Stainless steel fireplace stoves

In the manufacture of stainless steel fireplace stoves, heat-resistant material with a thickness of 3 ÷ 4 mm is used. The surface of the finished product is coated with a matt or glossy flame retardant powder paint applied by spraying. There are not as many stainless steel stoves on sale as cast iron or black steel, since they have a very high cost.

The service life of such models is mainly determined by the quality of the welds. The fact is that stainless steel is welded using special equipment. And if the technology is not followed, then when exposed to high temperatures in the areas of the joint, destruction of the metal will begin over time. The features of products made from this material include the following points:

- Unlike cast iron fireplaces, steel stoves warm up much faster, which helps to heat the premises in a shorter time. At the same time, the heat capacity of steel appliances is much lower. So, when the fuel burns out, the walls of the furnaces cool down quickly. To keep the oven warm longer, manufacturers have developed models with an external ceramic finish.

- When welded properly, stainless steel furnaces are corrosion resistant. This ensures the durability of their operation.

- The disadvantages of stainless steel include its instability to the effects of open fire, which heats it to very high temperatures. With strong heating, the walls of the combustion chamber can deform. To avoid this phenomenon, the firebox is lined with fireclay bricks or tiles.

- In terms of weight, steel furnaces are much lighter than cast iron options, which greatly facilitates their transportation and installation.

- The service life of a high-quality stainless steel heating unit is 20-25 years.

What are the fireplace stoves for giving

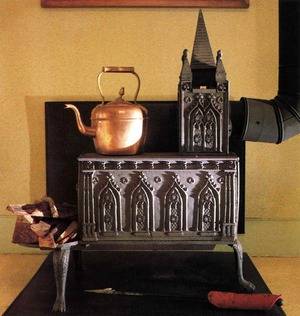

The types of modern fireplace stoves are different. The most popular products are made from steel and cast iron. Moreover, the cast-iron models are very similar to the old stoves. Thanks to their original design, they can easily fit into any interior, related to the retro style. There are also combined ones. They are made of metal and brick. Various types of fireplace stoves contributed to the fame of Kaw-Met - a company from Poland and a Canadian company Wermont Castings. The thermal efficiency of the furnaces they make reaches 80%.

On this topic:

BACK

FORWARD

1 of 15

Therefore, they are purchased for houses in which people do not live permanently. Cast iron models gradually cool down and, after heating, can still warm the surrounding space.

Regarding the location in the room, corner fireplaces and side stoves are distinguished. Any option can turn out to be a real decoration of the interior, as it looks just as impressive as a decorative fireplace, thanks to the installed glasses.

A fireplace stove for a house with a water circuit is made not only of cast iron and steel, but also of bricks.

Usually, when choosing it, you need to consider:

- area to be heated;

- correspondence of the base for the furnace and the mass of the entire structure;

- product power and functionality;

- whether this stove will be able to provide sufficiently effective heating of the house;

- dimensions of the furnace, its model and design style.

However, these are the best stove fireplaces for a country house. Since people live in it permanently and have the opportunity to create an autonomous heating system.

There are constructions based on talcomagnesite, the main properties of which are:

- resistance to any kind of deformation that can occur when temperature drops from low to high, and during cooling, on the contrary, from high to low;

- high reliability and durability.

Popular models of fireplace stoves

We have come to the most interesting section of our review - to the description of rating long-burning fireplace stoves for summer cottages and country houses.We present five excellent models for your attention.

Fireplace stove Brandenburg

An extremely neat and compact unit for heating a small country house. It belongs to the pyrolysis type fireplaces with a large firebox. The power of the unit is 9 kW, the heated volume is up to 120 cubic meters. The stove is made of steel and includes a combustion chamber lined with fireclay bricks. The front door is made using the "clean glass" technology and is not covered with soot even after prolonged use - an excellent option for your country house.

META Enisey

Before us is one of the most popular and mentioned long-burning fireplaces on the Internet. The unit can burn on one tab of firewood for up to 8 hours. And to create the most comfortable atmosphere, it is equipped with regulation of the intensity of combustion. The appearance of this unusual unit is also interesting - there are three viewing windows at once for observing the flame. Around the fireplace, you can comfortably sit with the whole family and spend the evening with a sincere conversation, enjoying the warmth and comfort.

