Popular brands

The best automated units are produced by European manufacturers. The Western powers do not particularly need non-volatile models, so the whole emphasis is on improving electronic systems.

1. Germany.

Traditionally reliable and consistently expensive heating technology. Almost all German firms are focused on the production of premium equipment.

Bosch.

In the assortment of this company you can find types that work both on household gas and on liquefied gas.

Particular attention has been paid to wall-mounted models, but it will not be difficult to find a suitable floor-standing gas boiler

Buderus.

Produces high power sectional systems for large facilities ranging from hundreds to thousands of square meters. But this equipment, despite the cost, is more like a DIY constructor. Important components like a boiler or a control have to be purchased and installed separately. But the Buderus gas boiler will last at least 30 years.

Vaillant.

A pleasant exception in our review. Units of this brand have a completely democratic price, but in reliability they are not inferior to more eminent brands.

Bosch and Vaillant are also launching 30-40 kW models to partially cover this niche. However, everything rests on the exorbitant cost of both the acquisition and maintenance of German equipment. And buyers in the reviews give no less worthy examples of boilers from other manufacturers, which have a much better price.

2. Italy.

This country produces ergonomic and visually attractive mid-range devices. Moreover, the cost reduction is achieved not due to a decrease in performance, but due to large production volumes. So everyone who wants to buy a good boiler for heating a private house with a full range of useful functions often turns to Italian brands.

Ferroli.

The manufacturer did not skimp on copper heat exchangers for all of its models, so the efficiency of its equipment is beyond doubt. The only drawback is that in order not to burn the circuit ahead of time, you need a delicate setting of automatic systems.

Economical models with an average heating power of about 24 kW. However, in the assortment of this company, you can choose a double-circuit gas boiler with more serious characteristics - a cast-iron heat exchanger allows this.

Baxi.

Quite good boilers with self-diagnostics. They have only one drawback - they are demanding on operating conditions (quality of water and current in the network). But their efficiency indicators are quite decent - from 85 to 93%.

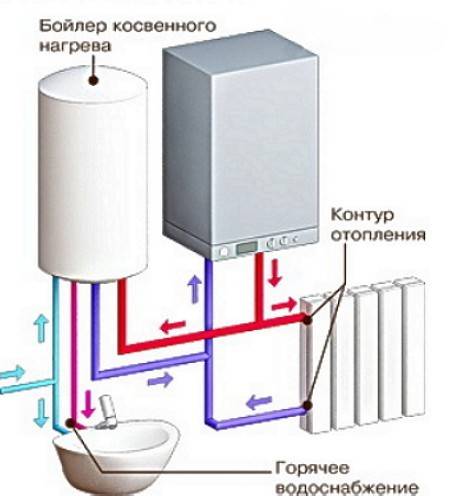

By the way, it is Italians who are most active in promoting units to the market, where a double-circuit floor-standing gas boiler is complemented by a built-in boiler for several tens of liters. Such designs show themselves well in DHW systems, while the storage tank allows hot water to be consumed without affecting the operation of the heating circuit.

3. Russia.

Our manufacturers produce reliable gas non-volatile boilers. But automated models also deserve attention, however, the "filling" in them is often not domestic, but Italian.

Zhukovsky plant.

Offers inexpensive equipment with power from 11 kW. Good reviews were deserved by the floor-standing series Comfort and ZhUK with steel heat exchangers and a productivity of 17-29 kW.

Conord.

Rostovites offer gas double-circuit non-volatile floor-standing boilers and wall-mounted models with stainless or cast-iron heat exchangers. The former are weaker - they can be chosen from a line from 8 to 31 kW, the latter are more reliable and powerful (16-33 kW).

It assembles Siberia devices with a maximum power of 35 kW, as well as weaker units for small private houses - AOGV (8-17 kW).

