By and large, all the requirements for stairs and stepladders can be expressed in two words - they are convenience and safety, but behind this there are many more nuances that give meaning to these definitions. In addition, there are certain GOSTs and SNiPs, developed in the Soviet Union and still in force, thanks to which the necessary dimensions, slopes, and fire safety measures are determined.

We will now discuss this topic, and also watch a video in this article that will shed more light on this issue.

Determining the required parameters

All requirements - for stairs, platforms and fences, are quite different, because such structures can be made of different materials, have different sizes, greater or less slope and be mounted both outdoors and indoors. But if the characteristics of factory-made reinforced concrete stairs are strictly regulated, then home-made metal and wooden stairs are made arbitrarily, so instructions on their parameters and production will never be superfluous.

Concrete marches and platforms

| Marking | GOST | Dimensions in mm (LxBxH) | Weight in kg | Volume in m3 |

| LM 12.19.09-5-d | 9818 | 1860x1200x900 | 1440 | 0?576 |

| LM 19.13.5.09-5-d | 9818 | 1860x1350x900 | 1620 | 0,648 |

| LM 19.13.09-5-d | 9818 | 1860x1300x900 | 1560 | 0,624 |

| LM 09.22.10.5-5-d | 9818 | 2160x900x1050 | 1250 | 0,5 |

| LM 22.10.10.5-5-d | 9818 | 2160x1000x1050 | 1390 | 0,556 |

| LM 10/28/13.5-5-d | 9818 | 2760x1000x1350 | 1760 | 0,704 |

| LM 28.12.5.13.5-5-d | 9818 | 2760x1250x1350 | 2200 | 0,88 |

| LM 19.12.5.09-5-d | 9818 | 1860x1250x900 | 1500 | 0,6 |

| LM 22.10.5.10.5-5-d | 9818 | 2160x1050x1050 | 1460 | 0,584 |

| LM 22.11.5.10.5-5-d | 9818 | 2160x1150x1050 | 1595 | 0,638 |

| LM 22.1110.5-5-d | 9818 | 2160x1100x1050 | 1525 | 0,61 |

| LM 22.12.5.10.5-5-d | 9818 | 2160x1250x1050 | 1735 | 0,6928 |

| LM 22.12.10.5.-5-d | 9818 | 2160x1200x1050 | 1655 | 0,666 |

| LM 22.13.10.5-5-d | 9818 | 2160x1350x1050 | 1875 | 0?75 |

| LM 22.13.10.5-5-d | 9818 | 2160x1300x1050 | 11805 | 0,722 |

| LM22.09.12-5-d | 9818 | 2460x900x1200 | 1415 | 0,566 |

| LM 25.10.5.12-5-d | 9818 | 2460x1050x1200 | 1685 | 0,674 |

| LM 10.25.12-5-d | 9818 | 2460x1000x1200 | 1575 | 0,63 |

| LM 25.11.5.12-5-d | 9818 | 2460h1150h1200 | 1845 | 0,738 |

| LM 11/25/12-5-d | 9818 | 2460x1100x1200 | 1730 | 0,692 |

| LM 25.12.5.12-5-d | 9818 | 2460x1250x1200 | 1965 | 0?786 |

| LM 12/25/12-5-d | 9818 | 2460x1200x1200 | 1925 | 0,77 |

