Two types of combustion - two different designs of a stove

There are two different types of potbelly stoves, differing in design and the principle of heat resource distribution.

Potbelly stove classic

In the classic design, air is fed into the firebox from below through the grate and the blower space. In this case, the combustion zone is located in the grate zone under the fuel, which is self-heating from incandescent gases. The combustion air passing through the hot grates is preheated. The process is avalanche in nature and is regulated only by limiting the flow of air.

Bottom combustion is characterized by a very fast heating of the stove, the convenience of placing fuel on top of the combustion zone, and intense heat release. In addition, this type of flame is stable with very large differences in the ranges of air supply and thrust force. Its main disadvantage is fast, but incomplete combustion of fuel, reduced efficiency.

Long burning oven

For a long-burning stove stove, a single-chamber scheme should be used. Combustion air is fed directly into the combustion chamber, over the combustion zone. This creates conditions for a slower surface combustion of fuel.

The main advantages of this method:

- long time interval between fuel supply;

- proximity to pyrolysis combustion;

- increased efficiency.

Main disadvantages:

- more complex ignition;

- the need for metered air supply;

- the fuel is loaded after the previous batch has completely burned out.

Stove stove design

The potbelly stove is made of cast iron and steel and is a firebox with a door. The chimney is an obligatory element. Some options can be equipped with a hob. A home-made potbelly stove must be equipped with holes sufficient for the intake of combustion air.

You can make a potbelly stove yourself from anything, as long as its size suits you. For example, a do-it-yourself brick stove made of bricks, which can be made from a milk can, with a volume of 40 liters:

- A chisel should make a slit for the blower slightly below the neck.

- Punch the bottom of the can and insert a curved chimney through the branch pipe. The branch pipe can be bought ready-made, or you can weld it yourself if you have a similar skill.

- We make a snake-like grate from thick steel wire and insert it into the can through the neck.

- We experimentally stretch the grate to the desired size. The efficiency of fuel combustion will depend on this.

- We make a support for the stove, insert the chimney and take it outside. The potbelly stove is ready.

The longer your chimney is, the less heat loss your stove will have. The better the tightness of the joints you ensure, the less smoke you will have in your room.

Potbelly stove from a barrel. A 200-liter fuel barrel is especially popular with folk craftsmen. An excellent potbelly stove comes out of it. The barrel diameter of 600 mm allows a hexagon with a side of 314 mm to fit into it, which meets the conditions prescribed for the allowances for the installation of standard heaters. Also, a potbelly stove can be made from a gas cylinder or from a pipe.

It would seem that the stove is ready, but the efficiency of such a device will be somewhere in the region of 15%, which is definitely not enough for a stove. If the oven is shielded, its service life will be unacceptably reduced. The reason for this dilemma lies in the size of the barrel - it is too high. Practice shows that the height of the firebox should not exceed one and a half times the size of its depth.

It would seem that the stove is ready, but the efficiency of such a device will be somewhere in the region of 15%, which is definitely not enough for a stove. If the oven is shielded, its service life will be unacceptably reduced. The reason for this dilemma lies in the size of the barrel - it is too high. Practice shows that the height of the firebox should not exceed one and a half times the size of its depth.

There are two ways to fix this problem:

- Brick the barrel by a third or half.

- In the extra part of the furnace space, arrange a kind of oven from the refractory, through which to pass the chimney.

- In both cases, the problem will only be partially solved, so another solution should be sought.

The original solution to the issue of heating the garage will be a stove from a gas cylinder. An ordinary household propane cylinder is perfect if you put it on its side and use its neck to connect the chimney. But a potbelly stove from a gas cylinder with high efficiency will not work in this way - according to the rules, the chimney must be equipped in the far part of the firebox, but this will not work in a cylinder.

Potbelly stove from a cylinder

Do-it-yourself potbelly stove from a gas cylinder is the best way to make it at home. It is ideal for heating the garage, and small utility rooms.

Getting started:

We take as a basis a gas cylinder with a volume of fifty liters. To start cutting it with a grinder, you need to clamp the cylinder in a vice, this is done for the lower part. Then we take the gas key, put it on the valve. Now, we put on a long pipe on the handles of the key, which will act as a lever for us. Gradually and slowly we begin to unscrew the valve

Attention! Even if the cylinder is empty, there will always be residual gas in it. You have to be extremely careful with him.