Russian manufacturers have successfully occupied the niche of inexpensive non-volatile equipment capable of heating in any conditions - there would be gas. Most of the manufactured models are impeccably reliable, not tied to the whims of power grids, although they are not powerful enough. Judging by the reviews, our double-circuit boilers are not yet capable of equally efficient work both for heating a country house and for hot water supply. A pleasant exception is only the Lemax floor-standing version with power ratings of up to 60 kW, but there is Russian - except perhaps the Cyrillic alphabet in the designations. These units are assembled from imported components.

Advantages of a double-circuit boiler

A gas double-circuit boiler will be equally effective for use in an apartment and for use in houses of a wide variety of sizes. Such heating has many advantages that allow a wide range of consumers to use the systems.

So, gas double-circuit boilers are a relatively inexpensive way to organize not only a heating system, but also hot water supply. Thus, utility bills will only go to pay for gas and cold water.

Heating and water supply from a double-circuit boiler

Heating and water supply from a double-circuit boiler

If you choose a single-circuit boiler, then in order to obtain hot water, you will have to separately mount a special boiler. The dual-circuit system will effortlessly simultaneously heat your room and provide you with the hot water you need.

In addition, modern models have automatic systems that not only protect the mechanism, but also increase the level of comfort when working with it.

Mounting

Any gas equipment can be installed and put into operation only if there is a project for the installation and after agreement with the gas service. If the project was completed with errors, or if they were allowed during installation, the boiler will not be approved for use.

In order for the boiler to work normally, a number of conditions must be met:

- A positive temperature must be constantly maintained in the boiler room;

- During the installation of the boiler, the fire safety instructions must be observed (for example, the walls near which the boiler is installed must be protected with non-combustible materials);

- When installing the boiler on your own, for its first start-up, it is imperative to invite a specialist who will be able to make sure with an experienced eye that the boiler is installed correctly and that there are no errors in its operation.

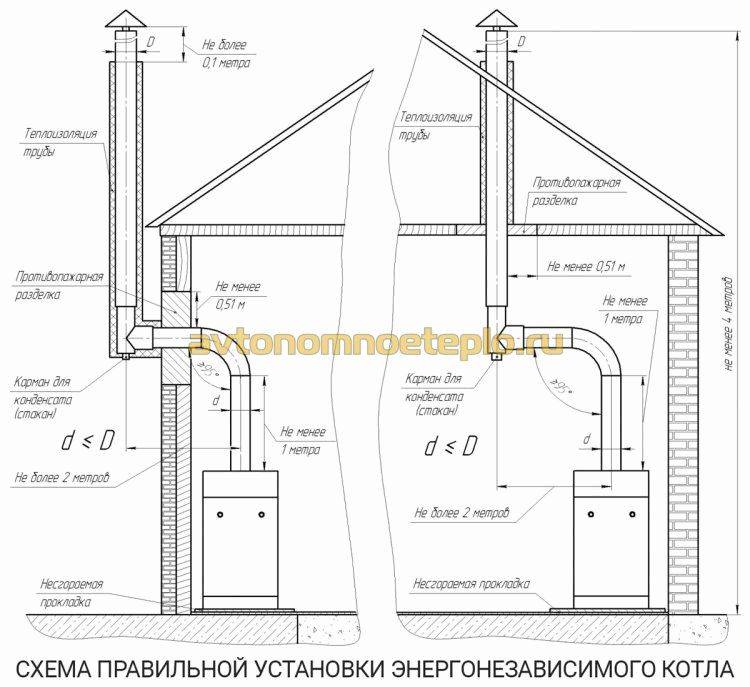

When designing a boiler installation scheme, you need to think not only about the unit itself, but also about the installation of the chimney system. The chimney must be installed in accordance with a number of requirements, which depend on the characteristics of the boiler and the characteristics of a particular building. Each individual boiler must be provided with its own chimney, but if necessary, several boilers can be reduced to one chimney duct, the cross-section of which corresponds to the sum of the cross-sections of the outlets of each boiler.

According to the norms, if the chimney is brought out to the roof and installed at a distance of 1.5 meters from the ridge, then the height of the pipe must exceed 0.5 meters. In the event that the distance between the ridge and the edge of the pipe is from 1.5 to 3 meters, the chimney must be brought out at least one level with the ridge.