| LM 25.13.5.12-5-d | 9818 | 2460x1350x1200 | 2125 | 0?85 |

| LM 25.13.12-5-d | 9818 | 2460x1300x1200 | 2045 | 0,818 |

| LM 09.20.13.5-5-d | 9818 | 2760x900x1350 | 1585 | 0,634 |

| LM 28.10.5.13.5-5-d | 9818 | 2760x1050x1350 | 1850 | 0?74 |

| LM 28.11.5.13.5-5-d | 9818 | 2760x1150x1350 | 2025 | 0,81 |

| LM 28.11.13.5-5-d | 9818 | 2760x1100x1350 | 1935 | 0,774 |

| LM 28.12.13.5-5-d | 9818 | 2760x1200x1350 | 2110 | 0,844 |

| LM 28.13.5.13.5-5-d | 9818 | 2760x1350x1350 | 2375 | 0,95 |

| LM 28.13.13.5-5-d | 9818 | 2760x1300x1350 | 2290 | 0,916 |

| LM 30.10.5.14-5-d | 9818 | 2760x1050x1400 | 1850 | 0,74 |

| LM 10.10.14-5-d-2 | 9818 | 2760x1950x1400 | 1710 | 0,684 |

| LM 30.11.5.14-5-d-2 | 9818 | 2760x1150x1400 | 2025 | 0,81 |

| LM 11/30/14-5-d-2 | 9818 | 2760x1100x1400 | 1880 | 0,752 |

| LM 12/30/14-5-d-2 | 9818 | 2760x1200x1400 | 2115 | 0,846 |

| LM 09/30/15-5-d | 9818 | 3060x900x1500 | 1750 | 0,7 |

| LM 31.10.5.15-5-d | 9818 | 3060x1050x1500 | 2050 | 0,82 |

| LM 10/31/15-5-d | 9818 | 3060x1000x1500 | 1945 | 0,778 |

| LM 31.11.5.15-5-d | 9818 | 3060x1150x1500 | 2225 | 0,89 |

| LM 31.11-15-5-d | 9818 | 3060x1100x1500 | 2150 | 0,86 |

| LM 31.12.5.15-5-d | 9818 | 3060x1250x1500 | 2430 | 0,972 |

| LM 12/31/15-5-d | 9818 | 3060x1200x1500 | 2325 | 0,93 |

| LM 31.13.5.15-5-d | 9818 | 3060x1350x1500 | 2575 | 1,03 |

| LM 31.13.15-5-d | 9818 | 3060x1300x1500 | 2530 | 1,012 |

| LM 34.10.5.17-5-d | 9818 | 3360x1050x1650 | 2235 | 0,894 |

| LM 34.11.5.17-5-d | 9818 | 3360x1150x1650 | 2445 | 0,978 |

| LM 34.12.17-5-d | 9818 | 3360x1200x1650 | 2550 | 1,02 |

| LM 34.13.5.17-5-d | 9818 | 3360x1350x1650 | 2825 | 1,13 |

| LM 37.09.18-5-d | 9818 | 3660x900x1800 | 2085 | 0,834 |

| LM 37.10.5.18-5-d | 9818 | 3660x1050x1800 | 2425 | 0,97 |

| LM 37.10.18-5-d | 9818 | 3660x1000x1800 | 2320 | 0,928 |

| LM 31.11.5.18-5-d | 9818 | 3660x1150x1800 | 2655 | 1,062 |

| LM 37.11.18-5-d | 9818 | 3660x1100x1800 | 2550 | 1,02 |

| LM 37.12.5.18-5-d | 9818 | 3660x1250x1800 | 2900 | 1,16 |

| LM 37.12.18-5-d | 9818 | 3660x1200x1800 | 2775 | 1,11 |

| LM 37.13.5.18-5-d | 9818 | 3660x1350x1800 | 3125 | 1,25 |

| LM 37.13.18-5-d | 9818 | 3660x1300x1800 | 3015 | 1,206 |

| LM 09.19.09.-5-d | 9818 | 1860x900x900 | 1080 | 0?432 |

| LM 19.10.09-5-d | 9818 | 1860x1000x900 | 1200 | 0,48 |

| LM 19.10.5.09-5-d | 9818 | 1860x1050x900 | 1260 | 0,506 |

| LM 11.19.09-5-d | 9818 | 1860x11100x900 | 1320 | 0?528 |

| LM 19.11.5.09-5-d | 9818 | 1860x1150x900 | 1380 | 0,552 |

Stairways (LM)

