About the cost of installation work

Of course, installing a chimney with your own hands allows you to save a little money, nevertheless, it is still better to entrust this work to professionals. Despite the fact that the installation procedure at first glance seems simple, there are a number of nuances (we mentioned some of them) that only experienced specialists know about. The approximate cost of assembling and installing a sandwich chimney today is 1,700 rubles per meter. Yes, the amount is rather big, but in return you will get the most important thing - quality.

Of course, this figure may vary depending on the number of overlaps and the installation method. There are two such ways.

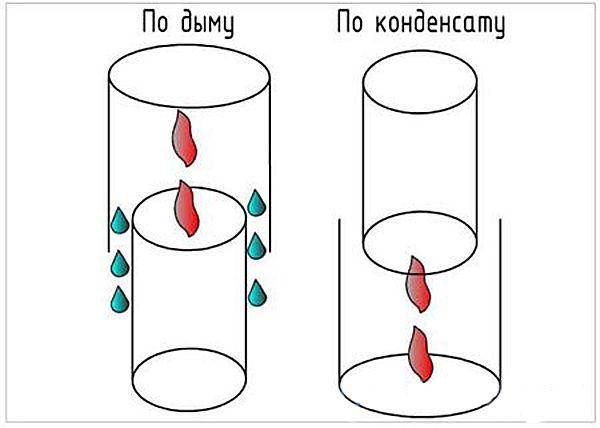

- For smoke-free installations, tees are used to drain the condensate.

- Condensate mounting does not provide for the use of additional elements.

In a word, installing a chimney is an important procedure, so if you decide to carry out it yourself, you will have to take the issue with full responsibility and follow safety rules.

Incorrectly insulated junction of the ceiling to the chimney

Design features of a chimney sandwich

Thanks to the British, all designs that consist of more than three layers are called "sandwiches". And, of course, there is a chimney with a similar name, where there is a thermal insulation layer between the two circuits (mainly from materials based on basalt).

Thanks to this, the combustion products are removed from the combustion chamber as efficiently as possible, since:

- internal surfaces perfectly tolerate the effects of condensing moisture and high temperatures;

- thermal insulation layer prevents overheating of the external circuit;

- excellent traction is achieved;

- design features do not allow moisture to get onto the thermal insulator.

The interior of the chimney is made of stainless steel and is known to be resistant to rust. As for the external, it is often made from galvanized steel, which is less durable, but cheaper. Therefore, you will have to choose between quality (read: stainless steel) and economy (galvanized). And if the inner pipes are primarily required to endure critical temperatures well, then the outer ones must be just strong, so that the shape of the entire structure does not change.

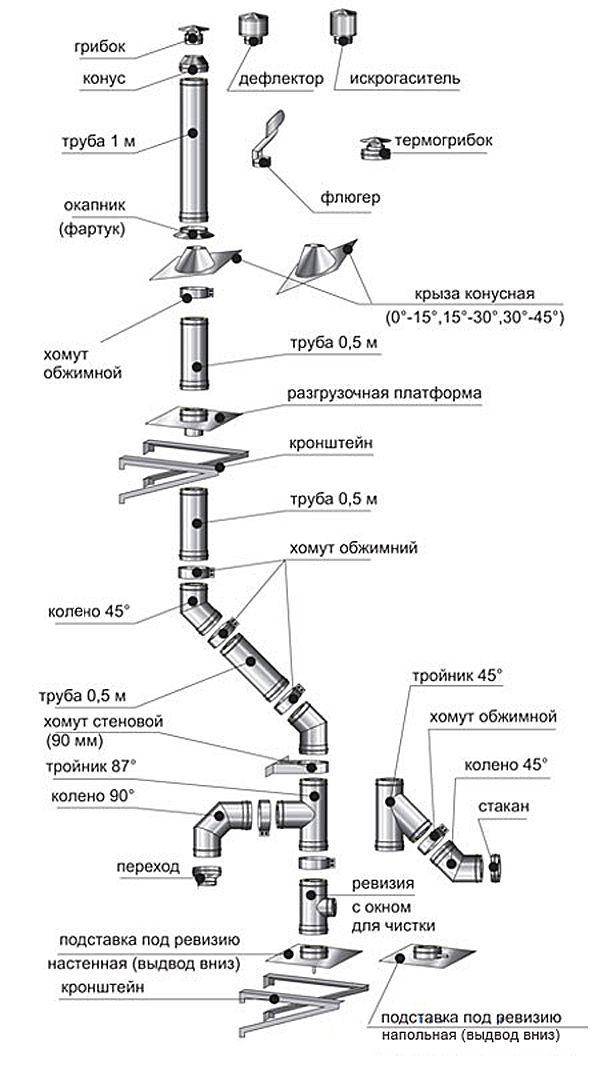

In addition to the chimney itself, during installation you will need:

- special "adapter" for passing through the roof;

- brackets for fixing pipes;

- unloading platform - it will allow you to evenly distribute the weight and relieve the base from the load;

- revision with a window for cleaning;

- clamps for fastening structural elements;

- adapters;

- knee 90 or 45 degrees (in order to change the direction of the chimney);

- adapters.