It is recommended to make the chimney completely straight, but if this is not possible, then several turns can be made (no more than three along the entire length of the chimney duct). The total length of the chimney must exceed 5 m. From above, the chimney is closed with a metal fungus, which prevents dirt and moisture from entering the structure.

A private version of the chimney is coaxial pipes, the possibility of using which is determined individually (it is advisable to consult a specialist). Coaxial flues can be installed at a low height and led directly into the wall. Installation is inexpensive, and its technology is extremely simple.

Combustion products removal

Since the boiler equipment is non-volatile, a passive chimney must be installed to remove combustion products, which include gas and smoke. Most often, such a chimney goes outside through the roof to ensure sufficient air draft. It should also be borne in mind that with a passive chimney, part of the carbon monoxide still enters the room, therefore, to ensure human health safety, it is necessary to ensure good ventilation of the room, or install boiler equipment in a separate room. Most often, floor-standing non-volatile gas heating boilers are installed either in the annexes to the building, or in a separate boiler room. Modern non-volatile gas boilers, whether floor-standing or wall-mounted, are equipped with a draft control system. With a decrease in draft, the gas supply decreases, and in the absence of draft or even reverse draft, the burner automatically shuts off, thereby ensuring the safe operation of the boiler equipment.

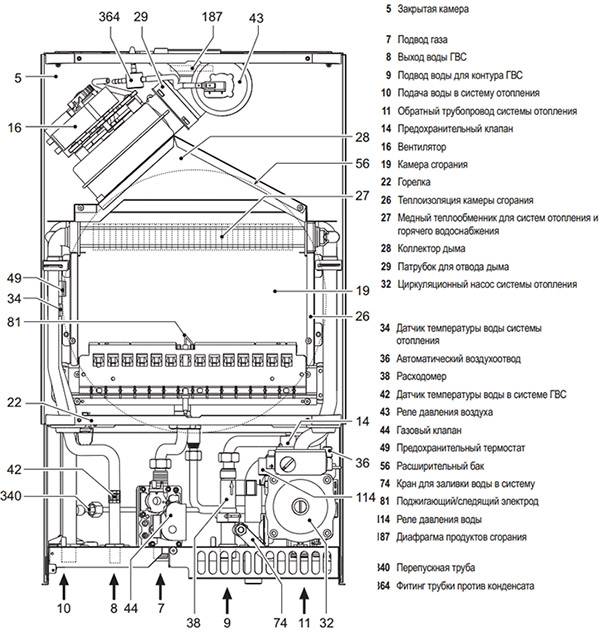

Boiler design feature

Floor structure diagram

The unit does not need to be connected to the power supply, since it works due to the thermogenerator built into it. There is an opinion that this type of double-circuit boilers is already outdated, but this is erroneous. Foreign manufacturers manufacture the latest models of non-volatile gas boilers, and their performance does not differ from devices operating from the mains.

Their important feature is that they can only work with heating systems where water circulates by gravity. When heated, the coolant rises in the boiler, and then enters the outlet pipe, heading to the heating system

When moving, hot water cools down and because of this, it can stop its circulation. To prevent such a phenomenon, large-diameter pipes are used when installing heating, and they must be located at a certain angle.

When heated, the coolant rises in the boiler, and then enters the outlet pipe, heading to the heating system. When moving, hot water cools down and because of this, it can stop its circulation. To prevent such a phenomenon, large-diameter pipes are used when installing heating, and they must be located at a certain angle.

For better functioning of non-volatile boilers, circulation pumps are used. When pumping liquid through themselves, they accelerate its movement. Such devices work only on electricity, and when it is turned off, the heating system switches to a gravity principle.

Variety of boiler models

The model stands out for its low gas consumption, which is currently very important. The German manufacturer cares about its customers, so everything is thought out in this unit, from design to maintenance.

Proterma gas automatics ensure stable operation in the event of a decrease in gas pressure, which will protect heating system from freezing. The boiler efficiency reaches 92.8%. It can operate on both natural and liquefied gas. Equipped with protective devices.

