Can a ladder with forging be made from start to finish with your own hands, if you do not have a forge or the appropriate skills at your disposal? You will be surprised, but the answer will be yes.

Advantages and disadvantages

Let's start with the main thing: is it worth the candle? How good is art forging as a decoration for stairs and railings?

Dignity

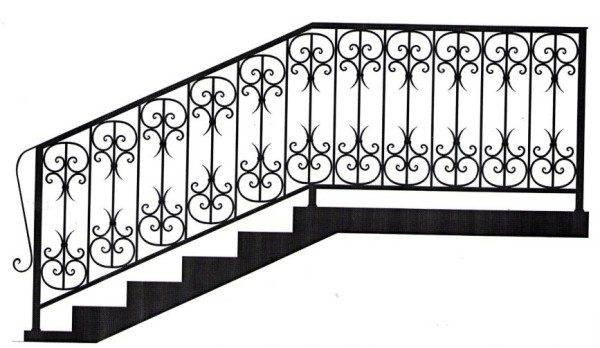

- The first and main thing in the list of advantages of the solution is, of course, appearance... Forged fencing lattices, metal elements of stairs are quite beautiful and cause genuine respect for the creators who created them.

- The metal is durable. Accidental damage to the fence or other forged structural elements is not threatened.

- Life time steel indoors can be considered unlimited. At least - exceeding the duration of a human life.

However: on the street, forged fencing lattice will exist happily ever after only with proper care. At a minimum, periodic rust removal and painting will be required.

disadvantages

You can't do without them either. Forging stairs requires a significant investment - either money or time. Sometimes - both: often, for self-assembly of stairs, artistic forging is ordered by an experienced craftsman. Finished forged elements, of course, need to be combined with the rest of the structure.

Replacing a forged fence with a varnished bar may well reduce the cost of a staircase by 3-4 times.

The battle for economy

With independent construction, both money and time will always be a sore point. Is it possible to reduce the costs of both?

- On sale it is easy to find ready-made forged fences of stairs, and, moreover, their price will not scare off even the most economical builder. Scattered over the surface of the fence, these elements can significantly enliven its appearance. At the same time, the time spent against the background of conventional steel railings will increase slightly.

- An alternative is the already mentioned cold forging, which allows you to get by with minimal costs. However, it will take a lot of time. But in this case, you can be proud: all the work will be done by you - from the concept to the smallest detail of practical implementation.

Cold forging

The kingdom of paradoxes

What is forging in the usual sense of the word? How are complex shapes forged?

The iron is heated in a furnace (forced-draft furnace) to a cherry or even white glow and deformed by hammer blows on a massive anvil. In this case, not only the curvature of a rod or any other iron object can change, but also its linear dimensions.

Steel differs from pure iron by the impurities of other metals, which give it greater strength, hardness, corrosion resistance and a host of other useful properties. However, ductility usually deteriorates.

However, tears are rarely shed on this occasion:

- The art of forging is not very popular now because of its low-tech. The time required for each item is too high for in-line production.

- Now they hammer with a hand hammer only in small villages. Usually, a hydraulic or pneumatic mechanism is used for this, which is much better than a person coping with the function of a hammer.

Where is the paradox here? It lies in the fact that for the cold forging of steel in its simplest, home-made version, neither a hammer (manual or mechanical), nor a forge, nor a blacksmith is needed.

To be fair: the legitimacy of using the term "forging" in this case is rather doubtful.For literalists, the definition of "cold deformation of metal" is probably more suitable.

Tools

The absence of the need for a full-fledged blacksmith does not mean that all the work can be done with bare hands.

We still need many tools (including quite expensive ones).

- Welding machine. Better - an inverter designed for a current of 160-200 amperes. Of course, a mask, holder, workpiece grounding cable and electrodes will also come in handy.

- Smooth wide table, the surface of which is not a pity to bring to ... let's say, not the most aesthetic state. A wide steel workbench is ideal. As a last resort, a flat concrete floor is also suitable.

- Bulgarian with metal cut-off and grinding wheels.

- Metal brush. The sweep circle will probably not go everywhere.

- Rope. It is important that it does not stretch.

- Marker.

- Vise.

- Hammer. Not a blacksmith's hammer - a regular heavy hammer.

- A pair of M16 bolts and a section of a profile or round pipe with a cross section of 30 millimeters or more. Having welded the bolts with their heads to the pipe, we get an improvised tool - a fork, which is convenient for bending a bar.

- Blowtorch or gas torch useful if you plan to make bent elements from a profile pipe.

Materials (edit)

- What to make the frame of the fence element is completely at your discretion. Usually a profile pipe 20x40 - 40x40 is used, but the reader may have his own opinion on this matter.

- Bent volumetric elements are made from a square pipe with a section of 20x20 millimeters.

- Most of the artistic composition is made from a round or square bar. Thickness - 10 - 12 millimeters.

Work order

Is there an instruction for the order of basic operations? Of course.

It could be something like this:

- We select a drawing. The sketch should be simple enough: steel is not the most ductile material. The more points of contact between the elements, the stronger the railing will be.

- We clean the purchased metal from rust. It is much easier to clean straight rods and pipes with a brush or a grinding wheel than a finished structure of a complex shape.

- Putting the frame together. Sections of the profile pipe are laid out on the table and grabbed in the corners. Then the workpiece is straightened: the diagonals measured with a rope should be the same. After the first corner has been welded, check the diagonals again: the frame may lead.

- The drawing inside the frame is applied directly to the surface on which it lies.

- Then, laying out the rope along the contour of the drawing, we measure the length of each element. We cut the blanks with a small margin.

- To bend the bar, we use a fork made by us. Either she or the end of the fence element is clamped in a vice.

Bending an element, we periodically check the template. We bend the profiled pipe, holding it in a vice and heating the inner side of the bent section with a blowtorch or a torch. To obtain a smooth bend, we shift the heating area.

Tip: use a # 3 - # 4 gas wrench or a larger pipe as a lever.

- Having laid out the elements of the composition in the frame and, if necessary, trimming them, we connect them with tacks and, making adjustments if necessary, we boil all the connections completely. Of course, on both sides.

- We clean the welding points from slag and sagging.

We will leave the methods of connecting the fence with the staircase frame to the discretion of the reader: this operation will not create problems with welding.

Final cover

The finished fence should be cleaned from dust and sawdust, which could well remain on it due to magnetization. Then comes the turn of paint and brushes.

Traditionally, painting starts with an alkyd primer. It is better not to use a contrasting color to the final coating: the slightest paint defects will be clearly visible.Steel elements are painted with ordinary PF-115 alkyd enamel or its imported analogue.

The most versatile color is black; if you want to add variety, part of the composition can be painted with gold enamel.

Success in creative work!