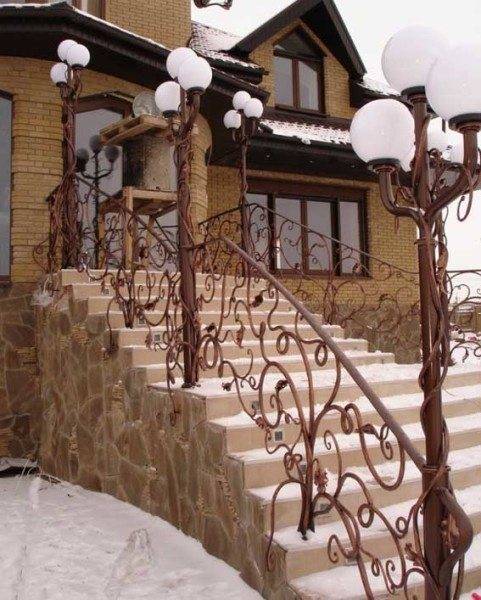

An indispensable component of every building is an external staircase. It is not only a connecting link between external and internal space, but also personifies any structure as a whole, forming its image. Entrance stairs in private houses deserve special attention, because it is at the entrance that the first impression of the owner of the home is created.

Unlike internal ones, external stairs are necessary even in one-story buildings, since there is always at least a slight difference in levels. However, for the comfortable and safe movement of a person, a lifting device is definitely required. Without it, it is impossible to climb to the height - this is how people are arranged. Therefore, when building a house, it is necessary to remember about such a very important architectural attribute.

The main qualities that outdoor stairs should have

In addition to the fact that the outdoor lifting device should be organically combined with the style of the building and make up a compositional unity with the landscape design, the staircase at the entrance to the house must have other specific qualities.

So, the mandatory properties for this design are:

- Security.

- Reliability.

- Comfort.

- Strength.

- Durability.

All of the above points depend on many factors:

- The material from which such a staircase is made.

- How accurately the technology for the construction of the lifting device is observed.

- Is the correct type of construction selected?

- Whether the required proportions of the lift are exactly observed, and so on.

There are many types of stairs to enter the house. Before building them, of course, you must first decide on this issue.

You will also need to choose a solid material from which it will be built. This nuance must be approached with the utmost seriousness.

Note! The final price of the lift and its compliance with the style of the house will directly depend on the material chosen. In addition, since any external structure, even with a visor, is more susceptible to the negative effects of the external environment than internal structures, the durability of the external staircase will also depend on the strength qualities of the selected material.

Construction of the entrance staircase

Now the modern market offers various ready-made entrance lifts, but, as a rule, they are not cheap. Therefore, if finances are limited and there is a skill in construction, then, with the right approach to business, the entrance staircase to a private house can be erected with your own hands. This will help significantly save your family budget.

Types of entrance stairs

How not to get confused with the type of construction and the choice of material? First of all, it should be noted that there are basic materials from which stairs are usually erected. They are often combined with each other.

These include:

- concrete;

- metal;

- brick;

- less often a tree;

- natural or artificial stone.

External lifting structures, according to the configuration of the flights, are divided into such basic types as:

- straightforward;

- curvilinear;

- combined.

Also, the entrance staircase can have a platform (porch) in its device, which surrounds the steps. Her figure is often determined by the form of the march.

Since it is impossible to describe the manufacturing process of each structure here, then using the example of such the most optimal and widely used option as a single-flight straight staircase made of concrete, we will consider the entire construction procedure in stages. So how to make a do-it-yourself concrete lift?

Concrete inlet hoisting technology

The entire procedure for the construction of a concrete entrance staircase can be conditionally divided into such stages as:

- Calculation of the parameters of the lift.

- Drawing up a drawing.

- Laying the base for the stairs.

- Assembling the formwork.

- Installation of the reinforcement cage.

- Filling the structure with concrete.

- Installation of handrails (if necessary).

- Finish the inlet hoist with various materials.

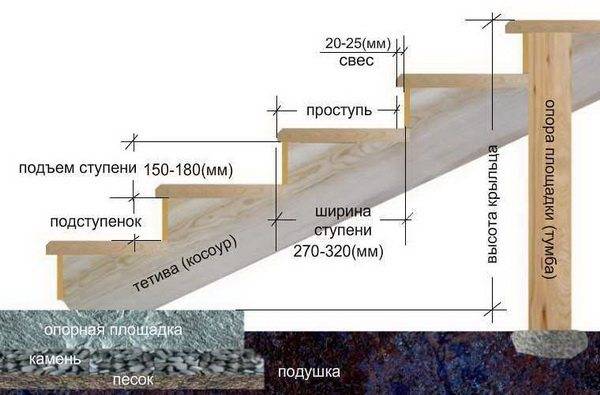

When erecting an entrance structure, you should adhere to generally accepted standards:

- the height of the stair risers - from 15 to 18 cm;

- tread depth - from 27 to 32 cm;

- platform width - at least 1 m;

- the angle of inclination of the stairs is 30 degrees.