Viadrus. The Viadrus G36 (BM) gas boiler is produced in several modifications that differ in power. To determine the choice, you will need to familiarize yourself with the technical characteristics of the device, as a result of which you can find out whether it is suitable for a specific heating system.

Viadrus G36 does not depend on power supply. An atmospheric steel burner is mounted in it. To ensure the smooth operation of the gas valve, a thermocouple is built into the unit, capable of generating the required amount of electricity. This model is adapted to local operating conditions, heating the coolant to a level of 45 degrees or more.

If it is necessary to connect pumping equipment in order to increase the pressure of the working environment, it is advisable to have additional uninterruptible power supplies at home.

For Viadrus G36, in addition to the traditional chimney, a coaxial one is suitable. An indirect heating boiler can be connected to the boiler. The power of the selected boiler must be 15% higher than the required one.

Protherm Bear TLO. Of the positive characteristics of these non-volatile boilers, it should be noted that they work in systems with an open movement of the coolant, the presence of piezo ignition, an open combustion chamber, a cast-iron heat exchanger, a high efficiency of 87 - 92%, a stainless steel burner, one-stage power control, protection against overheating. It also provides control over the intensity of the flame, operation on main or liquefied gas and many other options.

The presence of the above qualities makes it easy to operate this heating equipment. The unit has compact dimensions, which does not affect the efficiency of its work.

Design features

If you only plan to install equipment in a house that was not originally intended for autonomous heating, then you will have to make a chimney or look for a model that will work without this communication. So, the combustion products will be discharged through the wall with a special pipe. In the same way, the air that is necessary for the combustion process will be supplied.

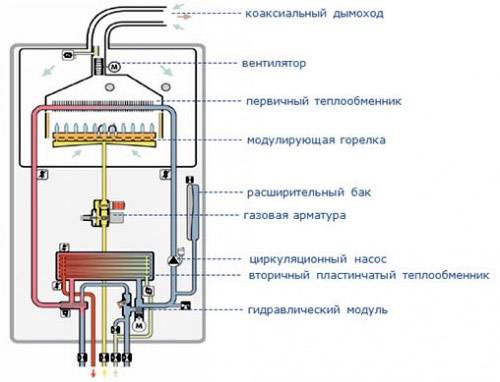

The structure of a double-circuit boiler

The structure of a double-circuit boiler

In some models, the heating is turned off during heating. In this case, a separate heat exchanger is used for hot water supply. Other gas-fired heating boilers, non-volatile, double-circuit have a combined heat exchanger. Such a system is more effective, however, in the event of a breakdown, the repair of such a unit will require large financial investments. The cost of such boiler models is also higher, but it will be more comfortable to use them.

What are non-volatile gas boilers?

The main difference between the equipment and a standard heater is the absence of a circulation pump, which is responsible for maintaining the intensity of the circulation of the coolant in the system. A pump is a network element, for the operation of which it is necessary to be supplied with electricity, if there is no current, the pump does not turn on, the whole system gets up and can freeze. In order for the gas boiler to work without electricity, the design does not provide for the presence of volatile elements, which is what the autonomy of the heating unit is achieved.

The automatic system of the non-volatile boiler also operates without power supply. The device from the Italian factory (model 630 EUROSIT) is triggered when the burner blows out, which eliminates the risk of explosion. To turn on the equipment after the electromechanical protection has worked, you will have to press the start button for some time in order for the thermocouple to heat up, creating an EMF, from which the solenoid valve is triggered.

After the burner is turned off, the thermocouple temperature decreases, which causes the fuel supply valve to close.

Principle of operation

The operation of non-volatile automation is based on two effects:

- thermal expansion of materials;

- Seebeck effect. Consists of EMF thermogeneration. If two conductors of dissimilar metals are soldered with their ends to each other and then in some way provide a temperature difference at the points of contact, for example, heat one of them, an EMF will appear in this element.