Unscrewing the valve, pour water into the middle, to the very top

When the container is full of water, you can start cutting. This is necessary to avoid an explosion from a spark, even if the cylinder is empty, there is residual gas in the micropores.

We arm ourselves with a grinder with a disc for metal. The first step is to cut off the aluminum label.

We take the selected chimney pipe. We install it in place of the valve, draw a circle around the pipe with a marker or pencil. We cut out this section with a grinder.

We retreat three centimeters down from the first top seam, draw a straight line in a circle. Now cut off the top of the balloon along the line. It is undesirable to cut the seams with a grinder, there is a very thick metal.

We mark the location of the furnace and ash doors. Our combustion chamber door measures 25 by 20 centimeters, and the ash pan door is 25 by 10 centimeters. We made the body of the future potbelly stove from a gas cylinder with our own hands.

We cut out our door markings with a grinder. To make it convenient to weld the hinges, and they were evenly located, it is advisable not to make the cuts completely, it is better to leave half a centimeter. After the cuts, we place the canopies on the surface, weld them with a welding machine.

We clean the welding seams with a grinder. Then, we cut through the remnants of the metal on the doors. Now, we make a strip along the perimeter of the doors. We drill a hole closer to the edge. We make a handle latch. We drill a hole in the handle. We fix it to the door with a bolt. The nut can be gripped by welding.

We make a hook on the stove body, weld it. We weld a metal bracket above the handle. Making a potbelly stove in the garage with your own hands is almost complete.

We make the ash pan door in an identical way. Now, we need to weld the grates that will separate the ash pan and the firebox. It is desirable to make them from the 16th or 18th reinforcement.

In the upper part, it is necessary to weld in segments that will partially block the smoke from the furnace. And it will not immediately go outside, but first pass between these elements, due to which the unit will retain more heat.

On the upper part, which we cut off, we weld a piece of pipe. After that, we bring the top of the cylinder to its place and weld it with a continuous seam.

At this stage, the stove can be tested and, if everything is fine, you can install it indoors and warm up. It takes about a day to construct a potbelly stove from a cylinder. But the design itself is so simple that even a beginner can make it.

One, two and done

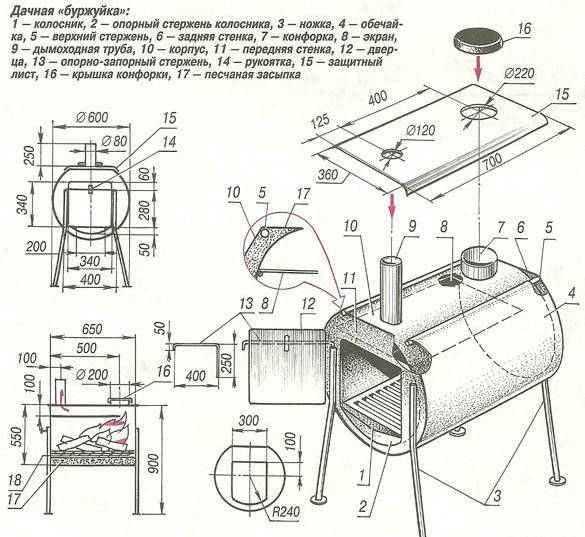

Currently, there are drawings of round and rectangular stoves. The figure shows a diagram according to which a potbelly stove can be made with your own hands from an ordinary milk can, a similar design can be made from a metal barrel.

Potbelly stove from a can

In order to make such a stove stove for a summer residence or garage with your own hands, you will need a minimum of tools and materials:

- Old milk can (if you chose the option of making from a barrel, then a barrel made of metal);

- Metal rod with a diameter of 6 mm;

- Branch. With the skill, you can make it yourself;

- Hammer;

- Chisel;

- File.

You can start working with your own hands. We did not specifically indicate the dimensions so that the master proceeded from the diameter of the barrel or can used.

First you need to make a blower. To do this, a rectangular hole is cut below the neck of the can (barrel). The edges of the hole are filed.