Note! The top of the pipe can be decorated with a cone or other elements - a fungus, a spark extinguisher, a whoopler, a weather vane, and so on. The sandwich chimney provides excellent thermal insulation, so it can be installed even outside the house

But it will function much better if you install it in the house, as close as possible to the heat source (this minimizes heat loss)

The sandwich chimney provides excellent thermal insulation, so it can be installed even outside the house. But it will function much better if you install it in the house, as close as possible to the heat source (this minimizes heat loss).

More on how to make a chimney for a solid fuel boiler

Previously, we have already considered the principles of installing such a chimney, you can read more about it here.

Stage three. Chimney fixing

All elbows and other structural parts are connected with clamps, and the tee is additionally attached with brackets. If the top of the structure is not secured, then it is additionally insured with at least the same guy wires.Additional fastening of the docking elements looks something like this: the pipes are fixed to each other by means of clamps, but with other elements (such as, for example, an adapter), also with clamps, but on both sides.

Note! The chimney bracket, if desired, can be made with your own hands. For this, a couple of corners are taken (5 and 3 centimeters, respectively) and everything is constructed using an electric drill, a grinder and bolts M-8 and M-10

Material from which pipes are made

For different heating devices and types of fuel, a specific type of steel is selected. It must be highly alloyed and stainless, suitable for the manufacture of chemically resistant and refractory flues.

In the chimney device, one of the main characteristics is the steel grade as a criterion for long-term service and resistance to external negativity.

When various substances are burned, chemically active substances can accumulate in the chimney: sulfuric acid, sulfur, hydrochloric acid. In addition, the temperature during combustion of different fuels can vary greatly.

When heated with wood or gas, it does not rise above 450 ° C, while burning coal, it can reach 700 ° C. Metals react differently to these indicators. Therefore, when choosing a system for removing smoke, they pay attention to the main characteristic - the quality and property of steel.

The main grades of steel alloys that are used for the production of sandwich chimneys:

- Titanium stabilized stainless steel (AISI 321). Used for wood burning equipment. Not resistant to corrosion in sulfur-containing environments. The permissible operating temperature is 600-800 ° C.

- Molybdenum stabilized stainless steel (AISI 316). Installation of a sandwich chimney made of this steel grade is carried out for heating installations that run on wood, gas, diesel fuel. The metal is acid-resistant, characterized by increased resistance to corrosion, aggressive environments of various nature.

- Heat resistant steel (AISI 304). The inclusion of chromium and nickel makes steel insensitive to high temperatures and acidic environments. It is used for the production of chimneys with a high exhaust gas temperature - about 1000 ° C. At temperatures of 600-800 ° C, it tends to lose toughness and ductility, leading to embrittlement.

- The widely used grades AISI 409 and 430 are weakly resistant to high temperatures and acids. Most of the Chinese products and some of the domestic ones are made from these steel grades.

Low-quality material will attract a magnet, metal with the addition of alloying additions will not.

When choosing pipes for a chimney, ask about their main characteristics. If you have doubts about the seller's honesty, take a magnet with you - it will be attracted to steel products with insufficient proportions of ligating additives

By itself, ferrous metal wears out quickly - it oxidizes and burns out. Therefore, special enamel is used to protect it. This increases the resistance to acidic environments.

The variety of shades of enameled pipes makes them quite popular

Enamelled pipes are used to remove combustion products from heating columns, stoves, heating boilers, fireplaces. Unlike steel, they can be painted in different colors. This allows you to select the right shades for the interior or facade of the house.

To reduce the cost of production, enterprises are trying to use cheaper materials. If the inner tube is made of expensive stainless steel, and the outer tube is made of galvanized or enamelled metal, this has little effect on the product's service life.

Worse, if it's the other way around: stainless steel is used outside, and cheap, low-quality material is hidden inside. With intensive use, such a pipe can last a year and fail, which will entail new costs for materials and installation.

Before buying, it is advisable to ask the accompanying documents for the goods in order to make sure of the quality of the pipe being purchased.

