two circuits. Since mainly heating is constantly working, water goes into it.

The hot water supply system (DHW) is used from time to time, therefore, in order for the liquid to enter the taps, a special valve shuts off the water supply to the heating devices. But there are also gas boilers with a built-in boiler - an independent water heating device. It is better to install them in houses where hot water supply is used frequently.

Boilers are also divided into convection (direct heating of the heat carrier) and condensing (additional heating due to evaporation).

Specifications

The technical parameters of floor-standing gas heating boilers include:

- power;

- the principle of heat release;

- volatility.

The calculation of the power shows which unit is needed for the room. This parameter is produced according to the formula: 1 kW per 10 m2 of area. But since it is not customary to operate heating boilers at the maximum power to increase the service life, the device is purchased with a margin of 20%.

Photo 1. Floor-standing double-circuit gas boiler, model KS-GS 5S, closed combustion chamber, manufacturer - "Taiga", Russia.

In other words, for a house with an area of 300 m2, a boiler with a capacity of not 30 kW, but 36 kW is required.

Important! Calculating the power of the gas boiler, the heat loss in the house is estimated. This parameter is influenced by the region, the location of the building, cracks in the building and other factors.

With large heat losses, you will have to increase power and fuel consumption.

The principle of heat release in a floor-standing gas unit depends on whether it is a convection boiler or a condensing boiler, as well as a closed or open combustion chamber. In a convection appliance, heat is transferred directly from the combustion gas to the heat exchanger, and the combustion products and steam are expelled through the chimney.

In condensation, steam is collected separately in a special tube and used for additional heat release. This significantly increases the boiler efficiency and reduces fuel consumption.

There are autonomous and volatile boilers. The former work without electricity.

It helps to save on expensive electricity and makes heating and water supply independent from possible power outages.

But safety and control systems, as well as digital control components, require a power supply. Their use is justified by the fact that it allows you to regulate the operation of equipment, reducing fuel consumption and creating a more comfortable microclimate.

Requirements for the premises

What you need to know about the rules for installing floor-standing gas boilers is spelled out in SNiP 42-01-2002 "Gas distribution systems". The equipment is installed in separate rooms as these are rather bulky units that require space and require a well-thought-out ventilation system. More often this applies to devices with an open combustion chamber.

Unlike systems with a closed chamber, air enters the devices with an open hearth from the surrounding space, and the combustion products are removed through the chimney, so the room must be well ventilated.

If the boiler is designed for high power, it can be quite heavy.

This is true for units with cast-iron heat exchangers, which already weigh so much by themselves, and together with boilers, the weight increases to several hundred kilograms. For such devices, a separate foundation is needed.

For boilers with a capacity of over 60 kW, installation rules require a separate room, or even better, a separate building. It should have a constant airflow, the installation area should be from 4 m2, the ceiling height should be 2.5 m, and there should also be a ground loop (for volatile models) and a door with a width of 0.8 m or more.

Since the permit for the operation of a gas boiler is issued by state authorities, it is better that the installation of equipment is carried out by professionals. They should also be entrusted with the piping of the boiler, which guarantees its correct operation, especially when it comes to a two-circuit system.

Gas equipment is strictly supervised, so the slightest deviation from the rules can block the use of a gas boiler in the house, even if it is the only source of heat. Experienced installers will prepare the room for the installation and operation of the device, carry out the necessary communications, connect the unit and adjust its operation.

Selection recommendations

Compared to wall-mounted units, floor-standing units are characterized by greater power and therefore fit perfectly into the heating system of a large country house. But in order for the equipment to efficiently use working resources, it is necessary to select it correctly, taking into account the key characteristics.

Criterias of choice

When buying heating equipment, a number of other features are taken into account, which greatly affect its operation.

Experts advise considering the following points:

- Rated power. This parameter is of primary importance. For this, the square of the room is calculated.

- Other performance characteristics. We are talking about fuel consumption and pressure indicators in communications.

- Work resource. Judging by the ratings, in which both wall and floor models from various manufacturers took part, a longer service life is observed precisely in domestic models. This is explained by the fact that foreign units are designed for operating conditions different from Russian ones.

- Efficiency. This characteristic is displayed in efficiency, where the optimal indicator will be from 85 to 92%.

- Manufacturer country. If we take into account these ratings, then the most popular are products created in Germany, followed by Italy and Sweden.

What to choose - flowing or accumulative

The flow-through one immediately prepares hot water, and the storage one does it for a certain time in a special large-volume tank.

The first type of thermal equipment is also called a column. Water heating is carried out according to the direct flow scheme. The heat from the heating heat exchanger is transferred to the water tube, which is why the water heats up instantly, immediately after opening the tap. Combustion products in such installations are removed through the chimney. Ignition can be either manual or automatic.

Based on the name of the storage devices, it becomes clear that they first accumulate cold water, and then heat it. The main element is a spacious tank, the capacity of which may vary depending on the model. On average, 50 liters of household water is enough for one person a day. The advantage of storage devices is that they automatically maintain the set water temperature.

How to calculate power

Power characteristics of modern units can vary from 7 to 100 kW

To determine the main indicator - power, many features are taken into account, since this is a complex and responsible task that directly affects the operation of the heating system

Consider the following:

- What is the size of the heated room? It is convenient to use a tape measure for measurements.

- Insulation of housing and possible heat loss. For example, if the house is new, with high-quality thermal insulation, underfloor heating, energy-saving windows, then the equipment is selected "end-to-end". If, after carrying out the calculations, the figure is 60 kW, you do not need to add anything to it. When the room is old, with insufficient quality thermal insulation, it is better to take more value.

- "In reserve". There are users who believe that if you take a unit in terms of power more than what you need, then there is nothing wrong with that. However, this may not lead to the best consequences, at least - an increase in bills and rapid wear and tear of equipment. It is allowed to add no more than 20% to the received calculations.

- Climatic features of the region. The house can be located both in the north, where the winters are severe, and in the south, where it is relatively warm.

A full-fledged power calculation is a time-consuming and complex procedure that is recommended to be entrusted to specialists. In addition to the above points, several more parameters are taken into account in the calculation formula. If you want to see an approximate figure, then there is a unified formula - for heating 10 m2, 1 kW of power is needed.

Troubleshooting Methods

Floor-standing double-circuit appliances deliver hot water and heat medium-sized buildings using cheap fuel.At the same time, the units require compliance with a set of measures for efficient operation.

For example, after prolonged operation, it may turn out that the boiler will not start. One of the reasons for this is clogging of the nozzles on which combustion occurs. To clean them, call the master, since such elements require careful handling.

Another malfunction is insufficient or excessive draft, which occurs in appliances with open combustion chambers.

In the first case, when checking, the flame of a brought match does not tilt inward, and in the second it immediately goes out.

This problem can be eliminated by yourself by adjusting the air inflow and outflow in the room. In addition, ice, which narrows the chimney diameter, can interfere with draft in winter. It just needs to be scraped off and the air exchange will be balanced.

Another common malfunction is called the case when the water heats up poorly and the room does not receive enough heat. This directly refers to a two-circuit system, in which the valve shuts off the water supply to the heating when the tap in the kitchen opens and the liquid is directed there.

This problem can be solved by installing a boiler or by purchasing a boiler with a built-in boiler, which will separately heat water for the DHW system. If water is turned on very often, then this method is the only way out so that both circuits work fully in the house.