After that, in the bottom of the can (barrel), it is necessary to cut a hole of such a diameter, so that later you can tightly insert the branch (see the article Chimney for a potbelly stove). This is done as follows:

- At the site of the future chimney, at the bottom of the can or barrel, markings are made. The diameter must be 2 mm less than the diameter of the bend

- Using a chisel and a hammer, a hole is cut along the markings

- The hole is leveled with a file. A round file is best for this.

- It is necessary to drive the bend tightly into the hole. If the branch is not included, the hole is finalized with a file. In any case, the tap must fit tightly

- A snake is bent from a metal rod, it will play the role of a grate

- The finished grill is folded so that it can be inserted into the neck

- The inserted grate is aligned already inside the can (barrel). The grate is made of reinforcement and welded to the body. As you can see from the picture, there are two doors for the blower and the firebox. Such ovens are able not only to warm up the room well and quickly, but they can successfully cook food.

The potbelly stove is ready. If you wish, you can make a stand for it with your own hands. If you install a blower flap, you get a stove with adjustable draft. It is quite simple to arrange such a damper.

As you can see, a potbelly stove with your own hands can be made without special tools and materials. Just place the stove, made from a barrel or can, in the right place and connect the chimney. Your potbelly stove from a barrel will regularly warm the room until you install stationary heating.

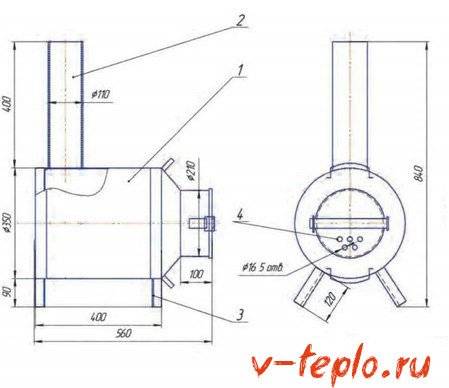

How to make a potbelly stove from steel sheets with your own hands

The design of the furnace of such a furnace should provide for partitions, which will save you the need to spend a large amount of fuel to maintain the operation of the furnace.

Furnace assembly materials

To make a similar version of a stove-stove, you will need the following materials:

- steel sheets that will go to the furnace body, with a thickness of 4 mm;

- steel sheets from which the partitions will be made, at least 1 cm thick;

- lattice;

- chimney pipe;

- welding machine.

The first thing you need to do for the potbelly stove being built with your own hands is a drawing that will simplify the task of making it for you. Next, you need to take the sheets and cut out the elements for the stove body and two partitions from them. The latter must be installed in the upper part of the furnace, in the future they will provide a complex, winding path for flue gases, which will ensure a higher efficiency of heat energy generation by the furnace.

In the upper part it is necessary to make a hole for the chimney with a diameter of 110 mm. You also need to place an opening for the hob, the diameter of which should be 150 mm.

Next, we take the sidewalls and attach them by welding to the bottom of the body. Steel strips 30 mm thick must be welded to the walls. They will serve as the basis for the grill. It can also be created from steel sheet, in which you must first make a hole with a diameter of 20 mm.To create a grate, you can use reinforcing bars or purchase ready-made products in the store.

Buleryan furnace structure and principles of operation

A heater with a high efficiency of about 80%, operating on all types of solid fuels, with the exception of coal. We will consider several models in order to make a homemade buleryan.

The device and the principle of operation of the boiler Buleryan

We will understand the very structure of this wonderful oven and determine the principle of operation. In simple human terms, the Buleryan stove is a heat-resistant metal structure with a number of pipes that carry out natural circulation.

This air heater is designed for heating residential and non-residential premises. Depending on the size and efficiency of the stove, it can heat both a small country house and a warehouse or production room or a greenhouse.

Buleryan stove

The basic principle of the furnace is in the device of two chambers. One of the chambers is filled with fuel. The fuel filling chamber is specially designed so that it contains a small amount of oxygen and the fuel does not completely ignite. With a lack of oxygen, firewood or briquettes slowly smolder, forming a pyrolysis gas, which burns out in the second of the chambers. Maximum fuel economy - on one tab and high efficiency in comparison with similar devices. This explains why the Buleryan oven is so popular among users. After studying this article, you can make buleryan with your own hands.

Simple constructions

A stove stove for a summer residence is, as a rule, a kind of elementary fireplace stove. The simplest do-it-yourself stove stove is obtained from a metal barrel. To do this, you need to use some locksmith skills.

