The use of metal for the construction of stairs is due to many factors. Among them, one of the most significant - the metal has the best bearing capacity and operational durability. A metal staircase, made by hand, is able to perfectly fit into almost any interior composition.

The presence of special technological qualities in metal makes it possible to create structures with small dimensions and low weight. In addition, their configuration can be of any type as well as of varying complexity.

They can be installed indoors and, of course, outside. They allow you to get into both household and residential premises of the house.

Making metal stairs with your own hands is quite possible, having trained on the simplest welded structureshaving acquired the necessary experience and skills, you can proceed to exclusive facilities.

Classification of metal stairs

The design features of metal stairs, both external and internal, are exactly the same as those of concrete or wooden ones. Typical rules and regulations provide, first of all, design, which displays the most rational form of design for a particular case.

Methods for making stairs can also include welding and forging. The forging technique is quite complex and takes a long time to master, but welding skills can be acquired with a few hands-on lessons. And this means that making a metal staircase with your own hands by a welded method is quite possible.

Types of stair designs

The most common are the following designs, projects of which can be implemented independently:

- Designs with special stringers - a kind of ridges, to which the steps are installed.

- Metal stairs on the bolts - here, on the contrary, there are no frames, they are separate steps attached to the wall with special bolts.

- Metal construction, the fastening of the elements of which is made by bolts to inclined supporting beams, called bowstrings. Between them are treads, risers, or perhaps only treads.

- Screw structures, in which the steps are arranged in a spiral and a bearing central column.

Do-it-yourself metal spiral staircases can be assembled from modules that are manufactured at the factory. There is an option to entrust its production to experienced specialists.

Attention: Heavy structures can only be supported on ceilings. To increase the reliability of the structure, supports can be installed under the landings under the segments with run-in steps.

If you build a concrete or brick interior wall specifically for a metal structure, then it will successfully perform the function of a load-bearing element.

Combined options

Metal, being a technological, durable material, which perfectly combines any type of finish, as well as materials such as wood, concrete, brick, natural stone, glass and its organic counterpart. Metal structures can be equipped with any kind of fencing.

Attention: fences and their parts are attached in two ways: they are mounted on the steps or fixed by welding or using bolts to the ends of the steps.

Depending on the operational specifics of the structure and its style, the load-bearing elements can be supplemented with steps made of different materials. The hall of the country house will be decorated with a metal staircase with wooden steps: you can do it yourself with your own hands.

A structure that is installed outside the building can be completely made of this material. But if it is located inside and consists only of metal, then, most likely, users will not be pleased with the lack of pleasant tactile sensations and the cold sparkle of metal. It is worth thinking about how to sheathe a metal staircase with wood with your own hands.

Self-construction stairs

Tools

To make a ladder, you must have:

- welding machine;

- tool for cutting metal;

- emery wheel to remove burrs;

- a circular saw is required for wood sheathing;

- clamps to temporarily dock parts;

- in addition, drills for metal are useful.

Using a pre-created project, the amount of material required is determined: metal profile, pipes, steel sheets and reinforcing steel.

Tip: In order to weld a decent metal ladder with your own hands, you need a certain skill - for confident use of the welding machine.

It is recommended to make the bearing beams from a channel, better than an I-beam, angle steel may be suitable, it is possible to use pipes with a rectangular cross section.

Elementary construction

To the point

Instructions according to which you can make the simplest metal stairs with your own hands. For its construction, you will need a channel measuring 8x10 cm.

If sheathing is planned, the steps can be made of sheet steel. For the steps of structures located outside the premises, sheets with a relief will be required.

It is possible to use a grating metal flooring or similar material that has anti-slip properties. Fences are made of angle steel, tread supports are made of reinforcement.

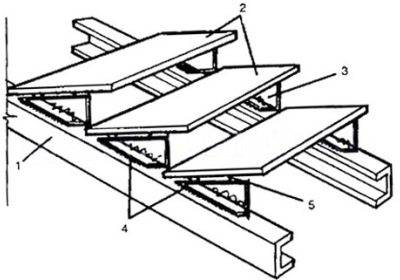

- From the reinforcement, according to the design dimensions, filly are made - these are supporting devices that are installed on the beam.

- Brackets for fastening are welded to the upper part of the filly, which directly serves as a support for the step.

- The channel is placed on the edge and fillets are welded on according to the precise markings made in advance.

- In order to achieve complete identity, the second channel is attached to the one where the filly is already welded and the markings are transferred to it.

Attention: if the ladder is up to a meter wide, then two stringers or two bowstrings are enough. A wider structure requires more beams.

- The next stage is assembly together using a welding machine, if all parts are metal.

- The finished structure is treated with a primer and coated with an anti-corrosion compound.

A more complicated version is possible, in which thick sheet steel is used, from which a sawtooth string is cut. All operations must be carried out very carefully, all dimensions must also be scrupulously observed. Only a careful attitude to the process and thoroughness will then lead to the fact that it will be easier to mount the steps.

Sheathing of steps with wood

If a decision is made on equipping a metal staircase with wooden steps, then, first of all, the probability of installing additional fasteners is estimated.

The action plan is as follows:

- On metal supports, holes are marked in which self-tapping screws and bolts with washers will be located.

- A plywood backing is mounted on metal treads. It is attached with a special assembly glue that has a filling effect, and after it hardens, no crushing occurs.

This glue, by filling the voids, helps to eliminate defects that appear, even if the welding was done well.

Tip: You should not use polyurethane foam, because of its instability to crush.

- The wooden plate is fixed with metal clamps and fastened with self-tapping screws or bolts with washers. Self-tapping screws are screwed from below, into the so-called podta, through drilled holes in the metal base.

Output

So, studying the simplest manufacturing methods, finding out how a metal staircase is welded, you can safely tackle the device at first with a simple design. After that, having gained experience, you will be quite capable of a more aesthetic design that you can be proud of.