The work of the following devices is based on the thermal expansion of materials:

The work of the following devices is based on the thermal expansion of materials:

- thermocouple. It is a copper flask with a capillary tube extending from it, filled with gas. When the thermocouple heats up, the gas expands and the copper tube deforms, affecting the controlled element. In non-volatile boilers, thermocouples are installed above the pilot burner (wick). The element heated by the flame keeps the gas valve open. If the gas supply is interrupted and the wick goes out, the thermocouple will cool down and the valve will close. Now, when the gas supply is resumed, it will not poison the residents;

- bimetallic plate.Consists of two metals with a very different coefficient of thermal expansion. Since both components do not change in size with temperature fluctuations, the plate bends, developing a sufficiently large force;

- lever system. The slight expansion of the heat exchanger or metal rod is multiplied by the leverage acting on the valve.

Thermogenerators are used as draft and flame sensors. The element is electrically connected to the solenoid gas valve. While the flame is burning and there is a draft in the pipe, the thermogenerators generate EMF.

Non-volatile gas boiler device

That is fed to the solenoid coil in the solenoid valve, and the magnetic field created here keeps the assembly open, overcoming the resistance of the spring. In the absence of thrust or flame attenuation, EMF is not generated and the spring closes the valve.

The EMF generated by the thermogenerator is small, therefore, gold-plated conductors and contacts are used in the circuit - they have the lowest resistance.

Strengths and weaknesses of floor standing boilers

The main difference between a floor-standing boiler and a wall-mounted one is that there are no restrictions on the dimensions and weight of the structure. The combustion chamber has a larger volume, which affects the performance of heating equipment.

Floor standing models differ in the following characteristics:

- Floor standing gas boilers are more reliable - the design uses a heat exchanger made of thick-walled steel or cast iron. The second circuit is made of copper or stainless steel. The service life of a steel boiler reaches 15-20 years, a cast iron boiler, 25-30 years.

- Independence from electricity - the practicality of floor-standing boilers lies in the fact that for the most part, stationary models are non-volatile, capable of working after a power outage.

- Performance - floor-standing versions are available in household, up to 50 kW, semi-industrial and industrial versions. The power limits are a few mW.

Disadvantages of boilers, with the possibility of installation on the floor in the room, are associated with the following points:

- Large weight of the structure - models with a cast-iron heat exchanger have a mass of several centners.

- The classic type of plug-in chimney.

- The need for placement in a separate room of a large area.

- Large dimensions and inconvenient floor standing. For the most part, stationary models use an atmospheric combustion chamber, which makes it impossible to hide the boiler in a niche or a special kitchen drawer, which is possible in the case of a wall-mounted version.

The device of non-volatile boilers

Wall-mounted and floor-standing non-volatile boilers are supplied with the same type of burner devices, which are several rows of tubes located in the same plane. Round or slot-like holes are made in them for the fuel outlet, as a result, an even stable flame is obtained along the entire lower plane of the furnace. A steel or cast-iron heat exchanger is located in the upper zone of the combustion chamber, which receives heat from the burner flame and combustion products passing through it.

Gas burner device

In single-circuit boilers, water circulates inside the heat exchanger through tubes, to which heat energy from fuel combustion is transferred. If it is necessary to additionally heat water for hot water supply, then a heat exchanger of a different design is installed in a double-circuit floor-standing non-volatile boiler. In each pipe with the coolant of this device, there is another built-in inner pipe through which water for hot water flows. Both streams move in the same direction, while the coolant is heated first, and already from it - water for the needs of hot water supply.

Each non-volatile gas heating boiler is necessarily equipped with a minimum set of safety and control automation required by regulatory documents for the use of gas installations. This kit includes:

- automatic multifunctional valve of Italian production EUROSIT or American HONEYWELL with a temperature sensor (thermocouple);

- chimney draft control sensor;

- thermometer.

The burner is ignited by means of an igniter that operates continuously. Fuel to the igniter and burner is supplied and controlled by an automatic valve. It switches off the boiler burner if:

- the draft in the chimney disappears;

- the pressure in the gas pipeline falls below the minimum;

- the flame of the burner goes out;

- the heating medium temperature has reached the set value.

How to choose a manufacturer?