- On the side surface of the barrel, just below the middle, we cut it out with a grinder or cut a rectangular hole with a chisel. This will be a firebox. We weld the cut-out sheet of metal onto the sheds and add the simplest locking mechanism - the firebox door is not at all difficult to manufacture.

- Cut out a smaller window below the furnace hole. This opening is a blower. We carry out the same operations as for the fire door to obtain a closing structure. Subsequently, by opening or closing the blower door, it will be possible to adjust the draft.

- Inside the barrel, above the upper opening of the blower, we construct grate bars. For this, you can use metal fittings. To make a grate out of it, drill a barrel from opposite sides and thread a bar of reinforcement through the hole so as to leave about 1 cm outside on each side. Welding is used to weld the bar. This process is repeated to form a grate inside the barrel. The grates can be made removable by welding the stops inside the barrel for their installation. Prefabricated cast iron grates are the best.

- A hole is cut out on the upper edge of the container and a chimney is welded in (a pipe of 4-5 inches is needed), and pipe cuttings are installed on the lower edge as legs.

It is possible to increase the efficiency of such a potbelly stove by installing an obstacle in the path of hot gases in the form of sheet metal sections welded onto the walls. The sections are installed in such a way that the heated gases pass through a serpentine path, giving off heat to the walls of the device more fully.

A good wood-burning stove is obtained from the old gas balloon. The wall thickness allows such a stove to work for a long time. When positioned vertically, the construction is the same as in the case of a barrel. However, by placing the cylinder horizontally, you can slightly increase the efficiency, creating a more difficult path for the exit of combustion products and increasing heat transfer.

Potbelly stove from an old gas cylinder - Photo 05

Potbelly stove from an old gas cylinder - Photo 06

With a horizontal arrangement, several rows of holes with a diameter of 10-12 mm are drilled at the bottom of the cylinder. They will act as a grate. These holes are covered with a metal box with a blower door. The box will act as an ash pan.The end of the cylinder is carefully cut off with a grinder, getting an original round door. On the other edge of the container, a hole is cut perpendicular to the surface and the chimney is welded in. A potbelly stove from a cylinder with your own hands can be built in a few hours, and it will serve for many years.

How to make a do-it-yourself stove-stove

First of all, you need to formulate the concept of "potbelly stove". As usual, it is a heat unit made of metal for the use of solid fuel. As a rule, firewood is used. For the removal of furnace gases, a metal pipe is installed, which is led out through a wall or window.

The advantage of this design is the rapid heating of the walls with subsequent heat transfer to the surrounding space. The disadvantage is that when the supply of firewood to the firebox is stopped, the stove cools down quickly, and you have to add them additionally in order to maintain the temperature in the room. Several such operations have to be performed during the night.

Potbelly stoves can be of various purposes

Advantages and disadvantages

Let's see what are good homemade stoves made by folk craftsmen:

- Cheap - most of the materials can be found for free or given a mere penny for them;

- Omnivorous - in fact, any solid fuel can burn in a stove;

- Simple construction - if we look at the drawings, we will not find anything complicated in them;

- Possibility of cooking - for this, stove stoves are equipped with cooking holes with lids;

- Ease of operation - provided that there is a good chimney, the stove will work properly and without fumes in the whole room.

Unfortunately, heating with a potbelly stove has its drawbacks:

- Low efficiency of the stove - without proper modernization, most of the heat will fly into the pipe;

- Not the most solid appearance - although some craftsmen make real works of art out of bourgeois;

- High temperature of the case - fraught with burns;

- High fuel consumption - in order for the stove to retain heat for a long time, without requiring the burning of tons of firewood, you will have to go to tricks.

Despite some shortcomings, simple wood-fired stoves are still in demand among those who need heat in the absence of a gas main.

Advantages of burzhuikas and their disadvantages

Cons inherent in such ovens:

- It is necessary to prevent the loss of combustion products (coals, sparks) from the furnace.

- To avoid burns (from the very hot walls of the stove), you should limit the access of children to it.

- Heating requires a large amount of combustible materials - it is more expedient to create a furnace for short-term use.

Pros of using burzhuikas:

- The choice of solid fuel is unlimited: you can buy peat or coal, prepare firewood for it or use sawdust and chips, briquettes and pellets are suitable, some use machine oil (recycled) as fuel.