| Marking | GOST | Dimensions in mm (LxBxH) | Weight in kg | Volume in m3 |

| LMP 43.11.15-4-1 | GOST 9818-85 | 44250x1050x1500 | 2500 | 1,0 |

| LMP43.11.15-4-2 | GOST 9818 | 4250x1050x1500 | 2475 | 0,99 |

| LMP 57.11.15-5r | GOST 9818 | 5650x1050x1500 | 2330 | 0,032 |

| LMP57-11-14-5 | Series 1.050.1.2.v.1.2 | 5650x1150x1400 | 2200 | 0,9 |

| LMP 60-11-17-5 | II-04-7 | 5980x1150x150 | 2600 | 1,04 |

| LMP 60-11-17-5-3 | II-04-7 | 4790x1150x150 | 2,1 | 0,84 |

| LMP 62-11-15 | GOST 9818 | 6200x1150x240 | 2450 | 0,98 |

Staircases with a platform (LMP)

| Marking | GOST | Dimensions in mm (LxBxH) | Weight in kg | Volume in m3 |

| 2LMF 39-12-17-5 | 1.251.1-4 | 3913x1200x295 | 1290 | 0,52 |

| 2LMF 39-14-17-5 | 1.251.1-4 | 3913x1350x1650 | 1420 | 0,568 |

| 2LMF 3914-17-5y | 1.251.1-4 | 3913x1350x1650 | 1243 | 0,5 |

| 2LMF 42-14-18-5 | 1.251.1-4 | 4249x1800x1200 | 1530 | 0,612 |

Stairways with a frieze step (LMF)

Explanations on marking: 27 - length; 11- width; 14 - vertical height; 4 - design load.