It is important that the inner element is made of high quality stainless steel. Between the two chimney sandwich pipes there is a layer of insulating material that retains heat inside and thus maintains good draft

Basalt or ceramic wool is used as insulation - fibrous materials with the highest fire resistance class

Between the two chimney sandwich pipes there is a layer of insulating material that keeps the heat inside and thus maintains good draft. Basalt or ceramic wool is used as insulation - fibrous materials with the highest fire resistance class.

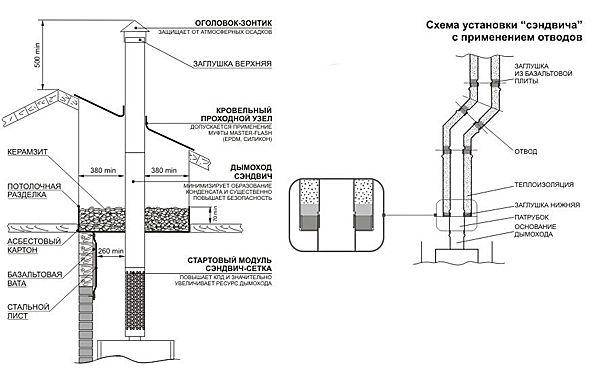

Passage of the chimney system through the attic floor

If the bath has a small attic room and the chimney outlet is carried out through it, then for this you can use a special dividing pipe made of galvanized metal of a suitable size, corresponding to the diameter of the pipe and the thickness of the ceiling.

Installation of a sandwich pipe in a bath through the ceiling is performed as follows:

- The branch pipe is sheathed with a foil-based insulation to protect the floor from fire.

- A hole of the appropriate size is made on the ceiling, into which a basalt or mineral wool insulation is placed.

- A heat-insulated pipe is installed in the ceiling-throughput unit. A metal panel is fixed to the ceiling with a circle made in the center for the pipe outlet.

- A pipe is installed in the prepared hole in the ceiling.

A more complex option is the connection of a brick pipe with a sandwich, which involves the use of special adapters: square nozzles and single-circuit elements. The adapters provide complete sealing of the structure at the joints.

Preliminary calculations

In addition to the section, you should also determine the length of the chimney and its correct location.

Length calculation

There are some requirements here, let's get acquainted with them.

- According to the same SNiP, the minimum chimney height should be 5 meters.

- If the roof covering in your case is a combustible material, then the chimney should rise above the ridge by another 1-1.5 meters.

- If the coating is non-combustible, then this height will be at least 0.5 meters.

Note! If there are extensions to the house, the height of which exceeds its height, then the chimney must be brought out above this particular extension.

Location

- If the roof is flat, then the pipe should rise above it by at least 0.5 meters.

- If the chimney is less than 1.5 meters from the ridge, then it must rise at least 0.5 meters above the ridge.

- If this distance fluctuates between 1.5-3 meters, then the height of the pipe should be equal to the height of the ridge.

- Finally, if the chimney is located further than 3 meters, then this height should be equal to the line drawn in the imagination from the ridge at an angle of 10 degrees relative to the horizon.

If all these requirements are taken into account, then the installation of the chimney will be performed correctly.

Chimney requirements for a gas boiler

How to install a chimney for a gas boiler, their design features and how to choose the correct location. You can find out the answers to these questions here

What else should you be aware of?

Installation of the structure should start from the heater and go up in stages.

Various utilities (such as electrical wiring, gas pipelines, etc.) should not touch the chimney.

It is impossible for the structure to have ledges.

The structure should be protected from the effects of atmospheric precipitation. This will require a deflector or any other device.

It is important, however, that such protection does not impede the free release of flue gases.

The temperature of the flue gases moving through the channel should not exceed 50 degrees.

During installation, all the nuances related to the installation of a sandwich chimney must be taken into account. So, if the roof is made of a flammable material, and peat or wood is used as fuel, then spark catchers should be installed, which are usually made from a metal mesh with a mesh size of 0.5x0.5 centimeters.

Pipe sections that are sloped must not be rough

In addition, their cross-sectional area must at least correspond to the vertical one.

Connection options

There are several ways to connect such chimneys:

- flanged;

- by condensate;

- bayonet;

- smoke;

- and, finally, in the cold.