- It can be created with your own hands and from readily available raw materials.

- She has a low cost.

- It is compact - it can fit even in a tight space, for example, you can design a stove stove for a garage.

- It is mobile, even when made from thick metal sheets.

- The heating of the room during its ignition occurs quickly.

Simple potbelly stove from a can

The simplest do-it-yourself potbelly stove is made from an ordinary can. There is no need to talk about the durability of such a structure, but it is quickly built, easily assembled and gives enough heat.

All work consists in the installation of the legs, the arrangement of the outlet pipe and some cosmetic operations. For work you need:

- Can

- Chimney pipe

- Grate wire

- Welding machine

- Tools

Getting started

- We set the can horizontally and mark where the blower will be, which has the shape of a rectangle or a sickle. Place it under the lid

- A hole is cut in the wall or bottom of the can, equal to the diameter of the chimney pipe

- To make a grate, you need to stock up on steel wire. It is bent, carried through the lid into the inside and gently unbent so that the zigzag is in the desired position, while it remains convenient to lay chips, firewood, etc.

- The can must be fixed on legs that are cut from tubes or corners and welded

- The chimney is welded

A reflector can be mounted on the outside of the tank, thanks to which less heat generated will escape. Having welded the handles from the sides, the structure can be transferred to any other place.

Pros and cons of homemade bourgeois

Among the many advantages of such a nondescript, but useful installation, there are:

- Full autonomy and energy independence

- Work on any solid fuel, including plant residues - this saves a lot of money

- Versatility of the design, which can not only be installed in various rooms, but also used for cooking

- A simple design that you can build yourself from the materials available in the garage

- There is no need to erect a monolithic foundation and install a capital chimney

But despite the significant and numerous advantages, there are a number of disadvantages of bourgeois:

- The high thermal conductivity of the metal leads to rapid fuel burnout and cooling of the furnace

- If the wall thickness is insufficient, they will soon begin to burn out and the furnace will fail.

- You need to watch the combustion process and throw up firewood in time, control the traction

- Tarry and damp logs cause stubborn soot in the chimney

Video - another option for making a furnace

In custody

A homemade potbelly stove is a reliable and effective assistant in a cold workroom or your own garage. Its production is not difficult, and there is no need for large material investments to start work.

Features of the operation of the stove with a water jacket

- It is advisable to install a temperature and pressure sensor in the hydraulic system.

- It is necessary to regulate the draft in the grate and in the chimney.

- The water circuit in both types of heat exchangers must be equipped with an expansion tank.

- The main-type water system needs a circulation pump installed on the return line, that is, on the lower pipe.

- A device with a storage tank requires a circulation pump if the diameter of the outlets is less than 75 mm.

- It is necessary to provide a place for draining the water.

- Do not heat the stove without water - the heat exchanger may burn out.

- After use, the water must be drained.

The temperature change in the heat exchanger occurs due to the burning speed of the furnace. The heat turns into radiation, the water heats up in the chimney, and after another half an hour in the pipes. The system is inertial due to the high heat capacity of water, so a large supply of fuel is needed.

A potbelly stove is a flammable design, it is necessary to start and place a fire extinguisher and a hook nearby.

Furnace cleaning and repair

With regular use, the chimney must be cleaned. The appearance of a 2-3 mm layer of soot reduces traction and reduces heat transfer.

You can disassemble the chimney and clean it with a brush, but this is time consuming and not always possible. If the potbelly stove is operated daily, then the chimney should be cleaned with fire:

- heat the stove with aspen wood once a week. Aspen has a high combustion temperature, which burns soot in the chimney. Apply a little after the main ignition;

-

after lighting the fire, add well-dried potato peels along with the wood.One backfill requires about half a bucket. It is enough to do this once or twice a week and the chimney will be free of soot. This method will not work if the chimney is already overgrown with a layer of soot of 1–2 cm, in which case the cleaning will only soften the soot, and you will have to clean it off the pipe walls with a brush or a metal scraper;

-

use special firewood or pellets that are added to the furnace during combustion. The most famous tool is "Chimney sweep log". It is burned with firewood about once every six months. It is best to put it on the hot coals left over from the furnace. A distinctive feature of this product is that it continues to act for two weeks after use, gradually softening the soot on the pipe walls.