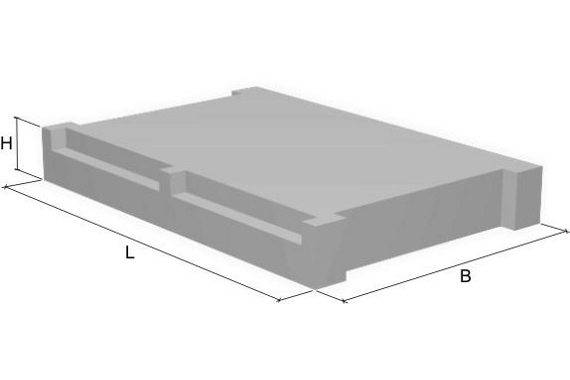

| Site marking | Platform dimensions in mm | Weight in tons | ||

| L (width) | B (Length) | H (height) | ||

| 1LP 30-15-4 | 2980 | 1500 | 320 | 1,4 |

| 1ЛП 30-15В-4 | 3040 | 1600 | 320 | 2,4 |

| 1LP 30-18-4 | 2980 | 1800 | 320 | 2,9 |

| 2LP 22-12-4 | 2200 | 1300 | 320 | 1,035 |

| 2LP 22-12-4K | 2200 | 1300 | 220 | 1,035 |

| 2LP 22-15 | 2200 | 1600 | 220 | 1,2 |

| 2LP 22-15-4 | 2200 | 1600 | 320 | 1,2 |

| 2LP 22-15-4K | 2200 | 1600 | 320 | 1,2 |

| 2LP 22-18 | 2480 | 1900 | 320 | 1,37 |

| 2LP 22-18-4 | 2480 | 1900 | 320 | 1,37 |

| 2LP 22-18-4K | 2200 | 1900 | 320 | 1,37 |

| 2LP 25-12 | 2500 | 1300 | 320 | 1,16 |

| 2LP 25-12-4 | 2500 | 1300 | 320 | 1,16 |

| 2LP 25-12-4K | 2500 | 1300 | 320 | 1,16 |

| 2ЛП 25-12В-4K | 2780 | 1300 | 320 | 1,16 |

| 2LP 25-15-4 | 2480 | 1600 | 320 | 1,345 |

| 2LP 25-15-4K | 2480 | 1600 | 320 | 1,345 |

| 2ЛП 25-15В-4K | 2500 | 1600 | 320 | 1,37 |

| 2LP 25-18-4 | 2500 | 1900 | 320 | 1,463 |

| 2LP 25-18-4ML | 2500 | 1900 | 320 | 1,395 |

| 2LP 25-18-4MLV | 2500 | 1900 | 320 | 1,47 |

| 2LP 25-18-4K | 2500 | 1800 | 280 | 1,533 |

| LP 1-26-18 | 2680 | 1860 | 160 | 1,942 |

| LP 15-14 | 1385 | 1490 | 300 | 0,585 |

| LP 1P | 2820 | 1370 | 320 | 1,14 |

| LP 1P1 | 2820 | 1370 | 320 | 1,14 |

| LP 22-16 | 2680 | 1860 | 160 | 1,865 |

| LP 22-15 | 2480 | 1600 | 320 | 1,15 |

| LP 22-16-1 | 2440 | 1440 | 300 | 0,397 |

| LP 24-14 | 2600 | 1150 | 250 | 0,775 |

| LP 25-15-4K | 2500 | 1600 | — | — |

| LP 28-13 | 3040 | 1060 | 350 | 0,87 |

| LP 28-15 | 3040 | 1260 | 350 | 0,98 |

| LP 28-17 | 3000 | 1540 | 250 | 1,1 |

| LP 30-13 | 3020 | 1330 | 200 | 1,148 |

| LP 30-18 | 3020 | 1830 | 320 | 1,875 |

| LP 30-18-1 | 3020 | 1830 | 320 | 1,875 |

| LP 32-18 | 3180 | 1780 | 320 | 4,527 |

| LPP 14-12V | 1440 | 1200 | 240 | 0,5 |

| BOB 14-13V | 1440 | 1325 | 240 | 0,6 |

| LPP 14-15V | 1440 | 1475 | 240 | 0,6 |

| BOB 15-1 | — | — | — | 0,413 |

| LPP 15-15V | 1540 | 1490 | 240 | 0,75 |

| BOB 15-6 | — | — | — | 0,25 |

| LPP 16-15V | 1610 | 1490 | 240 | 0,775 |

| LPF 25-10-5 | 2500 | 990 | 350 | 0,9 |

| LPF 25-11-5 | 2500 | 1140 | 350 | 0,98 |

| LPF 25-13-5 | 2500 | 1290 | 350 | 1,075 |

| LPF 28-11-5 | 2800 | 1140 | 350 | 1,1 |

| LPF 28-13-5 | 3080 | 1290 | 350 | 1,195 |

| LPF 31-13-5 | 3100 | 1290 | 350 | 1,315 |

| LPR 22-15K | 2480 | 1600 | 320 | 1,2 |

| LPR 22-18K | 2480 | 1900 | 320 | 1,4 |

| Decision maker 25-12 | 2780 | 1300 | 320 | 1,13 |

| Decision maker 25-18 | 2500 | 1900 | 320 | 1,73 |

| DM 25-18 MLA | 2500 | 1900 | 320 | 1,395 |

| Decision maker 25-18 MLB | 2500 | 1900 | 320 | 1,4 |

| LPR 25-18 MLS | 2500 | 1900 | 320 | 1,4 |

Stairways (LP)

Some explanations for labeling: LP and LPS - staircases; 1ЛП - for marches LM type; 2ЛП - ribbed platform for LM; LPF - ribbed platform for LMF; LPP - ribbed platform and p. / Platform for LMP; LPR - ribbed platform; K - support console.

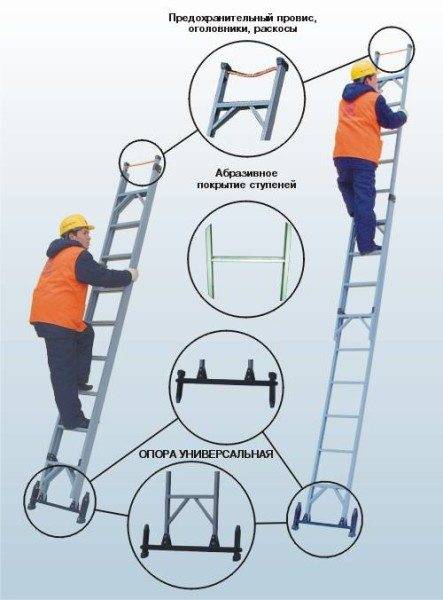

Structures for installation work

- Also, at factories or directly at the construction site, structures for construction and installation work are manufactured in accordance with GOST 2688-86.In accordance with it, requirements are imposed on metal stairs and platforms that are used at such facilities.

