A staircase is a rather complex architectural structure, and in addition to its attractive appearance, it must be strong enough. The popularity of iron and wooden stairs is growing rapidly, but they will never succeed in replacing monolithic ones, since the reliability of this variety remains unrivaled. And the reinforcement of a monolithic staircase is one of the most significant stages, providing it with maximum strength.

Quality of stairs made of in-situ concrete

Advantages of a monolithic staircase:

- durability and strength;

- fire safety;

- safety of movement;

- environmental friendliness (only natural materials are used);

- a variety of designs and decorative finishes;

- affordable price.

Positive characteristics and ease of installation ensure the popularity of reinforced concrete stairs. In practice, the advantages of concrete for the improvement of premises inside buildings and landscape areas have been proven. Do-it-yourself installation is practiced, providing maximum savings.

Depending on the purpose and the expected load level, it is recommended to use the appropriate grades of concrete:

- for outdoor use - structural and heavy concrete;

- for internal structures (for example, stairs) - porous, lightweight aggregates.

Concrete stairs do not require additional maintenance for a long time due to the absence of elements that can loosen from regular dynamic loading. An indisputable advantage is the exclusion of the likelihood of a squeak, even after prolonged operation and significant loads.

The specific features of the materials used make it possible to embody the most complex original ideas into reality: from the simplest marching ones to complex configurations.

How to reinforce stairs

Before proceeding with the reinforcement, it is necessary to prepare the materials provided for by the technology, the requirements of which are mandatory, regardless of whether it is a professional or an amateur.

So, you need:

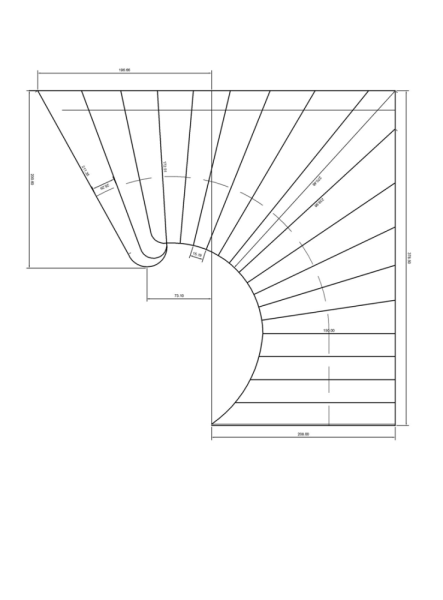

- high-quality drawings of reinforcement of a monolithic staircase;

- construction reinforcement, the choice of diameter must correspond to the expected loads;

- plastic clips;

- annealed knitting wire, the use of electrical plastic clamps is also practiced;

- for reinforcing the steps, a mesh (4 mm) is required.

Reinforcement of stairs is carried out using the following tools:

- Electric screwdriver;

- screwdriver hook;

- welding machine.

Having prepared everything you need, you can start working directly with the frame.

Operating procedure

- Using the drawings of the reinforcement of the stairs, draw up a diagram that will greatly facilitate the implementation of the work, help to avoid many mistakes. It should indicate the distances between the bars of the reinforcement, the individual design features are clearly defined.

- The laying of the frame bars is carried out in strict accordance with the scheme, as a result, the mesh cells must be of the same size.

- To exclude a change in the position of the valve during the installation work, it is necessary to ensure reliable fastening of individual elements to each other.

There are two types of fastening, corresponding to the capabilities and specific conditions of the object:

- welding;

- knitting.

It is widely believed that welding significantly reduces the strength of a structure, this is not entirely true. Exceptionally hardened high-strength reinforcement loses many quality characteristics. For ordinary fittings, you can safely use a welding machine. Negative consequences are excluded, while you will be able to save time.

In the absence of the possibility of using a welding machine, annealed knitting wire is used to create a mesh. For this purpose, a hook fixed in an electric screwdriver is put into operation.

Attention! The advent of modern building materials makes it possible to experiment, for example, plastic clamps are increasingly used as an alternative to wire.

Features of reinforcement knitting

When reinforcing monolithic stairs, you should carefully monitor the observance of the distance between the elements and the formwork - 3 cm. To facilitate compliance with this requirement, special plastic clips are used, characterized by a high level of strength. Visually, they resemble a chair.

Auxiliary elements are placed under the rods at the connection points (welding, wire). Compliance with the recommendations eliminates the likelihood of distortions and irregularities in the mesh.

It is very important when making the connection of power reinforcement, for which separate pieces are used, to provide for an overlap of the rods. After completing the installation of the base frame, you can proceed to fastening the mesh, which ensures the rigidity of the steps of the structure being erected.

Regarding the frame intended for a two-flight staircase, as well as complex structures, it is necessary to ensure strong fastening of their platforms. Reinforcement of monolithic stairs is carried out in compliance with generally accepted rules.

The creation of any concrete structure involves several mandatory steps:

- installation of formwork;

- assembly of the reinforcement cage;

- pouring concrete.

The instructions for the construction of a monolithic staircase provide for compliance with generally accepted rules. It is worth noting that the process of carrying out work is complicated by the specific features of the structure, its size, slope and shape.