Note! The structure is assembled by smoke to completely exclude the penetration of carbon monoxide into the room. But on the condensate, so that the condensed moisture flows freely along the walls due to the temperature difference

If the installation of a sandwich chimney with your own hands was made in the first way, then the flue gases will not encounter any obstacles and, thanks to the draft, will be quickly taken out into the street. But if the joints are poorly sealed at the same time, then the condensate can penetrate into the structure, which will have a very bad effect on the basalt insulation. In the second case, the inner tube is installed in the socket, so moisture cannot in any way penetrate inside. But if there is even a small gap, then the smoke can get into the room. So which option should you choose? Condensed moisture is harmful to the insulation, and flue gases are harmful to human health. The way out is obvious: regardless of the chosen method, all joints and cracks should be carefully sealed.

Note! It is advisable to install the internal pipes of the structure along the condensate so that it does not fall into the joints and does not leak. We also note that even with two layers, such chimneys require good insulation of those sections that are the most fireproof - we are talking about the roof, beams and floors.

Moreover, the sandwich should not be used to connect directly to the heater.

We also note that even with two layers, such chimneys require good insulation of those sections that are the most fireproof - we are talking about the roof, beams and floors. Moreover, the sandwich should not be used to connect directly to the heater.

So, you have already familiarized yourself with the technology. Now all that remains is to purchase all the necessary materials (be sure to be of high quality, certified) and get down to work!

Influence of the type of fuel on the choice of the chimney

The choice of the chimney is greatly influenced by the type of fuel burned in the thermal energy generator. The chemical composition of the combustion products is very important. When burning natural gas, water, carbon dioxide and a little soot are formed, and when burning wood, coal or liquid fuel, many chemically aggressive components are formed.

In any case, the inner surface of the chimney must have low adhesion and chemical inertness to acidic components.Solid or liquid fuels place increased demands on the quality of the materials from which the chimneys are made.

Advantages and disadvantages of sandwich chimneys

A sandwich chimney is a functional structure equipped with two circuits interconnected by heat-insulating material up to 65 mm thick.

Such a device has not only high performance characteristics, but also a number of significant advantages:

- Thermal insulation of the walls of the structure. The use of reliable insulation prevents a decrease in smoke draft in the system and contributes to the rapid removal of combustion products of fuel material without the formation of condensation.

- Simplicity and availability of installation. Any homeowner can correctly install the chimney, since the process itself is similar to the work of assembling a technical designer.

- A wide range of modifications and types of designs. On sale there are rectangular and angular structures designed for installation through the roof or on the wall, equipped with additional architectural elements.

- Slight build-up of deposits on the walls. The smooth surface of the pipes prevents the accumulation of ash and soot during the combustion of fuel material.

- Low weight. The assembled chimney of sandwich pipes has a low mass, so it does not require to equip the foundation for it.

However, the use of stainless steel pipes in the manufacture of sandwich chimneys did not eliminate the existing problems that are inherent in metal products:

- Possibility of depressurization of the structure due to excessive heating and cooling of the system.

- The high cost of consumables for the assembly and installation of the chimney.

- Short service life of the finished system, not exceeding 17 years, while brick chimneys can be operated for up to 25 years.

Advantages of double wall pipes

In the past, stove and boiler chimneys were built of red brick. The material is durable and not afraid of heat, but porous, and this is a problem. In the street part of the canal, condensation forms in winter and is absorbed into the brick walls. Subsequently, it freezes, and the ice begins to destroy the masonry, peeling small crumbs from the brick.

Kaolin wool high temperature chimney

Three-layer chimneys in the form of a sandwich are devoid of the listed disadvantages. Smooth metal walls contribute to good traction, and the insulation prevents condensation from forming. If moisture nevertheless appears or enters the vertical channel from the outside, then a condensate collector is provided in the lower section of the barrel to drain it. The rest of the advantages of insulated chimneys are as follows:

- the outer shell of the products heats up little during operation;

- the modular system can be assembled both outside and inside the house with different types of ceilings, including wooden ones;

- relatively low weight;

- the finished structure looks great against the background of the building;

- the installation is quite simple and completed in a short time.

The formed condensate is discharged through this tube.

The cost of a sandwich flue is higher than that of a conventional iron pipe for obvious reasons. But if you compare it with how much a brick mine with ceramic inserts costs, then the difference will not be in favor of the latter option.

Installation of a sandwich chimney made of stainless steel

Installation of elements of a metal chimney is simple, the main thing is to observe the direction of connection of the elements "by smoke" and "by condensate". What does it mean? When the stove is fired, the smoke rises. If an obstacle is encountered in its path in the form of even an insignificant plane formed by the previous element and facing downward, solid particles of smoke settle on it, and the chimney becomes clogged over time.