The main activities for the repair of the furnace are:

- Pipe repair. The chimney pipe is the weakest point in a potbelly stove. If it burns out, it needs to be changed.

- Heat exchanger repair. The main heat exchanger can be removed by unsoldering it from the furnace body. But the capacitive circuit will have to be welded again after a few years.

- Elimination of defects in the furnace body. If the wall or back surface burns out, usually a metal patch is welded onto this area. The slots can be welded with scraps of metal rods.

All operations are quite simple and straightforward, so maintenance of the stove-stove will not cause big problems.

Video: stove-stove for a garage and cleaning a chimney

For the third hundred years, the oven invented by Benjamin Franklin has been serving us. It is still easy to manufacture and unpretentious to work with. A potbelly stove with a water jacket is not only about heating and cooking. This is hot water in the house, in the garden, in the garage, in a warehouse or on a construction site. New technologists have made this stove topical even today.

Make the right choice

Potbelly stove has its advantages and disadvantages. The undoubted advantages of such a heater include:

- energy independence and autonomy;

- cheap fuel in the form of coal, firewood, sawdust, wood chips, peat, waste industrial oil, diesel fuel, paint waste, etc .;

- quick warm-up;

- small size;

- installation without foundation;

- no capital chimney is needed;

- ease of use;

- low financial costs in the case of making a stove with your own hands.

However, the potbelly stove also has disadvantages:

- good ventilation in the room is required;

- high fuel consumption;

- the need for constant monitoring of the fuel level;

- rapid cooling (however, we can fix this drawback - to increase the efficiency, the stove can be overlaid with a brick).

First, let's talk about purchased stove-stoves, the cost of which starts from about 4,000 rubles (for example, the Ugolek stove) and rises to 40,000 rubles and above (this cost is typical for stove-stoves with beautiful names "Bavaria", "Baron" and NS.).

Furnace Bavaria with heat exchanger

Furnace Bavaria with heat exchanger Potbelly stove Baron

Potbelly stove Baron

In the middle of this price range there are, for example, stoves with a water heating circuit and a heat exchanger, an army cast-iron stove, a long-burning stove of the Klondike type.

Klondike potbelly stove

Klondike potbelly stove

Materials for stoves and fireplaces-stoves, made in workshops, usually become stainless steel and cast iron. The standard drawing assumes the presence of a hopper with a firebox door, an ash pan, a chimney pipe. However, it happens that a stove stove is equipped with a hob, burners and even an oven. At the enterprises, they also make heating stoves, as well as stove-stoves, in which a ceramic or steel casing is installed to increase the efficiency, which significantly increases heat transfer. If you wish, you can buy a stove-stove or just a stove with a gas generator for your home.

Advantages and disadvantages of using stoves

Despite the primitive design, the potbelly stove is a fairly popular heating unit, its use has many advantages:

- simplicity in making a do-it-yourself stove stove;

- the ability to quickly install anywhere in the room;

- homemade potbelly stove in the manufacture does not require expensive materials and special tools;

- runs on any available fuel;

- has an increased heat transfer, as a result of which it warms up the air in a matter of minutes.

At the same time, it would be correct to mention the disadvantages of this type of heating, inherent in almost all models:

- low heat capacity (heating lasts exactly as long as the fuel burns);

- frequent fuel filling (this statement refers to simple models, since at present there are several more complex designs that can work for days);

- very low efficiency;

- the need for maintenance of the chimney;

- high fire hazard of this type of heating devices.

Still, a potbelly stove in a garage is the cheapest solution, so this one advantage more than covers some of the disadvantages and inconvenience in maintenance.

Disadvantage or advantage?

The main advantage of stove stoves is quick warm-up. But it is also their main drawback, they cool down quickly. This is understandable, metal is a very poor heat accumulator.

This disadvantage can be easily eliminated by lining the furnace - potbelly stoves with bricks. Brick, unlike metal, perfectly accumulates heat. However, if you just lay a brick on a metal stove, then such a structure will warm up for a very long time and, accordingly, it is ineffective for heating the room.

But this can be successfully avoided if you do not just lay a brick on the stove, but build a brick screen in a certain way, with a device for ventilation holes. A similar brick stove made of brick with your own hands is perfect for a bath.