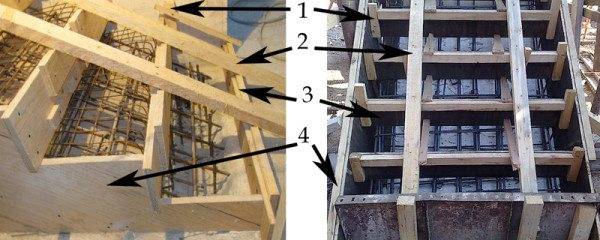

Photo of the formwork device for the concrete entrance staircase, which consists of:

- 1 - bars, with the help of which the formwork is fastened;

- 2 - bars for fastening sheets that form steps;

- 3 - boards forming steps;

- 4 - end formwork.

Step-by-step instructions for building a concrete staircase include the following steps:

- At the first stage, a platform for the stairs is made. To do this, you first need to lay a cushion of rubble and sand over the entire area of its location, after removing the soil layer by about 2-3 cm. Then the porch is poured with concrete mortar. The principle is the same as for making a concrete screed. The site will serve as the foundation of the entire structure. In this case, you should definitely make sure that it turns out to be strictly horizontal.

- Further, after the solution has dried, so that the entrance staircase to the house is smooth and beautiful, you need to build a rigid and durable formwork... For this, waterproof plywood with a cross section of about 20 mm is used, from which it is convenient to make curved parts of stairs. You will also need flat semi-edged or edged boards with a thickness of about 30 mm. They are used for the side parts of the formwork and for shaping the steps. All formwork blanks are cut in accordance with the dimensions of the drawing. Parts of this design are fastened with metal corners or wooden bars, which should be screwed in with self-tapping screws. Props can also be made of them. It should be borne in mind that they must be strong, since concrete is heavy, and the main load after pouring the solution will fall on them. You will also need to install racks. They can be strengthened with plank jumpers, which will increase the rigidity of the structure. It should be noted that all parts of the formwork must fit tightly to each other, since the mortar can flow out through the cracks formed.

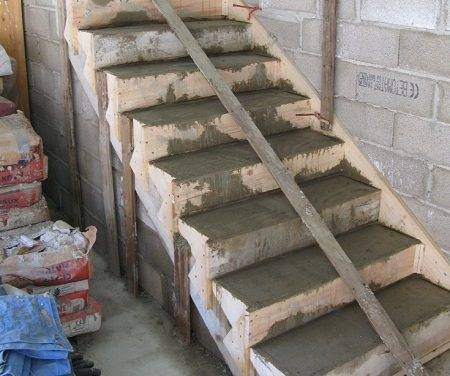

- After the manufacture of the formwork, you can proceed to the reinforcement. To do this, steel bars should be laid along the march of the lift, as well as the bearing edges of the formwork. It is convenient to fasten them together with cross ties using a wire. In order to prevent crumbling of the leading edge and steps of the lift, such places should also be reinforced with transverse reinforcement.

- Pouring of concrete mortar should be started from the first lower stage. The composition of the mixture must include fine-grained crushed stone (10-20 mm). The strength of the structure as a whole will depend on how tightly the solution settles, therefore, it is best to compact it using a special construction vibrator. The mixture should dry out gradually and, therefore, after pouring, the stairs should be covered with plastic wrap. This will prevent the formation of microcracks in the structure. The formwork and supports should be removed no earlier than 3 weeks after the work.Before pouring the solution, you must not forget to install metal columns, where the railings will be mounted in the future.

- The installation of the railings and the finishing of the stairs takes place at the last stage. Handrails can be purchased as a finished product or made by hand. This concrete staircase can be tiled with ceramic tiles, wood, stone and so on. The only thing, when choosing a finishing material, you should remember that in the winter or rainy season, the steps must be safe. Preference should be given to surfaces with a rough and anti-slip structure.

Note! The components of the inlet lift solution must be thoroughly mixed. For its preparation, the following proportions are used: 1 part of cement, 4 parts of crushed stone, 2 parts of sand. Just as much water is required as is needed in order for the mixture to have the consistency of thick sour cream.

Conclusion

In conclusion, it should be noted that concrete entrance lifting devices, made in compliance with all technical rules, serve a long time and are the most reliable structures. In the video presented in this article, you will find additional information on this topic (also learn how to carry out an independent calculation of the steps of the stairs).