The long-burning fireplace stove META Yenisei, like the previous model we have considered, is equipped with a "clean glass" system. Therefore, you do not have to constantly clean the viewing windows. For quick cleaning, the fireplace has a pull-out ash drawer - if it is full, just pull it out and empty its contents into the trash can. A compartment for storing firewood is provided under the ash box.

We recommend not to discard the ash formed during the combustion process, but to store it for further fertilization of the garden.

META Pechora Aqua

The long-burning stove-fireplace META Pechora Aqua has an excellent appearance - its design includes two tiled walls. The model belongs to the wall-mounted, its power is 13 kW. Burning time from one solid fuel fill is about 8 hours. In addition to the large combustion chamber, the stove has a long burning system. The shape of the oven is rather unusual, somewhat reminiscent of a rhombus. The door here is curved, with three viewing windows (all with the same "clean glass" system).

An additional advantage of a long-burning fireplace stove will be that it is equipped with a hob. Also, its design provides for a heat exchanger for connecting a heating system - a fireplace can warm several rooms at once. The housing is made of robust steel for a long service life. The maximum heated volume is 260 cubic meters. The power of the heat exchanger is 5 kW, thanks to which it is possible to heat another 40-50 sq. m of dacha living space.

MBS Thermo Vesta plus

Before us is a long burning fireplace stove with a water circuit. The unit can heat up to 200 cubic meters. m, with a power of 11 kW. It is made in a strict rectangular body made of durable cast iron. The efficiency is 80-83%, and to ensure the maximum duration of combustion, a pyrolysis system is provided here. The stove is available in three colors - dark red, cream and red. Thanks to this, you can always choose the most suitable option for the interior of a country house.

META Cupid

Do not think that we have forgotten about long-burning corner fireplaces - this is one of these options. The unit is made of steel and equipped with a door with a viewing window (with a "clean glass" system). Also, the design provides a compartment for storing firewood and a drawer for ash. The veneering ceramics are visible from the sides. The power of the unit is 9 kW, the maximum amount of loaded wood is 4 kg, the duration of combustion is 5-6 hours.

Invicta Sologne

As a bonus, consider the Invicta Sologne long burning stove.It is impossible to pass by such a curious sample just like that - the fireplace is made in a round vertical floor case and has an interesting design with metal volumetric patterns. The body, as you would expect, is made of cast iron. The power is 8 kW, the heated volume is up to 105 cubic meters. m. Due to its exquisite design, this fireplace will ideally fit into a room with no less sophisticated design.

Review of popular models

Table 2. Overview of popular models and their characteristics

| Models appearance | Specifications |

|---|---|

Stove of the Bavaria series from EcoFireplace Stove of the Bavaria series from EcoFireplace

|

This Russian manufacturer has been presenting its products for only fifteen years, but this was quite enough for the approval of its high-quality and aesthetic products on the market. In particular, steel and combined fireplace stoves from the Bavaria series with a capacity of 9-11 kW are very popular. The photo shows a version with a steel body, cast iron plate and tiled cladding, which is capable of heating 110 m³ of premises. The burning time is 5 hours, the firewood consumption during this time will be 7-7.5 kg. |

Fairway Gunther Fairway Gunther

|

Another Russian manufacturer specializing in the production of compact cast-iron fireplace stoves, which are ideal for summer cottages. In particular, here is the GUNTER model, capable of heating a house with an area of 140 m² with very modest dimensions of 750 * 750 * 560 mm. Its power is 14 kW, it can work both on wood and on wood briquettes. |