During normal operation, the gas unit benefits the home. It provides heat and hot water supply. In the event of an emergency, the unit is dangerous. A high-quality and modern boiler should include a valve that cuts off the gas fuel supply, as well as a security system that is equipped with sensors of various types.

The termination of the flow of fuel into the unit can be observed in a wide variety of situations. As a rule, fuel stops flowing if the flame on the gas equipment has died out, the voltage in the electrical network has disappeared, the water level in the unit is too low or the pressure has dropped.

Today, on the consumer market, one can purchase boiler equipment from a wide variety of manufacturers: Russian and foreign. The modern equipment is of good quality, equipped with an automatic security system.

When buying a gas unit, pay attention to the availability of a guarantee. Study its terms carefully

Even the most expensive boiler can fail, so warranty service is mandatory. Before choosing a gas boiler, it is advisable to consult with a specialist or read reviews.

For our country, the instability of the gas network, low temperatures are a frequent occurrence. The water is also of poor quality. Choose a unit that will be optimally adapted to Russian conditions.

Single-circuit or double-circuit?

Hot water supply is necessary in any home, especially during the cold season. The question is how to obtain this water correctly and most economically. It all depends on the maximum flow rate in the DHW network, the number of consumers and the simultaneity of their work. Double-circuit heat generators with a flow-through heat exchanger are relevant in the case when it is necessary to provide 2-3 consumers while simultaneously turning on no more than 2 taps.

But what if the consumption and the number of consumers are higher? For this, there are heat sources with a built-in or external storage tank. Then, within a certain period of time, the container will provide a sufficiently large amount of hot water prepared in advance. The duration of this segment directly depends on the capacity of the tank.

Oddly enough, in order to supply a large amount of hot water, the use of double-circuit boilers is not required. On the contrary, you should buy and install a powerful single-circuit heat generator and an indirect heating boiler. This scheme is gaining more and more popularity, since it allows you to easily obtain the required amount of hot water, although the initial investment in equipment is quite high.

It cannot be said unequivocally which of the boilers is better for all occasions, much depends on the operating conditions and the wishes of the user. For example, high-tech wall-mounted boilers are more suitable for apartments and small houses, although they can also be used in cottages with several floors. In turn, a stationary unit is a symbol of reliability and good quality, but it is absolutely not suitable for an apartment.

The concept of independent heating and the principle of operation of gas boilers

Heat supply systems for buildings can provide for either connection to central heating networks of settlements powered by CHP or boiler houses, or the use of their own heat sources. In the first case, a dependent connection of the heating system to the heating mains is possible using the network heat carrier directly for heating the batteries and independent, with its own heat carrier, which is heated by water from the heating main through a heat exchanger. Both of these connections have nothing to do with autonomous heating.

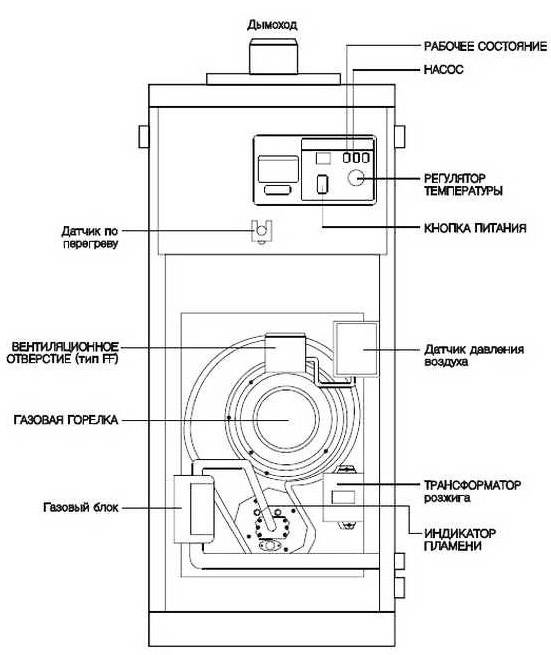

Sectional view of a non-volatile gas boiler

Truly independent heating can only be obtained by installing an autonomous boiler. In this case, the consumer decides for himself when the heating season begins: cold - turned on the device, warmer - turned off. If double-circuit models or single-circuit models are used, to which storage water heaters of indirect heating are connected, residents are not threatened with interruptions in the supply of hot water. Recall that when connected to central heating networks, interruptions in the supply of coolant for several days occur annually during the summer repair campaign.