| Marking | Full name | Material for construction |

| PLC | Ladder platforms | Steel |

| PLA | Aluminum alloy | |

| PKS | Platforms hung on building structures | Steel |

| PKA | Aluminum alloy | |

| LPNS | Inclined ladders | Steel |

| LPNA | Aluminum alloy | |

| LPVS | Vertical extension ladders | Steel |

| LPVA | Aluminum alloy | |

| LNS | Hinged ladders | Steel |

| LNA | Aluminum alloy | |

| LSS | Free-standing stairs | Steel |

| LSA | Aluminum alloy |

Fire safety requirements for stairs and landings by material

| Structural elements | Compliance of materials with climatic standards according to GOST 15150-69 | |||

|

Have |

HL |

|||

| steel grade | Aluminum alloy grade | steel grade | Aluminum alloy grade | |

| Load-bearing elements | VSt3ps6 and VSt3sp5 in accordance with GOST 380-88 and TU 14-1-3023-80 | AMg6 and 1915 in accordance with GOST 4784-74 | 09G2S12 and 15HSND12 in accordance with GOST 19281-73 and GOST 19282-73 | AMg6 and 1915 in accordance with GOST 4784-74 |

| Fencing elements | St3kp2 in accordance with GOST 380-88 | AMg6 and 1915 in accordance with GOST 4784-74 | VSt3ps6 and VSt3sp5 in accordance with GOST 380-88 | AMg6 and 1915 in accordance with GOST 4784-74 |

Material marking

Note. It is also possible to use other grades of steel and aluminum alloys as agreed with the customer. But in any case, the brand should not be lower than the one shown in the table.

Fire safety

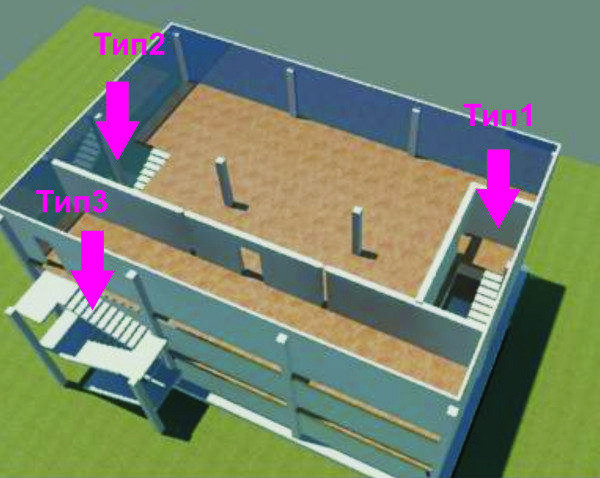

- SNiP 21-01-97 * stipulates fire requirements for staircases, as well as requirements for fire escapes, which must be strictly observed during the construction of buildings and structures. In the event of a fire in the premises, the cells can manifest themselves as ordinary or non-smoky. They are also divided by the method of lighting, where L1 is lighting through glazed or open openings in the wall and L2 is lighting through glazed or open openings in the roof.

- Smoke-free cells in public buildings and residential buildings differ in the method of protection: H1 - the entrance is carried out from the floor through the smoke-free zone along an open passage; H2 - in case of fire, air is pressurized on the cage; Н3 - the entrance is carried out on each floor through a vestibule lock, where in case of a fire, air is supplied.

- The requirements for wooden staircases are somewhat special, so such structures can be installed only in two-story houses. The steps and risers of the stairs are mounted either on bowstrings or on kosoura, which rest on boarding ladders attached to beams. If they settle in the entrances, then the steps from the bottom are sewn up with boards and plastered to protect them from fire.

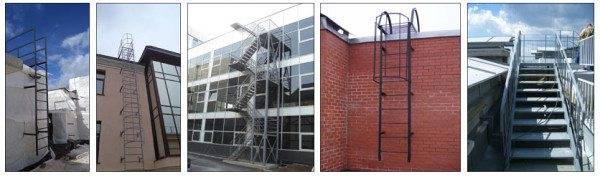

- According to NPB 245-97, the requirements for a fire ladder are mainly reduced to its strength and incombustibility of the material (this is mentioned above, in the table "Marking of materials"). So, such structures, as a rule, are made of concrete or metal, and can be located both inside and outside the building, and can also be strictly vertical or inclined. In addition, when approaching them, on the escape routes there should be no foreign objects obstructing the passage and restricting movement.