JOTUL oven, model F 3TD BP JOTUL oven, model F 3TD BP

|

Fireplace stoves from the Norwegian company Jotul (which has been on the market for 150 years) are known and loved all over the world. A huge assortment of models covers a wide variety of consumer needs. The rating presents a modest in power (7 kW) and very compact (dimensions 577 * 707 * 484 mm and weighing only 106 kg) cast-iron model for summer cottages. It provides for secondary afterburning of fuel, glass self-cleaning and the ability to connect a chimney both from the top and from the back. It can heat a room with a volume of 60 m³. On a note! This manufacturer gives a 10-year warranty for its stoves, while Russian-made models have a maximum of 5 years. |

Tim Sistem, model Alma Mons Tim Sistem, model Alma Mons

|

The Serbian manufacturer of metal furnaces Tim Sistem is well known not only in Europe but also abroad. In our rating, we present the ALMA MONS model (R - with red cladding, but there are options with black and white design), capable of heating up to 180 m³ of living space. It has not only a hob, but also an oven. The top and door of the firebox are cast-iron, but the body is made of sheet steel, painted with heat-resistant enamel. There are three burners on the hob, below there is a convenient box for storing firewood. By removing or installing an additional grate, the volume of the firebox can be increased or decreased accordingly. This stove is intended not so much for heating as for cooking, therefore it has increased dimensions of 925 * 800 * 550 mm with a power of 6 kW. Weighs only 80 kg. |

GreiVari, ref. 1.100 Screen GreiVari, ref. 1.100 Screen

|

Another model of the Russian manufacturer, designed not only for heating, but also for cooking and heating food. It is made of steel, has a power of 10 kW, which makes it possible to heat up to 130 m³ of room air. It provides for different modes of heat transfer - not only intensive, but also economical. It can operate on all types of wood fuel, and, provided that the furnace is fully loaded, it can function continuously for up to 5 hours. |

Thermofor Herma Thermofor Herma

|

The German steel furnace from the Russian manufacturer Termofor, with dimensions of 450 * 645 * 1080 mm, is capable of heating at least 250 m³ of air volume. The hob is small in size, but there is a recess in the form of an open oven, in which a kettle or utensils with food can stay hot for a long time. The stove has a large, spacious firebox with a volume of 125 liters, an impressive power of 13 kW. |

Here is a far from complete list of manufacturers of fireplace stoves whose products are present on the Russian market. Among them, there are many domestic brands that produce models that are very worthy in terms of characteristics and external performance. And all would be nothing.Yes, only buyers are alarmed by the ridiculously small one year warranty, which is determined by some of our manufacturers. For Chinese teapots - and even then the guarantee is greater.

Furnace fuel

Wood with a moisture content of no more than 20% serves as fuel for long-burning stoves - it can be whole logs of the same length, waste from the woodworking industry, chips and other sawn timber. In addition, pellets, fuel briquettes and coal are used. For this type of furnace, it is better to choose brown coal, since other varieties are more energy-intensive, which can lead to burnout of the surfaces of the walls of the device, especially if the furnace is made in a combined version, that is, it is assembled from different materials, and steel is used as the walls of the furnace.

The moisture content of the fuel has a great influence on the quality of heating, since raw wood significantly reduces the efficiency of the device, and also contributes to the formation of soot deposits on the walls of the chimney. In addition, the processes of pyrolysis in such wood are defective.

Features of combustion technology

High performance is not the only advantage of this design. Long-burning stoves are economical due to the fact that not all the firewood burns at once, but partially, only the upper layer. In this regard, smoldering is very slow. Moreover, the designs of long-term combustion are not so in demand in terms of humidity and fuel quality as pyrolysis units. Of course, when using wet firewood, the performance of such a boiler will also drop (up to about 30%), but in any case it is more than in pyrolysis ones.

High performance is not the only advantage of this design. Long-burning stoves are economical due to the fact that not all the firewood burns at once, but partially, only the upper layer. In this regard, smoldering is very slow. Moreover, the designs of long-term combustion are not so in demand in terms of humidity and fuel quality as pyrolysis units. Of course, when using wet firewood, the performance of such a boiler will also drop (up to about 30%), but in any case it is more than in pyrolysis ones.

Many long-term combustion models can operate with high efficiency on lumber waste: chips, sawdust or trimmings. But this option is suitable for furnaces made in factories. If we talk about home-made devices, it is better to use firewood as fuel.