Non-volatile floor standing boiler at the installation site

Gas boilers minimize the dependence of home comfort on utilities. Their working principle is simple. The fuel is burned in the combustion chamber, transfers its heat to the water, and it, circulating through the pipes, gives it to the premises through the heating radiators. The cooled coolant is returned to the boiler. The cycle repeats itself.

The gas is ignited by a special device - an igniter, and it, in turn, is manually ignited by a piezoelectric element. Maintaining the required level of heating of the coolant in many models occurs automatically, but there are options with manual adjustment, when the user himself sets the fuel consumption and, accordingly, changes the temperature in the house.

The circulation of water in the heating system occurs naturally. This is due to the difference in the weight of the heated and cooled coolant: cold is heavier.

Household floor-standing non-volatile gas boilers

All the main functions and the device that floor-standing non-volatile gas boilers have are carried out in a completely autonomous mode. For the operation of the boiler equipment, no electricity is required. Non-volatile boilers, the optimal solution for areas where there are frequent power outages.

How non-volatile floor-standing gas boilers work

The principle of operation of a non-volatile boiler has several distinctive features that affect fuel consumption, the accuracy of adjusting settings, etc. All units of boiler equipment operate in a mode completely independent of electricity:

Automation - adjustments are made by thermomechanical devices. A thermocouple is used to start and open the gas valve. When heated, it generates a low-voltage voltage of sufficient power to hold the valve stem open.

The heating temperature is regulated by a thermomechanical valve. There is a thin metal rod inside the regulator. When heated, the core heats up and the needle closes the gas nozzle.

Types of floor-standing non-volatile boilers

According to their technical characteristics, non-volatile floor-standing boilers are divided by power and the number of heat exchangers or circuits. There is a classification according to the main purpose, depending on the performance:

Another difference between heat generators is the type of heat exchanger, more precisely, the material from which it is made. Cast iron boilers are distinguished by their reliability, long service life, high weight. Steel counterparts are 1.5-2 times cheaper, but have the worst thermal performance.

Double-circuit non-volatile

Floor standing double-circuit non-volatile gas boiler, designed for heating and hot water supply. Primary heat exchanger made of structural steel or stainless steel. The coil is traditionally made of copper. The latest generation of non-volatile boilers, as a secondary heat exchanger, began to use an aluminum alloy tube.

Single-circuit non-volatile

The floor-standing non-volatile single-circuit gas heating boiler, unlike its counterparts with two heat exchangers, is designed exclusively for heating living quarters. This type of heating equipment is distinguished by its maximum performance. If over time there is a need for hot water, an indirect heating boiler is connected to the heating system.

How to choose a non-volatile gas boiler

After determining which boiler is better, one or two-circuit, you will need to choose a manufacturer of heating equipment. The rating for reliability is headed by German technology, but its popularity is reduced by the prohibitively high cost.

Advantages and disadvantages of a non-volatile gas boiler

Of course, like any other heating equipment, non-volatile models have their advantages and disadvantages. Considering the pros and cons, mistakes in choosing the right boiler can be kept to a minimum.

Stable work regardless of external factors.

Higher gas consumption - the intensity of heating is controlled by measuring the temperature of the coolant. The thermostatic valve has a large error.

A non-volatile boiler is the best option for heating rooms with a large area, especially in areas where there are problems with power supply. The equipment is easy to operate, it is cheaper, repairs, adjustments are practically not required. Often, this type of equipment is used for heating country houses, country houses.

