Perhaps, making metal stairs with your own hands is the simplest and most convenient, in contrast to the same concrete or wood. But in this case, just like in any other, it is necessary to know the basic principles on which the safety and convenience of such structures depends. Now we will discuss the basic rules, as well as watch a video in this article on this topic.

Metal stairs

Below we will not focus on the production process itself, that is, on welding and assembly, but pay attention to the features and drawings of stairs made of metal with our own hands, according to which it will not be difficult for you to assemble the entire structure. In this case, we are interested in structures with stringers or load-bearing beams, on which steps are located.

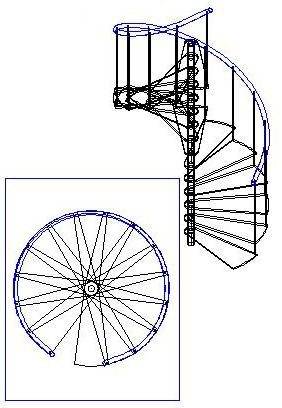

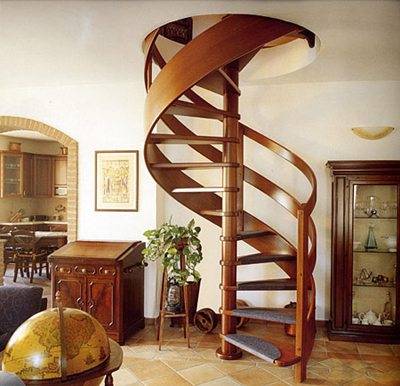

And also screw without kosour, which are more often called spiral, since the screw structure can be with kosour and even with intermediate platforms.

Slopes and steps

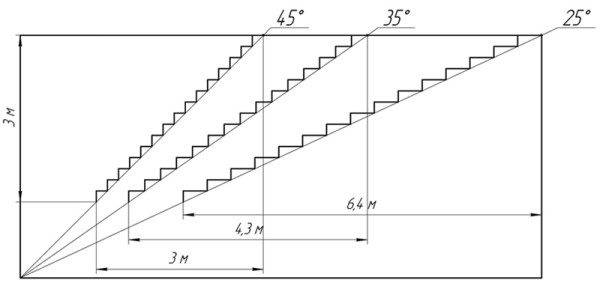

- The most commonly applicable for stair flights are slopes from 25⁰ to 45, ⁰ and we will now learn how to calculate the height of steps for such devices... But it should be mentioned right away that with an incline from 40⁰ to 45⁰, only physically strong people can ascend and descend without problems, while the rest of these exercises cause shortness of breath. Such stairs are best used for communication with low-traffic rooms and, as a last resort, to save living space. The most comfortable for marches is the slope from 30⁰ to 35⁰.

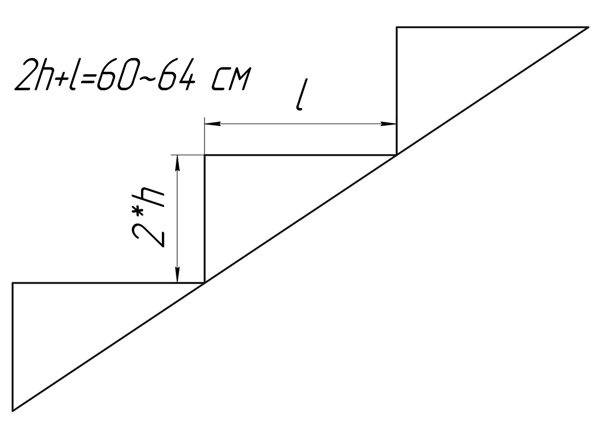

- In order to calculate the height of the steps, it is necessary to determine what a person needs for convenience, and the average step length of an individual with a height of 160-180 cm is 60-64 cm and this must be taken as a basis... So, to calculate the steps, we use the formula 2h + L≈60≈64 cm, that is, two riser heights plus the tread width should be from 60 to 64 cm, so you will get the most comfortable ascent and descent. For example, if the step height is 16 cm, then the tread width will be sufficient 29-31 cm - 16 * 2 + 30 = 62 cm.

Advice. In order for a person to feel safe, his foot should be at least 70% on a solid foundation, so the width of the tread should be on average 25-30 cm (as much as possible). In situations where it is necessary to make a steep staircase (more than 45⁰), you will not be able to make the tread wide, so you can use the run-in steps, where the tread will hang, but no more than 5 cm above the lower one.

In those cases when it is necessary to make a ladder, then for the convenience of lifting, the distance between the rungs (gaps) should be half the average step of a person. That is, the instruction requires that this distance be somewhere in the region of 30-35 cm (see also the article Wooden ladders: self-made).

Kosoura

- Sawtooth bowstring;

- Bowstring made of sheet metal;

- Serrated section;

- Channel bowstring;

- Box-shaped kosour;

- I-beam kosour;

- Kosour without brackets;

- Kosour with brackets.

- The schematic figure above shows how to make a staircase out of metal with your own hands, or rather, the principle of assembling the base and what profiles are required for this. In most cases, electric welding is used to assemble the structural base, and bolts or bolts are used for other structures. Although, for stringer metal stairs, threaded connections can be used when installing handrails, for balusters and handrails.

- Channel bar;

- Proceed;

- Consoles for attaching treads and risers (optional);

- Console attachment area;

- Area for fastening treads (welding or bolts).

- On the stringer of the stairs, as a rule, there is a comb under the steps, that is, triangular consoles made of a metal strip, angle or hollow profile are welded to the beam, and sheet metal panels, called treads, are welded onto them. Risers in swampy cases are made of finishing materials - wood or laminate.

Advice. If for metal stairs in the house, the treads are made of corrugated sheet steel, then on the street it is better to use fittings for this. The rods are welded with a step of 5-7 mm so that the trampled snow does not linger between them.

Screw structures

- The average diameter of such a structure is from 1.2 to 2.0 m, but this is a diameter, which means that the width of the staircase will be more than halved, that is, the minimum width, taking into account the support post and the railing, will be only 50 cm.Of course, for the passage this is quite enough, but here a problem arises - the treads are attached to the pillar almost on the same line, with a minimum shift, and the other end is fanned out. Therefore, it turns out that do-it-yourself metal spiral staircases have a lower throughput.

<ulStair tread width norm, as well as other standards of its characteristics "href =" https://flwn.imadeself.com/33/osobennosty/53-norma-shiriny-stupeni-lestnicy "> Stair tread width norm, as well as other standards its characteristics).