Today, more and more Russians are buying suburban housing. As a rule, private houses have two or more floors, which leads to a natural question: how to provide the most convenient and safe way to move between floors?

The answer, at first glance, is obvious: an ordinary staircase for a country house; however, the modern market offers such a choice of designs that an untrained consumer is easily confused.

Ladders for private houses

Functions

Stairs in country houses are a complex object that performs several functions:

- Firstly, they fulfill their direct task - they are the only transport artery for moving between the floors of the building;

- Due to the danger of falling from a height of two or more meters, another task is assigned to the structure - ensuring the safety of the movement of people;

- In addition, one should not forget that the staircase to a country house should be chosen wisely: it is a large and very noticeable object that affects the general appearance of rooms and plays an important role in the formation of the interior ensemble, therefore, when choosing an interfloor structure, it is necessary to take into account the stylistic and artistic combination of interior elements;

- Finally, when designing a staircase to a country house, it is worth remembering the rational use of the usable space that remains under the steps and in other areas around the structure.

Important!

When choosing the design of an interfloor staircase, it is necessary to solve a difficult problem: to choose such a configuration that will be both convenient, safe, appropriate from the point of view of design and the most acceptable from the point of view of rational use of the space of the room.

To solve such a problem, it is necessary to consider the features of the structures in more detail.

Materials (edit)

One of the characteristic features of today's construction market is the unprecedented choice of materials of both artificial and natural origin. Of which parts and elements of almost any shape are produced, while quite successfully achieving the compliance of the product parameters with the calculated or desired values.

This trend has also affected modern stairs: now they use a much wider range of materials for their manufacture.

There are such types of products:

- Wooden;

- Metallic;

- Concrete;

- Combined: metal-glass, metal-wood, plastic-wood, plastic-metal, etc.;

- Stone;

- Metal-polymer.

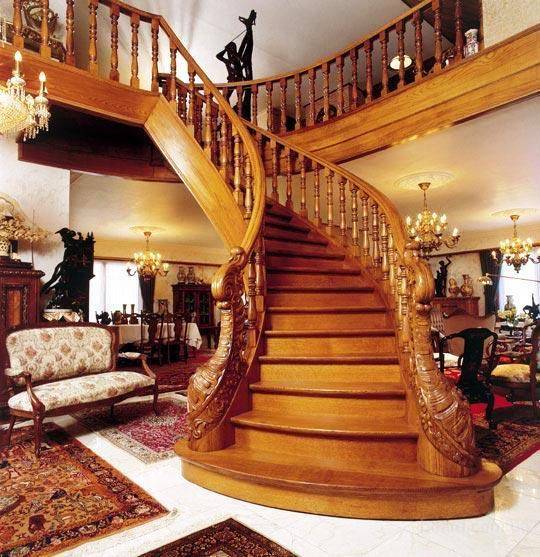

Wooden stairs were and remain one of the most demanded models.

There are a lot of reasons for this:

- relative cheapness and availability of wood;

- its environmental safety and naturalness;

- warm and pleasant to the touch material;

- wood does not slip as intensely as polished metal or stone;

- and will not cause such serious damage or injury if dropped or bumped.

In addition, wood has a unique pattern that is so familiar to the human eye. The tree fits perfectly into almost any style of interior decoration, be it classic, modern or high-tech. Good wood does not deteriorate over time, but, on the contrary, acquires solidity and special beauty.

The wooden structure weighs less and does not cause problems with delivery and assembly, since it does not require heavy special equipment, expensive rare tools or a large number of qualified installers. Two or three people can handle the assembly.

In some styles of interior design, the wooden staircase has become a classic. This applies to traditional trends: country music, chalets, folklore from different countries, especially Russian, Scandinavian and Western European wooden houses.

Metal stairs are reliable, strong, durable and durable. Especially good are metal fences, which better than any others will protect you and your loved ones from falls, injuries and other accidents.

It is also worth saying that metal allows you to create quite bold and non-standard shapes with curved, rotary, spiral-screw and straight elements.

Forged products are very popular, especially handrails, handrails and other parts of stair railings. With the help of machines for cold and hot artistic forging, it is possible to create unique elements and their combinations in large volumes, which reduces the final cost and makes such structures available to the ordinary consumer.

However, the price of forged products is still high and many buyers cannot afford to fully use them. This is where the main problem of metal structures arises: they are not able to fit into any interior.

Metal structures bring an industrial touch, reminiscent of industrial architecture, which is great for contemporary styles and totally unacceptable in traditional and classical design schools.

Also, do not discount concrete stairs, which are not inferior to metal ones in terms of reliability and strength, but at the same time they are ahead of them in terms of prevalence and popularity. Due to their large dead weight, these structures are especially resistant to loads, vibrations, oscillatory processes and other similar influences.

Concrete stairs are solid and monumental, durable, stable and strong. However, they take up a lot of space and are very heavy. In addition, the fabrication and installation of these structures is complex compared to other materials.