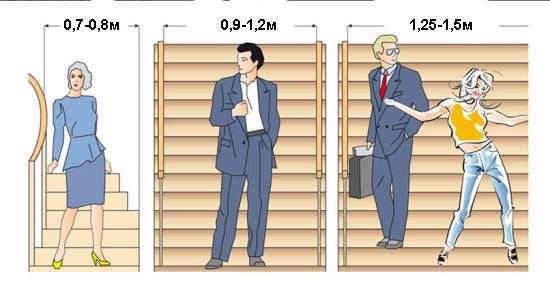

- It is very important to comply with the requirements for flights of stairs in their width to create ease of movement and fire safety. The maximum allowable span is considered to be from 70 to 80 cm wide, where one person can freely move and such dimensions are used for messages with low traffic. But most often they adhere to standard sizes - from 90 to 120 cm, but it is difficult for two people to miss it, but in elite and public buildings the width of the march can be 125-ё50 cm, where two people can easily pass.

Homemade constructions

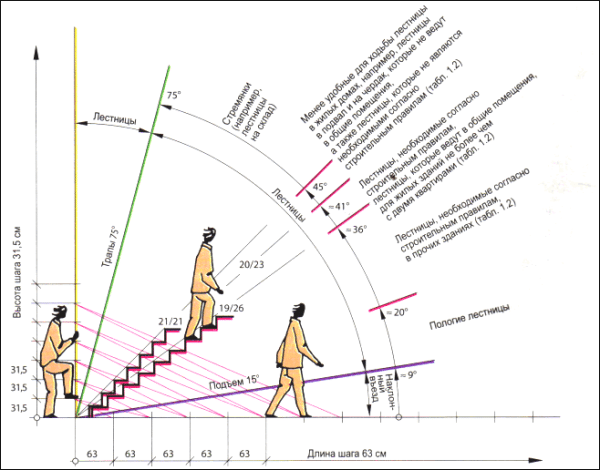

- Most often, a violation of norms and requirements occurs during the manufacture and installation of stairs with your own hands, and such deviations usually arise in order to save space in the room. Usually, living space is saved by increasing the slope, but the most optimal slope of the march for the average person is 30⁰-35⁰... It is believed that spans in 40⁰-45⁰ freely surmountable only for athletic people, but not for an ordinary person, and even more so for children and the elderly.

- Nevertheless, in order to save free space, the slopes of marches sometimes reach 50⁰, but at short distances this can be tolerated. In addition, the maximum slope of the structure saves materials, and the price of the ladder goes down, which almost always matters.

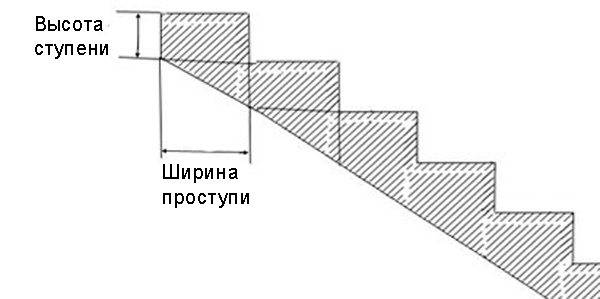

- There are also special requirements for the steps of the stairs, or rather, for their dimensions, which must correspond to the average step of a person (60-64 cm). So, the tread in width (see the figure above) should be at least 70% of the foot of an adult (25-30 cm). In this case, the height of the riser together with the thickness of the tread multiplied by 2 in total with the width should be equal to this 60-64 cm.

- For example, if the step height is 17 cm and the tread width is 28 cm, then 17 * 2 + 28 = 62 cm is just what we need.

Conclusion

All requirements for stairs and landings are written in GOSTs, but, as you understand, it is not always possible to comply with such standards at home. Therefore, try to optimally adhere to at least fire safety rules (read also GOST on fire escapes).