Many long-term combustion models can operate with high efficiency on lumber waste: chips, sawdust or trimmings. But this option is suitable for furnaces made in factories. If we talk about home-made devices, it is better to use firewood as fuel.

The long burning design has appeared on the market relatively recently. In the early 2000s, engineer Edmuntas Stropaitis found a solution to the problem of constantly adding fuel to the boiler. It was he who invented the supply of oxygen from above, which gave rise to the term "continuous combustion". The coefficient of utility of this method is on average 90-100%.

Such a system becomes possible due to the supply of air from above through a special tube. A portion of air is delivered, and the top layer of firewood is burned. After this layer has burned out, another portion of air enters, moreover, as much as is needed for the combustion of the upper layer. Thus, you can completely control the combustion process and adjust the duration of the wood burning.

Such a system becomes possible due to the supply of air from above through a special tube. A portion of air is delivered, and the top layer of firewood is burned. After this layer has burned out, another portion of air enters, moreover, as much as is needed for the combustion of the upper layer. Thus, you can completely control the combustion process and adjust the duration of the wood burning.

The main factor that allows you to save is the long burning process, in which the wood gradually releases a large amount of heat. Primary combustion takes place in the first chamber, and secondary (afterburning) - in the second.

The main factor that allows you to save is the long burning process, in which the wood gradually releases a large amount of heat. Primary combustion takes place in the first chamber, and secondary (afterburning) - in the second.

If the oven is equipped with an ash pan, then it plays a purely technical formal role. It consists in cleaning the container from ash, which remains a little after a long and double combustion. Due to the fact that air in such a system enters only through a special tube from above, the ash pan door must be hermetically closed. Otherwise, such a system cannot be called long-term, since air through the ash pan will flow from below and the firewood will burn very quickly.

The following features of the oven can be noted:

- large volume of the combustion chamber;

- dividing the firebox into two parts;

- no blower;

- air is supplied only from the top.

For high efficiency, it is recommended to use firewood with a relative humidity of no more than 20%.

general characteristics

Solid fuel stoves of modern production are very compact and have a very aesthetic appearance. Most models have fireproof glass sealed doors for viewing the flames.

With all the variety of models, all devices consist of the following parts

- metal body (cast iron or steel);

- combustion chambers - furnaces (many models have a secondary combustion chamber);

- ash pan;

- air passages;

- a branch pipe for exhausting gases into the secondary chamber;

- cast iron grate;

- water jacket (for ovens with a water circuit).

Thus, the main advantage of the fireplace stove over other heating devices is the long operating time between the woods, on average, depending on the model's characteristics, from 6 to 12 hours.

The main types of long burning stoves

In addition to the fact that these devices can be conventional and have a water circuit, they are subdivided according to other criteria.

So, units of several modifications are produced:

- Heating models.

- Heating and cooking stoves with a hob and even an oven.

- Furnaces with a tank for heating water.

- Multifunctional ovens that include all of the above functions in their design.

Long-burning stoves can have different shapes and sizes - this variety allows you to choose the desired option, depending on the area and place of installation.

Corner models of long burning cast iron stoves are usually compact in size, so they can be installed even in the smallest room. I must say that corner devices are most often made of various materials used in combination. For example, the body is made of high-quality steel with a thickness of 4 ÷ 5 mm, and the grate, combustion chamber and other internal elements in contact with an open fire are made of cast iron.

Corner oven

Wall mounted radiators can also vary greatly in size, depending on their functionality. They are intended both for installation in kitchens and for living rooms, as they are often given a very original design.

Cast iron stove with ceramic exterior

Quite often, cast iron stoves are faced with various types of ceramic tiles, or even artificial stone. This finish performs several functions at once:

- helps to keep the generated heat for a longer period;

- the surface of such a finish does not heat up to dangerously high temperatures, since ceramics have a lower thermal conductivity compared to metal - it is much less likely to get an accidental burn.

- finishing tiles will be an excellent decorative decoration of the stove surfaces, as they can have a variety of colors and relief patterns. Some of its types imitate tile cladding.