If the production of standard concrete flights and platforms for access stairs is carried out at the factory and due to this it is not so expensive, then the production of non-standard models for individual projects requires significant material and labor resources, which naturally affects the final cost of the product.

Often, concrete stairs are made on site, for which a wooden formwork of the desired shape is mounted in the design position, which is then poured with concrete of a suitable grade. Such work requires a complex and competent design, the participation of engineers and experienced installers, concrete workers, welders and carpenters.

This is due to a number of difficulties associated with concrete flights and structures:

- The finished product made of reinforced concrete has a huge weight, which complicates delivery and installation;

- Concrete products do not tolerate transportation and handling poorly, in which the slightest oversight of a slinger or crane operator can lead to irreversible damage;

- Concrete structures cannot be broken down into small component parts, therefore, it is necessary to manipulate dimensional parts, the dimensions of which do not always allow them to move freely inside the premises, moreover, it is often simply impossible.

Advice!

If you have a small country house and a limited budget, then the choice of a concrete staircase, especially of a non-standard shape, does not seem quite rational in terms of the total cost of work and materials, as well as in terms of saving space and space.

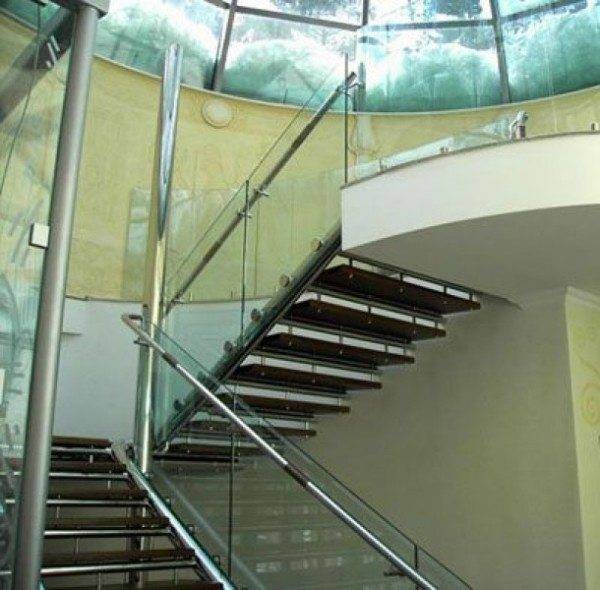

The most promising, widespread and popular are combined designs. This approach allows you to use the strengths of different materials where it is most critical.

So, we see that it is advisable to make railings and fences from durable metal, the fences can be filled with glass or plastic, handrails and steps can be made of wood, and the supporting structures can be made of stone and steel.

The vast selection of building materials allows engineers to invent more and more new combinations of their uses, gradually reducing the cost and increasing the efficiency of their structures.

Also, such a wide selection of materials allows designers to turn around, who are able to convey almost any atmosphere, emphasize certain features of the interior, create the desired entourage and surprise the most sophisticated consumer.

Constructions

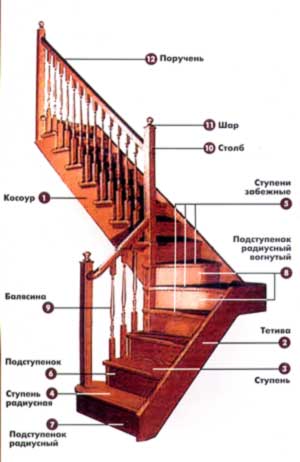

Another important parameter of any staircase is its design and configuration. They are external and internal, straight and swivel, spiral and spiral, modular and stairs on the bolts, with right angles and winders and curved products. Not only the appearance depends on the configuration, but also the convenience, safety and stability of the structure.

The safest and most stable, according to many experts, are the march type constructions. They are characterized by straight stair runs connecting landings on floors and in gaps. The number of gaps depends on the lift height and the angle of inclination of the marches.

But this design has one significant drawback: it is very cumbersome and in rooms with an area of less than 100 sq. m looks a little ridiculous.

A way out of the situation in the event of a shortage of free space can be the use of rotary structures. Due to one or several turns, the stairway is divided into several sections, the duration of the ascent increases, and the steepness decreases.

At the same time, the space under the stairs remains empty and can be used to organize utility rooms, wardrobes, bookcases, storage rooms and other niches.

Rectangular rotary structures with winder steps are considered quite simple for self-assembly in private construction, therefore they are popular.

The use of helical and spiral structures has also become a successful solution in the search for rational use of space. These are products that are quite difficult to manufacture and install and have a high cost.

Attention!

Modular ladders deserve special mention, since they can be used to assemble almost any structure, including rotary and screw ones.

At the same time, modular products take up a minimum of space, are simple, reliable and relatively cheap, and their assembly can be done by hand without much difficulty.

Output

As you can see, choosing a ladder is a serious and important task. It is best to determine the type, configuration and material of the stairs at the design stage, then there will be no problems with compliance with the design, transportation and installation. In the video presented in this article, you will find additional information on this topic.