Calculation of the power and temperature of a warm water floor

Heating boiler power selection calculator

Calculator for calculating the number of radiator sections

Calculator for calculating the footage of a pipe for a warm water floor

Calculation of heat loss and boiler performance

Calculation of the cost of heating depending on the type of fuel

Calculator calculating the volume of the expansion tank

Calculator for calculating heating PLEN and electric boiler

Heating costs by boiler and heat pump

Pros and cons of non-volatile units

In some settlements, only a non-volatile gas boiler can be the only reliable source of heating. In order for it to additionally perform the function of heating water, it is equipped with an indirect heating boiler. Such a non-volatile device has many advantages:

- works without electricity in difficult conditions;

- easy to operate;

- long service life;

- an uninterruptible power supply is unnecessary;

- saves energy.

The disadvantages of non-volatile units are as follows:

- limited set of functions;

- low efficiency;

- takes up a lot of space;

- you will need a separate room device;

- requires the installation of a classic chimney and good draft.

Of course, volatile units have more functions and capabilities than those independent of electricity, but you will not be left without heating if the electricity is turned off.Manufacturers are trying to equip new models with additional features and increase their competitiveness in the market.

Note! Non-volatile devices are capable of working only if the pressure in the gas line corresponds to the indicator of the heating boiler's passport data.

Market overview - brands and prices

One of the leaders in the gas equipment market is the German company Vaillant. The two-circuit models of the VUW line can have a closed or open combustion chamber (modifications, respectively, Turbotec and Atmotec). They are equipped with protection against freezing, jamming of the pump and the directional changeover valve, a mode using partial power, electronic ignition, technical condition monitoring, a convenient LCD display, etc. as well as a built-in analog pressure gauge. The price for such a unit can be approximately $ 1100-1600.

Gas boilers from Viessmann (Germany), which have an efficiency of about 93%, are no less popular. The boiler can be connected to a PDA and adjusted according to changes in the room temperature. Another advantage of these boilers is the quick-release couplings, which greatly simplify the installation. A number of models are adapted to work in Russian heating systems. The price can be $ 650-1200.

German Bosch gas boilers are also quite reliable, which can work in parallel with a solar collector. If necessary, the design can be modified to operate on liquefied fuel. Ionization control of the flame, which does not allow the burner to go out, as well as a number of protective and control devices protect the device from damage. Prices range from $ 650-1000.

Models of gas boilers "Chao-Nord" produced by the Italian company Beretta are equipped with a closed combustion chamber and are considered the best option for the northern regions. These boilers are characterized by an original design of the control panel, an improved model of the heat exchanger and a three-speed Grundfos pump. The unit price can be $ 400-650.

Reliability and high efficiency made modern Protherm gas boilers made in the Czech Republic popular.

Models of the Tiger series have a modern control panel, and those who are looking for a gas boiler with a simple push-button interface should pay attention to the Panther range. Increased protection against moisture allows these units to be installed even in bathrooms

The price range is $ 600-2000.

A wide selection of gas by-pass boilers is provided by the Italian company Ferroli. In addition to protection systems, self-diagnostics and electronic control, these devices are equipped with a special bimetallic heat exchanger that is resistant to possible breakdowns. Prices range from $ 350-1500.

What parameters to pay attention to when choosing a gas boiler?

The purchase of a gas boiler for a private house is a rather crucial step, since a large number of important points are required to be adopted. First of all, determine the requirements for the heat source and the operating points. Power is required to be selected from the overall dimensions of the building.

Pay attention to the materials from which the walls and floors of the building are made. They must be non-flammable

The wall must be able to support the weight of the heating equipment.

In the process of installing boiler equipment, it will be necessary to provide for the presence of an additional room, which will be equipped with ventilation and have windows of the required dimensions for the removal of combustion products.

Heating boilers do not tolerate power outages. In case of private network outages, the automatic system may fail. The gas supply must also be reliable.If your house is at the end of the street, there are interruptions in the gas supply, then think about purchasing a unit that runs on a different type of fuel, since at negative temperatures outside the window you run the risk of being left without heat.

The issue of selecting a reliable heating device can be considered both at the stage of designing a house and upon completion of construction. The first method is the most convenient, since you will be able to foresee all inaccuracies in advance, and experts will tell you which unit is best suited for your home.