Metal, as the main material for the manufacture of an interlevel staircase for a house or apartment, always stands out for its optimal bearing capacity and durability in operation.

Interfloor metal structures

The technological qualities of metal allow you to create stairs of any format, dimensions, while these will be lightweight structures that can perfectly fit into any interior.

In addition, a simple straight-line metal staircase to the second floor, created with your own hands, is a fairly easy option, which is assembled with little skills in working with welding.

In terms of design features, a metal staircase will not differ in any way from analogs made of wood or concrete, that is, the same design and calculation principles are used everywhere.

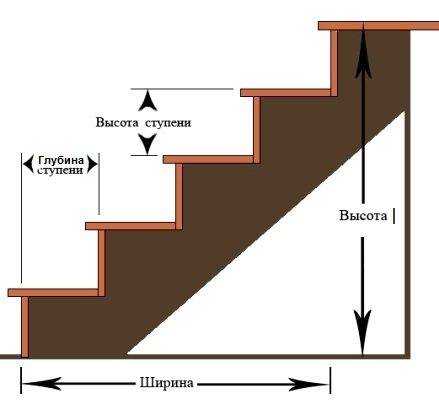

Basically, this speaks of the standard standards adopted for any staircase structure, namely:

- The width of the stairs should not be less than 900 mm... This applies specifically to the intra-apartment option, which is also used in private houses.

- The greatest slope - 1:1,25, and the slope should be constant, and not change the indicators throughout the flight of stairs.

- The height of the steps must be the same and correspond to 15-18 cm.

- Depth 30-35 cm.

Important! The staircase is a kind of risk zone, therefore, not only the slope, but also the fence is of great importance.

- Fences, any, including metal spiral staircases to the second floor must be strong so that they can withstand a side load of 100 kg.

- The distance between the vertical posts of the fence should not exceed 150 mm, or 120 if there are children.

In terms of the manufacturing method, the metal staircase structure can be forged and welded.

Project types

The most suitable projects of metal staircase structures that you can make and assemble yourself are:

- Stairs on kosoura - iron support beams on which the entire staircase is mounted.

- On one stringer. An I-beam or channel is located in the middle and steps are attached to it.

- Ladder on the bolts. There is no frame here, and the steps are attached to the wall with special bolts - bolts.

- Construction on iron bowstrings, support beams (steps are installed here between the bowstrings).

- Screw versionwhere the supporting center pillar acts as a load-bearing element.

Important! In principle, almost all structures can be independently assembled, except for the screw, for which complex calculations are required. And the very work of preparing all the components is quite complicated.

Work

First you need to decide on the dimensions. The dimensions are selected for an example of the manufacture of a simple single-flight staircase, these are:

- Width - 900 mm.

- Slope 45 degrees.

- Step height - 15 cm.

- Depth 30 cm.

Depending on the height of the room, the number of steps is calculated, for example, with a room height of 2800 mm, there can be 11-12 steps.

Next, you need a set of a certain tool:

- Welding machine.

- Grinder with cutting discs for metal.

- Emery wheel.

- Clamps.

- Drill and drill bits for metal.

Of the materials, you will need two channels of 8x10 cm in size, these will be bowstrings, sheet steel, these will be steps, and a corner from which the "filly" will be made.

Important! It is recommended to purchase steel sheets with a relief, it can be a pressed grating or a similar material, but the main thing is that such a structure has anti-slip properties.

Assembly and welding

Further instructions assume the following actions:

- First, filly are made. Here it is necessary to calculate everything exactly, steps will be installed on them. The filly should be congruent to each other, that is, mirrored each other.

- The filly is made from a steel angle. In this case, a bracket for fastening will need to be installed on the part of the device on which the step will lie.

- The channel is installed on the edge and marked out.

- According to the markings, the fillets are welded to the edge of the bowstring.

To make the design completely identical, the second channel can be attached to the first one, and the markings can be completely adjusted with the fillets already welded on. It can also be noted that if the dimensions of the staircase, or rather the width, are assumed to be more than 1.2 meters, then it is recommended to use an additional third bowstring.

In the project under consideration, width 0.9 metersso the two support beams fit perfectly.

Once all the fillies are ready, you can cook all parts of the stairs. The bowstrings are attached at the lowest point to a metal support post, which can be installed in concrete, and here the interfloor metal stairs can be welded to the brackets in the wall, if one bowstring is wall-mounted.

The option of such a wall mount gives the structure additional rigidity. The upper part of the bowstring is welded to a steel support leg, which is bolted to the ceiling with steel anchors.

After everything is assembled, it remains to install the steps. There are two ways to go here. Either simply weld the steps to the filly, which are set perfectly straight from the beginning, or use the bolt-on method.

Output

More complex designs will simply require more care, but the basic principles of working with metal remain the same. And this is a huge plus of hardware, and in the video presented in this article you will find additional information on this topic.