Assembly of chimney elements "by smoke" and "by condensate"

When working, be sure to use thick gloves - thin metal can cut the skin. When installing the elements, it is necessary to check their verticality using a level and make sure that the distance to non-insulated combustible structures does not exceed 25 cm for sandwich elements and 60 cm for single pipes.

1. A single metal pipe is installed at the outlet of the smoke collector of the furnace. Its height determines the heat transfer to the inside of the room. The pipe is placed "in smoke" - put on the outside of the pipe. Before or after the pipe, a gate is placed that blocks the chimney. All joints are coated with heat-resistant sealant.

2. A starting sandwich-chimney is installed on a single pipe: a double pipe, closed at the bottom end. Sandwich pipes are subsequently installed on it. The starting element is mounted on the pipe "through the smoke", put on the pipe. The joints are also coated with a sealant.

3. Begin the assembly of the chimney from the necessary elements, the possible elements of the chimney are shown in the figure. Pipes and elbows are mounted "by condensate", that is, they are inserted inside the previous element so that the dripping condensate does not get into the fibrous insulation. It is also advisable to coat the joints with a sealant.

Metal sandwich chimney elements

4. When passing through the ceilings, unloading platforms are used, and the pipe itself is tightened with clamps every two meters and fixed to rigid structures. It is better to do this in the places where the pipes are connected, as this gives additional strength to the entire chimney. The pipe is separated from the combustible structures with a layer of basalt wool, laid in a special box.

Chimney passage through combustible structures

5. For pipes with many bends and branches, it is mandatory to install inspection elements with a cleaning window. They are installed in places with open access to the pipe, also "by condensate".

6. Passage through the roof and sealing is performed using a special lining - a conical roof, and an apron. The upper part of the pipe is equipped with a head or deflector.

7. When the pipe is first fired and heated, the sealant hardens and creates additional strength and impermeability to smoke and condensation.

Structural elements and their features

This type of chimney includes multilayer prefabricated chimneys made of stainless steel or ceramic. They are produced in the form of ready-made elements, assembled into a single structure. Both types of sandwich chimneys have their own characteristics, but their installation is generally similar.

Ceramic chimneys are made of heat-resistant ceramics, covered from the inside with high-strength glaze, and from the outside wrapped in heat-insulating mats. This structure is placed in an outer shell of expanded clay or foam concrete blocks.

Due to their construction and thermal insulation layer, sandwich chimneys from the outside never reach high temperatures that could lead to a fire. This feature, as well as quick and easy installation, make them popular with builders.

Metal and ceramic chimneys, despite the similarity in design, have differences, and the main one is weight. A full-fledged ceramic chimney can weigh about a ton, while the weight of a stainless steel chimney does not exceed a couple of hundred kilograms. For a ceramic chimney, a foundation is required, for a metal chimney, there are enough unloading platforms at each floor level.

Chimney manufacturers have developed more than twenty different elements to facilitate installation.

The main structural elements of the chimney are:

- Straight pipe sections. Sections 80-600 mm in diameter, up to 1 m long.The ideal chimney design is straight, but this is difficult to achieve in practice.

- Knees and tees. They are used if it is necessary to bring the chimney through the wall, outside the building, or bypass the structural elements of the house - beams, rafters. Sometimes for turns (especially straight, 90 °), revision tees are used - they allow you to clean the chimney in hard-to-reach places. They are installed and reinforced with brackets so that they do not carry the weight of the above structure.

- Lead-through pipe. It insulates the pipe from the interfloor partitions, serves as a fastener for the chimney.

- Roof cutting. It is a metal cone that is attached to the roof at a certain angle. Helps to pass the pipe through the roof without breaking its tightness and increasing fire safety. Instead, a special silicone seal can be used, which serves as a better protection against leakage.

In addition to the above elements, there are a lot of devices for installing a chimney from sandwich pipes, as well as its further operation.

The chimney is fixed with brackets every two meters. Fasteners for fixing the clamps on the wall are selected in accordance with the material from which it is folded

Stage four. Features of the installation of sandwich-class chimneys

When installing a chimney, you must take into account a number of features.

- Most of the chimney should be indoors. This will reduce heat loss during heating.

- If horizontal sections are allowed in the structure, then the length of each of them should be a maximum of one meter.

- The chimney should not come into contact with other communications (especially gas) - these are elementary safety measures.

- Clamps used for fastening must be of a special shape.

- The pipe must be fixed with brackets with a minimum pitch of 2.2 meters.

- The installation must not be erroneous. The most common of them are incorrect calculation, incorrect installation of the ventilation system, poor-quality thermal insulation.

- Finally, do not forget about installing a special revision with a door designed to clean the chimney from combustion products.