The figure shows a diagram of the device of a brick screen for a potbelly stove, if you overlay the stove in this way, then the efficiency of the stove will increase.

Brick screen

As you can see, the brick screen is installed at some distance from the walls of the stove. If you make the structure in the described way, then this will maximize the use of the heat generated by the furnace.

Potbelly stove - correct installation of a brick screen

A do-it-yourself potbelly stove for a garage with a brick screen is completely devoid of the lack of rapid cooling.

- When the stove is in operation, the heat emanating from it heats up the brick, which accumulates heat well, and after stopping the stove it heats up the room for a long time.

- The brickwork is made at a distance of 100 - 150 mm from the metal walls of the furnace and has ventilation holes at the bottom and top.

- Due to the heating of the air inside the screen, air circulates, warm air enters the room, and cold air, flowing around the metal walls of the furnace, cools them, thereby preventing the walls from burning out quickly.

- The absence of a gap prevents the room from quickly warming up, and the excess heat in the firebox simply flies into the pipe and the fuel is wasted.

- The checkerboard pattern impedes normal air circulation, and the brick area is much less solid, which leads to its rapid cooling, that is, this version of the screen does little to increase efficiency.

- Heat radiation from the oven simply passes through it like a sieve, and 50% of the heat energy is lost.

- The room heats up quickly, but just as quickly and cools down

- This method is very convenient when building a new house, when heat is required, and the main heating has not yet been installed.

Superburger - just a little desire

As mentioned above, a potbelly stove can be built in a few hours from scrap materials, but there will always be remnants of a brick at any construction site. Even broken brick is suitable, of course, if you do not plan to use this stove for a long time.

For the manufacture of a potbelly stove, you can also use metal boxes or make a furnace from rectangular sheet iron.

Below is a drawing of a stove - rectangular stove.

Potbelly stove with smoke circulation

As you can see from the drawing, if you wish, you can make a potbelly stove with your own hands with smoke turns, thereby you can significantly reduce fuel consumption, and the installation of doors with which you can adjust the traction further reduces its consumption.

Installation of smoke circulation and draft control dampers allows the use of potbelly stoves, significantly saving on fuel. And if for a summer residence you need to make a more serious heating option, then a do-it-yourself potbelly stove with a water circuit will help solve the problem.

From this it becomes clear that the name of the stove has nothing to do with the excessive consumption of fuel during its operation. This is just a misinterpretation, which, at someone's suggestion, clung to a wonderful oven, and then was spread all over the world.

But in no case should we forget about the need to comply with fire safety rules. Firstly, a do-it-yourself potbelly stove must be made of high-quality materials.

Secondly, the stove must be installed on a fire-resistant surface and make sure that there are no flammable objects nearby. In addition, in the room where the stove will be installed, you need to arrange a good ventilation system.

Assembling a stove-stove from a pipe

In this case, you cannot do without a welding machine. The function of the base of the structure will be performed by a segment of an ordinary metal pipe. Even an old barrel will do. The assembly will be carried out according to the scheme you are already familiar with. Make a grate from the bars and fasten it to the body. The connection is made by welding... This potbelly stove will have 2 dampers at once: a blower and a firebox. The model can be successfully used both for heating various rooms and for preparing a variety of food.

Assembling a stove-stove from a pipe

Potbelly stoves are appreciated precisely because they are able to warm up the room in the shortest possible time. But at the same time, there is also the main disadvantage of such stoves is that after stopping burning, they cool down as quickly as they heat up... Metal practically does not accumulate heat.

To eliminate the above disadvantage, it is enough to impose a home-made potbelly stove with refractory bricks

To eliminate the above disadvantage, it is enough to impose a home-made potbelly stove with refractory bricks. It accumulates heat well and continues to give it away to the surrounding space for a long time after the stove is finished. However, in order for the room to warm up, the stove will have to be heated longer than without such a brick fence. But this disadvantage can be easily eliminated. It is enough just to make a few ventilation holes in the brick screen. Such systems are often used in saunas.

The brick screen is laid out at some distance from the walls of the unit. This is a very important point. When choosing a suitable distance, one should be guided by the area of the heated room and the dimensions of the furnace itself.