Furnace selection recommendations

Regardless of what the heat source will be, it must provide complete heating of all areas of the house. Whether a stove for a summer residence is capable of this, will tell its characteristics:

- power;

- heat transfer;

- Efficiency (coefficient of performance).

Power is an indicator of the properties and efficiency of the furnace, but you need to understand that in different modes of operation of the heat source, it will show different power. And yet this is the main criterion to be guided by when choosing heating equipment.

On average, heating 25 m3 of heated space requires 1 kW of rated power. They also take into account the state of the house, its ability to retain heat. In this regard, the average equipment efficiency is adjusted in one direction or another. Taking into account the state of the house, 1 kW of heating equipment power is sufficient for heating:

- 14-15 m3 of a building without thermal insulation located in a cold climatic zone;

- 25–27 m3 in a house with thermal insulation in a region with a cold climate;

- 33–35 m3 in a heat-insulated building in a warm climatic zone.

The next important indicator of equipment efficiency is efficiency, the value of which is calculated by the formula: a-b = efficiency

Where "a" is the amount of thermal energy that is obtained with the complete combustion of the fuel;

"B" is the amount of heat energy actually transferred by the stove to heat the room.

The characteristics of the furnaces directly depend on their geometric parameters and material of manufacture. Therefore, large-sized heating devices are not always more efficient than small-sized ones, since the latter can be made of a material with a higher heat transfer.

Furnaces-fireplaces for summer cottages, their distinctive properties and features

Cast iron fireplace stoves, as the main heating device for small houses and summer cottages, are ideal, and have a long operating period. Thick walls are not able to quickly burn out and disable the entire structure. This will take them several decades. But they cool down for a long time, although they slowly heat up.

The assembly of parts of all modern models of furnaces is carried out using bolts or tenons and grooves. This allows you to easily replace parts and assemblies that are out of order. When buying cast-iron fireplace stoves for a summer residence, you need to know not only the mass, but also the weight of the chimney and the fuel they use. If the total weight does not exceed 200 kg, you can do without a foundation, but the wooden floor will still need to be strengthened.

For summer cottages, fireplace stoves made of black steel are often purchased, since their cost is much less than the rest. But there is one drawback - the fast burning of the walls. In order to exclude this phenomenon, steel is chosen, the thickness of which is about 8 mm. So that the products are not damaged by corrosion, they are covered with special paints. Expensive models are made of structural steel. They weigh less and cost significantly more. But they easily tolerate high temperatures, which allows the use of metal sheets of thinner thickness

Manufacturing stainless steel heating structures is a rather costly process. The walls of such fireplaces stoves are approximately 3 to 4 mm, and the surface is covered with heat-resistant paints. But the duration of their operation completely depends on the quality of the welds, which are produced in a special environment and with the help of expensive equipment. It cannot be otherwise - the metal in the area of the seams made under normal conditions loses its heat resistance and is corroded.

Safe use rules

Following simple rules will help avoid potentially dangerous situations.

If a stove with a fireplace is installed in a wooden house, there must be a fire extinguisher in the room.

All combustible substances, fabrics and objects should not be located closer than 1-2 m from the fireplace. The oven must be equipped with a protective screen against flying sparks.

It is not recommended to use flammable liquids that could spill on the floor to kindle the fireplace or store them near the fireplace. Do not pour water on fire - red-hot brick or metal may crack.

Attention! Do not leave small children unattended by the stove, and do not perform any kind of ignition work in a state of extreme fatigue or intoxication. To extend the service life, it is recommended to clean the fireplace in a timely manner, and at the end and at the beginning of the heating season, thoroughly check the equipment for wear and tightness of the seams.

With proper operation, a country fireplace will last for many years and will give home a lot of warm family evenings under the cozy crackling of firewood in a burning flame

To extend the service life, it is recommended to clean the fireplace in a timely manner, and at the end and at the beginning of the heating season, thoroughly check the equipment for wear and tightness of the seams. With proper operation, a country fireplace will last for many years and will give home a lot of warm family evenings under the cozy crackling of firewood in a burning flame.