The most difficult stage is the creation of the formwork. Reinforcement of flights of stairs rather requires attention, following the recommendations will greatly facilitate the work.

Features of building staircases

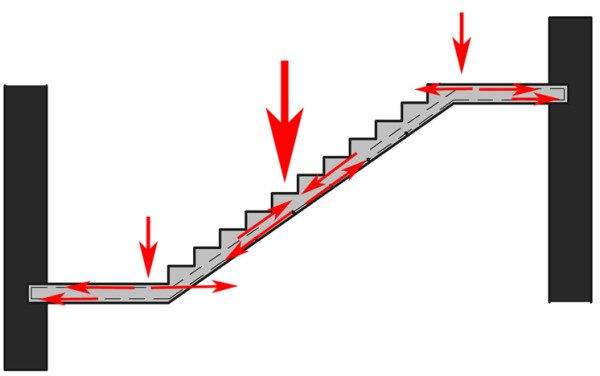

Reinforcement of a flight of stairs requires certain knowledge, and attention should be paid to the study of the forces that affect the strength. For example, consider the steps of a one-flight staircase.

The force of gravity arising under the influence of the mass of the structure, the weight of people, objects moved from one floor to another, affects the structure.

As a result of regular exposure to gravity:

- at the bottom, the concrete is stretched;

- at the top it is compressed.

For single-flight stairs, the best option is a reinforcing cage located in the lower part, this is quite enough, proven by practical tests.

One of the most common reinforcement methods, which can be easily mastered by a person who does not have professional skills, is laying a steel mesh in the upper part (the standard mesh size is 100 x 100 x 5).

The purpose of this mesh is to protect the surface from impacts and chips, the rigidity of the structure remains unchanged. For a two-flight staircase, you need to create a frame for the lower and upper parts.

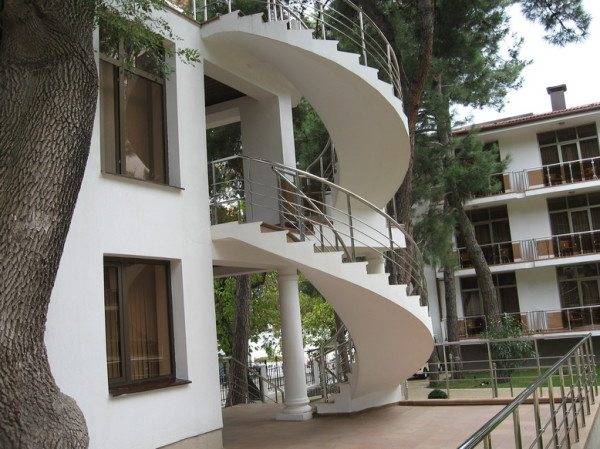

Features of spiral staircases

As an example, consider a spiral staircase. The period of its creation will stretch somewhat due to the specific design features:

- creation of curved formwork, which requires a significant number of shields and supports;

- a complex reinforcement cage for this type of structure can be created by a professional; independent work can lead to disappointing consequences.

If there is a need for independent construction work, it is recommended to give preference to simple structures that do not require professional skills.

Choice of fittings

As a rule, fittings are used for independent work:

- Ø14 mm А 400 С;

- Ø8 mm А 400 С;

- wire Ø4 mm BP-I. Marches and platforms are reinforced with a double mesh;

- for reinforcement of marches, the best option is reinforcement Ø14 mm A 400 C, the recommended distance for laying is 150 mm;

- for transverse reinforcement, you should purchase Ø8 mm A 400 C;

- for the platform - Ø14 mm, step 200 mm;

- to separate the two grids, a special retainer is used, for the manufacture of which they use reinforcement Ø8 mm A 400 C. Its height must be at least 100 mm;

- hooks (120 mm) are used to connect the nets. Hooks are mounted staggered on longitudinal reinforcement. In order to make it easier to navigate, they should be installed through one rod.

Sequence of work

Reinforcement of the stairs should start from the bottom, this is justified by the fact that the pressure is directed from above, respectively, the reinforcement should be from the opposite side.

The most popular is steel reinforcement, this material is out of competition due to its strength, reliability, resistance to external influences. It allows you to create original designs.

The use of steel mesh is practiced, but this method is characterized by minimal strength.

A distinctive feature of a monolithic structure in comparison with a wooden one, for example, is that structures must be manufactured during construction at the site of the intended location.

It is permissible to start the construction of a complex functional structure only after drawing up an accurate drawing and carrying out calculations.

The most common mistakes when choosing a project:

- placement of the structure in the opening 1.5 x 1.5 meters;

- installation of narrow screw models for overweight and too tall people.

Advice. The design of the stairs is carried out in parallel with the development of the project for the whole house.

Conclusion

Construction errors can have serious consequences. A ladder requires compliance with many rules, on which strength, reliability, and, accordingly, the safety of people depend.

The services of professional builders are considered an ideal option. If you have decided to carry out the work on your own, take a ready-made project drawn up by a professional designer. In the video presented in this article, you will find additional information on this topic.